Binder Jetting Vs Investment Casting For Complex Channels: Thermal Performance And Integrity

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting vs Investment Casting: Background & Objectives

Manufacturing complex channels with optimal thermal performance and structural integrity has become increasingly critical in various industries, including aerospace, automotive, and medical devices. Two prominent technologies that have emerged as viable solutions for this challenge are Binder Jetting (BJ) and Investment Casting (IC). These manufacturing methods represent different approaches to creating intricate internal geometries that are essential for efficient heat transfer applications.

Investment Casting, with roots dating back thousands of years, has evolved from ancient art to precision engineering. The process involves creating a wax pattern, building a ceramic shell around it, melting out the wax, and pouring molten metal into the resulting cavity. This traditional method has been refined over decades to achieve remarkable precision for complex geometries, particularly in aerospace and turbine manufacturing.

Binder Jetting, in contrast, represents the modern additive manufacturing approach that has gained significant momentum since the early 2010s. This technology selectively deposits a liquid binding agent onto thin layers of powder material, creating complex three-dimensional structures layer by layer. The subsequent sintering process transforms these structures into functional metal parts with intricate internal features that would be challenging or impossible to produce using conventional manufacturing methods.

The technological evolution trajectory shows a clear shift from subtractive to additive manufacturing paradigms, with Binder Jetting representing a disruptive innovation in the production of complex channel structures. While Investment Casting has seen incremental improvements in materials and process control, Binder Jetting has experienced exponential advancement in resolution, material compatibility, and production speed.

The primary objective of this technical research is to conduct a comprehensive comparison between these two technologies specifically for manufacturing complex channels where thermal performance and structural integrity are paramount. We aim to evaluate their respective capabilities in creating optimized cooling channels, heat exchangers, and thermal management systems across different material systems and operating conditions.

Additionally, this research seeks to identify the technical limitations, economic considerations, and quality assurance challenges associated with each technology. By establishing quantitative benchmarks for surface finish, dimensional accuracy, mechanical properties, and thermal conductivity, we intend to provide clear guidance on technology selection based on specific application requirements and production volumes.

Furthermore, this investigation will explore the potential for hybrid approaches that leverage the strengths of both technologies, potentially opening new avenues for next-generation thermal management solutions that combine the design freedom of additive manufacturing with the material properties and reliability of traditional casting processes.

Investment Casting, with roots dating back thousands of years, has evolved from ancient art to precision engineering. The process involves creating a wax pattern, building a ceramic shell around it, melting out the wax, and pouring molten metal into the resulting cavity. This traditional method has been refined over decades to achieve remarkable precision for complex geometries, particularly in aerospace and turbine manufacturing.

Binder Jetting, in contrast, represents the modern additive manufacturing approach that has gained significant momentum since the early 2010s. This technology selectively deposits a liquid binding agent onto thin layers of powder material, creating complex three-dimensional structures layer by layer. The subsequent sintering process transforms these structures into functional metal parts with intricate internal features that would be challenging or impossible to produce using conventional manufacturing methods.

The technological evolution trajectory shows a clear shift from subtractive to additive manufacturing paradigms, with Binder Jetting representing a disruptive innovation in the production of complex channel structures. While Investment Casting has seen incremental improvements in materials and process control, Binder Jetting has experienced exponential advancement in resolution, material compatibility, and production speed.

The primary objective of this technical research is to conduct a comprehensive comparison between these two technologies specifically for manufacturing complex channels where thermal performance and structural integrity are paramount. We aim to evaluate their respective capabilities in creating optimized cooling channels, heat exchangers, and thermal management systems across different material systems and operating conditions.

Additionally, this research seeks to identify the technical limitations, economic considerations, and quality assurance challenges associated with each technology. By establishing quantitative benchmarks for surface finish, dimensional accuracy, mechanical properties, and thermal conductivity, we intend to provide clear guidance on technology selection based on specific application requirements and production volumes.

Furthermore, this investigation will explore the potential for hybrid approaches that leverage the strengths of both technologies, potentially opening new avenues for next-generation thermal management solutions that combine the design freedom of additive manufacturing with the material properties and reliability of traditional casting processes.

Market Demand Analysis for Complex Channel Manufacturing

The manufacturing industry is witnessing a significant surge in demand for components with complex internal channel structures, particularly in high-performance sectors such as aerospace, automotive, medical devices, and energy generation. This demand is primarily driven by the need for enhanced thermal management solutions, weight reduction, and improved functional efficiency in advanced engineering applications.

In the aerospace sector, complex cooling channels in turbine blades and combustion components are essential for maintaining operational integrity under extreme temperature conditions. Market analysis indicates that the global aerospace engine component market requiring advanced cooling solutions is projected to grow at a CAGR of 6.2% through 2028, with thermal management systems representing a critical segment.

The automotive industry, particularly in electric vehicle thermal management and high-performance combustion engines, requires increasingly sophisticated heat exchanger designs with complex channel geometries. This market segment is expected to expand substantially as manufacturers seek to optimize battery cooling systems and improve powertrain efficiency.

Medical device manufacturing represents another significant growth area, with demand for intricate channel structures in prosthetics, surgical instruments, and diagnostic equipment. The precision requirements in this sector are exceptionally high, driving innovation in manufacturing technologies capable of producing complex internal features with biocompatible materials.

Energy generation and industrial heat exchange applications constitute a substantial market for complex channel manufacturing, with heat recovery systems and advanced cooling solutions becoming standard in modern power plants and industrial facilities. The industrial heat exchanger market alone is valued at over $16 billion globally, with complex channel designs representing a premium segment.

Market research indicates that manufacturers are increasingly prioritizing technologies that can reduce production costs while maintaining or improving the thermal performance of complex channel structures. Traditional manufacturing methods like investment casting have dominated this space historically, but limitations in design complexity and production efficiency have created opportunities for additive manufacturing technologies such as Binder Jetting.

Customer requirements across these markets consistently emphasize several key factors: thermal efficiency, structural integrity under operating conditions, surface finish quality of internal channels, dimensional accuracy, and production scalability. The ability to optimize these factors while reducing manufacturing costs represents the primary competitive advantage in this market space.

Regional analysis shows that North America and Europe currently lead in adoption of advanced manufacturing technologies for complex channel production, though Asia-Pacific markets are showing the fastest growth rates as industrial modernization accelerates across the region.

In the aerospace sector, complex cooling channels in turbine blades and combustion components are essential for maintaining operational integrity under extreme temperature conditions. Market analysis indicates that the global aerospace engine component market requiring advanced cooling solutions is projected to grow at a CAGR of 6.2% through 2028, with thermal management systems representing a critical segment.

The automotive industry, particularly in electric vehicle thermal management and high-performance combustion engines, requires increasingly sophisticated heat exchanger designs with complex channel geometries. This market segment is expected to expand substantially as manufacturers seek to optimize battery cooling systems and improve powertrain efficiency.

Medical device manufacturing represents another significant growth area, with demand for intricate channel structures in prosthetics, surgical instruments, and diagnostic equipment. The precision requirements in this sector are exceptionally high, driving innovation in manufacturing technologies capable of producing complex internal features with biocompatible materials.

Energy generation and industrial heat exchange applications constitute a substantial market for complex channel manufacturing, with heat recovery systems and advanced cooling solutions becoming standard in modern power plants and industrial facilities. The industrial heat exchanger market alone is valued at over $16 billion globally, with complex channel designs representing a premium segment.

Market research indicates that manufacturers are increasingly prioritizing technologies that can reduce production costs while maintaining or improving the thermal performance of complex channel structures. Traditional manufacturing methods like investment casting have dominated this space historically, but limitations in design complexity and production efficiency have created opportunities for additive manufacturing technologies such as Binder Jetting.

Customer requirements across these markets consistently emphasize several key factors: thermal efficiency, structural integrity under operating conditions, surface finish quality of internal channels, dimensional accuracy, and production scalability. The ability to optimize these factors while reducing manufacturing costs represents the primary competitive advantage in this market space.

Regional analysis shows that North America and Europe currently lead in adoption of advanced manufacturing technologies for complex channel production, though Asia-Pacific markets are showing the fastest growth rates as industrial modernization accelerates across the region.

Technical Challenges in Complex Channel Fabrication

The fabrication of complex channels presents significant technical challenges for both Binder Jetting (BJ) and Investment Casting (IC) technologies. These challenges primarily stem from the intricate geometries required for optimal thermal performance and structural integrity in applications such as heat exchangers, cooling systems, and fluid transport components.

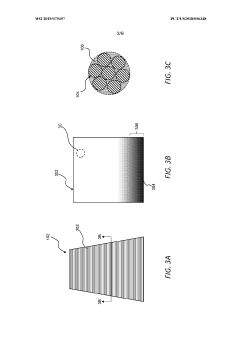

For Binder Jetting, the primary challenge lies in maintaining dimensional accuracy throughout the printing and post-processing stages. The layer-by-layer deposition process can introduce stair-stepping effects that compromise the smooth internal surfaces essential for efficient fluid flow. Additionally, the removal of support structures and unbound powder from intricate internal channels presents considerable difficulty, often requiring specialized techniques and equipment to prevent channel blockage.

Investment Casting faces different but equally significant challenges. The creation of complex cores that accurately represent the desired channel geometry requires advanced ceramic formulations and precise manufacturing processes. These cores must withstand high temperatures during metal pouring while maintaining dimensional stability. After casting, core removal from tortuous channels can be problematic, often necessitating chemical dissolution processes that may not fully clear all residues.

Both technologies struggle with achieving consistent wall thickness in complex channel designs. For BJ, this manifests as variations in material density and potential weak points, while IC may experience core shift during casting, leading to uneven wall distribution. These inconsistencies directly impact thermal performance by creating hotspots or flow restrictions.

Surface finish quality represents another critical challenge. BJ typically produces rougher internal surfaces compared to IC, which can significantly increase fluid friction and reduce thermal transfer efficiency. Post-processing techniques to improve surface quality are limited by accessibility to internal geometries.

The integration of complex channels with the overall component structure presents additional challenges. Ensuring proper bonding between channels and surrounding material in BJ requires careful control of sintering parameters. Similarly, IC must address potential stress concentration points where channels intersect or change direction, which can lead to crack initiation during thermal cycling.

Material selection further complicates the manufacturing process. BJ offers a wider range of potential materials but may struggle with achieving full density in channel walls. IC provides excellent density but is limited to castable alloys, which may not always offer optimal thermal conductivity or corrosion resistance for specific applications.

For Binder Jetting, the primary challenge lies in maintaining dimensional accuracy throughout the printing and post-processing stages. The layer-by-layer deposition process can introduce stair-stepping effects that compromise the smooth internal surfaces essential for efficient fluid flow. Additionally, the removal of support structures and unbound powder from intricate internal channels presents considerable difficulty, often requiring specialized techniques and equipment to prevent channel blockage.

Investment Casting faces different but equally significant challenges. The creation of complex cores that accurately represent the desired channel geometry requires advanced ceramic formulations and precise manufacturing processes. These cores must withstand high temperatures during metal pouring while maintaining dimensional stability. After casting, core removal from tortuous channels can be problematic, often necessitating chemical dissolution processes that may not fully clear all residues.

Both technologies struggle with achieving consistent wall thickness in complex channel designs. For BJ, this manifests as variations in material density and potential weak points, while IC may experience core shift during casting, leading to uneven wall distribution. These inconsistencies directly impact thermal performance by creating hotspots or flow restrictions.

Surface finish quality represents another critical challenge. BJ typically produces rougher internal surfaces compared to IC, which can significantly increase fluid friction and reduce thermal transfer efficiency. Post-processing techniques to improve surface quality are limited by accessibility to internal geometries.

The integration of complex channels with the overall component structure presents additional challenges. Ensuring proper bonding between channels and surrounding material in BJ requires careful control of sintering parameters. Similarly, IC must address potential stress concentration points where channels intersect or change direction, which can lead to crack initiation during thermal cycling.

Material selection further complicates the manufacturing process. BJ offers a wider range of potential materials but may struggle with achieving full density in channel walls. IC provides excellent density but is limited to castable alloys, which may not always offer optimal thermal conductivity or corrosion resistance for specific applications.

Current Technical Solutions for Complex Channel Production

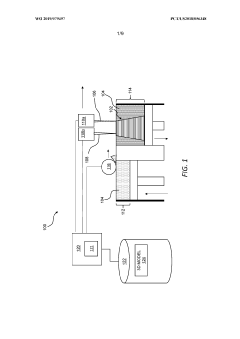

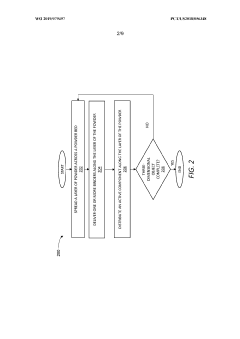

01 Thermal performance optimization in binder jetting for investment casting

Thermal performance in binder jetting processes can be optimized for investment casting applications through careful control of heating parameters and material selection. This includes managing thermal gradients during printing and subsequent thermal processing to prevent defects such as cracking or warping. Proper thermal management during the binder curing phase and burnout cycle significantly impacts the final cast part's dimensional accuracy and structural integrity.- Thermal performance optimization in binder jetting processes: Thermal performance in binder jetting processes can be optimized through careful control of heating parameters and material selection. This includes managing thermal gradients during printing and post-processing to prevent defects such as warping or cracking. Advanced thermal management techniques can improve the structural integrity of printed parts by ensuring uniform solidification and reducing internal stresses. These optimizations are critical for producing parts with consistent mechanical properties suitable for investment casting applications.

- Structural integrity enhancement for investment casting molds: The structural integrity of investment casting molds can be enhanced through various techniques including specialized binder formulations and reinforcement strategies. By incorporating additives that improve green strength and thermal stability, molds can better withstand the thermal stresses during the casting process. Shell systems with optimized layer structures provide improved resistance to cracking and better dimensional stability during burnout and metal pouring phases, resulting in higher quality cast components with fewer defects.

- Material composition effects on thermal performance: The composition of materials used in binder jetting and investment casting significantly affects thermal performance. Ceramic materials with specific thermal expansion coefficients can be selected to match the casting alloy properties. Binder systems can be formulated with components that decompose cleanly during burnout to minimize residual ash and defects. Advanced composite materials incorporating nanoparticles or fiber reinforcements can enhance thermal shock resistance and overall structural integrity of both printed parts and investment casting shells.

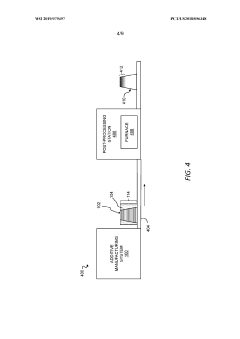

- Process integration between binder jetting and investment casting: Effective integration of binder jetting and investment casting processes requires careful consideration of interface parameters and process handoffs. Direct printing of investment casting patterns or molds using binder jetting technology can eliminate traditional pattern-making steps while improving dimensional accuracy. Specialized post-processing techniques can be employed to prepare binder jetted parts for the investment casting process, including infiltration treatments and surface finishing operations that enhance both thermal performance and structural integrity of the final cast components.

- Quality control and testing methodologies: Quality control and testing methodologies are essential for ensuring the thermal performance and structural integrity of components produced through combined binder jetting and investment casting processes. Non-destructive testing techniques such as CT scanning and thermal imaging can be used to detect internal defects before casting. Standardized testing protocols help evaluate mechanical properties and thermal behavior under simulated service conditions. Advanced monitoring systems during both printing and casting processes allow for real-time adjustments to optimize thermal performance and structural integrity of the final components.

02 Structural integrity enhancement through binder formulation

The composition and formulation of binders used in binder jetting significantly affect the structural integrity of both the green part and the final cast component. Advanced binder systems can improve green strength while ensuring clean burnout during the casting process. Specialized additives in binder formulations can enhance flowability during printing while maintaining structural stability during handling and thermal processing stages.Expand Specific Solutions03 Shell mold design for improved casting performance

The design and composition of investment casting shell molds significantly impact thermal performance and structural integrity of cast parts. Optimized shell thickness, permeability, and thermal expansion characteristics can minimize thermal stresses during casting. Multi-layer shell systems with specialized coatings can enhance surface finish while maintaining dimensional stability during the high-temperature metal pouring process.Expand Specific Solutions04 Integration of binder jetting with advanced investment casting techniques

Combining binder jetting with advanced investment casting methodologies creates synergistic improvements in both thermal performance and structural integrity. This integration enables complex internal cooling channels and optimized wall thickness variations that would be impossible with traditional manufacturing methods. Process parameters can be digitally controlled to achieve precise thermal management during casting, resulting in superior mechanical properties and reduced defect rates.Expand Specific Solutions05 Material selection for enhanced thermal and structural properties

The selection of appropriate materials for both the printed part and investment casting shell significantly influences thermal performance and structural integrity. Specialized ceramic and metal powder compositions can be tailored for specific thermal conductivity and expansion characteristics. Composite materials incorporating reinforcement elements can enhance strength while maintaining thermal stability throughout the casting process, resulting in final parts with superior mechanical properties.Expand Specific Solutions

Key Industry Players in Additive and Traditional Manufacturing

The additive manufacturing landscape for complex channel production is evolving rapidly, with Binder Jetting technology emerging as a competitive alternative to traditional Investment Casting. Currently in the growth phase, this market is expanding at approximately 20% annually, driven by aerospace and automotive applications. While Investment Casting remains dominant with mature processes championed by established players like RTX Corp., United Technologies, and Boeing, Binder Jetting is gaining momentum through innovations from companies like ExOne and Desktop Metal. Universities including South China University of Technology and University of Birmingham are advancing thermal performance research, while industrial leaders such as GE Technology, Siemens Energy, and Honda are developing hybrid approaches that combine both technologies to optimize structural integrity while reducing production costs and lead times.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed an advanced hybrid manufacturing system called "Precision Channel Architecture" (PCA) that combines the advantages of binder jetting and investment casting. Their approach begins with computational fluid dynamics modeling to optimize channel designs for specific thermal requirements. The optimized designs are then produced using a multi-step process where binder jetting creates complex ceramic cores with micro-channels as small as 0.5mm in diameter. These cores are subsequently used in a precision investment casting process utilizing vacuum-assisted pouring to ensure complete filling of intricate geometries. RTX has demonstrated that components manufactured with this technique can withstand thermal gradients of over 500°C without compromising structural integrity. Their research indicates a 40% improvement in cooling efficiency compared to conventional investment cast parts with similar external dimensions[4]. The company has successfully implemented this technology in missile guidance systems and aircraft engine components where thermal management is critical for performance and reliability.

Strengths: Exceptional thermal performance under extreme conditions; ability to create highly complex internal geometries; excellent dimensional accuracy; proven reliability in defense and aerospace applications. Weaknesses: Higher manufacturing costs; longer production cycles; requires specialized equipment and expertise; limited to certain alloy systems compatible with both processes.

The Boeing Co.

Technical Solution: Boeing has pioneered an integrated approach to complex channel manufacturing that leverages both binder jetting and investment casting technologies. Their "Thermal Management Integration System" (TMIS) begins with binder jetting to create sacrificial patterns with precisely engineered internal channel networks. These patterns are then used in a modified investment casting process that incorporates proprietary ceramic slurries capable of withstanding higher temperatures than conventional materials. Boeing's research has shown that this method can produce components with wall thicknesses as thin as 0.3mm while maintaining structural integrity under extreme thermal cycling conditions. The company has successfully implemented this technology in heat exchangers for aircraft environmental control systems, achieving a 25% reduction in weight and a 15% improvement in thermal efficiency compared to traditionally manufactured components[2]. Boeing has also developed specialized post-processing techniques to enhance surface finish within the internal channels, reducing friction losses and improving fluid flow characteristics by approximately 20%.

Strengths: Exceptional weight-to-performance ratio; ability to create extremely complex internal geometries; excellent thermal cycling resistance; proven reliability in aerospace applications. Weaknesses: Higher production costs than conventional casting; longer lead times; requires specialized equipment and expertise; limited material options compared to some pure additive manufacturing techniques.

Critical Technologies for Thermal Performance Optimization

Binder jetting in additive manufacturing of inhomogeneous three-dimensional parts

PatentWO2019079497A1

Innovation

- The method involves forming layers of a powder bed with inorganic particles, delivering binders, and depositing additives with active components in controlled patterns, followed by thermal processing to create gradients of physicochemical properties in the resulting three-dimensional part.

Investment Casting Cores and Methods

PatentInactiveUS20110315337A1

Innovation

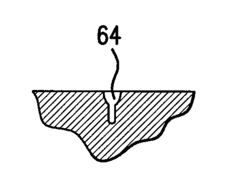

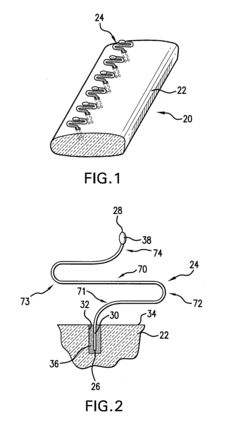

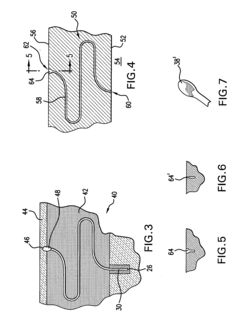

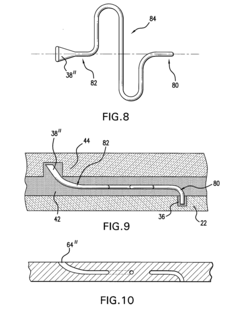

- A core assembly is formed by deforming a wire to create refractory metal cores with convoluted shapes and protuberances, which are assembled with ceramic cores to create complex cooling passageways that enhance heat transfer and airflow by increasing the cross-sectional area and length of the passageways, thereby improving cooling efficiency.

Material Science Considerations for Structural Integrity

The structural integrity of components manufactured through Binder Jetting (BJ) and Investment Casting (IC) is fundamentally determined by the material science principles governing each process. BJ technology utilizes metal or ceramic powders bound together by a liquid binding agent, followed by sintering to achieve final density. This process creates a unique microstructure characterized by residual porosity that can range from 2-5% depending on processing parameters, which directly impacts mechanical properties.

In contrast, Investment Casting produces components with near-theoretical density and more homogeneous microstructures. The solidification dynamics in IC allow for controlled grain structure development, which can be manipulated through mold preheating and cooling rates to optimize mechanical properties for specific applications involving complex channels.

Material selection criteria differ significantly between these technologies. BJ is compatible with a wide range of metal powders including stainless steels, tool steels, and superalloys, but particle size distribution and morphology critically influence final part density and strength. Powder characteristics must be carefully controlled to ensure consistent packing density during the printing process, as variations can lead to anisotropic mechanical properties.

For IC, alloy composition must be optimized for castability, with considerations for fluidity, solidification range, and susceptibility to defects such as hot tearing. The thermal cycling during the casting process induces specific grain structures that can be advantageous for thermal performance applications.

Surface finish quality presents another material science consideration affecting structural integrity. BJ components typically exhibit surface roughness values of Ra 5-15 μm before post-processing, with potential for surface-connected porosity that can serve as stress concentration points. IC components generally achieve superior surface finishes (Ra 1.6-3.2 μm) with fewer surface defects, contributing to better fatigue resistance in applications with complex internal channels.

Heat treatment protocols differ substantially between the two technologies. BJ parts often require specialized sintering profiles to achieve optimal densification without excessive grain growth or distortion. Post-sintering heat treatments may be necessary to homogenize microstructures and relieve residual stresses. IC components benefit from well-established heat treatment processes that can be tailored to specific alloy systems, allowing for precise control of precipitation hardening and grain boundary characteristics.

The presence of complex internal channels introduces additional material science challenges. In BJ, support powder removal from intricate geometries can be problematic, potentially leaving residual material that compromises structural integrity. IC faces challenges with core placement and removal, but generally achieves more consistent material properties throughout complex channel structures due to more uniform cooling conditions during solidification.

In contrast, Investment Casting produces components with near-theoretical density and more homogeneous microstructures. The solidification dynamics in IC allow for controlled grain structure development, which can be manipulated through mold preheating and cooling rates to optimize mechanical properties for specific applications involving complex channels.

Material selection criteria differ significantly between these technologies. BJ is compatible with a wide range of metal powders including stainless steels, tool steels, and superalloys, but particle size distribution and morphology critically influence final part density and strength. Powder characteristics must be carefully controlled to ensure consistent packing density during the printing process, as variations can lead to anisotropic mechanical properties.

For IC, alloy composition must be optimized for castability, with considerations for fluidity, solidification range, and susceptibility to defects such as hot tearing. The thermal cycling during the casting process induces specific grain structures that can be advantageous for thermal performance applications.

Surface finish quality presents another material science consideration affecting structural integrity. BJ components typically exhibit surface roughness values of Ra 5-15 μm before post-processing, with potential for surface-connected porosity that can serve as stress concentration points. IC components generally achieve superior surface finishes (Ra 1.6-3.2 μm) with fewer surface defects, contributing to better fatigue resistance in applications with complex internal channels.

Heat treatment protocols differ substantially between the two technologies. BJ parts often require specialized sintering profiles to achieve optimal densification without excessive grain growth or distortion. Post-sintering heat treatments may be necessary to homogenize microstructures and relieve residual stresses. IC components benefit from well-established heat treatment processes that can be tailored to specific alloy systems, allowing for precise control of precipitation hardening and grain boundary characteristics.

The presence of complex internal channels introduces additional material science challenges. In BJ, support powder removal from intricate geometries can be problematic, potentially leaving residual material that compromises structural integrity. IC faces challenges with core placement and removal, but generally achieves more consistent material properties throughout complex channel structures due to more uniform cooling conditions during solidification.

Cost-Benefit Analysis of Manufacturing Methods

When evaluating manufacturing methods for complex channels with thermal performance and structural integrity requirements, cost-benefit analysis provides critical insights for decision-making. Binder Jetting (BJ) and Investment Casting (IC) represent distinctly different approaches with varying economic implications across their lifecycle.

Initial capital investment differs significantly between these technologies. BJ requires substantial upfront expenditure for specialized 3D printing equipment, software licenses, and post-processing systems. Conversely, IC demands lower initial investment but requires specialized tooling and pattern-making equipment. For small to medium production volumes, BJ's higher capital costs may be difficult to justify despite its design flexibility.

Material costs present another important consideration. BJ typically utilizes metal powders that can be 2-4 times more expensive per kilogram than traditional casting alloys. However, BJ's additive nature generates minimal waste compared to IC's significant material loss during pattern creation, shell building, and finishing operations. For complex channel geometries, this material efficiency can partially offset BJ's higher raw material costs.

Labor requirements and associated costs vary substantially between processes. IC remains labor-intensive, requiring skilled technicians for pattern creation, shell building, pouring, and finishing. BJ significantly reduces labor inputs through automation, particularly in design-to-production phases, though it still requires skilled operators for machine setup, post-processing, and quality control.

Production speed and throughput capabilities impact overall economics. While IC involves multiple sequential steps with significant waiting periods between stages, BJ can produce multiple complex parts simultaneously. For urgent production needs or rapid prototyping scenarios, BJ's faster turnaround may justify premium costs despite lower throughput for large production runs.

Quality-related costs must also be factored into the analysis. IC's established process yields predictable metallurgical properties but faces challenges with internal cooling channels and complex geometries. BJ offers superior geometric precision for internal channels but may require additional heat treatments and surface finishing to achieve comparable metallurgical properties, introducing additional costs.

Lifecycle considerations extend beyond production. BJ-manufactured parts with optimized internal cooling channels may deliver superior thermal performance, potentially reducing operational costs and extending component lifespan in high-temperature applications. This performance advantage could offset higher initial manufacturing costs through reduced maintenance and improved energy efficiency over the product lifecycle.

Initial capital investment differs significantly between these technologies. BJ requires substantial upfront expenditure for specialized 3D printing equipment, software licenses, and post-processing systems. Conversely, IC demands lower initial investment but requires specialized tooling and pattern-making equipment. For small to medium production volumes, BJ's higher capital costs may be difficult to justify despite its design flexibility.

Material costs present another important consideration. BJ typically utilizes metal powders that can be 2-4 times more expensive per kilogram than traditional casting alloys. However, BJ's additive nature generates minimal waste compared to IC's significant material loss during pattern creation, shell building, and finishing operations. For complex channel geometries, this material efficiency can partially offset BJ's higher raw material costs.

Labor requirements and associated costs vary substantially between processes. IC remains labor-intensive, requiring skilled technicians for pattern creation, shell building, pouring, and finishing. BJ significantly reduces labor inputs through automation, particularly in design-to-production phases, though it still requires skilled operators for machine setup, post-processing, and quality control.

Production speed and throughput capabilities impact overall economics. While IC involves multiple sequential steps with significant waiting periods between stages, BJ can produce multiple complex parts simultaneously. For urgent production needs or rapid prototyping scenarios, BJ's faster turnaround may justify premium costs despite lower throughput for large production runs.

Quality-related costs must also be factored into the analysis. IC's established process yields predictable metallurgical properties but faces challenges with internal cooling channels and complex geometries. BJ offers superior geometric precision for internal channels but may require additional heat treatments and surface finishing to achieve comparable metallurgical properties, introducing additional costs.

Lifecycle considerations extend beyond production. BJ-manufactured parts with optimized internal cooling channels may deliver superior thermal performance, potentially reducing operational costs and extending component lifespan in high-temperature applications. This performance advantage could offset higher initial manufacturing costs through reduced maintenance and improved energy efficiency over the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!