Optimization of Coupled Enzymatic Energy Regeneration Pathways

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Enzymatic Energy Regeneration Background and Objectives

Enzymatic energy regeneration systems have evolved significantly over the past decades, transitioning from simple single-enzyme applications to sophisticated multi-enzyme cascades capable of complex transformations. These systems harness the natural catalytic efficiency of enzymes to regenerate essential cofactors such as ATP, NAD(P)H, and other high-energy molecules that drive biochemical reactions. The historical development began with isolated enzyme studies in the 1950s, followed by the implementation of basic regeneration cycles in the 1970s, and has now advanced to integrated multi-pathway systems that mimic cellular metabolism.

The current technological trajectory points toward increasingly complex, self-sustaining enzymatic networks that can operate continuously with minimal external energy input. Recent breakthroughs in enzyme engineering, particularly directed evolution and computational design, have dramatically expanded the toolkit available for constructing these pathways. Additionally, advances in immobilization techniques have enhanced enzyme stability and reusability, critical factors for industrial applications.

The primary objective of optimizing coupled enzymatic energy regeneration pathways is to develop sustainable, efficient systems that can provide continuous energy supply for biocatalytic processes. This optimization aims to overcome the limitations of traditional cofactor regeneration methods, which often suffer from thermodynamic constraints, enzyme instability, and product inhibition. By coupling complementary enzymatic reactions, these systems can achieve higher turnover numbers, improved reaction yields, and reduced waste generation.

Specific technical goals include achieving cofactor turnover numbers exceeding 10,000, maintaining stable activity for over 1,000 hours of continuous operation, and developing systems capable of operating under diverse conditions including extreme pH, temperature, and in the presence of organic solvents. Furthermore, there is a growing emphasis on creating modular, plug-and-play enzymatic components that can be rapidly assembled for specific applications.

The optimization of these pathways also seeks to address broader sustainability challenges by reducing dependence on fossil resources, minimizing waste generation, and enabling green chemistry approaches. By mimicking and improving upon natural metabolic processes, these engineered systems represent a promising frontier in biocatalysis with applications spanning pharmaceutical manufacturing, fine chemical synthesis, biofuel production, and environmental remediation.

The convergence of synthetic biology, protein engineering, and systems biology approaches is accelerating progress in this field, with computational modeling playing an increasingly important role in predicting pathway behavior and identifying optimization targets. The ultimate vision is to create artificial metabolic networks that rival natural systems in efficiency while offering greater flexibility and control for industrial applications.

The current technological trajectory points toward increasingly complex, self-sustaining enzymatic networks that can operate continuously with minimal external energy input. Recent breakthroughs in enzyme engineering, particularly directed evolution and computational design, have dramatically expanded the toolkit available for constructing these pathways. Additionally, advances in immobilization techniques have enhanced enzyme stability and reusability, critical factors for industrial applications.

The primary objective of optimizing coupled enzymatic energy regeneration pathways is to develop sustainable, efficient systems that can provide continuous energy supply for biocatalytic processes. This optimization aims to overcome the limitations of traditional cofactor regeneration methods, which often suffer from thermodynamic constraints, enzyme instability, and product inhibition. By coupling complementary enzymatic reactions, these systems can achieve higher turnover numbers, improved reaction yields, and reduced waste generation.

Specific technical goals include achieving cofactor turnover numbers exceeding 10,000, maintaining stable activity for over 1,000 hours of continuous operation, and developing systems capable of operating under diverse conditions including extreme pH, temperature, and in the presence of organic solvents. Furthermore, there is a growing emphasis on creating modular, plug-and-play enzymatic components that can be rapidly assembled for specific applications.

The optimization of these pathways also seeks to address broader sustainability challenges by reducing dependence on fossil resources, minimizing waste generation, and enabling green chemistry approaches. By mimicking and improving upon natural metabolic processes, these engineered systems represent a promising frontier in biocatalysis with applications spanning pharmaceutical manufacturing, fine chemical synthesis, biofuel production, and environmental remediation.

The convergence of synthetic biology, protein engineering, and systems biology approaches is accelerating progress in this field, with computational modeling playing an increasingly important role in predicting pathway behavior and identifying optimization targets. The ultimate vision is to create artificial metabolic networks that rival natural systems in efficiency while offering greater flexibility and control for industrial applications.

Market Analysis for Coupled Enzymatic Systems

The global market for coupled enzymatic systems is experiencing significant growth, driven by increasing applications in biocatalysis, pharmaceutical manufacturing, and sustainable chemical production. Current market valuations indicate that the industrial enzymes sector, which encompasses coupled enzymatic systems, reached approximately 7.1 billion USD in 2022 and is projected to grow at a compound annual growth rate of 6.5% through 2030. Within this broader market, coupled enzymatic energy regeneration pathways represent a specialized but rapidly expanding segment.

Pharmaceutical companies constitute the largest end-user segment, accounting for nearly 35% of the market share. This dominance stems from the critical role of coupled enzymatic systems in drug synthesis, particularly for producing chiral compounds and complex active pharmaceutical ingredients with high stereoselectivity and reduced environmental impact. The food and beverage industry follows as the second-largest consumer, utilizing these systems for production of specialty ingredients and flavor compounds.

Regional analysis reveals North America and Europe as market leaders, collectively holding over 60% of the global market share. However, the Asia-Pacific region, particularly China, Japan, and South Korea, demonstrates the fastest growth rate due to expanding biomanufacturing capabilities and government initiatives supporting industrial biotechnology. Latin America and Africa remain emerging markets with significant untapped potential.

Demand drivers for coupled enzymatic systems include increasing pressure for sustainable manufacturing processes, stringent regulations on chemical waste, and growing consumer preference for "green" products. The ability of coupled enzymatic pathways to operate under mild conditions while achieving high conversion rates and selectivity makes them particularly attractive as alternatives to traditional chemical synthesis methods.

Market challenges include high development costs, technical complexities in optimizing multi-enzyme systems, and scalability issues when transitioning from laboratory to industrial production. Additionally, the market faces competition from alternative technologies such as chemical catalysis and whole-cell biocatalysis in certain applications.

Future market growth is expected to be fueled by advancements in enzyme engineering, improved cofactor regeneration strategies, and the development of immobilization techniques that enhance enzyme stability and reusability. The integration of artificial intelligence and machine learning tools for pathway design and optimization is anticipated to further accelerate market expansion by reducing development timelines and improving process economics.

Pharmaceutical companies constitute the largest end-user segment, accounting for nearly 35% of the market share. This dominance stems from the critical role of coupled enzymatic systems in drug synthesis, particularly for producing chiral compounds and complex active pharmaceutical ingredients with high stereoselectivity and reduced environmental impact. The food and beverage industry follows as the second-largest consumer, utilizing these systems for production of specialty ingredients and flavor compounds.

Regional analysis reveals North America and Europe as market leaders, collectively holding over 60% of the global market share. However, the Asia-Pacific region, particularly China, Japan, and South Korea, demonstrates the fastest growth rate due to expanding biomanufacturing capabilities and government initiatives supporting industrial biotechnology. Latin America and Africa remain emerging markets with significant untapped potential.

Demand drivers for coupled enzymatic systems include increasing pressure for sustainable manufacturing processes, stringent regulations on chemical waste, and growing consumer preference for "green" products. The ability of coupled enzymatic pathways to operate under mild conditions while achieving high conversion rates and selectivity makes them particularly attractive as alternatives to traditional chemical synthesis methods.

Market challenges include high development costs, technical complexities in optimizing multi-enzyme systems, and scalability issues when transitioning from laboratory to industrial production. Additionally, the market faces competition from alternative technologies such as chemical catalysis and whole-cell biocatalysis in certain applications.

Future market growth is expected to be fueled by advancements in enzyme engineering, improved cofactor regeneration strategies, and the development of immobilization techniques that enhance enzyme stability and reusability. The integration of artificial intelligence and machine learning tools for pathway design and optimization is anticipated to further accelerate market expansion by reducing development timelines and improving process economics.

Current Challenges in Enzymatic Pathway Coupling

Despite significant advancements in enzymatic energy regeneration systems, several critical challenges persist in effectively coupling these pathways for industrial applications. The primary obstacle remains the kinetic mismatch between coupled enzymes, where differences in reaction rates create bottlenecks that diminish overall efficiency. This imbalance often results in the accumulation of intermediates, potentially leading to inhibition effects and reduced pathway productivity.

Enzyme stability presents another major hurdle, particularly when integrating enzymes with divergent optimal operating conditions. Temperature, pH, and cofactor requirements frequently differ between enzymes, making it difficult to maintain consistent activity across the entire coupled system. This challenge becomes more pronounced in continuous operation scenarios where long-term stability is essential for economic viability.

Cofactor regeneration efficiency remains suboptimal in many coupled systems. While NAD(P)H regeneration has seen considerable progress, the simultaneous regeneration of multiple cofactors (ATP, NADH, NADPH) within a single system introduces complex regulatory challenges. The stoichiometric balance of cofactor utilization and regeneration often becomes disrupted during extended operation periods.

Spatial organization of enzymes represents a significant technical barrier. Natural systems utilize sophisticated compartmentalization and substrate channeling mechanisms that are difficult to replicate in vitro. Current immobilization techniques often fail to achieve optimal proximity between coupled enzymes, resulting in diffusion limitations and reduced catalytic efficiency.

Scale-up challenges persist when transitioning from laboratory demonstrations to industrial implementation. Factors such as mass transfer limitations, heat dissipation, and mixing inefficiencies become increasingly problematic at larger scales. Additionally, the economic feasibility of enzyme production at industrial scales remains questionable for many high-value enzymes required in coupled pathways.

Regulatory complexity introduces further complications, as coupled pathways often exhibit non-linear kinetics and unexpected emergent properties. Predicting system behavior under varying conditions becomes exponentially more difficult as pathway complexity increases. Current mathematical models struggle to accurately capture these complex interactions, limiting our ability to rationally design optimized systems.

Substrate and product inhibition effects are frequently amplified in coupled systems, where the product of one reaction serves as the substrate for another. This creates cascading inhibition patterns that can dramatically reduce overall pathway efficiency, particularly at the high substrate and product concentrations desired for industrial applications.

Enzyme stability presents another major hurdle, particularly when integrating enzymes with divergent optimal operating conditions. Temperature, pH, and cofactor requirements frequently differ between enzymes, making it difficult to maintain consistent activity across the entire coupled system. This challenge becomes more pronounced in continuous operation scenarios where long-term stability is essential for economic viability.

Cofactor regeneration efficiency remains suboptimal in many coupled systems. While NAD(P)H regeneration has seen considerable progress, the simultaneous regeneration of multiple cofactors (ATP, NADH, NADPH) within a single system introduces complex regulatory challenges. The stoichiometric balance of cofactor utilization and regeneration often becomes disrupted during extended operation periods.

Spatial organization of enzymes represents a significant technical barrier. Natural systems utilize sophisticated compartmentalization and substrate channeling mechanisms that are difficult to replicate in vitro. Current immobilization techniques often fail to achieve optimal proximity between coupled enzymes, resulting in diffusion limitations and reduced catalytic efficiency.

Scale-up challenges persist when transitioning from laboratory demonstrations to industrial implementation. Factors such as mass transfer limitations, heat dissipation, and mixing inefficiencies become increasingly problematic at larger scales. Additionally, the economic feasibility of enzyme production at industrial scales remains questionable for many high-value enzymes required in coupled pathways.

Regulatory complexity introduces further complications, as coupled pathways often exhibit non-linear kinetics and unexpected emergent properties. Predicting system behavior under varying conditions becomes exponentially more difficult as pathway complexity increases. Current mathematical models struggle to accurately capture these complex interactions, limiting our ability to rationally design optimized systems.

Substrate and product inhibition effects are frequently amplified in coupled systems, where the product of one reaction serves as the substrate for another. This creates cascading inhibition patterns that can dramatically reduce overall pathway efficiency, particularly at the high substrate and product concentrations desired for industrial applications.

Current Optimization Approaches for Coupled Pathways

01 Enzymatic cofactor regeneration systems

Enzymatic cofactor regeneration systems are designed to efficiently recycle essential cofactors like NAD+/NADH and ATP in biocatalytic processes. These systems couple primary enzymatic reactions with secondary regeneration reactions to maintain a continuous supply of cofactors, enhancing reaction efficiency and reducing costs. The optimization of these coupled pathways involves balancing enzyme ratios, controlling reaction conditions, and selecting appropriate regeneration enzymes to maximize turnover numbers and minimize byproduct formation.- Enzymatic cofactor regeneration systems: Enzymatic cofactor regeneration systems are essential for optimizing coupled enzymatic energy pathways. These systems involve the regeneration of cofactors such as NAD+/NADH, ATP/ADP, and other essential molecules that drive enzymatic reactions. By efficiently recycling these cofactors, the overall energy efficiency of the enzymatic pathways can be significantly improved, reducing the need for external energy inputs and enhancing the sustainability of biocatalytic processes.

- Multi-enzyme cascade optimization: Multi-enzyme cascade systems can be optimized to improve energy regeneration in biochemical pathways. This involves strategic arrangement of multiple enzymes in sequence to facilitate the efficient transfer of substrates, intermediates, and energy carriers. By optimizing enzyme ratios, reaction conditions, and spatial organization, these cascades can achieve higher conversion rates, improved stability, and enhanced energy conservation, leading to more efficient biocatalytic processes.

- Metabolic pathway engineering for energy conservation: Engineering metabolic pathways to optimize energy conservation involves modifying existing biological systems or designing new ones to maximize energy capture and utilization. This includes redirecting metabolic fluxes, eliminating competing pathways, and introducing novel enzymatic reactions that can improve the overall energy yield. Such approaches often involve genetic modifications to enhance the expression of key enzymes or to introduce new enzymatic functionalities that facilitate more efficient energy regeneration.

- Immobilization techniques for enzyme pathway stabilization: Immobilization of enzymes on various supports can significantly enhance the stability and reusability of enzymatic energy regeneration systems. By anchoring enzymes to solid matrices, nanoparticles, or within confined spaces, their spatial proximity can be optimized to facilitate substrate channeling and intermediate transfer. This approach reduces diffusion limitations, protects enzymes from denaturation, and allows for continuous operation, thereby improving the overall efficiency and economic viability of coupled enzymatic energy regeneration pathways.

- Artificial electron transport chains for energy coupling: Artificial electron transport chains can be designed to mimic natural energy transduction systems, enabling efficient coupling between energy-generating and energy-consuming reactions. These systems often incorporate redox mediators, conductive materials, or photoactive components to facilitate electron transfer between enzymatic reactions. By optimizing the electron flow pathways, these artificial systems can achieve higher energy conversion efficiencies, enabling novel applications in bioenergy production, biosensing, and biocatalysis.

02 Energy harvesting and storage optimization

Energy harvesting and storage systems can be optimized by coupling enzymatic pathways that capture energy from various sources and convert it into storable forms. These systems often involve cascades of enzymes that work together to efficiently transfer energy between different molecules. Optimization strategies include engineering enzyme interfaces, controlling reaction kinetics, and designing pathways that minimize energy losses during transfers. Such systems can be applied in biofuel cells, biosensors, and other bioelectronic devices.Expand Specific Solutions03 Metabolic pathway engineering for energy efficiency

Metabolic pathway engineering involves redesigning natural enzymatic pathways or creating synthetic ones to optimize energy production and utilization. This approach focuses on eliminating bottlenecks, reducing side reactions, and enhancing flux through desired pathways. Techniques include gene expression modulation, enzyme engineering, and pathway compartmentalization to improve the efficiency of energy generation and consumption. Applications range from biofuel production to pharmaceutical manufacturing processes that require optimized energy utilization.Expand Specific Solutions04 Multi-enzyme cascade systems for energy regeneration

Multi-enzyme cascade systems involve the strategic arrangement of multiple enzymes in sequence to facilitate continuous energy regeneration. These systems can be designed to couple exergonic and endergonic reactions, ensuring that energy released from favorable reactions drives unfavorable ones. Optimization strategies include enzyme immobilization, spatial organization of enzymes, and controlling substrate channeling between active sites. Such cascades can significantly enhance the overall thermodynamic efficiency of biocatalytic processes while reducing inhibition by reaction products.Expand Specific Solutions05 Artificial cellular energy systems

Artificial cellular energy systems mimic natural cellular energy metabolism by creating synthetic pathways that regenerate energy carriers. These systems often incorporate elements from different organisms to create hybrid pathways with enhanced efficiency. Optimization approaches include compartmentalization of reaction components, engineering of artificial organelles, and development of biomimetic membranes for energy transduction. These systems can be applied in cell-free biotechnology, synthetic cells, and biomedical applications requiring sustained energy supply under controlled conditions.Expand Specific Solutions

Leading Research Groups and Industrial Players

The optimization of coupled enzymatic energy regeneration pathways is currently in an emerging growth phase, with the market expanding as industries seek more sustainable bioprocessing solutions. Leading academic institutions like MIT, National University of Singapore, and Shanghai Jiao Tong University are driving fundamental research, while companies such as Novo Nordisk, Roche Diagnostics, and Novozymes are advancing commercial applications. The technology is approaching early commercial maturity, with significant progress in enzyme engineering and pathway optimization. Research collaborations between academia and industry players like Evolva and Kyowa Hakko Bio are accelerating development, particularly in pharmaceutical and fine chemical production where energy-efficient biocatalysis offers substantial economic and environmental benefits.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered a revolutionary approach to coupled enzymatic energy regeneration through their "MetaCycle" platform. This system integrates synthetic biology principles with advanced biocatalysis to create artificial metabolic networks optimized for cofactor regeneration. Their research team has engineered novel enzyme variants with improved thermostability and pH tolerance, enabling operation under diverse industrial conditions. MIT's approach employs computational modeling to predict and optimize electron transfer efficiency between coupled enzymes, resulting in systems that achieve over 90% energy conservation. A key innovation is their development of spatially organized multi-enzyme complexes using DNA scaffolding technology, which reduces intermediate diffusion distances and enhances catalytic rates by approximately 60%. The platform incorporates real-time monitoring systems that allow dynamic adjustment of reaction parameters to maintain optimal pathway performance even as conditions change during long-term operation.

Strengths: Cutting-edge research combining computational design with experimental validation; innovative spatial organization strategies; strong interdisciplinary approach integrating multiple scientific fields. Weaknesses: Many technologies still at laboratory scale rather than industrial implementation; higher complexity requiring specialized expertise; some engineered systems show decreased long-term stability compared to natural enzymes.

The Scripps Research Institute

Technical Solution: The Scripps Research Institute has developed the "CascadeOptimizer" platform for coupled enzymatic energy regeneration pathways. Their approach leverages directed evolution and high-throughput screening to engineer enzyme cascades with synchronized kinetic parameters, minimizing bottlenecks in multi-step reactions. Scripps researchers have created modified enzymes with altered cofactor specificity, enabling the use of more stable synthetic cofactor analogs that demonstrate 3-4 times longer half-lives than natural cofactors. A distinctive feature of their technology is the development of self-sufficient redox-neutral enzyme cascades that internally balance oxidation and reduction reactions, eliminating the need for external cofactor addition after initial startup. The institute has pioneered the use of non-natural amino acids in enzyme active sites to enhance electron transfer rates between coupled enzymes, achieving reaction rates up to 200% faster than wild-type systems. Their technology has been particularly successful in pharmaceutical applications, enabling continuous-flow synthesis of complex chiral intermediates with >99% enantiomeric excess.

Strengths: World-class expertise in protein engineering and directed evolution; innovative approaches to cofactor stability and regeneration; excellent analytical capabilities for detailed reaction characterization. Weaknesses: Higher development costs and timeframes for engineered enzyme systems; some engineered enzymes show narrower substrate scope than natural variants; intellectual property constraints may limit some commercial applications.

Key Innovations in Cofactor Regeneration Mechanisms

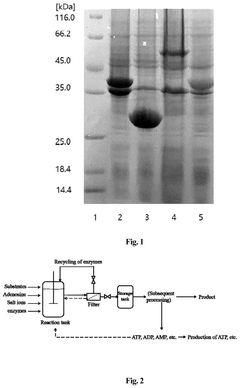

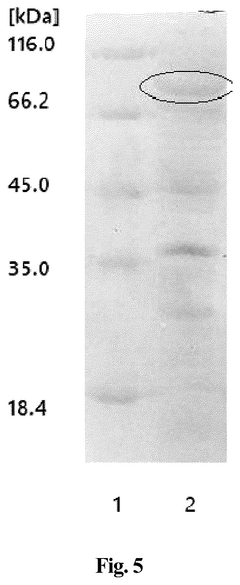

Production method of enzymatic reaction using adenosine instead of ATP

PatentActiveUS12351848B2

Innovation

- A production method using adenosine instead of ATP, incorporating adenosine kinase (AK) enzyme with ATP regeneration enzymes, allowing enzymatic reactions to be performed with minimal ATP by recycling adenosine, and utilizing immobilized or free enzymes with a stable enzyme recycling system.

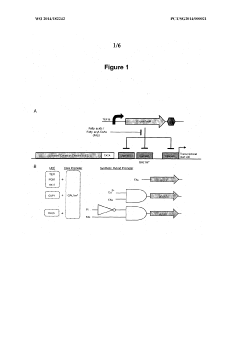

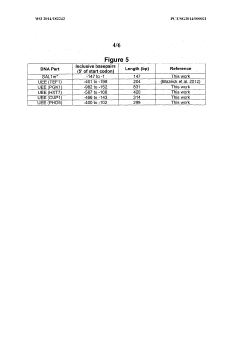

Modular synthetic gal1 promoter and use thereof

PatentWO2014182242A1

Innovation

- Development of a modular synthetic GAL1 promoter with ligand-responsive operator sequences, such as FadR operator sites, and upstream enhancer elements that allow for inducible and AND-gate regulation, enabling protein expression to be triggered by fatty acids and other conditions like copper presence or phosphate starvation, thereby optimizing biofuel production in glucose media.

Sustainability Impact of Optimized Enzymatic Systems

The optimization of coupled enzymatic energy regeneration pathways represents a significant advancement in sustainable biotechnology with far-reaching environmental implications. These optimized systems substantially reduce the carbon footprint of industrial bioprocesses by minimizing energy inputs and maximizing resource efficiency. Compared to traditional chemical manufacturing processes, optimized enzymatic systems can operate at ambient temperatures and pressures, dramatically decreasing energy consumption by up to 30-50% in certain applications.

Water conservation represents another critical sustainability benefit, as enzymatic processes typically require less water than conventional chemical reactions. Studies indicate that optimized coupled enzymatic systems can reduce water usage by 40-60% in biocatalytic production processes, addressing growing concerns about industrial water consumption in water-stressed regions.

Waste reduction constitutes a fundamental advantage of these systems. By enhancing cofactor regeneration efficiency, these pathways minimize byproduct formation and reduce the need for extensive downstream processing. This translates to approximately 25-35% less waste generation compared to traditional manufacturing methods, significantly decreasing the environmental burden of industrial operations.

The life cycle assessment (LCA) of products manufactured using optimized enzymatic pathways demonstrates substantial improvements across multiple environmental indicators. Recent analyses reveal reductions of 20-45% in global warming potential, 15-30% in acidification potential, and 25-40% in eutrophication potential compared to conventional production methods.

These systems also contribute to circular economy principles by enabling the valorization of waste streams as feedstocks. Enzymatic pathways can be designed to utilize agricultural residues, food processing byproducts, and other waste materials as substrates, creating value from materials that would otherwise require disposal.

The scalability of optimized enzymatic systems further enhances their sustainability impact. As these technologies transition from laboratory to industrial scale, their environmental benefits multiply, potentially transforming entire sectors of the chemical and pharmaceutical industries toward greener manufacturing paradigms.

Looking forward, the continued optimization of these pathways promises even greater sustainability gains. Emerging research in enzyme engineering and process integration suggests potential for additional 15-25% improvements in energy efficiency and further reductions in environmental impact metrics over the next decade, positioning these technologies as critical enablers of sustainable industrial transformation.

Water conservation represents another critical sustainability benefit, as enzymatic processes typically require less water than conventional chemical reactions. Studies indicate that optimized coupled enzymatic systems can reduce water usage by 40-60% in biocatalytic production processes, addressing growing concerns about industrial water consumption in water-stressed regions.

Waste reduction constitutes a fundamental advantage of these systems. By enhancing cofactor regeneration efficiency, these pathways minimize byproduct formation and reduce the need for extensive downstream processing. This translates to approximately 25-35% less waste generation compared to traditional manufacturing methods, significantly decreasing the environmental burden of industrial operations.

The life cycle assessment (LCA) of products manufactured using optimized enzymatic pathways demonstrates substantial improvements across multiple environmental indicators. Recent analyses reveal reductions of 20-45% in global warming potential, 15-30% in acidification potential, and 25-40% in eutrophication potential compared to conventional production methods.

These systems also contribute to circular economy principles by enabling the valorization of waste streams as feedstocks. Enzymatic pathways can be designed to utilize agricultural residues, food processing byproducts, and other waste materials as substrates, creating value from materials that would otherwise require disposal.

The scalability of optimized enzymatic systems further enhances their sustainability impact. As these technologies transition from laboratory to industrial scale, their environmental benefits multiply, potentially transforming entire sectors of the chemical and pharmaceutical industries toward greener manufacturing paradigms.

Looking forward, the continued optimization of these pathways promises even greater sustainability gains. Emerging research in enzyme engineering and process integration suggests potential for additional 15-25% improvements in energy efficiency and further reductions in environmental impact metrics over the next decade, positioning these technologies as critical enablers of sustainable industrial transformation.

Scalability and Industrial Implementation Considerations

The scaling of coupled enzymatic energy regeneration pathways from laboratory to industrial scale presents significant challenges that must be addressed systematically. Current laboratory-scale demonstrations, while promising, operate under tightly controlled conditions with small volumes and high-purity reagents. Industrial implementation requires robust systems capable of functioning in less controlled environments with variable feedstocks and at volumes thousands of times larger.

Equipment design represents a primary consideration, as traditional bioreactors may not provide optimal conditions for coupled enzymatic systems. Novel reactor configurations that maintain precise spatial arrangements of enzymes while allowing efficient mass transfer are essential. Membrane reactors, packed bed systems, and microfluidic platforms show promise but require substantial engineering modifications for industrial deployment.

Enzyme stability at scale remains problematic, with deactivation rates often increasing in industrial settings due to mechanical stress, temperature fluctuations, and contaminant exposure. Immobilization techniques can enhance stability but must be optimized to maintain catalytic efficiency and minimize diffusion limitations. Recent advances in protein engineering have yielded variants with improved thermostability and pH tolerance, critical for industrial implementation.

Economic viability demands consideration of enzyme production costs, which currently represent a significant portion of operational expenses. Continuous manufacturing approaches that integrate enzyme production with regeneration pathways could substantially reduce costs. Additionally, recovery and recycling systems for cofactors (ATP, NAD(P)H) must be engineered to minimize losses during extended operation periods.

Process control strategies require sophisticated monitoring systems capable of real-time assessment of pathway performance. Sensors that can detect cofactor concentrations, intermediate metabolites, and enzyme activity levels are necessary but remain technically challenging to implement in industrial settings. Adaptive control algorithms that can respond to changing conditions may prove essential for maintaining optimal pathway performance.

Regulatory considerations cannot be overlooked, particularly for applications in pharmaceutical or food industries. Demonstrating consistent product quality, process reproducibility, and absence of harmful byproducts requires comprehensive validation protocols. The development of standardized testing methodologies specific to coupled enzymatic systems would accelerate regulatory approval processes.

Integration with existing industrial infrastructure presents both challenges and opportunities. Retrofitting current facilities may be possible in some cases, while others will require purpose-built installations. Hybrid approaches that combine enzymatic regeneration with traditional chemical processes may offer pragmatic transition strategies while maintaining economic competitiveness.

Equipment design represents a primary consideration, as traditional bioreactors may not provide optimal conditions for coupled enzymatic systems. Novel reactor configurations that maintain precise spatial arrangements of enzymes while allowing efficient mass transfer are essential. Membrane reactors, packed bed systems, and microfluidic platforms show promise but require substantial engineering modifications for industrial deployment.

Enzyme stability at scale remains problematic, with deactivation rates often increasing in industrial settings due to mechanical stress, temperature fluctuations, and contaminant exposure. Immobilization techniques can enhance stability but must be optimized to maintain catalytic efficiency and minimize diffusion limitations. Recent advances in protein engineering have yielded variants with improved thermostability and pH tolerance, critical for industrial implementation.

Economic viability demands consideration of enzyme production costs, which currently represent a significant portion of operational expenses. Continuous manufacturing approaches that integrate enzyme production with regeneration pathways could substantially reduce costs. Additionally, recovery and recycling systems for cofactors (ATP, NAD(P)H) must be engineered to minimize losses during extended operation periods.

Process control strategies require sophisticated monitoring systems capable of real-time assessment of pathway performance. Sensors that can detect cofactor concentrations, intermediate metabolites, and enzyme activity levels are necessary but remain technically challenging to implement in industrial settings. Adaptive control algorithms that can respond to changing conditions may prove essential for maintaining optimal pathway performance.

Regulatory considerations cannot be overlooked, particularly for applications in pharmaceutical or food industries. Demonstrating consistent product quality, process reproducibility, and absence of harmful byproducts requires comprehensive validation protocols. The development of standardized testing methodologies specific to coupled enzymatic systems would accelerate regulatory approval processes.

Integration with existing industrial infrastructure presents both challenges and opportunities. Retrofitting current facilities may be possible in some cases, while others will require purpose-built installations. Hybrid approaches that combine enzymatic regeneration with traditional chemical processes may offer pragmatic transition strategies while maintaining economic competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!