Binder Jetting Vs FDM: Geometric Complexity, Surface Integrity And Application Fit

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Printing Evolution and Objectives

The evolution of 3D printing technology has transformed manufacturing paradigms since its inception in the 1980s. Initially developed as a rapid prototyping tool, 3D printing has evolved into a sophisticated manufacturing methodology capable of producing functional end-use parts. This technological progression has been marked by significant innovations in materials science, process control, and machine design, enabling unprecedented geometric freedom and customization capabilities.

Binder Jetting and Fused Deposition Modeling (FDM) represent two distinct branches in this evolutionary tree. FDM, pioneered by Stratasys in the late 1980s, has become the most widely adopted 3D printing technology due to its accessibility and relatively low cost. The technology has progressed from basic thermoplastic extrusion to incorporate composite materials and high-performance polymers, expanding its application scope.

Binder Jetting, developed in the early 1990s at MIT, has followed a different trajectory, focusing on powder-based fabrication that offers unique advantages in geometric complexity and material diversity. The technology has evolved from producing fragile concept models to creating functional metal, ceramic, and composite parts through significant advancements in binder chemistry and sintering processes.

The current technological landscape is characterized by a growing convergence between traditional manufacturing constraints and additive manufacturing capabilities. Both Binder Jetting and FDM technologies are evolving toward higher precision, improved surface quality, and enhanced material properties to meet industrial requirements. This evolution is driven by the increasing demand for complex geometries that optimize functionality while maintaining structural integrity.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of Binder Jetting and FDM technologies across three critical dimensions: geometric complexity capabilities, surface integrity characteristics, and application suitability. This analysis aims to establish clear parameters for technology selection based on specific manufacturing requirements and end-use applications.

Additionally, this research seeks to identify the technological trajectories of both printing methodologies, forecasting future developments that may alter their comparative advantages. By understanding the fundamental principles, current limitations, and development trends of these technologies, organizations can make informed decisions about technology investment and application development strategies.

The findings from this research will contribute to the broader understanding of additive manufacturing capabilities and limitations, potentially influencing design methodologies, material development priorities, and manufacturing strategy formulations across multiple industries.

Binder Jetting and Fused Deposition Modeling (FDM) represent two distinct branches in this evolutionary tree. FDM, pioneered by Stratasys in the late 1980s, has become the most widely adopted 3D printing technology due to its accessibility and relatively low cost. The technology has progressed from basic thermoplastic extrusion to incorporate composite materials and high-performance polymers, expanding its application scope.

Binder Jetting, developed in the early 1990s at MIT, has followed a different trajectory, focusing on powder-based fabrication that offers unique advantages in geometric complexity and material diversity. The technology has evolved from producing fragile concept models to creating functional metal, ceramic, and composite parts through significant advancements in binder chemistry and sintering processes.

The current technological landscape is characterized by a growing convergence between traditional manufacturing constraints and additive manufacturing capabilities. Both Binder Jetting and FDM technologies are evolving toward higher precision, improved surface quality, and enhanced material properties to meet industrial requirements. This evolution is driven by the increasing demand for complex geometries that optimize functionality while maintaining structural integrity.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of Binder Jetting and FDM technologies across three critical dimensions: geometric complexity capabilities, surface integrity characteristics, and application suitability. This analysis aims to establish clear parameters for technology selection based on specific manufacturing requirements and end-use applications.

Additionally, this research seeks to identify the technological trajectories of both printing methodologies, forecasting future developments that may alter their comparative advantages. By understanding the fundamental principles, current limitations, and development trends of these technologies, organizations can make informed decisions about technology investment and application development strategies.

The findings from this research will contribute to the broader understanding of additive manufacturing capabilities and limitations, potentially influencing design methodologies, material development priorities, and manufacturing strategy formulations across multiple industries.

Market Analysis for Additive Manufacturing Technologies

The additive manufacturing market has experienced significant growth over the past decade, with the global market value reaching $13.7 billion in 2021 and projected to exceed $50 billion by 2030, representing a CAGR of approximately 20%. Within this expanding landscape, Binder Jetting and Fused Deposition Modeling (FDM) technologies occupy distinct market segments with different growth trajectories and application focuses.

FDM technology currently dominates the consumer and prosumer segments, accounting for approximately 65% of desktop 3D printer sales globally. This dominance stems from its accessibility, relatively low equipment costs (starting from $200 for basic models to $20,000 for industrial systems), and straightforward operational requirements. The FDM materials market is similarly robust, with standard filaments like PLA and ABS priced competitively at $20-50 per kilogram, while specialized engineering materials can command $100-300 per kilogram.

Binder Jetting, conversely, has established a growing presence in industrial manufacturing sectors, particularly metal parts production. The market for Binder Jetting systems has grown at 35% annually over the past three years, outpacing the broader additive manufacturing market. System costs typically range from $100,000 to over $1 million, positioning this technology firmly in the industrial and enterprise segments.

Market segmentation analysis reveals distinct application preferences. FDM technology maintains strong market share in prototyping (45% of applications), educational settings (25%), and consumer products (15%). Binder Jetting has gained significant traction in automotive components (30% of applications), aerospace parts (25%), and medical devices (20%), where geometric complexity and material properties are paramount considerations.

Regional market distribution shows North America leading adoption of both technologies, accounting for 40% of the global market, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the fastest growth rate at 25% annually, driven by rapid industrialization and manufacturing innovation initiatives in China, Japan, and South Korea.

Customer segmentation indicates FDM technology appeals primarily to small and medium enterprises, educational institutions, and hobbyists, while Binder Jetting customers are predominantly large manufacturing enterprises, specialized service bureaus, and research institutions with substantial capital expenditure capabilities.

Market forecasts suggest Binder Jetting will experience accelerated growth (30% CAGR) over the next five years compared to FDM (15% CAGR), driven by increasing industrial adoption of additive manufacturing for end-use parts production rather than merely prototyping applications. This shift reflects the broader market transition from additive manufacturing as a prototyping technology to a viable production methodology for complex, high-value components.

FDM technology currently dominates the consumer and prosumer segments, accounting for approximately 65% of desktop 3D printer sales globally. This dominance stems from its accessibility, relatively low equipment costs (starting from $200 for basic models to $20,000 for industrial systems), and straightforward operational requirements. The FDM materials market is similarly robust, with standard filaments like PLA and ABS priced competitively at $20-50 per kilogram, while specialized engineering materials can command $100-300 per kilogram.

Binder Jetting, conversely, has established a growing presence in industrial manufacturing sectors, particularly metal parts production. The market for Binder Jetting systems has grown at 35% annually over the past three years, outpacing the broader additive manufacturing market. System costs typically range from $100,000 to over $1 million, positioning this technology firmly in the industrial and enterprise segments.

Market segmentation analysis reveals distinct application preferences. FDM technology maintains strong market share in prototyping (45% of applications), educational settings (25%), and consumer products (15%). Binder Jetting has gained significant traction in automotive components (30% of applications), aerospace parts (25%), and medical devices (20%), where geometric complexity and material properties are paramount considerations.

Regional market distribution shows North America leading adoption of both technologies, accounting for 40% of the global market, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the fastest growth rate at 25% annually, driven by rapid industrialization and manufacturing innovation initiatives in China, Japan, and South Korea.

Customer segmentation indicates FDM technology appeals primarily to small and medium enterprises, educational institutions, and hobbyists, while Binder Jetting customers are predominantly large manufacturing enterprises, specialized service bureaus, and research institutions with substantial capital expenditure capabilities.

Market forecasts suggest Binder Jetting will experience accelerated growth (30% CAGR) over the next five years compared to FDM (15% CAGR), driven by increasing industrial adoption of additive manufacturing for end-use parts production rather than merely prototyping applications. This shift reflects the broader market transition from additive manufacturing as a prototyping technology to a viable production methodology for complex, high-value components.

Binder Jetting and FDM Technical Challenges

Both Binder Jetting and Fused Deposition Modeling (FDM) face distinct technical challenges that impact their performance, application scope, and adoption rates. Binder Jetting encounters significant issues with material porosity, as the binding process often leaves microscopic voids within printed parts, resulting in reduced mechanical strength compared to traditionally manufactured components. This inherent porosity necessitates post-processing infiltration techniques to enhance density and structural integrity, adding complexity to the production workflow.

The binder chemistry itself presents another critical challenge, as it must be precisely formulated to ensure proper adhesion between powder particles without compromising the final part's mechanical properties. Achieving consistent binder distribution throughout complex geometries remains problematic, particularly in areas with intricate internal features where binder saturation may vary.

Resolution limitations also affect Binder Jetting technology, with minimum feature sizes typically constrained to approximately 100 microns. While superior to some additive manufacturing methods, this resolution threshold restricts applications requiring extremely fine details or microstructures.

FDM technology confronts a different set of challenges, primarily related to layer adhesion and anisotropic mechanical properties. The layer-by-layer deposition process creates inherent weakness along the Z-axis, resulting in parts that exhibit significantly different strength characteristics depending on load orientation. This anisotropy limits FDM's applicability in components subjected to multi-directional stress.

Surface finish quality represents another persistent challenge for FDM, with visible layer lines creating a characteristic "stepped" appearance that often requires extensive post-processing to achieve acceptable surface integrity. The stair-stepping effect becomes particularly pronounced on curved or angled surfaces, compromising both aesthetic appeal and functional performance.

Material constraints further limit FDM applications, as the technology primarily utilizes thermoplastic filaments with temperature limitations and mechanical properties inferior to engineering-grade materials. While high-performance filaments containing carbon fiber or other reinforcements have emerged, they introduce additional challenges related to nozzle wear, printing parameters, and increased equipment costs.

Support structure requirements present challenges for both technologies but manifest differently. FDM typically requires substantial support structures for overhangs and complex geometries, which must be mechanically removed and often leave surface artifacts. Binder Jetting, while offering greater geometric freedom, still requires careful consideration of powder removal from internal channels and cavities.

Temperature management during printing constitutes another significant challenge, particularly for FDM. Thermal gradients can cause warping, delamination, and dimensional inaccuracies, especially when printing large parts or using high-temperature materials. Binder Jetting faces less severe thermal issues but requires precise environmental control during curing and sintering phases.

The binder chemistry itself presents another critical challenge, as it must be precisely formulated to ensure proper adhesion between powder particles without compromising the final part's mechanical properties. Achieving consistent binder distribution throughout complex geometries remains problematic, particularly in areas with intricate internal features where binder saturation may vary.

Resolution limitations also affect Binder Jetting technology, with minimum feature sizes typically constrained to approximately 100 microns. While superior to some additive manufacturing methods, this resolution threshold restricts applications requiring extremely fine details or microstructures.

FDM technology confronts a different set of challenges, primarily related to layer adhesion and anisotropic mechanical properties. The layer-by-layer deposition process creates inherent weakness along the Z-axis, resulting in parts that exhibit significantly different strength characteristics depending on load orientation. This anisotropy limits FDM's applicability in components subjected to multi-directional stress.

Surface finish quality represents another persistent challenge for FDM, with visible layer lines creating a characteristic "stepped" appearance that often requires extensive post-processing to achieve acceptable surface integrity. The stair-stepping effect becomes particularly pronounced on curved or angled surfaces, compromising both aesthetic appeal and functional performance.

Material constraints further limit FDM applications, as the technology primarily utilizes thermoplastic filaments with temperature limitations and mechanical properties inferior to engineering-grade materials. While high-performance filaments containing carbon fiber or other reinforcements have emerged, they introduce additional challenges related to nozzle wear, printing parameters, and increased equipment costs.

Support structure requirements present challenges for both technologies but manifest differently. FDM typically requires substantial support structures for overhangs and complex geometries, which must be mechanically removed and often leave surface artifacts. Binder Jetting, while offering greater geometric freedom, still requires careful consideration of powder removal from internal channels and cavities.

Temperature management during printing constitutes another significant challenge, particularly for FDM. Thermal gradients can cause warping, delamination, and dimensional inaccuracies, especially when printing large parts or using high-temperature materials. Binder Jetting faces less severe thermal issues but requires precise environmental control during curing and sintering phases.

Comparative Analysis of Binder Jetting and FDM Methods

01 Geometric complexity capabilities in Binder Jetting vs FDM

Binder Jetting generally offers superior geometric complexity capabilities compared to FDM. Binder Jetting can produce intricate internal channels, complex lattice structures, and fine details without support structures due to the powder bed providing natural support. FDM has limitations in creating overhangs and complex internal geometries due to the need for support structures, which can be difficult to remove and may affect surface quality. The layer-by-layer deposition method in both technologies affects geometric accuracy differently, with Binder Jetting typically achieving more complex shapes.- Geometric complexity capabilities in Binder Jetting vs FDM: Binder Jetting generally offers superior geometric complexity capabilities compared to FDM. Binder Jetting can produce intricate internal channels, complex lattice structures, and fine details without support structures due to the powder bed providing natural support. FDM has limitations in creating overhangs and complex internal geometries due to the need for support structures, which can be difficult to remove and may affect surface quality. The layer-by-layer deposition process in both technologies affects geometric accuracy differently, with Binder Jetting typically achieving higher resolution for complex features.

- Surface integrity comparison between additive manufacturing technologies: Surface integrity varies significantly between Binder Jetting and FDM processes. FDM typically produces visible layer lines and stair-stepping effects on curved surfaces, requiring post-processing for smooth finishes. Binder Jetting can achieve better surface smoothness initially but may have issues with porosity and mechanical strength. Surface roughness in FDM is influenced by layer height, extrusion width, and printing speed, while in Binder Jetting it depends on powder particle size, binder saturation, and post-processing techniques. Both technologies require specific post-processing methods to achieve optimal surface integrity for functional applications.

- Material considerations affecting geometric precision and surface quality: Material properties significantly impact the achievable geometric precision and surface quality in both Binder Jetting and FDM processes. In FDM, thermoplastic materials with different melting points, shrinkage rates, and flow characteristics affect feature resolution and surface finish. Binder Jetting uses powdered materials whose particle size, shape, and flow properties directly influence surface roughness and detail resolution. Material-specific challenges include warping and shrinkage in FDM, and powder spreading uniformity and green strength in Binder Jetting. Advanced composite materials can enhance both processes by improving dimensional stability and surface characteristics.

- Process parameters optimization for improved surface integrity: Optimizing process parameters is crucial for enhancing surface integrity in both technologies. For FDM, key parameters include nozzle temperature, printing speed, layer height, and cooling rate, which must be balanced to minimize defects like stringing or under-extrusion. In Binder Jetting, parameters such as binder saturation, drying time, layer thickness, and powder spreading speed significantly affect surface quality and dimensional accuracy. Advanced slicing algorithms and toolpath strategies can reduce surface irregularities in FDM, while optimized binder-powder interactions and curing conditions improve Binder Jetting results. Adaptive parameter control systems that adjust settings based on geometry complexity can further enhance surface quality.

- Post-processing techniques for enhanced surface quality: Post-processing techniques are essential for achieving high-quality surface finishes in additively manufactured parts. FDM parts often undergo mechanical finishing (sanding, tumbling), chemical treatments (vapor smoothing with solvents), or coating applications to reduce layer lines and improve surface smoothness. Binder Jetted parts typically require infiltration with resins or metals to enhance density and strength, followed by surface treatments like shot peening or polishing. Advanced post-processing methods include automated robotic finishing systems, selective laser surface modification, and hybrid manufacturing approaches that combine additive and subtractive processes to achieve superior surface integrity while preserving geometric complexity.

02 Surface integrity comparison between additive manufacturing technologies

Surface integrity varies significantly between Binder Jetting and FDM processes. FDM typically produces visible layer lines and stair-stepping effects on curved surfaces, requiring post-processing for smoother finishes. Binder Jetting can achieve better surface smoothness initially but may have issues with porosity and mechanical strength. Surface roughness is influenced by factors including layer thickness, printing orientation, and material properties. Post-processing techniques such as sanding, polishing, and infiltration are often necessary to improve surface integrity for both technologies, with different approaches required for each process.Expand Specific Solutions03 Material considerations affecting geometric precision and surface quality

Material properties significantly impact the achievable geometric precision and surface quality in both Binder Jetting and FDM processes. In FDM, filament properties such as viscosity, thermal expansion, and shrinkage affect dimensional accuracy and surface finish. Binder Jetting's powder characteristics including particle size distribution, flowability, and packing density influence resolution and surface roughness. Composite materials and specialized formulations have been developed to enhance geometric capabilities while maintaining structural integrity. Material selection must be optimized based on the specific geometric requirements and intended application of the printed parts.Expand Specific Solutions04 Process parameters optimization for improved geometric accuracy

Optimizing process parameters is crucial for achieving high geometric accuracy in both Binder Jetting and FDM. For FDM, parameters such as nozzle temperature, printing speed, layer height, and extrusion width significantly impact dimensional accuracy and surface quality. In Binder Jetting, factors including binder saturation, drying time, layer thickness, and powder spreading mechanisms affect geometric precision. Advanced slicing algorithms and toolpath strategies can compensate for known deformations and improve feature resolution. Calibration procedures and in-process monitoring systems help maintain consistent geometric accuracy throughout the build process.Expand Specific Solutions05 Hybrid approaches and post-processing techniques

Hybrid manufacturing approaches combining Binder Jetting or FDM with traditional manufacturing methods can overcome geometric limitations and improve surface integrity. Post-processing techniques such as infiltration, sintering, and heat treatment for Binder Jetted parts, and chemical vapor smoothing, mechanical finishing, and coating applications for FDM parts, can significantly enhance surface quality. Multi-material printing strategies enable complex geometries with varying mechanical properties. Advanced finishing technologies including CNC machining of critical features after printing and automated surface treatment systems help achieve precision tolerances and superior surface finishes that may not be possible with additive manufacturing alone.Expand Specific Solutions

Industry Leaders in 3D Printing Solutions

Binder Jetting and FDM technologies are currently in a growth phase within the additive manufacturing market, which is projected to reach $35 billion by 2027. The competitive landscape is characterized by established players like Desktop Metal, 3D Systems, and HP Development focusing on industrial applications, while newer entrants such as Meta Additive and Evove are driving innovation in material science. Technical maturity varies significantly between the technologies: FDM is more mature with widespread adoption across consumer and industrial sectors, while Binder Jetting is rapidly evolving with companies like Desktop Metal and ExOne advancing capabilities for high-volume production. The market shows increasing specialization with Ricoh, Seiko Epson, and Heidelberger Druckmaschinen leveraging their printing expertise to develop hybrid solutions addressing geometric complexity and surface integrity challenges.

Desktop Metal, Inc.

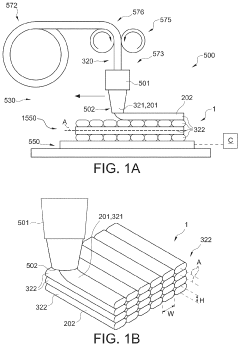

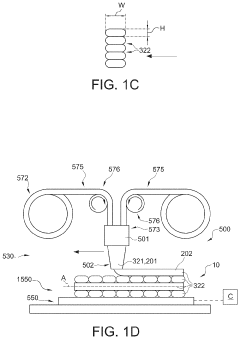

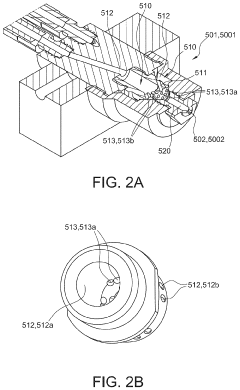

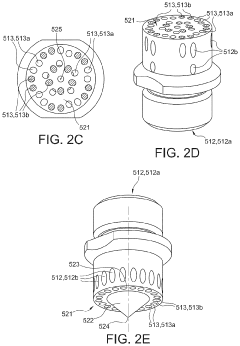

Technical Solution: Desktop Metal has pioneered binder jetting technology through their Production System™ platform, which utilizes Single Pass Jetting™ technology to achieve print speeds up to 12,000 cm³/hr. Their approach involves a bidirectional printing process where printheads deposit both binding agent and anti-sintering agent in a single pass across the build area. This technology enables the production of complex geometries with fine features (down to 50 μm) while maintaining high throughput. Desktop Metal's binder jetting solution incorporates advanced powder spreading mechanisms that achieve layer thicknesses as low as 30 μm, contributing to superior surface finish compared to typical FDM processes. Their proprietary binders are designed to optimize green part strength while minimizing distortion during sintering, addressing one of the historical challenges of binder jetting technology. The company has also developed specialized software tools that automatically generate support structures optimized for metal binder jetting, reducing post-processing requirements.

Strengths: Superior geometric complexity capabilities with ability to produce intricate internal channels and lattice structures impossible with FDM; significantly higher production speeds (up to 100x faster than FDM); excellent material efficiency with recyclable powder. Weaknesses: Requires post-processing sintering step adding production time; potential for warping during sintering; higher initial equipment investment compared to FDM systems.

Meta Additive Ltd.

Technical Solution: Meta Additive has developed a novel approach to binder jetting technology through their Metamorphic Manufacturing process, which utilizes chemically-active binders that react with the powder substrate to form strong green parts. Their technology employs a multi-material jetting system capable of depositing multiple binder formulations within a single build, enabling functionally graded materials and localized property control. Meta Additive's process achieves layer thicknesses down to 20 μm, resulting in exceptional surface finish quality with measured roughness values of Ra 3-8 μm in as-sintered parts. For geometric complexity, their system can produce internal channels with diameters as small as 0.3mm and overhanging structures up to 45° without supports. Meta Additive has focused on developing specialized binders that reduce sintering shrinkage to less than 12%, compared to industry standards of 15-20%, improving dimensional accuracy of final parts. Their technology also incorporates advanced powder recycling systems that achieve powder reusability rates exceeding 95% through automated sieving and characterization processes. Meta Additive's comparative studies have demonstrated that their binder jetting approach achieves approximately 40% higher geometric complexity capabilities than FDM while maintaining comparable mechanical properties after sintering.

Strengths: Superior surface finish quality compared to both traditional binder jetting and FDM; innovative multi-material capabilities enabling functional gradients; reduced sintering shrinkage improving dimensional accuracy. Weaknesses: Newer technology with less established track record; more limited material portfolio compared to larger competitors; higher technical complexity in process parameter optimization.

Key Patents in Geometric Complexity and Surface Integrity

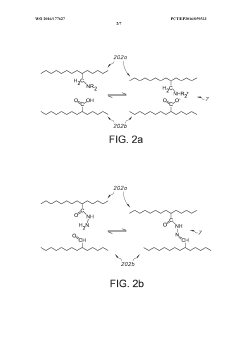

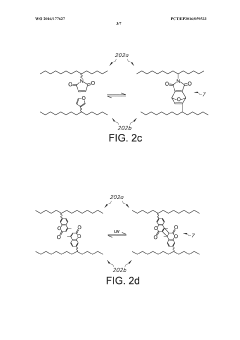

Materials that modify the interface properties of printed materials for obtaining objects with improved strength

PatentWO2016177627A1

Innovation

- A method for 3D printing that involves depositing polymeric materials with reactive groups or reversible bonds, allowing for chemical and electrostatic bonding between layers or filaments, enhancing the strength of the bond between 3D printed item parts, which can be achieved by using polymers with specific reactive groups or bonds that interact during the printing process, potentially incorporating heat and light to initiate bonding reactions.

Color mixing nozzle

PatentActiveUS20230071919A1

Innovation

- A multi-channel mixing head with distribution elements and a combination chamber is used, where materials are distributed through outlets that are configured to alternate spatially, combining into a single exit tube with a smaller diameter, allowing for the combination of materials with varying properties, such as color and optical properties, below the resolution of the human eye.

Material Science Advancements for 3D Printing

Recent advancements in material science have significantly expanded the capabilities and applications of 3D printing technologies, particularly in the comparison between Binder Jetting and Fused Deposition Modeling (FDM). Material innovations have directly addressed the fundamental differences in geometric complexity, surface integrity, and application suitability between these two processes.

For Binder Jetting, the development of advanced binding agents has revolutionized the technology's capabilities. New polymer-based binders with enhanced adhesion properties allow for more intricate geometric structures while maintaining structural integrity. These binders, combined with increasingly refined powder materials, have reduced the minimum feature size achievable to sub-millimeter precision, enabling complex internal channels and lattice structures previously unattainable.

Surface quality improvements have been achieved through post-processing material treatments specifically designed for binder jetted parts. Infiltration materials with optimized viscosity and curing properties now penetrate porous structures more effectively, resulting in smoother surface finishes and improved mechanical properties. Ceramic-polymer composite materials have emerged as particularly promising, offering both high-temperature resistance and reduced post-processing requirements.

In the FDM domain, material science has focused on developing composite filaments that overcome traditional limitations. Carbon fiber and glass fiber reinforced thermoplastics now provide significantly improved mechanical properties while maintaining processability through standard FDM equipment. These materials have expanded FDM applications into functional prototyping and end-use parts where mechanical performance is critical.

Novel support material formulations have addressed one of FDM's primary geometric limitations. Water-soluble and chemically-dissolvable support materials now enable more complex overhanging structures while ensuring clean removal without damaging the primary part geometry. This has particularly benefited medical applications where internal channels and complex organic shapes are common requirements.

Temperature-responsive materials represent another breakthrough, allowing for programmable shape changes after printing. These "4D printing" materials expand FDM capabilities beyond static geometries, creating opportunities in soft robotics and adaptive structures. Meanwhile, antimicrobial and biocompatible filaments have opened new possibilities in medical device manufacturing.

Cross-process material standardization efforts are beginning to emerge, with researchers developing materials that can be effectively processed through both Binder Jetting and FDM technologies. These hybrid approaches leverage the geometric complexity advantages of Binder Jetting with the material strength benefits of thermoplastic extrusion, potentially offering the best of both technologies for specific applications.

For Binder Jetting, the development of advanced binding agents has revolutionized the technology's capabilities. New polymer-based binders with enhanced adhesion properties allow for more intricate geometric structures while maintaining structural integrity. These binders, combined with increasingly refined powder materials, have reduced the minimum feature size achievable to sub-millimeter precision, enabling complex internal channels and lattice structures previously unattainable.

Surface quality improvements have been achieved through post-processing material treatments specifically designed for binder jetted parts. Infiltration materials with optimized viscosity and curing properties now penetrate porous structures more effectively, resulting in smoother surface finishes and improved mechanical properties. Ceramic-polymer composite materials have emerged as particularly promising, offering both high-temperature resistance and reduced post-processing requirements.

In the FDM domain, material science has focused on developing composite filaments that overcome traditional limitations. Carbon fiber and glass fiber reinforced thermoplastics now provide significantly improved mechanical properties while maintaining processability through standard FDM equipment. These materials have expanded FDM applications into functional prototyping and end-use parts where mechanical performance is critical.

Novel support material formulations have addressed one of FDM's primary geometric limitations. Water-soluble and chemically-dissolvable support materials now enable more complex overhanging structures while ensuring clean removal without damaging the primary part geometry. This has particularly benefited medical applications where internal channels and complex organic shapes are common requirements.

Temperature-responsive materials represent another breakthrough, allowing for programmable shape changes after printing. These "4D printing" materials expand FDM capabilities beyond static geometries, creating opportunities in soft robotics and adaptive structures. Meanwhile, antimicrobial and biocompatible filaments have opened new possibilities in medical device manufacturing.

Cross-process material standardization efforts are beginning to emerge, with researchers developing materials that can be effectively processed through both Binder Jetting and FDM technologies. These hybrid approaches leverage the geometric complexity advantages of Binder Jetting with the material strength benefits of thermoplastic extrusion, potentially offering the best of both technologies for specific applications.

Sustainability Impact of Different Printing Technologies

The environmental impact of 3D printing technologies varies significantly between different processes, with Binder Jetting and Fused Deposition Modeling (FDM) representing contrasting approaches with distinct sustainability profiles.

Binder Jetting demonstrates several environmental advantages, particularly in material efficiency. The process selectively deposits binding agents onto powder beds, resulting in minimal material waste compared to subtractive manufacturing methods. Additionally, Binder Jetting operates at room temperature, requiring significantly less energy than high-temperature processes. The technology also excels in material recyclability, with unused powder from print jobs being almost entirely recoverable for future use, creating a near-closed material loop system.

However, Binder Jetting presents certain sustainability challenges. The binding agents often contain volatile organic compounds (VOCs) that may contribute to air pollution and pose potential health risks. Post-processing requirements, including infiltration and curing, can introduce additional chemical agents and energy demands that impact the overall environmental footprint.

In contrast, FDM technology offers different sustainability considerations. The process typically utilizes thermoplastics derived from petroleum sources, though the growing availability of bio-based and recycled filaments is improving its environmental profile. FDM generally consumes moderate energy during operation due to heating requirements for material extrusion, though significantly less than industrial manufacturing processes.

Support structures represent a notable sustainability challenge for FDM, as they generate material waste that is often difficult to recycle effectively. However, the technology benefits from minimal post-processing requirements, reducing additional chemical usage and energy consumption compared to Binder Jetting.

Life cycle assessment studies indicate that the primary environmental impact of both technologies stems from electricity consumption during operation and the raw material production phase. Binder Jetting typically demonstrates lower energy consumption per part but may have higher material preparation impacts, while FDM shows higher operational energy requirements but potentially lower material-related impacts when using sustainable filaments.

The sustainability equation also extends to application longevity. Binder Jetting's superior geometric complexity capabilities enable optimized designs that can reduce material usage and improve functional efficiency in end applications. Meanwhile, FDM parts, while potentially less geometrically optimized, often exhibit better durability in certain applications, extending product lifecycles and reducing replacement frequency.

Binder Jetting demonstrates several environmental advantages, particularly in material efficiency. The process selectively deposits binding agents onto powder beds, resulting in minimal material waste compared to subtractive manufacturing methods. Additionally, Binder Jetting operates at room temperature, requiring significantly less energy than high-temperature processes. The technology also excels in material recyclability, with unused powder from print jobs being almost entirely recoverable for future use, creating a near-closed material loop system.

However, Binder Jetting presents certain sustainability challenges. The binding agents often contain volatile organic compounds (VOCs) that may contribute to air pollution and pose potential health risks. Post-processing requirements, including infiltration and curing, can introduce additional chemical agents and energy demands that impact the overall environmental footprint.

In contrast, FDM technology offers different sustainability considerations. The process typically utilizes thermoplastics derived from petroleum sources, though the growing availability of bio-based and recycled filaments is improving its environmental profile. FDM generally consumes moderate energy during operation due to heating requirements for material extrusion, though significantly less than industrial manufacturing processes.

Support structures represent a notable sustainability challenge for FDM, as they generate material waste that is often difficult to recycle effectively. However, the technology benefits from minimal post-processing requirements, reducing additional chemical usage and energy consumption compared to Binder Jetting.

Life cycle assessment studies indicate that the primary environmental impact of both technologies stems from electricity consumption during operation and the raw material production phase. Binder Jetting typically demonstrates lower energy consumption per part but may have higher material preparation impacts, while FDM shows higher operational energy requirements but potentially lower material-related impacts when using sustainable filaments.

The sustainability equation also extends to application longevity. Binder Jetting's superior geometric complexity capabilities enable optimized designs that can reduce material usage and improve functional efficiency in end applications. Meanwhile, FDM parts, while potentially less geometrically optimized, often exhibit better durability in certain applications, extending product lifecycles and reducing replacement frequency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!