Binder Jetting Powder Stewardship: Storage, Humidity Control And Oxidation Prevention

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Powder Technology Background and Objectives

Binder Jetting (BJ) technology has emerged as a significant advancement in the field of additive manufacturing since its inception in the early 1990s at MIT. This powder-based 3D printing process selectively deposits a liquid binding agent onto thin layers of powder materials, creating complex three-dimensional structures through a layer-by-layer approach. The evolution of this technology has been marked by continuous improvements in resolution, material compatibility, and process reliability.

The powder materials used in Binder Jetting represent a critical component of the technology ecosystem. Initially limited to ceramics and metals, the material portfolio has expanded significantly to include a diverse range of metal alloys, ceramics, composites, and even pharmaceutical compounds. This material versatility has positioned Binder Jetting as a versatile manufacturing solution across multiple industries including aerospace, automotive, healthcare, and consumer products.

Recent technological developments have focused on enhancing powder characteristics and behavior during the printing process. Particularly, the control of powder rheology, particle size distribution, and surface properties has become increasingly important for achieving optimal print quality and mechanical properties in final parts. The industry has witnessed a shift from first-generation systems with limited material options to advanced platforms capable of processing highly specialized powders with tailored properties.

A significant challenge in the Binder Jetting ecosystem involves the proper stewardship of powder materials throughout their lifecycle. Powder degradation due to environmental factors such as humidity and oxidation can severely impact print quality, dimensional accuracy, and mechanical properties of finished parts. This has necessitated the development of comprehensive powder management protocols to maintain material integrity from production through storage, handling, and printing.

The primary objective of this technical research is to establish a thorough understanding of the factors affecting powder stability in Binder Jetting processes, with particular emphasis on storage conditions, humidity control mechanisms, and oxidation prevention strategies. By identifying critical parameters and developing effective mitigation approaches, we aim to enhance powder longevity, reduce material waste, and improve manufacturing consistency.

Additionally, this research seeks to map the technological trajectory of powder stewardship solutions, identifying emerging innovations and best practices that can be implemented across various operational scales. The goal is to develop a framework that balances technical effectiveness with practical implementation considerations, enabling manufacturers to optimize their powder management processes regardless of production volume or facility constraints.

As regulatory frameworks around additive manufacturing continue to evolve, particularly in critical applications like aerospace and medical devices, establishing robust powder stewardship protocols becomes increasingly important for compliance and certification. This research will also examine how powder management practices align with current and emerging industry standards and regulatory requirements.

The powder materials used in Binder Jetting represent a critical component of the technology ecosystem. Initially limited to ceramics and metals, the material portfolio has expanded significantly to include a diverse range of metal alloys, ceramics, composites, and even pharmaceutical compounds. This material versatility has positioned Binder Jetting as a versatile manufacturing solution across multiple industries including aerospace, automotive, healthcare, and consumer products.

Recent technological developments have focused on enhancing powder characteristics and behavior during the printing process. Particularly, the control of powder rheology, particle size distribution, and surface properties has become increasingly important for achieving optimal print quality and mechanical properties in final parts. The industry has witnessed a shift from first-generation systems with limited material options to advanced platforms capable of processing highly specialized powders with tailored properties.

A significant challenge in the Binder Jetting ecosystem involves the proper stewardship of powder materials throughout their lifecycle. Powder degradation due to environmental factors such as humidity and oxidation can severely impact print quality, dimensional accuracy, and mechanical properties of finished parts. This has necessitated the development of comprehensive powder management protocols to maintain material integrity from production through storage, handling, and printing.

The primary objective of this technical research is to establish a thorough understanding of the factors affecting powder stability in Binder Jetting processes, with particular emphasis on storage conditions, humidity control mechanisms, and oxidation prevention strategies. By identifying critical parameters and developing effective mitigation approaches, we aim to enhance powder longevity, reduce material waste, and improve manufacturing consistency.

Additionally, this research seeks to map the technological trajectory of powder stewardship solutions, identifying emerging innovations and best practices that can be implemented across various operational scales. The goal is to develop a framework that balances technical effectiveness with practical implementation considerations, enabling manufacturers to optimize their powder management processes regardless of production volume or facility constraints.

As regulatory frameworks around additive manufacturing continue to evolve, particularly in critical applications like aerospace and medical devices, establishing robust powder stewardship protocols becomes increasingly important for compliance and certification. This research will also examine how powder management practices align with current and emerging industry standards and regulatory requirements.

Market Analysis for Binder Jetting Additive Manufacturing

The global binder jetting additive manufacturing market has experienced significant growth in recent years, with a market value reaching $1.3 billion in 2022 and projected to expand at a compound annual growth rate of 21.5% through 2030. This robust growth trajectory is primarily driven by increasing industrial adoption across automotive, aerospace, healthcare, and consumer goods sectors seeking cost-effective manufacturing solutions with complex geometries.

Metal binder jetting represents the fastest-growing segment within this market, accounting for approximately 65% of the total market share. This dominance stems from the technology's ability to produce high-density metal parts with mechanical properties comparable to traditional manufacturing methods, but with greater design freedom and reduced material waste.

Powder management challenges, particularly related to storage, humidity control, and oxidation prevention, have emerged as critical factors influencing market adoption rates. Industry surveys indicate that 78% of end-users cite powder handling concerns as a significant barrier to wider implementation, highlighting the need for improved stewardship protocols and technologies.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing industrialization and government initiatives supporting advanced manufacturing technologies in countries like China, Japan, and South Korea.

The competitive landscape features both established players and innovative startups. Major industrial printer manufacturers hold approximately 55% of the market, while specialized powder suppliers control about 30%. The remaining market share is distributed among service providers and emerging technology developers focused on powder management solutions.

Customer segmentation analysis indicates that large enterprises constitute 62% of the current customer base, with small and medium enterprises (SMEs) representing 38%. However, the SME segment is growing at a faster rate as equipment costs decrease and awareness of the technology's benefits increases.

End-user demand patterns show increasing interest in complete ecosystem solutions rather than standalone equipment. Approximately 85% of potential customers express preference for integrated systems that address the entire workflow, including powder handling, recycling, and quality control measures that mitigate oxidation and humidity-related challenges.

Metal binder jetting represents the fastest-growing segment within this market, accounting for approximately 65% of the total market share. This dominance stems from the technology's ability to produce high-density metal parts with mechanical properties comparable to traditional manufacturing methods, but with greater design freedom and reduced material waste.

Powder management challenges, particularly related to storage, humidity control, and oxidation prevention, have emerged as critical factors influencing market adoption rates. Industry surveys indicate that 78% of end-users cite powder handling concerns as a significant barrier to wider implementation, highlighting the need for improved stewardship protocols and technologies.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to increasing industrialization and government initiatives supporting advanced manufacturing technologies in countries like China, Japan, and South Korea.

The competitive landscape features both established players and innovative startups. Major industrial printer manufacturers hold approximately 55% of the market, while specialized powder suppliers control about 30%. The remaining market share is distributed among service providers and emerging technology developers focused on powder management solutions.

Customer segmentation analysis indicates that large enterprises constitute 62% of the current customer base, with small and medium enterprises (SMEs) representing 38%. However, the SME segment is growing at a faster rate as equipment costs decrease and awareness of the technology's benefits increases.

End-user demand patterns show increasing interest in complete ecosystem solutions rather than standalone equipment. Approximately 85% of potential customers express preference for integrated systems that address the entire workflow, including powder handling, recycling, and quality control measures that mitigate oxidation and humidity-related challenges.

Current Challenges in Powder Stewardship and Preservation

The powder management process in binder jetting additive manufacturing presents significant challenges that impact production efficiency, part quality, and operational costs. Moisture absorption remains one of the most critical issues, as metal and ceramic powders are highly susceptible to humidity. When exposed to ambient conditions, these materials can rapidly absorb atmospheric moisture, leading to agglomeration, reduced flowability, and compromised powder spreadability. This directly affects layer uniformity and ultimately results in dimensional inaccuracies and structural defects in final parts.

Oxidation represents another major challenge, particularly for reactive metal powders such as aluminum, titanium, and their alloys. Even minimal exposure to oxygen can trigger surface oxidation, altering the powder's chemical composition and physical properties. The formation of oxide layers not only affects the sintering behavior during thermal processing but also introduces potential weak points in the finished components, compromising mechanical performance and reliability in critical applications.

Powder degradation through repeated use cycles constitutes a persistent issue in production environments. The recycling of unused powder is economically necessary, but each processing cycle subjects particles to mechanical stress, potential contamination, and gradual property changes. Current monitoring systems lack the sensitivity to detect subtle alterations in powder characteristics until they manifest as visible defects in manufactured parts, creating quality control challenges.

Storage infrastructure deficiencies exacerbate these preservation challenges. Many facilities lack properly controlled environments with appropriate temperature and humidity regulation. Standard industrial storage containers often provide insufficient protection against environmental factors, while specialized containers with inert gas purging capabilities remain prohibitively expensive for smaller operations, creating a significant barrier to entry for new market participants.

Cross-contamination between different powder batches or materials represents an underappreciated risk in multi-material production facilities. Even trace amounts of foreign particles can compromise material properties and introduce unpredictable behavior during processing. Current cleaning protocols between material changes are often inadequate, time-consuming, and difficult to validate without sophisticated analytical equipment.

The absence of standardized handling protocols further complicates powder management. Unlike well-established manufacturing processes, binder jetting lacks comprehensive industry standards for powder handling, leading to inconsistent practices across organizations. This variability makes it difficult to establish reliable quality benchmarks and troubleshoot processing issues when they arise, ultimately slowing industry-wide advancement and knowledge sharing.

Oxidation represents another major challenge, particularly for reactive metal powders such as aluminum, titanium, and their alloys. Even minimal exposure to oxygen can trigger surface oxidation, altering the powder's chemical composition and physical properties. The formation of oxide layers not only affects the sintering behavior during thermal processing but also introduces potential weak points in the finished components, compromising mechanical performance and reliability in critical applications.

Powder degradation through repeated use cycles constitutes a persistent issue in production environments. The recycling of unused powder is economically necessary, but each processing cycle subjects particles to mechanical stress, potential contamination, and gradual property changes. Current monitoring systems lack the sensitivity to detect subtle alterations in powder characteristics until they manifest as visible defects in manufactured parts, creating quality control challenges.

Storage infrastructure deficiencies exacerbate these preservation challenges. Many facilities lack properly controlled environments with appropriate temperature and humidity regulation. Standard industrial storage containers often provide insufficient protection against environmental factors, while specialized containers with inert gas purging capabilities remain prohibitively expensive for smaller operations, creating a significant barrier to entry for new market participants.

Cross-contamination between different powder batches or materials represents an underappreciated risk in multi-material production facilities. Even trace amounts of foreign particles can compromise material properties and introduce unpredictable behavior during processing. Current cleaning protocols between material changes are often inadequate, time-consuming, and difficult to validate without sophisticated analytical equipment.

The absence of standardized handling protocols further complicates powder management. Unlike well-established manufacturing processes, binder jetting lacks comprehensive industry standards for powder handling, leading to inconsistent practices across organizations. This variability makes it difficult to establish reliable quality benchmarks and troubleshoot processing issues when they arise, ultimately slowing industry-wide advancement and knowledge sharing.

Current Solutions for Humidity Control and Oxidation Prevention

01 Humidity control systems for powder storage

Specialized humidity control systems are essential for binder jetting powder storage to maintain optimal moisture levels. These systems typically include dehumidifiers, desiccants, and environmental monitoring equipment that continuously regulate the relative humidity within storage containers or rooms. Maintaining proper humidity levels prevents powder agglomeration, ensures consistent flow properties, and extends shelf life by preventing moisture-induced degradation of the powder materials.- Humidity control systems for powder storage: Specialized humidity control systems are essential for binder jetting powder storage to maintain optimal moisture levels. These systems typically include dehumidifiers, desiccants, and environmental monitoring equipment to prevent powder agglomeration and maintain flowability. Controlled humidity environments help preserve powder quality by preventing moisture absorption that could compromise the printing process and final part properties.

- Sealed storage containers with inert gas environments: Specialized storage containers designed with airtight seals and inert gas purging capabilities protect metal and reactive powders from oxidation. These containers often incorporate argon or nitrogen gas systems that displace oxygen, creating a protective atmosphere. Some advanced designs feature pressure monitoring, gas replenishment systems, and specialized sealing mechanisms to maintain the inert environment during both storage and powder handling operations.

- Powder conditioning and treatment technologies: Various powder conditioning technologies help maintain optimal powder characteristics during storage. These include surface treatments that create protective barriers against moisture and oxidation, thermal conditioning processes to remove absorbed moisture, and additive treatments that improve flow properties and reduce sensitivity to environmental conditions. These treatments extend powder shelf life and ensure consistent performance in binder jetting applications.

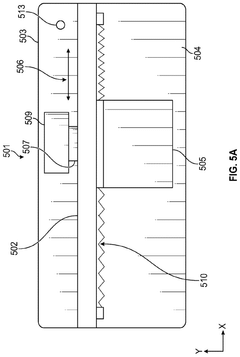

- Automated powder handling and storage systems: Automated systems for powder handling and storage minimize exposure to ambient conditions. These systems incorporate sealed transfer mechanisms, robotic handling, and integrated environmental controls to maintain powder integrity throughout the workflow. Advanced systems feature continuous monitoring of environmental parameters, automated alerts for condition deviations, and tracking of powder exposure history to ensure quality control in the binder jetting process.

- Specialized packaging and transportation solutions: Purpose-designed packaging solutions protect binder jetting powders during transportation and storage. These include multi-layer barrier materials, vacuum-sealed options, and moisture-absorbing components integrated into packaging. Some solutions incorporate humidity indicators, oxygen scavengers, and tamper-evident seals to ensure powder integrity is maintained from manufacturer to end-user, with specialized designs for different powder types based on their specific sensitivity to environmental factors.

02 Sealed container designs for oxidation prevention

Specialized sealed container designs help prevent oxidation of reactive metal powders used in binder jetting. These containers incorporate airtight seals, inert gas purging systems, and oxygen scavengers to create and maintain an oxygen-free environment. Some advanced containers feature pressure monitoring systems to detect potential leaks and multi-layer barrier materials that minimize gas permeation, ensuring long-term storage stability of oxygen-sensitive powders.Expand Specific Solutions03 Temperature-controlled storage solutions

Temperature-controlled storage solutions for binder jetting powders help maintain material stability and prevent degradation. These systems incorporate precise temperature regulation mechanisms, thermal insulation, and monitoring equipment to maintain optimal storage conditions. By preventing temperature fluctuations, these solutions minimize the risk of powder caking, moisture condensation, and chemical changes that could affect powder flowability and printing performance.Expand Specific Solutions04 Powder handling and transfer systems

Specialized powder handling and transfer systems are designed to minimize exposure to ambient conditions during the movement of binder jetting powders. These systems incorporate closed-loop transfer mechanisms, vacuum or inert gas-assisted transport, and static dissipation features to prevent contamination and oxidation during powder movement. Advanced systems may include automated dosing and weighing capabilities that minimize human interaction with the powder, further reducing exposure to humidity and oxygen.Expand Specific Solutions05 Powder conditioning and treatment methods

Various conditioning and treatment methods are employed to enhance the storage stability of binder jetting powders. These include surface treatments that create protective barriers against moisture and oxidation, addition of flow agents to prevent agglomeration, and specialized drying processes to achieve optimal moisture content before storage. Some methods incorporate antioxidant additives or passivation treatments that chemically stabilize reactive powder surfaces, extending shelf life while maintaining the powder's essential properties for the binder jetting process.Expand Specific Solutions

Leading Manufacturers and Material Suppliers Analysis

Binder Jetting Powder Stewardship is currently in a growth phase within the additive manufacturing industry, with the market expanding as technology matures. The global market is projected to reach significant scale as industrial applications increase, particularly in metal and ceramic parts production. Technical challenges around powder storage, humidity control, and oxidation prevention remain critical barriers to wider adoption. Companies like Desktop Metal and Resonac Corp. are leading innovation in powder handling systems, while established players such as 3M Innovative Properties and FUJIFILM Corp. contribute materials expertise. Research institutions including Brigham Young University and Centre National de la Recherche Scientifique are advancing fundamental understanding of powder degradation mechanisms, creating a competitive landscape balanced between specialized additive manufacturing firms and diversified materials science corporations.

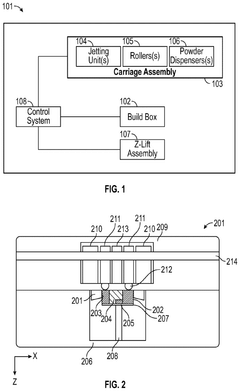

Desktop Metal, Inc.

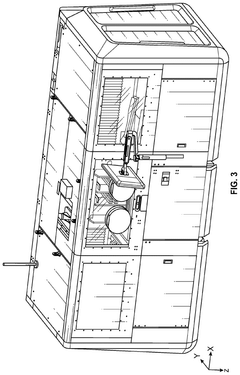

Technical Solution: Desktop Metal has developed comprehensive powder stewardship solutions specifically for Binder Jetting technology. Their approach includes a closed-loop powder handling system that minimizes exposure to ambient conditions during storage and transfer. The company's powder management system features humidity-controlled storage containers with integrated desiccants that maintain optimal moisture levels below 0.5% relative humidity. For oxidation prevention, Desktop Metal employs inert gas purging techniques using nitrogen or argon to displace oxygen in powder storage containers. Their Single Pass Jetting technology incorporates real-time powder condition monitoring with sensors that detect moisture content and oxidation levels, allowing for automated adjustments to printing parameters based on powder condition. Desktop Metal has also developed specialized powder recycling protocols that include sieving, drying, and quality assessment steps to ensure reclaimed powders maintain consistent properties across multiple print cycles.

Strengths: Desktop Metal's integrated approach provides comprehensive powder management throughout the entire workflow, reducing waste and ensuring consistent print quality. Their automated monitoring systems enable real-time quality control. Weaknesses: The sophisticated powder management systems require significant capital investment and technical expertise to operate effectively, potentially limiting accessibility for smaller operations.

FUJIFILM Corp.

Technical Solution: FUJIFILM has leveraged its extensive experience in handling sensitive photographic materials to develop advanced powder management solutions for binder jetting applications. Their technology centers on microencapsulation techniques that create protective barriers around individual powder particles, significantly reducing their reactivity with moisture and oxygen. FUJIFILM's proprietary HYDROSEAL technology creates a nanoscale hydrophobic coating on metal and ceramic powders that repels moisture while maintaining powder flowability. For storage, the company has developed specialized vacuum-sealed containers with oxygen scavengers that actively remove residual oxygen. Their humidity control systems incorporate phase-change materials that buffer against rapid environmental fluctuations, maintaining stable conditions even during container opening and closing operations. FUJIFILM has also pioneered advanced powder characterization techniques that can detect early signs of oxidation or moisture contamination before they affect print quality, allowing for preventive interventions.

Strengths: FUJIFILM's microencapsulation technology provides superior protection against environmental factors while preserving powder flowability and printability. Their solutions integrate seamlessly with existing powder handling workflows. Weaknesses: The specialized coatings may add cost to powder materials and could potentially require additional processing steps during recycling operations.

Key Innovations in Powder Storage Technologies

Gas management system for binder jetting additive manufacturing

PatentPendingUS20250153246A1

Innovation

- A gas management system is implemented within the binder jet printer to control the gaseous atmosphere, using partitions, baffles, and gas flow control mechanisms to maintain an inert environment, reduce powder migration, and prevent ignition sources from interacting with reactive powders.

Powder for additive manufacturing

PatentPendingEP4509485A1

Innovation

- The use of an additive manufacturing powder with controlled particle size distribution, specifically an inorganic oxide powder with D10 of 1.0 to 4.0 µm, D50 of 5.5 to 9.0 µm, and D90 of 20.0 to 40.0 µm, and a volume ratio of particles with a diameter of 16.8 to 60.0 µm between 15.0 to 22.0% by volume, enhances fluidity and bulk density, ensuring uniform layer formation and maintaining shape from binder application to sintering.

Environmental Impact and Sustainability Considerations

The environmental impact of binder jetting powder processes extends beyond operational efficiency, encompassing broader sustainability considerations that manufacturers must address. Metal and ceramic powders used in binder jetting require significant energy for production, with extraction and refinement processes contributing substantially to carbon emissions. Implementing closed-loop recycling systems for unused powders can significantly reduce this environmental footprint, with advanced recovery techniques now capable of reclaiming up to 98% of excess powder without quality degradation.

Humidity control systems, while essential for powder integrity, present their own environmental challenges. Traditional dehumidification technologies consume considerable energy, particularly in humid climates where continuous operation is necessary. Recent innovations in desiccant-based systems have reduced energy requirements by 30-40% compared to conventional methods, representing a significant sustainability improvement. Additionally, the development of biodegradable desiccants offers promising alternatives to conventional chemical options.

Oxidation prevention measures similarly present environmental trade-offs. Inert gas environments, commonly using argon or nitrogen, require energy-intensive gas production and present potential leakage concerns. The environmental impact varies significantly based on gas production methods, with renewable energy-powered production reducing the carbon footprint by up to 70%. Emerging technologies utilizing recyclable gas systems can further minimize environmental impact through closed-loop operation.

Waste management represents another critical environmental consideration. Improper disposal of metal powders can lead to soil and water contamination, with potential long-term ecological consequences. Industry best practices now include comprehensive waste characterization and specialized disposal protocols for different powder types. Some manufacturers have pioneered zero-waste initiatives through partnerships with specialized recycling facilities capable of processing contaminated or oxidized powders.

Regulatory frameworks increasingly address these environmental concerns, with jurisdictions implementing stricter requirements for powder handling and disposal. The EU's REACH regulations and similar frameworks in other regions now specifically address metal powder management, requiring detailed documentation of environmental impact mitigation strategies. Forward-thinking manufacturers are proactively exceeding these requirements, recognizing both regulatory trends and market demand for environmentally responsible production methods.

Humidity control systems, while essential for powder integrity, present their own environmental challenges. Traditional dehumidification technologies consume considerable energy, particularly in humid climates where continuous operation is necessary. Recent innovations in desiccant-based systems have reduced energy requirements by 30-40% compared to conventional methods, representing a significant sustainability improvement. Additionally, the development of biodegradable desiccants offers promising alternatives to conventional chemical options.

Oxidation prevention measures similarly present environmental trade-offs. Inert gas environments, commonly using argon or nitrogen, require energy-intensive gas production and present potential leakage concerns. The environmental impact varies significantly based on gas production methods, with renewable energy-powered production reducing the carbon footprint by up to 70%. Emerging technologies utilizing recyclable gas systems can further minimize environmental impact through closed-loop operation.

Waste management represents another critical environmental consideration. Improper disposal of metal powders can lead to soil and water contamination, with potential long-term ecological consequences. Industry best practices now include comprehensive waste characterization and specialized disposal protocols for different powder types. Some manufacturers have pioneered zero-waste initiatives through partnerships with specialized recycling facilities capable of processing contaminated or oxidized powders.

Regulatory frameworks increasingly address these environmental concerns, with jurisdictions implementing stricter requirements for powder handling and disposal. The EU's REACH regulations and similar frameworks in other regions now specifically address metal powder management, requiring detailed documentation of environmental impact mitigation strategies. Forward-thinking manufacturers are proactively exceeding these requirements, recognizing both regulatory trends and market demand for environmentally responsible production methods.

Safety Protocols and Regulatory Compliance for Powder Handling

The handling of metal and ceramic powders in binder jetting processes necessitates strict adherence to safety protocols and regulatory compliance frameworks. These materials often present significant hazards including respiratory risks, explosion dangers, and environmental concerns that must be systematically addressed through comprehensive safety management systems.

Occupational safety regulations such as OSHA in the United States, REACH in Europe, and similar frameworks globally mandate specific requirements for powder handling facilities. These include proper ventilation systems with HEPA filtration, designated powder handling areas with controlled access, and regular air quality monitoring to ensure particulate levels remain below permissible exposure limits.

Personal protective equipment (PPE) requirements for personnel working with binder jetting powders typically include respiratory protection with appropriate filtration ratings for the specific powder types, anti-static clothing to prevent spark generation, and eye protection against potential powder dispersion. Standard operating procedures must detail the proper donning and doffing sequences to prevent cross-contamination.

Powder classification systems based on explosion risk factors (Kst values) and toxicity profiles determine the specific handling protocols required. Fine metal powders, particularly aluminum and titanium alloys, present heightened explosion risks when airborne concentrations reach critical levels, necessitating specialized handling equipment with grounding mechanisms and explosion-proof electrical components.

Emergency response protocols must address potential powder-related incidents including spills, fires, and exposure events. These protocols should include evacuation procedures, containment strategies for different powder types, and decontamination methods. Regular emergency drills and scenario training are essential components of compliance programs.

Documentation and training requirements constitute a critical aspect of regulatory compliance. This includes maintaining material safety data sheets (MSDS) for all powder materials, detailed handling procedures, exposure monitoring records, and comprehensive training programs with regular recertification requirements for all personnel involved in powder handling operations.

Waste management protocols must address the proper disposal or recycling of unused powders, contaminated PPE, and filtration media. Many metal powders are classified as hazardous waste under environmental regulations, requiring specialized disposal procedures and documentation through licensed waste management providers.

Regular compliance audits and safety inspections represent best practices for maintaining regulatory alignment. These should include verification of engineering controls, procedural adherence, training currency, and documentation completeness. Third-party certification to standards such as ISO 45001 for occupational health and safety management systems provides additional assurance of comprehensive safety protocol implementation.

Occupational safety regulations such as OSHA in the United States, REACH in Europe, and similar frameworks globally mandate specific requirements for powder handling facilities. These include proper ventilation systems with HEPA filtration, designated powder handling areas with controlled access, and regular air quality monitoring to ensure particulate levels remain below permissible exposure limits.

Personal protective equipment (PPE) requirements for personnel working with binder jetting powders typically include respiratory protection with appropriate filtration ratings for the specific powder types, anti-static clothing to prevent spark generation, and eye protection against potential powder dispersion. Standard operating procedures must detail the proper donning and doffing sequences to prevent cross-contamination.

Powder classification systems based on explosion risk factors (Kst values) and toxicity profiles determine the specific handling protocols required. Fine metal powders, particularly aluminum and titanium alloys, present heightened explosion risks when airborne concentrations reach critical levels, necessitating specialized handling equipment with grounding mechanisms and explosion-proof electrical components.

Emergency response protocols must address potential powder-related incidents including spills, fires, and exposure events. These protocols should include evacuation procedures, containment strategies for different powder types, and decontamination methods. Regular emergency drills and scenario training are essential components of compliance programs.

Documentation and training requirements constitute a critical aspect of regulatory compliance. This includes maintaining material safety data sheets (MSDS) for all powder materials, detailed handling procedures, exposure monitoring records, and comprehensive training programs with regular recertification requirements for all personnel involved in powder handling operations.

Waste management protocols must address the proper disposal or recycling of unused powders, contaminated PPE, and filtration media. Many metal powders are classified as hazardous waste under environmental regulations, requiring specialized disposal procedures and documentation through licensed waste management providers.

Regular compliance audits and safety inspections represent best practices for maintaining regulatory alignment. These should include verification of engineering controls, procedural adherence, training currency, and documentation completeness. Third-party certification to standards such as ISO 45001 for occupational health and safety management systems provides additional assurance of comprehensive safety protocol implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!