Cell-free Protein Synthesis for Nanomaterial Conjugation

OCT 13, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFPS Technology Evolution and Objectives

Cell-free protein synthesis (CFPS) has evolved significantly since its inception in the 1960s when Nirenberg and Matthaei first demonstrated protein synthesis outside living cells. Initially developed as a research tool to decipher the genetic code, CFPS has transformed into a versatile biotechnological platform with applications spanning from fundamental research to industrial production of proteins and beyond.

The evolution of CFPS technology can be traced through several key developmental phases. The first generation systems relied on crude cell extracts with limited productivity and stability. The second generation, emerging in the 1980s-1990s, focused on optimizing reaction conditions and extract preparation methods, significantly improving protein yields. The third generation, from the early 2000s, introduced engineered cell extracts and defined reaction components, enabling precise control over the synthesis environment.

Recent advancements have propelled CFPS into its current fourth generation, characterized by the integration with other technologies such as microfluidics, continuous-exchange systems, and most notably, nanomaterial science. This convergence has opened new avenues for creating protein-nanomaterial conjugates with unprecedented properties and functionalities.

The primary objectives of modern CFPS in nanomaterial conjugation are multifaceted. First, to develop robust and scalable methods for producing functional proteins that can interface effectively with various nanomaterials including quantum dots, gold nanoparticles, carbon nanotubes, and two-dimensional materials. Second, to achieve precise spatial control over protein attachment to nanomaterials, enabling the creation of complex architectures with defined orientations and densities.

Another critical objective is to enhance the stability and activity of proteins when conjugated to nanomaterials, preserving their biological functions while leveraging the unique properties of the nanomaterial substrate. This includes developing strategies to minimize non-specific interactions and optimize the microenvironment at the protein-nanomaterial interface.

Furthermore, CFPS aims to enable the incorporation of non-canonical amino acids and post-translational modifications in proteins destined for nanomaterial conjugation, expanding the chemical toolkit available for creating functional interfaces. This capability is particularly valuable for introducing specific binding sites or reactive groups that facilitate controlled conjugation reactions.

The ultimate technological goal is to establish CFPS as a versatile platform for the rapid prototyping and production of protein-nanomaterial conjugates with tailored properties for applications in biosensing, catalysis, drug delivery, and bioelectronics. This requires addressing current limitations in scalability, cost-effectiveness, and the complexity of working with membrane proteins and multi-domain protein complexes.

The evolution of CFPS technology can be traced through several key developmental phases. The first generation systems relied on crude cell extracts with limited productivity and stability. The second generation, emerging in the 1980s-1990s, focused on optimizing reaction conditions and extract preparation methods, significantly improving protein yields. The third generation, from the early 2000s, introduced engineered cell extracts and defined reaction components, enabling precise control over the synthesis environment.

Recent advancements have propelled CFPS into its current fourth generation, characterized by the integration with other technologies such as microfluidics, continuous-exchange systems, and most notably, nanomaterial science. This convergence has opened new avenues for creating protein-nanomaterial conjugates with unprecedented properties and functionalities.

The primary objectives of modern CFPS in nanomaterial conjugation are multifaceted. First, to develop robust and scalable methods for producing functional proteins that can interface effectively with various nanomaterials including quantum dots, gold nanoparticles, carbon nanotubes, and two-dimensional materials. Second, to achieve precise spatial control over protein attachment to nanomaterials, enabling the creation of complex architectures with defined orientations and densities.

Another critical objective is to enhance the stability and activity of proteins when conjugated to nanomaterials, preserving their biological functions while leveraging the unique properties of the nanomaterial substrate. This includes developing strategies to minimize non-specific interactions and optimize the microenvironment at the protein-nanomaterial interface.

Furthermore, CFPS aims to enable the incorporation of non-canonical amino acids and post-translational modifications in proteins destined for nanomaterial conjugation, expanding the chemical toolkit available for creating functional interfaces. This capability is particularly valuable for introducing specific binding sites or reactive groups that facilitate controlled conjugation reactions.

The ultimate technological goal is to establish CFPS as a versatile platform for the rapid prototyping and production of protein-nanomaterial conjugates with tailored properties for applications in biosensing, catalysis, drug delivery, and bioelectronics. This requires addressing current limitations in scalability, cost-effectiveness, and the complexity of working with membrane proteins and multi-domain protein complexes.

Market Applications for Protein-Nanomaterial Conjugates

Protein-nanomaterial conjugates represent a rapidly expanding market with diverse applications across multiple industries. The healthcare sector currently dominates this market, with applications in targeted drug delivery systems, diagnostic imaging, and biosensors. These conjugates enable precise targeting of therapeutic agents to specific tissues, minimizing side effects while maximizing efficacy. The global targeted drug delivery market utilizing protein-nanomaterial conjugates is projected to grow substantially, driven by increasing cancer prevalence and demand for personalized medicine approaches.

Diagnostic applications constitute another significant market segment, where protein-nanomaterial conjugates enhance sensitivity and specificity of detection methods. These conjugates are particularly valuable in point-of-care diagnostics, enabling rapid detection of biomarkers with minimal sample preparation. The integration of these materials into lateral flow assays and electrochemical sensors has revolutionized disease detection capabilities in resource-limited settings.

The industrial biotechnology sector represents an emerging application area, where protein-nanomaterial conjugates serve as advanced biocatalysts with enhanced stability and reusability. These conjugates facilitate more efficient industrial processes by improving enzyme performance under harsh conditions, extending catalyst lifespan, and enabling simplified product recovery. Industries including biofuel production, food processing, and fine chemical synthesis are increasingly adopting these materials to reduce production costs and environmental impact.

Environmental monitoring and remediation applications are gaining traction as protein-nanomaterial conjugates demonstrate effectiveness in detecting and removing environmental contaminants. These materials can selectively bind pollutants including heavy metals, pesticides, and industrial chemicals, offering solutions for water purification and soil decontamination. The growing emphasis on environmental sustainability is expected to accelerate market growth in this segment.

Agricultural applications represent another promising market, with protein-nanomaterial conjugates being developed for controlled release of fertilizers, targeted delivery of pesticides, and enhanced crop protection. These materials can improve nutrient utilization efficiency and reduce environmental contamination from agricultural inputs, addressing key challenges in sustainable agriculture.

Consumer products incorporating protein-nanomaterial conjugates are emerging in cosmetics, textiles, and food packaging. In cosmetics, these materials enable controlled release of active ingredients and improved skin penetration. Antimicrobial textiles utilizing protein-nanomaterial conjugates offer enhanced protection against pathogens, while similar technologies in food packaging extend shelf life and indicate product freshness.

The market for protein-nanomaterial conjugates faces challenges including regulatory uncertainties, scale-up difficulties, and cost considerations. However, continued technological advancements in cell-free protein synthesis methods are expected to address these limitations, expanding market opportunities across these diverse application areas.

Diagnostic applications constitute another significant market segment, where protein-nanomaterial conjugates enhance sensitivity and specificity of detection methods. These conjugates are particularly valuable in point-of-care diagnostics, enabling rapid detection of biomarkers with minimal sample preparation. The integration of these materials into lateral flow assays and electrochemical sensors has revolutionized disease detection capabilities in resource-limited settings.

The industrial biotechnology sector represents an emerging application area, where protein-nanomaterial conjugates serve as advanced biocatalysts with enhanced stability and reusability. These conjugates facilitate more efficient industrial processes by improving enzyme performance under harsh conditions, extending catalyst lifespan, and enabling simplified product recovery. Industries including biofuel production, food processing, and fine chemical synthesis are increasingly adopting these materials to reduce production costs and environmental impact.

Environmental monitoring and remediation applications are gaining traction as protein-nanomaterial conjugates demonstrate effectiveness in detecting and removing environmental contaminants. These materials can selectively bind pollutants including heavy metals, pesticides, and industrial chemicals, offering solutions for water purification and soil decontamination. The growing emphasis on environmental sustainability is expected to accelerate market growth in this segment.

Agricultural applications represent another promising market, with protein-nanomaterial conjugates being developed for controlled release of fertilizers, targeted delivery of pesticides, and enhanced crop protection. These materials can improve nutrient utilization efficiency and reduce environmental contamination from agricultural inputs, addressing key challenges in sustainable agriculture.

Consumer products incorporating protein-nanomaterial conjugates are emerging in cosmetics, textiles, and food packaging. In cosmetics, these materials enable controlled release of active ingredients and improved skin penetration. Antimicrobial textiles utilizing protein-nanomaterial conjugates offer enhanced protection against pathogens, while similar technologies in food packaging extend shelf life and indicate product freshness.

The market for protein-nanomaterial conjugates faces challenges including regulatory uncertainties, scale-up difficulties, and cost considerations. However, continued technological advancements in cell-free protein synthesis methods are expected to address these limitations, expanding market opportunities across these diverse application areas.

Technical Barriers in Cell-free Bioconjugation

Despite significant advancements in cell-free protein synthesis (CFPS) systems for nanomaterial conjugation, several technical barriers continue to impede widespread implementation and commercialization. The primary challenge remains the stability of cell-free reaction components when interfaced with nanomaterials. Many nanomaterials exhibit surface properties that can denature proteins or inhibit enzymatic activities critical to the translation process, resulting in diminished protein yield and functionality.

Reaction efficiency presents another substantial hurdle. Current CFPS systems typically achieve protein yields of 0.5-2 mg/mL, which falls short of the concentrations required for efficient bioconjugation reactions. This limitation necessitates post-synthesis concentration steps that can compromise protein integrity and increase production costs. Furthermore, the energy regeneration systems in CFPS often deplete rapidly, limiting the duration of productive synthesis.

Specificity in bioconjugation represents a critical technical barrier. While several site-specific conjugation methods exist, including click chemistry and enzymatic approaches, achieving precise control over the orientation and stoichiometry of proteins on nanomaterial surfaces remains challenging. Non-specific adsorption frequently occurs alongside intended conjugation reactions, resulting in heterogeneous products with variable functionality.

Scale-up considerations pose significant obstacles for industrial applications. Most CFPS protocols have been optimized at laboratory scales (μL to mL), and linear scaling to industrial volumes introduces complications in mixing, temperature control, and component stability. The cost of reagents, particularly for energy regeneration systems and translation machinery, becomes prohibitive at larger scales.

Quality control and reproducibility issues further complicate cell-free bioconjugation processes. Batch-to-batch variations in extract preparation and nanomaterial properties can significantly impact conjugation efficiency and product characteristics. Current analytical methods often lack the resolution to fully characterize the resulting protein-nanomaterial interfaces, making process optimization challenging.

Regulatory considerations also present barriers, as novel protein-nanomaterial conjugates occupy an ambiguous position between biological and nanomaterial regulatory frameworks. The absence of standardized characterization protocols specifically designed for these hybrid materials complicates regulatory approval pathways.

Addressing these technical barriers requires interdisciplinary approaches combining protein engineering, nanomaterial surface chemistry, and process engineering. Recent innovations in continuous-flow CFPS systems, microfluidic platforms, and computational modeling of protein-nanomaterial interfaces show promise for overcoming these limitations and expanding the application scope of cell-free bioconjugation technologies.

Reaction efficiency presents another substantial hurdle. Current CFPS systems typically achieve protein yields of 0.5-2 mg/mL, which falls short of the concentrations required for efficient bioconjugation reactions. This limitation necessitates post-synthesis concentration steps that can compromise protein integrity and increase production costs. Furthermore, the energy regeneration systems in CFPS often deplete rapidly, limiting the duration of productive synthesis.

Specificity in bioconjugation represents a critical technical barrier. While several site-specific conjugation methods exist, including click chemistry and enzymatic approaches, achieving precise control over the orientation and stoichiometry of proteins on nanomaterial surfaces remains challenging. Non-specific adsorption frequently occurs alongside intended conjugation reactions, resulting in heterogeneous products with variable functionality.

Scale-up considerations pose significant obstacles for industrial applications. Most CFPS protocols have been optimized at laboratory scales (μL to mL), and linear scaling to industrial volumes introduces complications in mixing, temperature control, and component stability. The cost of reagents, particularly for energy regeneration systems and translation machinery, becomes prohibitive at larger scales.

Quality control and reproducibility issues further complicate cell-free bioconjugation processes. Batch-to-batch variations in extract preparation and nanomaterial properties can significantly impact conjugation efficiency and product characteristics. Current analytical methods often lack the resolution to fully characterize the resulting protein-nanomaterial interfaces, making process optimization challenging.

Regulatory considerations also present barriers, as novel protein-nanomaterial conjugates occupy an ambiguous position between biological and nanomaterial regulatory frameworks. The absence of standardized characterization protocols specifically designed for these hybrid materials complicates regulatory approval pathways.

Addressing these technical barriers requires interdisciplinary approaches combining protein engineering, nanomaterial surface chemistry, and process engineering. Recent innovations in continuous-flow CFPS systems, microfluidic platforms, and computational modeling of protein-nanomaterial interfaces show promise for overcoming these limitations and expanding the application scope of cell-free bioconjugation technologies.

Current Methodologies for Protein-Nanomaterial Coupling

01 Cell-free protein synthesis systems and components

Cell-free protein synthesis systems utilize cellular extracts containing the necessary machinery for protein translation without intact cells. These systems typically include ribosomes, translation factors, tRNAs, aminoacyl-tRNA synthetases, and energy regeneration components. Various extracts can be derived from different organisms such as E. coli, wheat germ, rabbit reticulocytes, or insect cells, each with specific advantages for different applications. These systems enable rapid protein production without the constraints of cell viability or growth.- Cell-free protein synthesis systems and components: Cell-free protein synthesis systems utilize cellular extracts containing the necessary machinery for protein translation without intact cells. These systems typically include ribosomes, translation factors, tRNAs, aminoacyl-tRNA synthetases, and energy regeneration components. Various extracts can be derived from different organisms such as E. coli, wheat germ, rabbit reticulocytes, or insect cells, each with specific advantages for different applications. These systems enable rapid protein production without the constraints of cell viability or growth.

- Energy regeneration and optimization in cell-free systems: Efficient energy supply is critical for sustained protein synthesis in cell-free systems. Advanced energy regeneration systems incorporate ATP regeneration pathways, phosphate recycling mechanisms, and optimized cofactor concentrations. These systems may include creatine phosphate/creatine kinase, phosphoenolpyruvate/pyruvate kinase, or glucose-based energy regeneration pathways. Optimization of energy components significantly extends reaction lifetimes and increases protein yields, making cell-free systems more economically viable for various applications.

- Continuous and high-yield cell-free protein synthesis: Continuous cell-free protein synthesis systems overcome limitations of batch reactions by constantly supplying substrates and removing inhibitory byproducts. These systems utilize dialysis membranes, microfluidic devices, or other continuous exchange mechanisms to maintain optimal reaction conditions. Advanced reactor designs incorporate controlled feeding strategies and real-time monitoring capabilities. These approaches significantly increase protein yields and enable the production of difficult-to-express proteins that may be toxic to living cells.

- Applications of cell-free protein synthesis in therapeutics and diagnostics: Cell-free protein synthesis enables rapid production of therapeutic proteins, vaccines, and diagnostic reagents. The open nature of these systems allows incorporation of non-natural amino acids and direct production of proteins with site-specific modifications. Applications include on-demand production of personalized medicines, point-of-care diagnostic tools, and rapid response to emerging pathogens. The technology enables production of proteins that are difficult to express in conventional systems due to toxicity, instability, or complex folding requirements.

- Enhancing protein folding and post-translational modifications: Cell-free systems can be supplemented with chaperones, disulfide bond formation enzymes, and other folding assistants to improve the production of correctly folded proteins. Advanced systems incorporate microsomes or modified extracts capable of performing post-translational modifications such as glycosylation, phosphorylation, and disulfide bond formation. These enhancements enable the production of complex eukaryotic proteins with proper structure and function, expanding the utility of cell-free systems for producing pharmaceutically relevant proteins.

02 Energy regeneration and optimization for cell-free systems

Efficient energy supply is critical for sustained protein synthesis in cell-free systems. Advanced energy regeneration systems incorporate ATP regeneration pathways, phosphate recycling mechanisms, and optimized cofactor concentrations. These systems may use phosphoenolpyruvate, creatine phosphate, or glucose-based energy sources to maintain ATP levels. Optimization of magnesium concentrations, nucleotide ratios, and redox conditions significantly enhances protein yield and system longevity, allowing for extended reaction times and higher productivity.Expand Specific Solutions03 Continuous and large-scale cell-free protein production

Scaling up cell-free protein synthesis involves continuous-exchange systems, bioreactors, and microfluidic platforms that allow for the replenishment of substrates and removal of inhibitory byproducts. These approaches overcome traditional batch reaction limitations by maintaining optimal reaction conditions over extended periods. Advanced reactor designs incorporate membrane-based exchange systems, dialysis cassettes, or hollow fiber modules to facilitate continuous operation. These technologies enable industrial-scale production of proteins for therapeutic, diagnostic, and research applications.Expand Specific Solutions04 Incorporation of non-natural amino acids and protein modifications

Cell-free systems offer unique advantages for incorporating non-canonical amino acids and post-translational modifications into proteins. By using engineered tRNAs, aminoacyl-tRNA synthetases, and supplementing with non-natural amino acids, these systems can produce proteins with novel functionalities. This approach enables site-specific labeling, creation of proteins with enhanced stability, and development of novel therapeutics with improved pharmacokinetic properties. The open nature of cell-free systems allows direct manipulation of the translation machinery to accommodate these modifications.Expand Specific Solutions05 Applications in diagnostics, therapeutics, and synthetic biology

Cell-free protein synthesis has diverse applications across multiple fields. In diagnostics, these systems enable rapid production of detection reagents and biosensors for point-of-care testing. For therapeutics, they allow production of difficult-to-express proteins, antibodies, and personalized medicines with reduced endotoxin contamination. In synthetic biology, cell-free systems serve as platforms for prototyping genetic circuits, metabolic pathways, and artificial cells. The versatility of these systems has led to innovations in vaccine development, protein evolution, and high-throughput screening technologies.Expand Specific Solutions

Leading Research Groups and Companies in CFPS

Cell-free Protein Synthesis for Nanomaterial Conjugation is in an emerging growth phase, with the market expanding due to increasing applications in biotechnology and materials science. The global market is estimated to reach $500 million by 2025, growing at a CAGR of 8-10%. Technologically, the field is transitioning from early development to commercial application, with varying maturity levels across players. Academic institutions like Northwestern University, Peking University, and Cornell University are driving fundamental research, while companies such as Sutro Biopharma, Cellfree Sciences, and New England Biolabs have developed more mature commercial platforms. Spiber and Toyobo are advancing industrial-scale applications, particularly in biomaterials. Government research organizations like CNRS and Japan Science & Technology Agency are bridging the gap between academic research and commercial implementation through strategic funding initiatives.

Cellfree Sciences Co., Ltd.

Technical Solution: Cellfree Sciences has developed a proprietary WEPRO® cell-free protein synthesis system based on wheat germ extract, specifically optimized for nanomaterial conjugation applications. Their technology enables the direct synthesis of proteins with site-specific modifications for controlled attachment to various nanomaterials including gold nanoparticles, quantum dots, and carbon-based structures. The company's approach incorporates modified tRNAs to introduce non-canonical amino acids with reactive functional groups at precise locations, facilitating oriented immobilization of proteins onto nanomaterials without compromising their biological activity. Their cell-free platform allows for rapid production cycles (typically 1-2 hours) compared to conventional cell-based systems that require days, and maintains high protein yield (up to 5 mg/mL) even when incorporating modified amino acids for conjugation purposes.

Strengths: Superior control over protein orientation during conjugation, resulting in higher functional retention; rapid production cycles enabling iterative optimization; absence of cellular membranes allowing direct introduction of nanomaterials during synthesis. Weaknesses: Higher cost per reaction compared to cell-based systems; limited scalability for industrial production; potential challenges with complex multi-domain proteins.

Sutro Biopharma, Inc.

Technical Solution: Sutro Biopharma has pioneered XpressCF®, an E. coli-based cell-free protein synthesis platform specifically engineered for site-specific conjugation of proteins to nanomaterials. Their technology incorporates their proprietary XtractCF® extract preparation method that removes inhibitory components while preserving translation efficiency. The platform enables incorporation of over 30 different non-natural amino acids through their expanded genetic code technology, providing precise control over conjugation chemistry. For nanomaterial applications, Sutro has developed specialized linker chemistries that maintain protein stability while creating defined interfaces with various nanomaterials including silica nanoparticles, magnetic beads, and polymeric scaffolds. Their system achieves protein yields of 0.5-2.0 g/L and allows for the co-translational incorporation of nanomaterials, enabling direct synthesis of protein-nanomaterial conjugates in a single reaction vessel without intermediate purification steps.

Strengths: Exceptional versatility in conjugation chemistry through their expanded genetic code technology; high-yield production system suitable for commercial applications; proprietary extract preparation method that enhances performance with nanomaterials. Weaknesses: Relatively high cost of reagents; intellectual property restrictions limiting broader adoption; potential immunogenicity concerns with non-natural amino acids in therapeutic applications.

Key Patents in Cell-free Synthesis for Bioconjugation

Method for cell-free protein synthesis using complementary oligonucleotide

PatentInactiveUS20070128688A1

Innovation

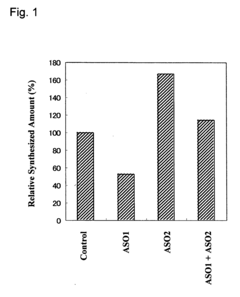

- A method involving a reaction solution with mRNA and a living cell-derived extract solution, supplemented with oligonucleotides complementary to the 3′ and 5′ terminal regions of mRNA, which enhances protein synthesis without the need for expensive cap structures or complex pretreatments.

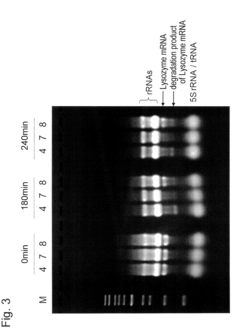

Cell-free protein synthesis method and cell-free protein synthesis reaction solution using adenosine 3',5'-bisphosphate

PatentInactiveUS20090155881A1

Innovation

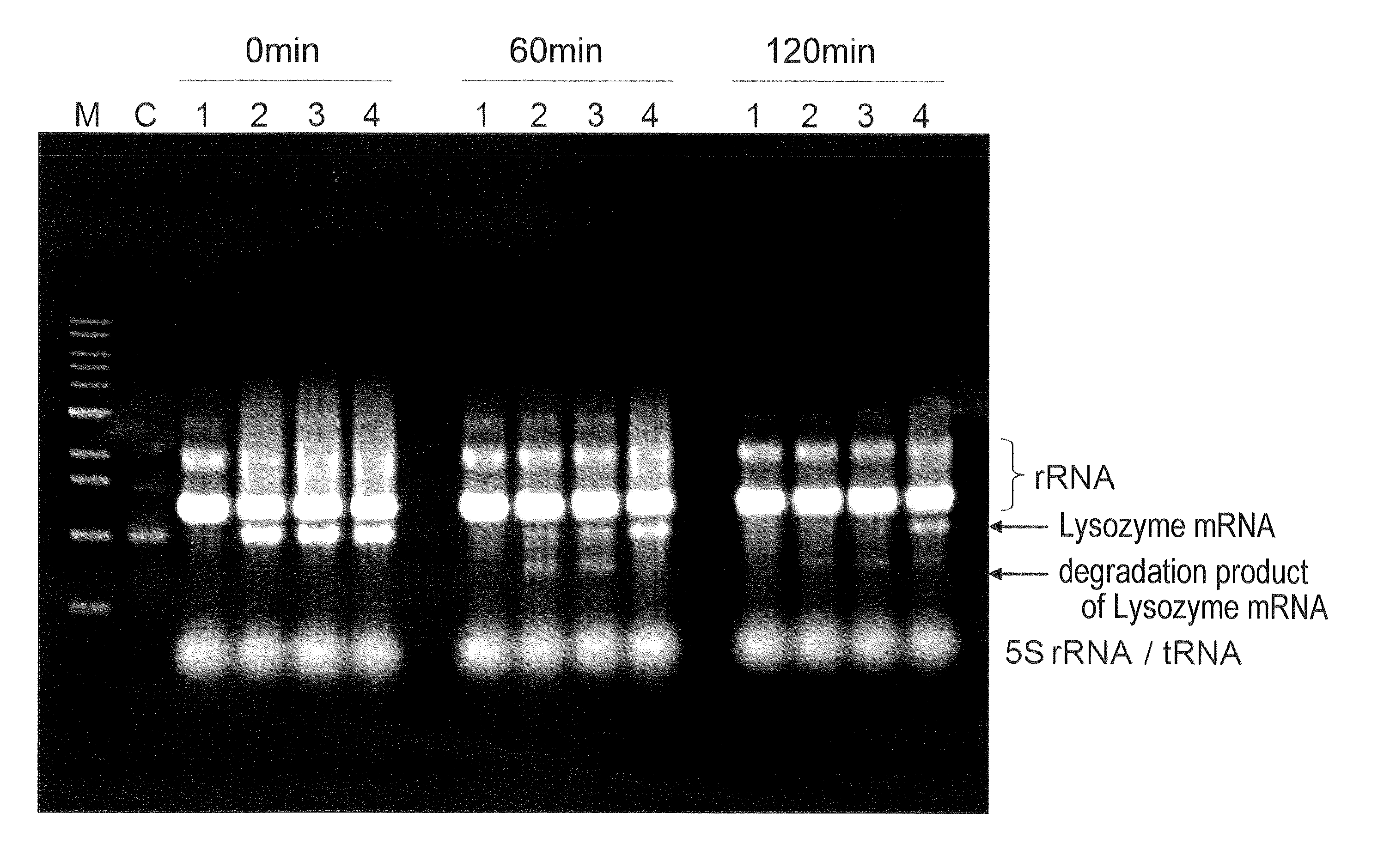

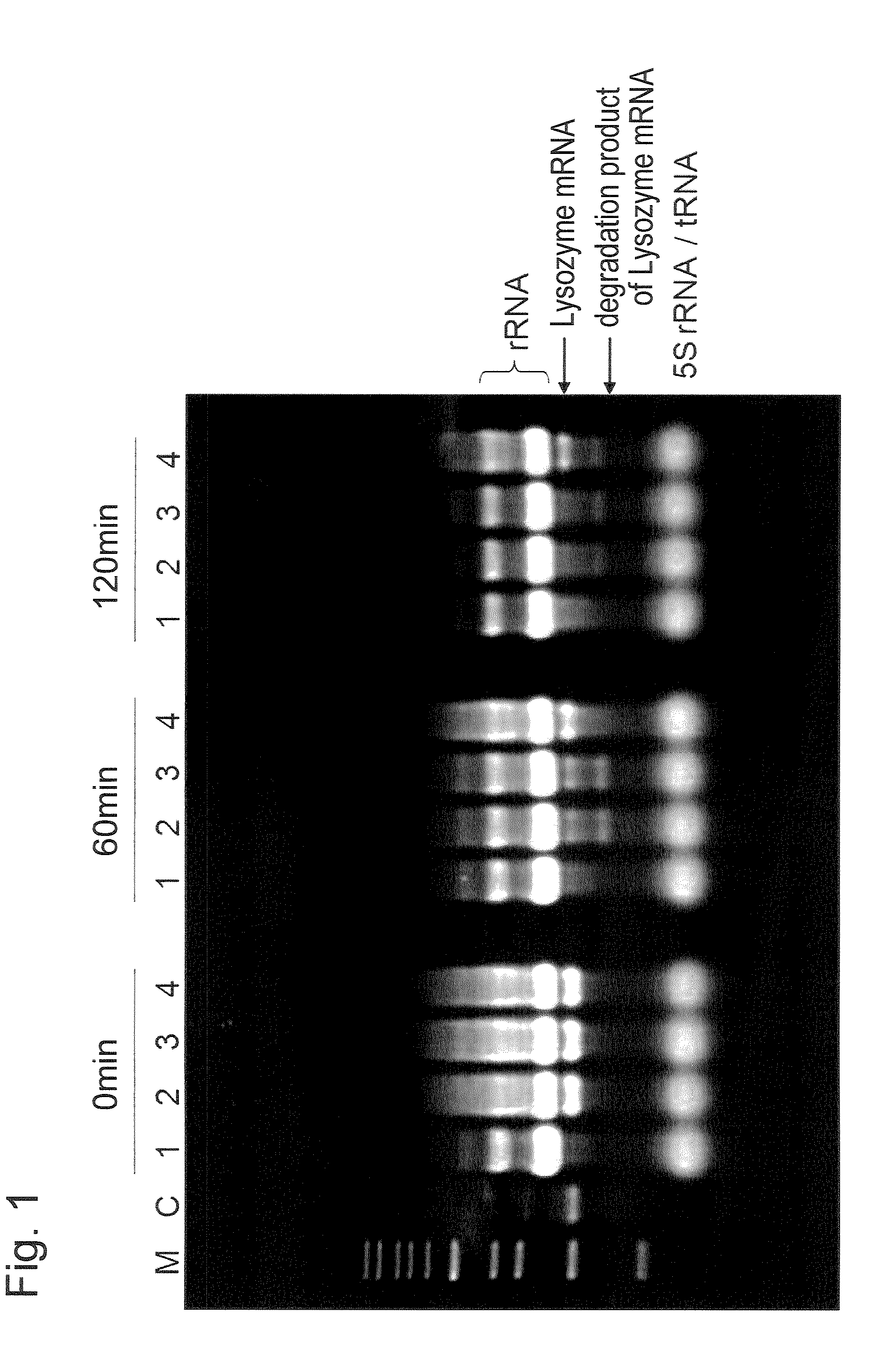

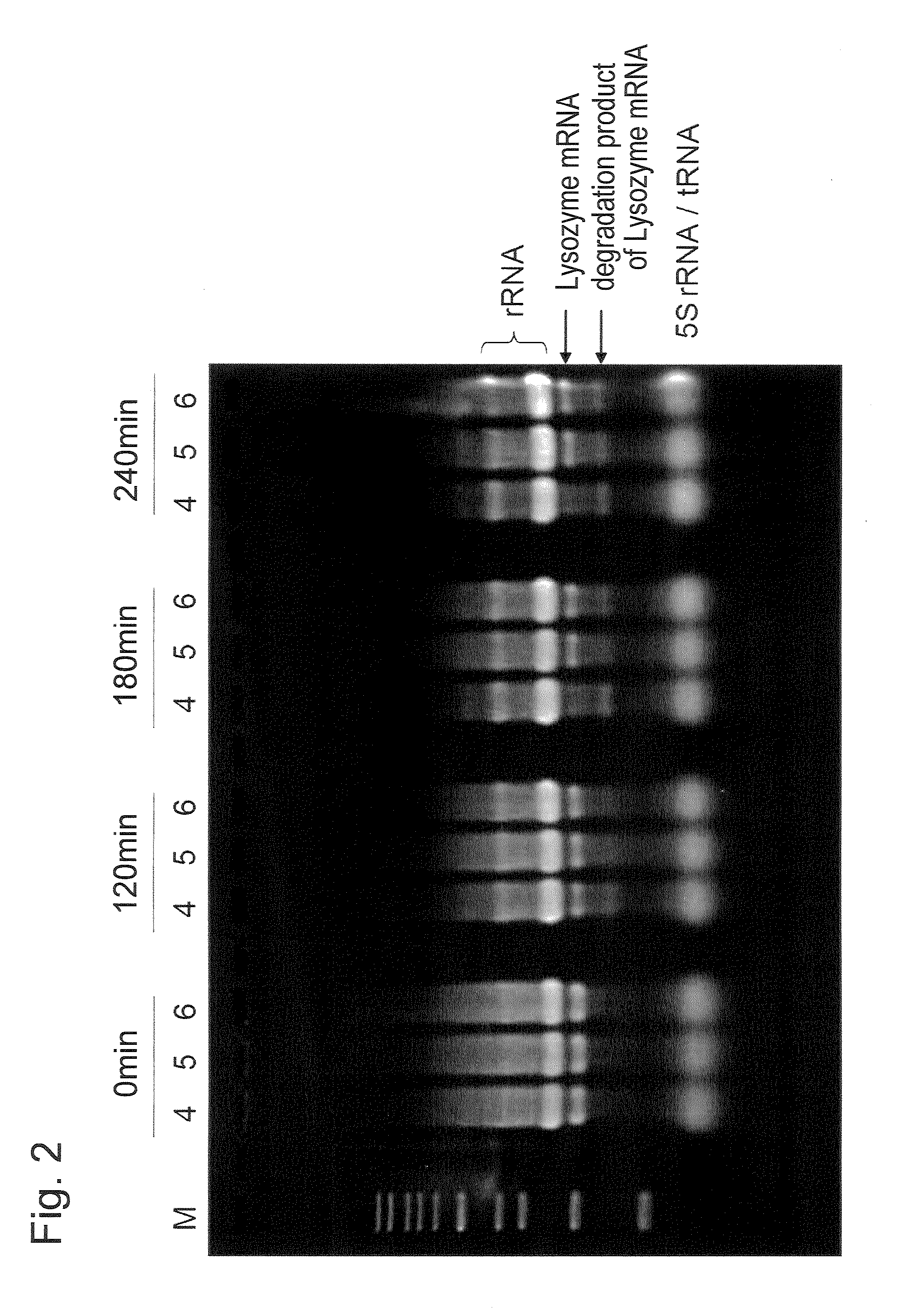

- Incorporating adenosine 3′,5′-bisphosphate (pAp) into the cell-free protein synthesis reaction solution, along with lithium ions, to suppress mRNA degradation, allowing for sustained and cost-effective protein synthesis without the need for labor-intensive pre-treatment methods or additional ribonuclease inhibitors.

Scalability and Manufacturing Considerations

Scaling up cell-free protein synthesis (CFPS) systems for nanomaterial conjugation presents significant challenges that must be addressed for industrial viability. Current laboratory-scale CFPS processes typically operate at volumes ranging from microliters to milliliters, which is insufficient for commercial applications. The transition to liter or industrial scales requires overcoming several technical hurdles, including maintaining reaction homogeneity, ensuring consistent protein quality, and preserving the functionality of conjugated nanomaterials.

The economics of large-scale CFPS production remains a critical consideration. The cost of reagents, particularly energy sources like ATP and GTP, amino acids, and nucleotides, can be prohibitively expensive at scale. Recent advancements have focused on developing more cost-effective energy regeneration systems and optimizing extract preparation methods to reduce overall production costs. For instance, continuous-exchange cell-free (CECF) systems have demonstrated up to 10-fold increases in protein yields while significantly reducing per-unit costs.

Manufacturing consistency represents another major challenge. Batch-to-batch variability in cell extracts can lead to unpredictable protein yields and quality, which is particularly problematic when precise nanomaterial conjugation is required. Standardization of extract preparation protocols and the development of quality control metrics are essential for reliable manufacturing processes. Some companies have begun implementing automated extract preparation systems to enhance reproducibility.

The integration of CFPS with nanomaterial conjugation processes adds another layer of complexity to scaling efforts. Current approaches often involve sequential steps—protein synthesis followed by purification and then conjugation—which is inefficient at larger scales. Emerging one-pot synthesis methods, where protein production and nanomaterial conjugation occur simultaneously, show promise for streamlining manufacturing processes, though challenges related to reaction conditions compatibility remain.

Regulatory considerations also impact scalability. As CFPS-nanomaterial conjugates move toward commercial applications, particularly in medical diagnostics and therapeutics, compliance with GMP (Good Manufacturing Practice) standards becomes necessary. This requires developing robust quality control procedures and validation methods specific to these hybrid biomolecular systems.

Infrastructure requirements for scaled production present additional challenges. Specialized equipment for maintaining optimal reaction conditions, monitoring protein synthesis in real-time, and characterizing nanomaterial conjugates is essential but often expensive. The development of modular, flexible manufacturing platforms that can accommodate different CFPS formulations and nanomaterial types would significantly advance industrial implementation.

The economics of large-scale CFPS production remains a critical consideration. The cost of reagents, particularly energy sources like ATP and GTP, amino acids, and nucleotides, can be prohibitively expensive at scale. Recent advancements have focused on developing more cost-effective energy regeneration systems and optimizing extract preparation methods to reduce overall production costs. For instance, continuous-exchange cell-free (CECF) systems have demonstrated up to 10-fold increases in protein yields while significantly reducing per-unit costs.

Manufacturing consistency represents another major challenge. Batch-to-batch variability in cell extracts can lead to unpredictable protein yields and quality, which is particularly problematic when precise nanomaterial conjugation is required. Standardization of extract preparation protocols and the development of quality control metrics are essential for reliable manufacturing processes. Some companies have begun implementing automated extract preparation systems to enhance reproducibility.

The integration of CFPS with nanomaterial conjugation processes adds another layer of complexity to scaling efforts. Current approaches often involve sequential steps—protein synthesis followed by purification and then conjugation—which is inefficient at larger scales. Emerging one-pot synthesis methods, where protein production and nanomaterial conjugation occur simultaneously, show promise for streamlining manufacturing processes, though challenges related to reaction conditions compatibility remain.

Regulatory considerations also impact scalability. As CFPS-nanomaterial conjugates move toward commercial applications, particularly in medical diagnostics and therapeutics, compliance with GMP (Good Manufacturing Practice) standards becomes necessary. This requires developing robust quality control procedures and validation methods specific to these hybrid biomolecular systems.

Infrastructure requirements for scaled production present additional challenges. Specialized equipment for maintaining optimal reaction conditions, monitoring protein synthesis in real-time, and characterizing nanomaterial conjugates is essential but often expensive. The development of modular, flexible manufacturing platforms that can accommodate different CFPS formulations and nanomaterial types would significantly advance industrial implementation.

Biosafety and Regulatory Framework

The integration of cell-free protein synthesis (CFPS) with nanomaterials presents unique biosafety and regulatory challenges that must be addressed before widespread commercial and clinical applications can be realized. Current regulatory frameworks were largely developed before the emergence of this hybrid technology, creating a complex landscape for researchers and companies working in this field.

Regulatory bodies including the FDA in the United States, the EMA in Europe, and similar organizations globally are still developing comprehensive guidelines specifically for CFPS-nanomaterial conjugates. These products often fall into regulatory gray areas between biological products, medical devices, and nanomaterials, each with distinct regulatory pathways. The classification challenge is particularly evident when CFPS-nanomaterial conjugates are intended for therapeutic or diagnostic applications.

Risk assessment protocols for these hybrid materials require special consideration of both the biological components from CFPS systems and the physicochemical properties of nanomaterials. Potential immunogenicity, cytotoxicity, and long-term accumulation effects represent critical safety concerns. Standard toxicology testing protocols may not adequately capture the unique interactions between cell-free expressed proteins and their conjugated nanomaterials.

Environmental considerations also play a significant role in the regulatory framework. The biodegradability and environmental fate of CFPS-nanomaterial conjugates must be thoroughly evaluated, particularly for applications involving environmental release or high-volume production. Current environmental risk assessment guidelines for nanomaterials may need adaptation to address the biological components introduced through CFPS.

International harmonization of regulations represents another significant challenge. Divergent approaches between regulatory jurisdictions create barriers to global development and commercialization. Organizations such as the International Council for Harmonisation (ICH) and ISO have begun developing standards that may eventually apply to CFPS-nanomaterial conjugates, but comprehensive international consensus remains elusive.

Industry stakeholders are increasingly engaging in proactive regulatory strategies, including early consultation with authorities and participation in regulatory science initiatives. Several companies pioneering CFPS-nanomaterial applications have established dedicated regulatory affairs teams specializing in this intersection of biotechnology and nanoscience to navigate the evolving requirements.

Academic-industry-regulatory partnerships are emerging as a valuable approach to developing appropriate frameworks. These collaborative efforts focus on establishing standardized characterization methods, reference materials, and risk assessment protocols specifically designed for CFPS-nanomaterial conjugates, potentially accelerating the development of clear regulatory pathways for this promising technology.

Regulatory bodies including the FDA in the United States, the EMA in Europe, and similar organizations globally are still developing comprehensive guidelines specifically for CFPS-nanomaterial conjugates. These products often fall into regulatory gray areas between biological products, medical devices, and nanomaterials, each with distinct regulatory pathways. The classification challenge is particularly evident when CFPS-nanomaterial conjugates are intended for therapeutic or diagnostic applications.

Risk assessment protocols for these hybrid materials require special consideration of both the biological components from CFPS systems and the physicochemical properties of nanomaterials. Potential immunogenicity, cytotoxicity, and long-term accumulation effects represent critical safety concerns. Standard toxicology testing protocols may not adequately capture the unique interactions between cell-free expressed proteins and their conjugated nanomaterials.

Environmental considerations also play a significant role in the regulatory framework. The biodegradability and environmental fate of CFPS-nanomaterial conjugates must be thoroughly evaluated, particularly for applications involving environmental release or high-volume production. Current environmental risk assessment guidelines for nanomaterials may need adaptation to address the biological components introduced through CFPS.

International harmonization of regulations represents another significant challenge. Divergent approaches between regulatory jurisdictions create barriers to global development and commercialization. Organizations such as the International Council for Harmonisation (ICH) and ISO have begun developing standards that may eventually apply to CFPS-nanomaterial conjugates, but comprehensive international consensus remains elusive.

Industry stakeholders are increasingly engaging in proactive regulatory strategies, including early consultation with authorities and participation in regulatory science initiatives. Several companies pioneering CFPS-nanomaterial applications have established dedicated regulatory affairs teams specializing in this intersection of biotechnology and nanoscience to navigate the evolving requirements.

Academic-industry-regulatory partnerships are emerging as a valuable approach to developing appropriate frameworks. These collaborative efforts focus on establishing standardized characterization methods, reference materials, and risk assessment protocols specifically designed for CFPS-nanomaterial conjugates, potentially accelerating the development of clear regulatory pathways for this promising technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!