Binder Jetting Defects: Cracking, Delamination And Porosity Mitigation In Metal Parts

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Objectives

Binder Jetting (BJ) technology emerged in the early 1990s at the Massachusetts Institute of Technology, representing a significant advancement in additive manufacturing. Initially developed for creating sand molds and ceramic parts, the technology has evolved substantially over the past three decades to accommodate metal powder processing, opening new possibilities for industrial applications.

The evolution of Binder Jetting can be traced through several distinct phases. The first generation (1990-2000) focused primarily on concept validation and basic process development, with limited material options and relatively low part density. The second generation (2000-2010) saw improvements in binder formulations and printing resolution, enabling more complex geometries and better surface finishes.

The third generation (2010-2020) marked a pivotal shift toward metal Binder Jetting, with significant advancements in sintering processes, material compatibility, and part density. This period witnessed the commercialization of metal BJ systems by companies like ExOne, Digital Metal, and Desktop Metal, bringing the technology into industrial manufacturing environments.

Currently, we are entering the fourth generation of Binder Jetting technology (2020-present), characterized by enhanced process control, advanced material systems, and improved post-processing techniques. This generation aims to address the persistent challenges of part quality, particularly defects such as cracking, delamination, and porosity in metal components.

The primary technical objectives for contemporary Binder Jetting research and development center around defect mitigation strategies. These include optimizing binder-powder interactions to minimize green part defects, developing advanced sintering protocols to reduce thermal stress-induced cracking, and implementing innovative densification techniques to minimize residual porosity.

Additional objectives include expanding the range of compatible metal alloys, improving dimensional accuracy during the sintering phase, and enhancing surface finish quality without extensive post-processing. The industry is also focused on scaling production capabilities while maintaining consistent part quality across build volumes.

Looking forward, the technology roadmap for Binder Jetting aims to achieve near-full density (>99%) metal parts with mechanical properties comparable to traditionally manufactured components, while maintaining the geometric freedom and cost advantages inherent to additive manufacturing. This will require interdisciplinary approaches combining materials science, process engineering, and computational modeling to understand and control the complex physical phenomena occurring during the printing and sintering processes.

The evolution of Binder Jetting can be traced through several distinct phases. The first generation (1990-2000) focused primarily on concept validation and basic process development, with limited material options and relatively low part density. The second generation (2000-2010) saw improvements in binder formulations and printing resolution, enabling more complex geometries and better surface finishes.

The third generation (2010-2020) marked a pivotal shift toward metal Binder Jetting, with significant advancements in sintering processes, material compatibility, and part density. This period witnessed the commercialization of metal BJ systems by companies like ExOne, Digital Metal, and Desktop Metal, bringing the technology into industrial manufacturing environments.

Currently, we are entering the fourth generation of Binder Jetting technology (2020-present), characterized by enhanced process control, advanced material systems, and improved post-processing techniques. This generation aims to address the persistent challenges of part quality, particularly defects such as cracking, delamination, and porosity in metal components.

The primary technical objectives for contemporary Binder Jetting research and development center around defect mitigation strategies. These include optimizing binder-powder interactions to minimize green part defects, developing advanced sintering protocols to reduce thermal stress-induced cracking, and implementing innovative densification techniques to minimize residual porosity.

Additional objectives include expanding the range of compatible metal alloys, improving dimensional accuracy during the sintering phase, and enhancing surface finish quality without extensive post-processing. The industry is also focused on scaling production capabilities while maintaining consistent part quality across build volumes.

Looking forward, the technology roadmap for Binder Jetting aims to achieve near-full density (>99%) metal parts with mechanical properties comparable to traditionally manufactured components, while maintaining the geometric freedom and cost advantages inherent to additive manufacturing. This will require interdisciplinary approaches combining materials science, process engineering, and computational modeling to understand and control the complex physical phenomena occurring during the printing and sintering processes.

Market Analysis for Defect-Free Metal Additive Manufacturing

The global metal additive manufacturing market is experiencing robust growth, projected to reach $10.9 billion by 2030 with a CAGR of 21.5% from 2023. Within this expanding sector, binder jetting technology represents a significant segment due to its cost-effectiveness and scalability advantages over other metal AM processes.

The demand for defect-free metal parts produced through binder jetting is primarily driven by aerospace, automotive, healthcare, and industrial manufacturing sectors. These industries require high-performance components with consistent mechanical properties and structural integrity. The aerospace industry alone accounts for approximately 29% of the metal AM market, with stringent requirements for parts that can withstand extreme conditions without failure.

Market research indicates that manufacturers are increasingly willing to invest in advanced binder jetting solutions that can mitigate common defects such as cracking, delamination, and porosity. A recent survey of manufacturing decision-makers revealed that 76% consider defect reduction as a critical factor in their AM technology adoption decisions.

The economic impact of defects in metal AM parts is substantial, with rework and scrap rates directly affecting production costs. Industry reports suggest that defect-related issues can increase part costs by 15-30%, creating a compelling business case for improved defect mitigation technologies. Companies that can demonstrate consistent quality production with minimal defects command premium pricing in the market.

Regional analysis shows North America leading the market for high-quality metal AM solutions, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate at 24.7% annually, driven by rapid industrialization and government initiatives supporting advanced manufacturing technologies.

Customer segmentation reveals three primary market tiers: high-end users requiring zero-defect parts regardless of cost (primarily aerospace and medical), mid-tier users balancing quality and cost considerations (automotive and general industrial), and cost-sensitive users seeking improved quality within strict budget constraints.

The competitive landscape features established AM equipment manufacturers expanding their binder jetting portfolios with enhanced defect mitigation capabilities, alongside specialized materials suppliers developing optimized powders and binders specifically designed to reduce common defects. This market dynamic is creating opportunities for technology providers focused on process monitoring, simulation software, and post-processing solutions that address the root causes of binder jetting defects.

The demand for defect-free metal parts produced through binder jetting is primarily driven by aerospace, automotive, healthcare, and industrial manufacturing sectors. These industries require high-performance components with consistent mechanical properties and structural integrity. The aerospace industry alone accounts for approximately 29% of the metal AM market, with stringent requirements for parts that can withstand extreme conditions without failure.

Market research indicates that manufacturers are increasingly willing to invest in advanced binder jetting solutions that can mitigate common defects such as cracking, delamination, and porosity. A recent survey of manufacturing decision-makers revealed that 76% consider defect reduction as a critical factor in their AM technology adoption decisions.

The economic impact of defects in metal AM parts is substantial, with rework and scrap rates directly affecting production costs. Industry reports suggest that defect-related issues can increase part costs by 15-30%, creating a compelling business case for improved defect mitigation technologies. Companies that can demonstrate consistent quality production with minimal defects command premium pricing in the market.

Regional analysis shows North America leading the market for high-quality metal AM solutions, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is experiencing the fastest growth rate at 24.7% annually, driven by rapid industrialization and government initiatives supporting advanced manufacturing technologies.

Customer segmentation reveals three primary market tiers: high-end users requiring zero-defect parts regardless of cost (primarily aerospace and medical), mid-tier users balancing quality and cost considerations (automotive and general industrial), and cost-sensitive users seeking improved quality within strict budget constraints.

The competitive landscape features established AM equipment manufacturers expanding their binder jetting portfolios with enhanced defect mitigation capabilities, alongside specialized materials suppliers developing optimized powders and binders specifically designed to reduce common defects. This market dynamic is creating opportunities for technology providers focused on process monitoring, simulation software, and post-processing solutions that address the root causes of binder jetting defects.

Current Challenges in Binder Jetting Metal Processing

Despite significant advancements in binder jetting technology, several critical challenges persist in metal processing applications. The primary technical hurdle remains the management of defects including cracking, delamination, and excessive porosity, which significantly impact the mechanical properties and functional performance of final parts.

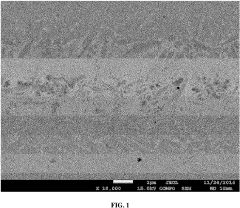

Cracking represents one of the most prevalent issues in binder jetted metal components, typically occurring during the sintering phase when thermal stresses develop due to non-uniform shrinkage. These cracks often initiate at stress concentration points or areas with density variations in the green part, propagating along weak interfaces. Current research indicates that crack formation is particularly problematic in large components or geometries with varying cross-sections.

Delamination presents another significant challenge, characterized by layer separation that compromises structural integrity. This defect commonly results from insufficient layer adhesion during printing, inadequate binder distribution, or excessive thermal gradients during thermal processing. The interface between layers represents a natural weakness in the additive manufacturing process that requires careful management through process optimization.

Porosity control remains perhaps the most persistent challenge in binder jetting metal processing. Unlike laser-based metal AM technologies that achieve near-full density through melting, binder jetted parts typically exhibit 15-30% residual porosity post-sintering without additional processing steps. This inherent porosity affects mechanical properties, particularly fatigue resistance and ductility, limiting applications in high-performance sectors.

Current industrial approaches to mitigate these defects include process parameter optimization, powder characteristics refinement, and post-processing techniques. However, these solutions often involve trade-offs between production speed, part quality, and cost-effectiveness. For instance, slower sintering cycles may reduce cracking but significantly increase production time and energy consumption.

Material-specific challenges further complicate defect management, as different metal alloys exhibit varying sintering behaviors, shrinkage rates, and susceptibility to defect formation. High-performance alloys like titanium and nickel-based superalloys present particular difficulties due to their oxidation sensitivity and complex sintering requirements.

The technical community has identified several critical research directions to address these challenges, including advanced simulation tools for predicting defect formation, in-situ monitoring systems for real-time process control, and novel binder formulations designed to enhance green part strength while minimizing residual carbon content after debinding.

Cracking represents one of the most prevalent issues in binder jetted metal components, typically occurring during the sintering phase when thermal stresses develop due to non-uniform shrinkage. These cracks often initiate at stress concentration points or areas with density variations in the green part, propagating along weak interfaces. Current research indicates that crack formation is particularly problematic in large components or geometries with varying cross-sections.

Delamination presents another significant challenge, characterized by layer separation that compromises structural integrity. This defect commonly results from insufficient layer adhesion during printing, inadequate binder distribution, or excessive thermal gradients during thermal processing. The interface between layers represents a natural weakness in the additive manufacturing process that requires careful management through process optimization.

Porosity control remains perhaps the most persistent challenge in binder jetting metal processing. Unlike laser-based metal AM technologies that achieve near-full density through melting, binder jetted parts typically exhibit 15-30% residual porosity post-sintering without additional processing steps. This inherent porosity affects mechanical properties, particularly fatigue resistance and ductility, limiting applications in high-performance sectors.

Current industrial approaches to mitigate these defects include process parameter optimization, powder characteristics refinement, and post-processing techniques. However, these solutions often involve trade-offs between production speed, part quality, and cost-effectiveness. For instance, slower sintering cycles may reduce cracking but significantly increase production time and energy consumption.

Material-specific challenges further complicate defect management, as different metal alloys exhibit varying sintering behaviors, shrinkage rates, and susceptibility to defect formation. High-performance alloys like titanium and nickel-based superalloys present particular difficulties due to their oxidation sensitivity and complex sintering requirements.

The technical community has identified several critical research directions to address these challenges, including advanced simulation tools for predicting defect formation, in-situ monitoring systems for real-time process control, and novel binder formulations designed to enhance green part strength while minimizing residual carbon content after debinding.

Existing Defect Mitigation Strategies and Techniques

01 Binder formulation optimization to reduce cracking

Optimizing binder formulations can significantly reduce cracking in binder jetting processes. By incorporating specific polymers, resins, or additives that enhance flexibility and strength, the printed parts can better withstand thermal stresses during curing and sintering. These improved formulations create stronger bonds between powder particles, minimizing the formation of cracks during processing and improving overall structural integrity of the final parts.- Binder composition optimization to reduce cracking: Optimizing binder compositions can significantly reduce cracking in binder jetting processes. By incorporating specific polymers, resins, or additives that enhance flexibility and strength, the printed parts can better withstand thermal stresses during curing and sintering. These improved binder formulations create stronger bonds between particles while maintaining appropriate viscosity for printing, resulting in parts with reduced crack formation and improved structural integrity.

- Process parameter control to prevent delamination: Controlling process parameters such as printing speed, layer thickness, drying time, and curing temperature is crucial for preventing delamination in binder jetted parts. Proper calibration of these parameters ensures optimal binder penetration and uniform distribution throughout each layer. Gradual heating and cooling cycles during post-processing help minimize thermal stresses that can cause layer separation. Advanced monitoring systems can detect potential delamination issues in real-time, allowing for immediate adjustments to the manufacturing process.

- Porosity management techniques: Managing porosity in binder jetted parts involves strategic approaches to control pore size, distribution, and connectivity. Techniques include adjusting powder particle size distribution, optimizing binder saturation levels, and implementing specialized post-processing treatments. Controlled porosity can be beneficial for certain applications requiring lightweight structures or fluid permeability, while unwanted porosity can be reduced through infiltration with secondary materials or modified sintering profiles. These techniques allow manufacturers to achieve desired mechanical properties while minimizing defects related to excessive porosity.

- Multi-material and composite approaches: Incorporating multiple materials or composites in binder jetting processes can address cracking, delamination, and porosity issues. By strategically combining materials with complementary properties, such as reinforcing fibers or particles within a matrix, the resulting parts exhibit enhanced structural integrity. Gradient material transitions can reduce stress concentrations at interfaces, while specialized binders designed for multi-material compatibility ensure strong interlayer adhesion. These approaches enable the production of complex parts with improved mechanical properties and reduced defect formation.

- Post-processing treatments for defect mitigation: Various post-processing treatments can effectively mitigate defects in binder jetted parts. These include specialized heat treatments to relieve internal stresses, infiltration with secondary materials to fill pores and strengthen the structure, surface treatments to seal microcracks, and hot isostatic pressing to reduce internal voids. Advanced curing methods using controlled atmospheres or pressure can also enhance part density and integrity. These post-processing approaches can transform parts with potential defects into high-quality components with improved mechanical properties and surface finish.

02 Post-processing techniques to address delamination

Various post-processing techniques can be employed to address delamination issues in binder jetted parts. These include controlled thermal treatments, infiltration with secondary materials, and specialized curing protocols. By carefully managing the transition from green state to final part, these methods help to maintain layer adhesion and prevent separation between printed layers, resulting in more cohesive and structurally sound components.Expand Specific Solutions03 Porosity control through particle size distribution

Controlling porosity in binder jetted parts can be achieved through careful management of powder particle size distribution. By utilizing optimized mixtures of fine and coarse particles, manufacturers can achieve desired porosity levels while maintaining structural integrity. This approach allows for better packing density during the printing process, reducing unwanted voids and creating more predictable and controlled porosity in the final parts.Expand Specific Solutions04 Process parameter optimization for defect reduction

Optimizing process parameters such as binder saturation levels, drying rates, and printing speeds can significantly reduce defects in binder jetted parts. By carefully controlling these variables, manufacturers can minimize issues like cracking, delamination, and uncontrolled porosity. Advanced monitoring systems and feedback controls help maintain optimal conditions throughout the printing process, resulting in higher quality parts with fewer structural defects.Expand Specific Solutions05 Material selection strategies to prevent defects

Strategic selection of powder materials and binder systems can prevent common defects in binder jetting. By choosing materials with compatible thermal expansion properties, appropriate particle morphologies, and suitable surface characteristics, manufacturers can minimize cracking and delamination. Additionally, incorporating specialized additives that enhance flowability, wettability, and green strength can lead to more uniform parts with reduced porosity issues and improved overall quality.Expand Specific Solutions

Leading Companies in Binder Jetting Technology Ecosystem

Binder Jetting technology for metal parts is currently in a growth phase, with the market expanding due to increasing industrial adoption. The technology faces challenges with defects like cracking, delamination, and porosity that limit widespread implementation. Key players including Desktop Metal, Xerox Holdings, and Intel are advancing solutions through material science innovations and process optimization. Academic institutions like Beijing University of Technology are collaborating with industrial partners such as Element Six and Mitsubishi Heavy Industries to develop defect mitigation strategies. The competitive landscape features both established manufacturing corporations and specialized additive manufacturing companies working to improve part quality and reliability, indicating a maturing but not yet fully mature technology ecosystem.

Xerox Holdings Corp.

Technical Solution: Xerox has leveraged its extensive expertise in material jetting technologies to develop innovative solutions for metal binder jetting defect mitigation. Their approach incorporates a proprietary multi-functional binder system that combines structural polymers with surfactants to optimize wetting behavior and minimize binder migration issues that lead to cracking. Xerox employs advanced jetting technology with precise droplet control, allowing for variable binder saturation across different regions of a part to address localized stress concentrations. Their process includes a specialized drying protocol with controlled humidity and temperature gradients to minimize warping and cracking during the critical green state phase. Xerox has developed an AI-driven process monitoring system that analyzes high-resolution images of each printed layer to detect potential defect precursors and automatically adjust printing parameters in real-time[6]. Additionally, they utilize a proprietary sintering support structure system that accommodates differential shrinkage rates across complex geometries, significantly reducing delamination risks during thermal processing.

Strengths: Exceptional expertise in precision fluid deposition systems; advanced process monitoring and control capabilities; strong intellectual property portfolio in jetting technologies. Weaknesses: Relatively newer entrant to metal binder jetting compared to some competitors; solutions may be more focused on printing process than post-processing optimization; limited track record with high-temperature metal alloys.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has developed a proprietary Single Pass Jetting (SPJ) technology that addresses common Binder Jetting defects. Their approach incorporates a specialized binder system with controlled rheological properties to minimize cracking during the drying phase. The company employs a multi-stage thermal processing protocol that includes carefully controlled debinding and sintering profiles to reduce thermal stresses that lead to delamination. To address porosity issues, Desktop Metal utilizes nanoscale metal powders with optimized particle size distribution and implements a proprietary infiltration process during sintering that fills microscopic voids with molten metal. Their Production System P-50 incorporates real-time monitoring with infrared sensors to detect potential defect formation during printing, allowing for immediate process adjustments[1][3]. The company has also developed specialized software algorithms that optimize print orientation and support structures to minimize internal stresses that contribute to cracking and delamination.

Strengths: Advanced real-time monitoring capabilities allow for immediate process corrections; proprietary binder formulations provide superior green part strength; integrated end-to-end manufacturing solution reduces handling-related defects. Weaknesses: Higher system costs compared to conventional binder jetting systems; requires specialized materials that may limit material selection flexibility; complex thermal processing protocols may extend production timeframes.

Critical Patents and Research on Binder Jetting Defect Control

Material system for 3D printing

PatentWO2022268546A1

Innovation

- A material system comprising polymer particles and a liquid binder with a polymerizable component and an oxygen scavenger containing a phosphor atom, enabling high monomer conversion and enhanced mechanical properties at ambient conditions, allowing for dense and robust 3D printed articles with improved tensile strength and elongation at break.

Infiltrated ferrous materials

PatentInactiveUS20230249250A1

Innovation

- A layer-by-layer construction method using iron-based alloys with spherical powders and infiltration with a suitable liquid phase to form a strong, wear-resistant metallic structure that is stable at high temperatures, eliminating the need for thermal hardening processes like quenching and tempering.

Material Science Advancements for Improved Binder Jetting

Recent advancements in material science have significantly contributed to improving binder jetting processes for metal additive manufacturing. The development of specialized binder formulations with enhanced rheological properties has addressed many traditional challenges in part cohesion and green strength. These next-generation binders incorporate polymeric additives that provide better particle-to-particle adhesion while maintaining optimal flow characteristics during deposition.

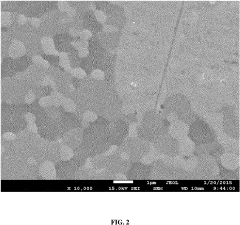

Powder metallurgy innovations have also played a crucial role in defect mitigation. Researchers have developed metal powders with optimized particle size distributions, typically featuring bimodal or trimodal distributions that maximize packing density while minimizing interstitial voids. These advanced powder systems achieve up to 15% higher green density compared to conventional powders, directly correlating with reduced final part porosity.

Surface modification technologies for metal powders represent another breakthrough area. Treatments such as plasma functionalization and chemical passivation have enhanced powder wettability and binder interaction. These modifications create stronger mechanical interlocking between particles during the green state, reducing the likelihood of delamination during subsequent processing steps.

Sintering aids and infiltration materials have evolved to address density challenges. Novel sintering additives that form transient liquid phases at lower temperatures facilitate densification while maintaining dimensional accuracy. These materials effectively reduce sintering temperatures by 50-100°C while achieving comparable or superior mechanical properties, thus minimizing thermal stress-induced cracking.

Composite binder systems combining organic and inorganic components have demonstrated superior performance in creating robust green parts. The organic components provide initial binding strength while the inorganic elements contribute to structural integrity during debinding and sintering. This dual-phase approach has been shown to reduce delamination defects by up to 40% in complex geometries.

Nanomaterial incorporation represents the cutting edge of binder jetting material science. The addition of nanoparticles such as silicon carbide, alumina, or carbon nanotubes in precise concentrations (typically 0.1-0.5 wt%) has demonstrated remarkable improvements in both green strength and sintered properties. These nanomaterials act as reinforcing agents and sintering activators, creating more homogeneous microstructures with reduced crack propagation pathways.

Powder metallurgy innovations have also played a crucial role in defect mitigation. Researchers have developed metal powders with optimized particle size distributions, typically featuring bimodal or trimodal distributions that maximize packing density while minimizing interstitial voids. These advanced powder systems achieve up to 15% higher green density compared to conventional powders, directly correlating with reduced final part porosity.

Surface modification technologies for metal powders represent another breakthrough area. Treatments such as plasma functionalization and chemical passivation have enhanced powder wettability and binder interaction. These modifications create stronger mechanical interlocking between particles during the green state, reducing the likelihood of delamination during subsequent processing steps.

Sintering aids and infiltration materials have evolved to address density challenges. Novel sintering additives that form transient liquid phases at lower temperatures facilitate densification while maintaining dimensional accuracy. These materials effectively reduce sintering temperatures by 50-100°C while achieving comparable or superior mechanical properties, thus minimizing thermal stress-induced cracking.

Composite binder systems combining organic and inorganic components have demonstrated superior performance in creating robust green parts. The organic components provide initial binding strength while the inorganic elements contribute to structural integrity during debinding and sintering. This dual-phase approach has been shown to reduce delamination defects by up to 40% in complex geometries.

Nanomaterial incorporation represents the cutting edge of binder jetting material science. The addition of nanoparticles such as silicon carbide, alumina, or carbon nanotubes in precise concentrations (typically 0.1-0.5 wt%) has demonstrated remarkable improvements in both green strength and sintered properties. These nanomaterials act as reinforcing agents and sintering activators, creating more homogeneous microstructures with reduced crack propagation pathways.

Quality Control Systems and Standards for Binder Jetting

Quality control systems for binder jetting technology have evolved significantly to address the critical defects of cracking, delamination, and porosity in metal parts. The industry has established comprehensive inspection protocols that combine in-process monitoring with post-production evaluation to ensure consistent part quality.

International standards organizations, including ASTM International and ISO, have developed specific guidelines for binder jetting processes. ASTM F3122 provides standard terminology for powder bed fusion, while ISO/ASTM 52901:2021 outlines requirements for purchased AM parts. These standards establish baseline quality expectations and testing methodologies specifically addressing common defects in metal binder jetted components.

Real-time monitoring systems have become essential in modern binder jetting setups. Advanced optical systems track powder spreading uniformity and binder deposition accuracy, while thermal imaging cameras monitor temperature gradients during sintering—a critical factor in preventing crack formation. Machine learning algorithms increasingly analyze this data to predict potential defect formation before parts complete processing.

Non-destructive testing (NDT) methods have been adapted specifically for binder jetted parts. X-ray computed tomography (CT) scanning allows for internal inspection of complex geometries, detecting internal cracks and voids with resolutions down to 5 microns. Ultrasonic testing has been modified to accommodate the unique material properties of binder jetted metals, particularly useful for identifying delamination between layers.

Statistical process control (SPC) methodologies tailored to binder jetting track key process parameters including binder saturation levels, drying rates, and sintering profiles. These systems establish control limits that, when maintained, significantly reduce defect occurrence rates. Leading manufacturers implement digital twin technology to compare actual production data against ideal process models in real-time.

Material certification systems have become increasingly stringent, with powder suppliers providing detailed characterization of particle size distribution, morphology, and chemical composition. Traceability requirements ensure that material properties can be tracked throughout the production process, enabling root cause analysis when defects occur.

Quality management systems for binder jetting operations typically integrate ISO 9001 frameworks with additive manufacturing-specific requirements. Documentation procedures capture process parameters, material certifications, and inspection results, creating comprehensive quality records for each production batch. This systematic approach has proven effective in reducing defect rates while providing necessary documentation for regulated industries.

International standards organizations, including ASTM International and ISO, have developed specific guidelines for binder jetting processes. ASTM F3122 provides standard terminology for powder bed fusion, while ISO/ASTM 52901:2021 outlines requirements for purchased AM parts. These standards establish baseline quality expectations and testing methodologies specifically addressing common defects in metal binder jetted components.

Real-time monitoring systems have become essential in modern binder jetting setups. Advanced optical systems track powder spreading uniformity and binder deposition accuracy, while thermal imaging cameras monitor temperature gradients during sintering—a critical factor in preventing crack formation. Machine learning algorithms increasingly analyze this data to predict potential defect formation before parts complete processing.

Non-destructive testing (NDT) methods have been adapted specifically for binder jetted parts. X-ray computed tomography (CT) scanning allows for internal inspection of complex geometries, detecting internal cracks and voids with resolutions down to 5 microns. Ultrasonic testing has been modified to accommodate the unique material properties of binder jetted metals, particularly useful for identifying delamination between layers.

Statistical process control (SPC) methodologies tailored to binder jetting track key process parameters including binder saturation levels, drying rates, and sintering profiles. These systems establish control limits that, when maintained, significantly reduce defect occurrence rates. Leading manufacturers implement digital twin technology to compare actual production data against ideal process models in real-time.

Material certification systems have become increasingly stringent, with powder suppliers providing detailed characterization of particle size distribution, morphology, and chemical composition. Traceability requirements ensure that material properties can be tracked throughout the production process, enabling root cause analysis when defects occur.

Quality management systems for binder jetting operations typically integrate ISO 9001 frameworks with additive manufacturing-specific requirements. Documentation procedures capture process parameters, material certifications, and inspection results, creating comprehensive quality records for each production batch. This systematic approach has proven effective in reducing defect rates while providing necessary documentation for regulated industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!