Binder Jetting Dimensional Recovery Techniques After Sintering

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Sintering Dimensional Recovery Background

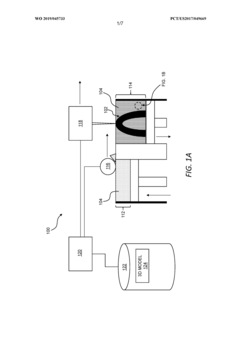

Binder Jetting (BJ) technology has emerged as a significant additive manufacturing process over the past two decades, offering unique capabilities for producing complex metal and ceramic components. This powder-based 3D printing technique selectively deposits a liquid binding agent onto thin layers of powder material, creating a "green part" that requires subsequent thermal processing to achieve final properties.

The dimensional recovery challenge in BJ technology stems from the fundamental physics of sintering. During the sintering process, green parts typically experience significant volumetric shrinkage, ranging from 10% to 30% depending on material composition, particle characteristics, and processing parameters. This shrinkage occurs as particles fuse together, eliminating pores and increasing density, but often leads to dimensional distortions that compromise geometric accuracy.

Historical approaches to addressing dimensional recovery have evolved from simple scaling factors applied uniformly to CAD models to more sophisticated compensation strategies. Early BJ systems in the 2000s relied on empirical shrinkage factors determined through iterative testing, which proved inadequate for complex geometries with non-uniform shrinkage behaviors.

The technical evolution of dimensional recovery techniques has been marked by several key milestones. The introduction of computational models for sintering simulation in the mid-2010s represented a significant advancement, allowing for predictive analysis of shrinkage patterns. Subsequently, the development of anisotropic scaling algorithms enabled differential compensation across various axes and regions of printed parts.

Current dimensional recovery challenges are multifaceted, involving the interplay between powder characteristics (particle size distribution, morphology), binder properties, printing parameters, and sintering conditions. The heterogeneous nature of powder packing in complex geometries creates variable green densities, leading to differential shrinkage during sintering that is difficult to predict and compensate for accurately.

Recent technological advancements have focused on integrating multi-physics simulation approaches with machine learning algorithms to create more accurate predictive models. These models increasingly account for material-specific behaviors, thermal gradients during sintering, and geometric constraints that influence dimensional changes.

The industry trajectory indicates a growing emphasis on closed-loop systems that incorporate in-situ monitoring during both printing and sintering stages, allowing for real-time adjustments to process parameters. Additionally, hybrid approaches combining predictive modeling with empirical data collection are emerging as promising strategies for achieving dimensional accuracy in BJ-manufactured components.

The dimensional recovery challenge in BJ technology stems from the fundamental physics of sintering. During the sintering process, green parts typically experience significant volumetric shrinkage, ranging from 10% to 30% depending on material composition, particle characteristics, and processing parameters. This shrinkage occurs as particles fuse together, eliminating pores and increasing density, but often leads to dimensional distortions that compromise geometric accuracy.

Historical approaches to addressing dimensional recovery have evolved from simple scaling factors applied uniformly to CAD models to more sophisticated compensation strategies. Early BJ systems in the 2000s relied on empirical shrinkage factors determined through iterative testing, which proved inadequate for complex geometries with non-uniform shrinkage behaviors.

The technical evolution of dimensional recovery techniques has been marked by several key milestones. The introduction of computational models for sintering simulation in the mid-2010s represented a significant advancement, allowing for predictive analysis of shrinkage patterns. Subsequently, the development of anisotropic scaling algorithms enabled differential compensation across various axes and regions of printed parts.

Current dimensional recovery challenges are multifaceted, involving the interplay between powder characteristics (particle size distribution, morphology), binder properties, printing parameters, and sintering conditions. The heterogeneous nature of powder packing in complex geometries creates variable green densities, leading to differential shrinkage during sintering that is difficult to predict and compensate for accurately.

Recent technological advancements have focused on integrating multi-physics simulation approaches with machine learning algorithms to create more accurate predictive models. These models increasingly account for material-specific behaviors, thermal gradients during sintering, and geometric constraints that influence dimensional changes.

The industry trajectory indicates a growing emphasis on closed-loop systems that incorporate in-situ monitoring during both printing and sintering stages, allowing for real-time adjustments to process parameters. Additionally, hybrid approaches combining predictive modeling with empirical data collection are emerging as promising strategies for achieving dimensional accuracy in BJ-manufactured components.

Market Analysis for Binder Jetting Dimensional Accuracy

The global market for binder jetting technology has experienced significant growth in recent years, with particular emphasis on dimensional accuracy challenges. Current market valuations indicate the metal binder jetting segment alone reached approximately $189 million in 2022, with projections suggesting a compound annual growth rate of 23.4% through 2030. This growth is primarily driven by increasing industrial adoption across aerospace, automotive, and medical device manufacturing sectors.

Market research reveals that dimensional accuracy remains a critical factor influencing adoption rates. A 2023 industry survey conducted among manufacturing decision-makers identified that 78% of potential adopters cite post-sintering dimensional control as their primary concern when evaluating binder jetting technologies. This represents a substantial market opportunity for solutions addressing dimensional recovery techniques.

The aerospace sector currently represents the largest market segment demanding high-precision binder jetting solutions, accounting for 34% of the total market share. This is followed by medical device manufacturing at 27% and automotive applications at 22%. These industries require components with dimensional tolerances typically within ±0.1% of specified dimensions, creating significant demand for advanced sintering compensation technologies.

Regional analysis shows North America leading the market with 42% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 27.3% annually, driven primarily by rapid industrialization in China and significant government investments in additive manufacturing technologies in Japan and South Korea.

Customer segmentation data indicates that large enterprises currently account for 65% of market revenue, while small and medium enterprises represent 35%. This distribution is gradually shifting as more accessible solutions emerge, with SMEs expected to increase their market share to 45% by 2027.

Pricing analysis reveals that manufacturers are willing to pay premium prices for solutions that can demonstrably improve dimensional accuracy after sintering. Current market offerings addressing dimensional recovery command price premiums of 15-30% compared to standard binder jetting systems without advanced compensation features.

Market forecasts suggest that the specific segment for dimensional recovery techniques in binder jetting will grow at 31.2% annually through 2028, outpacing the overall binder jetting market. This accelerated growth reflects the critical importance of dimensional accuracy in expanding binder jetting applications to more demanding industrial use cases.

Market research reveals that dimensional accuracy remains a critical factor influencing adoption rates. A 2023 industry survey conducted among manufacturing decision-makers identified that 78% of potential adopters cite post-sintering dimensional control as their primary concern when evaluating binder jetting technologies. This represents a substantial market opportunity for solutions addressing dimensional recovery techniques.

The aerospace sector currently represents the largest market segment demanding high-precision binder jetting solutions, accounting for 34% of the total market share. This is followed by medical device manufacturing at 27% and automotive applications at 22%. These industries require components with dimensional tolerances typically within ±0.1% of specified dimensions, creating significant demand for advanced sintering compensation technologies.

Regional analysis shows North America leading the market with 42% share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate at 27.3% annually, driven primarily by rapid industrialization in China and significant government investments in additive manufacturing technologies in Japan and South Korea.

Customer segmentation data indicates that large enterprises currently account for 65% of market revenue, while small and medium enterprises represent 35%. This distribution is gradually shifting as more accessible solutions emerge, with SMEs expected to increase their market share to 45% by 2027.

Pricing analysis reveals that manufacturers are willing to pay premium prices for solutions that can demonstrably improve dimensional accuracy after sintering. Current market offerings addressing dimensional recovery command price premiums of 15-30% compared to standard binder jetting systems without advanced compensation features.

Market forecasts suggest that the specific segment for dimensional recovery techniques in binder jetting will grow at 31.2% annually through 2028, outpacing the overall binder jetting market. This accelerated growth reflects the critical importance of dimensional accuracy in expanding binder jetting applications to more demanding industrial use cases.

Technical Challenges in Post-Sintering Dimensional Control

Dimensional control in post-sintering processes represents one of the most significant technical barriers in binder jetting additive manufacturing. The fundamental challenge stems from the inherent volumetric shrinkage that occurs during sintering, typically ranging from 10% to 30% depending on material composition and initial green part density. This shrinkage is non-uniform across different geometrical features, creating complex distortion patterns that are difficult to predict and compensate for.

The sintering process introduces anisotropic shrinkage behaviors where different axes experience varying degrees of contraction. This phenomenon is particularly problematic for complex geometries with varying wall thicknesses, internal channels, or overhanging structures. Current predictive models struggle to account for these variations, especially when dealing with novel material systems or multi-material components.

Thermal gradients during the sintering cycle further complicate dimensional control. Parts with uneven mass distribution experience differential heating and cooling rates, leading to internal stresses that manifest as warping, cracking, or unexpected deformation. The challenge intensifies with increasing part size, as larger components are more susceptible to these thermal gradient effects.

Material-specific challenges also emerge across different powder systems. Metal powders typically exhibit different sintering behaviors compared to ceramic materials, with factors such as particle size distribution, powder morphology, and composition significantly influencing dimensional outcomes. The industry lacks standardized approaches that can be universally applied across diverse material systems.

Support structures present another technical hurdle. Unlike laser-based additive manufacturing, binder jetting processes cannot easily incorporate sacrificial supports to maintain dimensional stability during sintering. This limitation restricts design freedom and complicates the production of geometries with substantial overhangs or unsupported features.

The interaction between binder chemistry and sintering behavior introduces additional complexity. Residual binder components can affect sintering kinetics and final densification, creating variations in shrinkage patterns that are difficult to predict from green part characteristics alone. This chemical-thermal interaction remains poorly understood for many advanced material systems.

Current simulation tools exhibit significant limitations in accurately predicting post-sintering dimensions. While finite element analysis and computational fluid dynamics have advanced considerably, they still struggle with the complex multi-physics nature of the sintering process, particularly when accounting for material-specific behaviors and process variations. The computational resources required for high-fidelity simulations often make them impractical for routine industrial applications.

The sintering process introduces anisotropic shrinkage behaviors where different axes experience varying degrees of contraction. This phenomenon is particularly problematic for complex geometries with varying wall thicknesses, internal channels, or overhanging structures. Current predictive models struggle to account for these variations, especially when dealing with novel material systems or multi-material components.

Thermal gradients during the sintering cycle further complicate dimensional control. Parts with uneven mass distribution experience differential heating and cooling rates, leading to internal stresses that manifest as warping, cracking, or unexpected deformation. The challenge intensifies with increasing part size, as larger components are more susceptible to these thermal gradient effects.

Material-specific challenges also emerge across different powder systems. Metal powders typically exhibit different sintering behaviors compared to ceramic materials, with factors such as particle size distribution, powder morphology, and composition significantly influencing dimensional outcomes. The industry lacks standardized approaches that can be universally applied across diverse material systems.

Support structures present another technical hurdle. Unlike laser-based additive manufacturing, binder jetting processes cannot easily incorporate sacrificial supports to maintain dimensional stability during sintering. This limitation restricts design freedom and complicates the production of geometries with substantial overhangs or unsupported features.

The interaction between binder chemistry and sintering behavior introduces additional complexity. Residual binder components can affect sintering kinetics and final densification, creating variations in shrinkage patterns that are difficult to predict from green part characteristics alone. This chemical-thermal interaction remains poorly understood for many advanced material systems.

Current simulation tools exhibit significant limitations in accurately predicting post-sintering dimensions. While finite element analysis and computational fluid dynamics have advanced considerably, they still struggle with the complex multi-physics nature of the sintering process, particularly when accounting for material-specific behaviors and process variations. The computational resources required for high-fidelity simulations often make them impractical for routine industrial applications.

Current Dimensional Recovery Solutions

01 Binder composition for dimensional recovery

Specific binder formulations can significantly impact dimensional recovery in binder jetting processes. These formulations typically include polymeric materials that provide elasticity and shape memory properties to the printed parts. By optimizing the binder chemistry, manufacturers can reduce shrinkage during sintering and improve the dimensional accuracy of final parts. Advanced binders may incorporate additives that create controlled expansion during curing to counteract subsequent shrinkage phases.- Material composition for dimensional recovery: Specific material compositions can be formulated to enhance dimensional recovery in binder jetting processes. These compositions may include specialized polymers, ceramic precursors, or metal powders with controlled particle size distributions that minimize shrinkage during sintering. By incorporating certain additives or binders with shape memory properties, the printed parts can better maintain their intended dimensions throughout the post-processing stages.

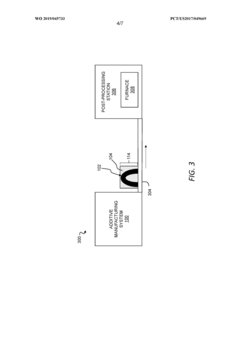

- Post-processing techniques for dimensional control: Various post-processing techniques can be employed to improve dimensional recovery in binder jetted parts. These include controlled heating rates during debinding and sintering, isostatic pressing, infiltration with secondary materials, and specialized curing methods. These techniques help to minimize distortion, warping, and shrinkage that typically occur during the transition from green part to final product, thereby enhancing dimensional accuracy.

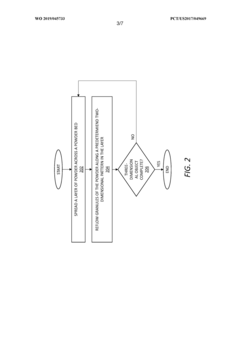

- Process parameter optimization for dimensional stability: Optimizing process parameters plays a crucial role in achieving dimensional recovery in binder jetting. Parameters such as layer thickness, binder saturation, drying time, printing orientation, and build chamber temperature can be fine-tuned to minimize dimensional variations. Advanced algorithms and machine learning approaches can be used to predict and compensate for expected dimensional changes during the printing and post-processing stages.

- Predictive modeling and compensation strategies: Predictive modeling and compensation strategies can be implemented to account for dimensional changes in binder jetting. These approaches involve using computational models to predict shrinkage patterns and then pre-compensating the design by scaling dimensions appropriately. Finite element analysis and simulation tools can help to anticipate dimensional changes during sintering, allowing for more accurate final dimensions through strategic design modifications.

- Novel binder systems for improved dimensional recovery: Innovative binder systems can significantly improve dimensional recovery in binder jetting processes. These may include multi-component binders, thermally responsive polymers, or cross-linkable resins that provide better structural integrity during the green state and controlled shrinkage during sintering. Some advanced binder systems incorporate nanoparticles or reinforcing agents that help maintain part geometry throughout the thermal processing stages.

02 Post-processing techniques for dimensional control

Various post-processing methods can be employed to enhance dimensional recovery in binder jetted parts. These include controlled thermal treatments, isostatic pressing, and specialized sintering profiles that minimize distortion. Some approaches involve multi-stage heating processes where initial low-temperature treatments stabilize the part structure before higher temperature sintering. Infiltration with secondary materials can also be used to compensate for dimensional changes and improve overall part accuracy.Expand Specific Solutions03 Powder characteristics affecting dimensional stability

The physical and chemical properties of the powder feedstock significantly influence dimensional recovery in binder jetting. Particle size distribution, shape, and packing density all affect how parts shrink during processing. Optimized powder blends can be designed with specific particle morphologies that promote more predictable and uniform dimensional changes. Some approaches incorporate sacrificial particles that decompose during sintering to counteract shrinkage in critical dimensions.Expand Specific Solutions04 Computational modeling for predicting dimensional changes

Advanced computational methods can be used to predict and compensate for dimensional changes in binder jetted parts. These include finite element analysis, machine learning algorithms, and physics-based models that simulate material behavior during the entire manufacturing process. By accurately predicting shrinkage patterns, parts can be designed with compensatory features or scaled appropriately before printing to achieve the desired final dimensions after processing.Expand Specific Solutions05 Process parameter optimization for dimensional accuracy

Careful control of process parameters throughout the binder jetting workflow can significantly improve dimensional recovery. Key parameters include printing speed, binder saturation levels, drying conditions, and sintering profiles. By optimizing these variables, manufacturers can minimize internal stresses that lead to warping and distortion. Some approaches involve adaptive processing where parameters are adjusted in real-time based on feedback from in-process monitoring systems to maintain dimensional accuracy.Expand Specific Solutions

Leading Companies in Binder Jetting Technology

Binder Jetting Dimensional Recovery Techniques After Sintering is currently in a growth phase, with the market expanding as additive manufacturing adoption increases. The global market is projected to reach significant scale as industries seek solutions for post-sintering dimensional accuracy. Technologically, the field shows varying maturity levels across players. Desktop Metal leads with advanced recovery algorithms and predictive modeling, while established manufacturers like GE and EOS offer integrated solutions. Emerging players such as Meta Additive and Ricoh are developing specialized approaches, while research institutions like University of Liverpool and Huazhong University contribute fundamental innovations. Material specialists including Evonik and Sumitomo Electric are advancing compatible materials that minimize dimensional changes during sintering processes.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has developed advanced Binder Jetting Dimensional Recovery Techniques through their Single Pass Jetting (SPJ) technology. Their approach incorporates predictive modeling software that anticipates shrinkage during sintering and compensates by scaling the green parts accordingly. The company utilizes a proprietary binder system with controlled rheology that minimizes distortion during the debinding phase. Their sintering process employs precise temperature profiles with controlled heating and cooling rates to manage dimensional changes. Desktop Metal has also implemented real-time monitoring systems that track dimensional changes during sintering, allowing for process adjustments. Their technology incorporates specialized support structures designed to maintain critical geometries during sintering, particularly for complex parts with varying wall thicknesses. The company's dimensional recovery techniques have demonstrated the ability to achieve final part tolerances within ±0.3% of the intended dimensions for most applications.

Strengths: Proprietary software algorithms provide highly accurate shrinkage compensation; integrated process chain from printing to sintering ensures consistency; specialized for high-volume production with repeatable results. Weaknesses: System requires significant initial calibration for new materials; premium pricing compared to competitors; limited material portfolio compared to some specialized competitors.

General Electric Company

Technical Solution: GE has developed comprehensive Binder Jetting Dimensional Recovery Techniques focusing on high-performance metal components for aerospace and energy applications. Their approach combines material science innovations with process engineering to address sintering-related dimensional changes. GE utilizes advanced simulation software that incorporates material-specific shrinkage models to predict and compensate for dimensional changes during sintering. Their technique includes specialized powder formulations with controlled particle size distributions and morphologies that promote uniform shrinkage. GE has developed multi-stage sintering protocols with precisely controlled atmosphere compositions that minimize distortion while maximizing density. The company employs in-situ monitoring systems using optical and thermal sensors to track dimensional changes during the sintering process, enabling real-time adjustments. GE's approach also incorporates post-sintering treatments including controlled cooling regimes and stress-relief processes to further enhance dimensional accuracy. Their techniques have been particularly successful with high-temperature superalloys and refractory metals used in turbine components.

Strengths: Exceptional expertise with high-performance alloys; integrated approach combining materials science and process engineering; robust quality control systems ensuring repeatability. Weaknesses: Solutions primarily optimized for aerospace and energy applications; techniques may be overly complex for simpler applications; higher implementation costs compared to more standardized approaches.

Key Patents in Sintering Compensation Methods

Particle agglomeration for additive metal manufacturing

PatentWO2019045733A1

Innovation

- The use of granules with agglomerated metallic particles and a binder system that can reflow to bind the particles together, allowing for the formation of dense parts with unique microstructures, overcoming the limitations of particle size and safety risks associated with ultrafine particles.

Method for sintering objects formed with aluminum powder

PatentInactiveUS20220226894A1

Innovation

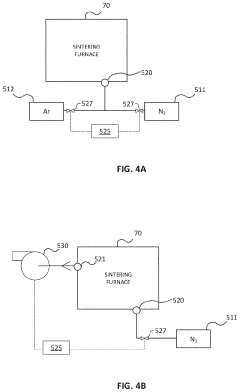

- The method involves sintering aluminum powder objects in a controlled atmosphere composed of Nitrogen and Argon, with optional partial vacuum, to balance mechanical strength and shrinkage, reducing shrinkage to less than 5% and maintaining mechanical strength within 10% of that achieved with pure Nitrogen.

Material Science Considerations for Dimensional Stability

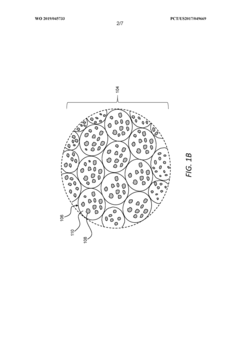

The material science aspects of dimensional stability in Binder Jetting processes represent a critical foundation for developing effective recovery techniques after sintering. The inherent properties of metal powders significantly influence shrinkage behavior during sintering, with particle size distribution playing a paramount role. Finer particles typically result in greater densification but also lead to more pronounced and potentially less predictable shrinkage patterns. The powder morphology—whether spherical, irregular, or flaky—directly impacts powder bed packing density and subsequent dimensional changes during thermal processing.

Alloy composition introduces another layer of complexity, as different metal systems exhibit varying sintering kinetics and phase transformation behaviors. For instance, stainless steels demonstrate different shrinkage characteristics compared to titanium alloys or nickel-based superalloys. The presence of alloying elements can alter melting points, diffusion rates, and ultimately affect the dimensional stability during sintering.

Powder bed homogeneity represents a crucial factor that is often overlooked. Inconsistent powder spreading or localized density variations within the green part create non-uniform shrinkage during sintering, resulting in warping and dimensional inaccuracies. Advanced powder characterization techniques, including dynamic angle of repose measurements and powder rheology assessments, have become essential tools for predicting flow behavior and resultant bed uniformity.

The sintering atmosphere chemistry interacts with material properties in ways that significantly impact dimensional stability. Reducing atmospheres may facilitate better sintering of certain alloys while potentially causing unwanted reactions in others. The presence of oxygen, even in trace amounts, can form oxide layers that impede diffusion bonding between particles, affecting both densification and dimensional predictability.

Thermal gradients during heating and cooling cycles create internal stresses that manifest as distortion in the final part. Materials with higher thermal conductivity generally exhibit more uniform shrinkage, while those with poor thermal conductivity may develop significant internal stress gradients. The coefficient of thermal expansion for specific alloys must be carefully considered when designing sintering profiles to minimize these effects.

Recent research has explored the development of specialized powder blends with controlled sintering behavior. By incorporating secondary phases with different sintering kinetics, researchers have demonstrated the ability to counterbalance shrinkage forces in critical regions of complex geometries. This materials science approach represents a promising direction for dimensional recovery techniques that address the fundamental causes of distortion rather than merely compensating for them after the fact.

Alloy composition introduces another layer of complexity, as different metal systems exhibit varying sintering kinetics and phase transformation behaviors. For instance, stainless steels demonstrate different shrinkage characteristics compared to titanium alloys or nickel-based superalloys. The presence of alloying elements can alter melting points, diffusion rates, and ultimately affect the dimensional stability during sintering.

Powder bed homogeneity represents a crucial factor that is often overlooked. Inconsistent powder spreading or localized density variations within the green part create non-uniform shrinkage during sintering, resulting in warping and dimensional inaccuracies. Advanced powder characterization techniques, including dynamic angle of repose measurements and powder rheology assessments, have become essential tools for predicting flow behavior and resultant bed uniformity.

The sintering atmosphere chemistry interacts with material properties in ways that significantly impact dimensional stability. Reducing atmospheres may facilitate better sintering of certain alloys while potentially causing unwanted reactions in others. The presence of oxygen, even in trace amounts, can form oxide layers that impede diffusion bonding between particles, affecting both densification and dimensional predictability.

Thermal gradients during heating and cooling cycles create internal stresses that manifest as distortion in the final part. Materials with higher thermal conductivity generally exhibit more uniform shrinkage, while those with poor thermal conductivity may develop significant internal stress gradients. The coefficient of thermal expansion for specific alloys must be carefully considered when designing sintering profiles to minimize these effects.

Recent research has explored the development of specialized powder blends with controlled sintering behavior. By incorporating secondary phases with different sintering kinetics, researchers have demonstrated the ability to counterbalance shrinkage forces in critical regions of complex geometries. This materials science approach represents a promising direction for dimensional recovery techniques that address the fundamental causes of distortion rather than merely compensating for them after the fact.

Quality Control Standards for Binder Jetted Components

Quality control standards for binder jetted components have evolved significantly to address the unique challenges associated with dimensional recovery after sintering. These standards now incorporate sophisticated measurement protocols that account for the predictable shrinkage patterns observed during the sintering process. Industry leaders have established multi-stage inspection procedures that begin with green part evaluation and continue through post-sintering dimensional verification.

The ASTM F3122 standard specifically addresses test methods for evaluating binder jetted specimens, while newer standards like ASTM F3301 provide guidelines for process characterization in metal additive manufacturing. These frameworks establish acceptable tolerance ranges for dimensional variations, typically allowing for 2-5% deviation depending on the material system and component complexity.

Statistical process control (SPC) methodologies have been adapted for binder jetting operations, with emphasis on critical dimensional features that experience the most significant changes during sintering. Control charts monitoring key dimensions across production batches help manufacturers establish process capability indices (Cpk) specific to post-sintering recovery techniques.

Non-destructive testing protocols have become integral to quality standards, with computed tomography (CT) scanning emerging as the preferred method for internal feature verification after sintering. These advanced inspection techniques allow manufacturers to validate internal channels, lattice structures, and wall thicknesses that are particularly susceptible to deformation during thermal processing.

Material-specific quality standards have also emerged, recognizing that different metal powders exhibit unique sintering behaviors. For instance, stainless steel components typically follow tighter dimensional control standards (±0.2%) compared to more challenging materials like tungsten carbide composites (±0.5%). These material-specific benchmarks are documented in supplier qualification procedures that have become standard practice in industries adopting binder jetting technology.

Traceability requirements within quality standards now mandate comprehensive documentation of sintering profiles, including temperature ramp rates, hold times, and cooling strategies, all of which significantly impact dimensional recovery. Digital twin approaches are increasingly referenced in advanced standards, enabling predictive quality control through simulation-based verification before physical production.

Industry-specific adaptations of these standards exist for medical, aerospace, and automotive applications, with the most stringent requirements found in implantable medical devices where dimensional accuracy directly impacts clinical outcomes. These specialized standards often incorporate additional requirements for surface finish characteristics that can be affected by sintering recovery techniques.

The ASTM F3122 standard specifically addresses test methods for evaluating binder jetted specimens, while newer standards like ASTM F3301 provide guidelines for process characterization in metal additive manufacturing. These frameworks establish acceptable tolerance ranges for dimensional variations, typically allowing for 2-5% deviation depending on the material system and component complexity.

Statistical process control (SPC) methodologies have been adapted for binder jetting operations, with emphasis on critical dimensional features that experience the most significant changes during sintering. Control charts monitoring key dimensions across production batches help manufacturers establish process capability indices (Cpk) specific to post-sintering recovery techniques.

Non-destructive testing protocols have become integral to quality standards, with computed tomography (CT) scanning emerging as the preferred method for internal feature verification after sintering. These advanced inspection techniques allow manufacturers to validate internal channels, lattice structures, and wall thicknesses that are particularly susceptible to deformation during thermal processing.

Material-specific quality standards have also emerged, recognizing that different metal powders exhibit unique sintering behaviors. For instance, stainless steel components typically follow tighter dimensional control standards (±0.2%) compared to more challenging materials like tungsten carbide composites (±0.5%). These material-specific benchmarks are documented in supplier qualification procedures that have become standard practice in industries adopting binder jetting technology.

Traceability requirements within quality standards now mandate comprehensive documentation of sintering profiles, including temperature ramp rates, hold times, and cooling strategies, all of which significantly impact dimensional recovery. Digital twin approaches are increasingly referenced in advanced standards, enabling predictive quality control through simulation-based verification before physical production.

Industry-specific adaptations of these standards exist for medical, aerospace, and automotive applications, with the most stringent requirements found in implantable medical devices where dimensional accuracy directly impacts clinical outcomes. These specialized standards often incorporate additional requirements for surface finish characteristics that can be affected by sintering recovery techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!