CFRP Durability Testing Under Cyclic Weather Conditions

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Durability Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various high-performance industries over the past four decades. Initially developed for aerospace applications in the 1970s, these lightweight yet incredibly strong composites have progressively expanded into automotive, civil infrastructure, renewable energy, and sporting goods sectors. The evolution of CFRP technology has been characterized by continuous improvements in manufacturing processes, matrix formulations, and fiber architectures to enhance performance characteristics.

The durability of CFRP under real-world environmental conditions represents one of the most critical challenges facing the widespread adoption of these materials. While CFRPs offer exceptional strength-to-weight ratios and corrosion resistance compared to traditional materials, their long-term performance under cyclic weather exposure remains incompletely understood. This knowledge gap creates significant uncertainty for engineers and designers when specifying service lifetimes and maintenance schedules for CFRP components.

Recent environmental and economic pressures have accelerated the need for comprehensive durability testing protocols. As industries push toward more sustainable practices, the extended service life of CFRP components becomes increasingly important for reducing lifecycle environmental impacts. Additionally, as CFRP applications expand into critical infrastructure with expected service lives of 50-100 years, the ability to accurately predict long-term performance becomes paramount.

The technical evolution of CFRP durability testing has progressed from simple accelerated aging tests to more sophisticated protocols that attempt to replicate complex real-world conditions. Early testing focused primarily on individual environmental factors such as UV exposure, moisture absorption, or temperature cycling. However, research has demonstrated that the synergistic effects of multiple environmental stressors often produce degradation mechanisms that cannot be predicted by studying isolated factors.

The primary objective of current CFRP durability testing research is to develop standardized protocols that accurately simulate cyclic weather conditions while accelerating the aging process to obtain meaningful data within practical timeframes. These protocols must balance the need for acceleration with the requirement to maintain the same fundamental degradation mechanisms that occur in natural exposure.

Secondary objectives include establishing reliable correlations between accelerated laboratory testing and real-world performance, developing predictive models for CFRP durability under various environmental conditions, and creating industry-specific testing standards that address the unique requirements of different applications. Additionally, there is growing interest in understanding how emerging CFRP formulations with bio-based components or recycled fibers perform in terms of long-term durability compared to traditional petroleum-based composites.

The durability of CFRP under real-world environmental conditions represents one of the most critical challenges facing the widespread adoption of these materials. While CFRPs offer exceptional strength-to-weight ratios and corrosion resistance compared to traditional materials, their long-term performance under cyclic weather exposure remains incompletely understood. This knowledge gap creates significant uncertainty for engineers and designers when specifying service lifetimes and maintenance schedules for CFRP components.

Recent environmental and economic pressures have accelerated the need for comprehensive durability testing protocols. As industries push toward more sustainable practices, the extended service life of CFRP components becomes increasingly important for reducing lifecycle environmental impacts. Additionally, as CFRP applications expand into critical infrastructure with expected service lives of 50-100 years, the ability to accurately predict long-term performance becomes paramount.

The technical evolution of CFRP durability testing has progressed from simple accelerated aging tests to more sophisticated protocols that attempt to replicate complex real-world conditions. Early testing focused primarily on individual environmental factors such as UV exposure, moisture absorption, or temperature cycling. However, research has demonstrated that the synergistic effects of multiple environmental stressors often produce degradation mechanisms that cannot be predicted by studying isolated factors.

The primary objective of current CFRP durability testing research is to develop standardized protocols that accurately simulate cyclic weather conditions while accelerating the aging process to obtain meaningful data within practical timeframes. These protocols must balance the need for acceleration with the requirement to maintain the same fundamental degradation mechanisms that occur in natural exposure.

Secondary objectives include establishing reliable correlations between accelerated laboratory testing and real-world performance, developing predictive models for CFRP durability under various environmental conditions, and creating industry-specific testing standards that address the unique requirements of different applications. Additionally, there is growing interest in understanding how emerging CFRP formulations with bio-based components or recycled fibers perform in terms of long-term durability compared to traditional petroleum-based composites.

Market Demand Analysis for Weather-Resistant CFRP

The global market for weather-resistant Carbon Fiber Reinforced Polymers (CFRP) has experienced significant growth in recent years, driven primarily by increasing demand in aerospace, automotive, and construction industries. These sectors require materials that can withstand harsh environmental conditions while maintaining structural integrity and performance characteristics.

In the aerospace industry, the demand for weather-resistant CFRP has been particularly strong, with an annual growth rate exceeding the overall composites market. Aircraft manufacturers are increasingly replacing traditional materials with CFRP components that can withstand extreme temperature variations, UV radiation, and moisture exposure during flight operations. This transition is motivated by the need for fuel efficiency through weight reduction while ensuring durability in diverse operating environments.

The automotive sector represents another substantial market for weather-resistant CFRP, especially in premium and electric vehicle segments. Manufacturers are incorporating these materials in exterior body panels, chassis components, and structural elements that are exposed to varying weather conditions. The market is responding to consumer expectations for vehicles that maintain aesthetic and structural properties despite prolonged exposure to environmental factors such as acid rain, road salt, and temperature fluctuations.

Construction and infrastructure applications constitute a rapidly expanding market segment for weather-resistant CFRP. Bridge rehabilitation, building reinforcement, and marine structures benefit from CFRP's corrosion resistance and durability under cyclic weather conditions. The infrastructure rehabilitation market in North America and Europe has shown particular interest in these materials as aging structures require reinforcement solutions that can withstand seasonal weather variations.

Market research indicates that customers across industries are willing to pay premium prices for CFRP materials with proven weather resistance capabilities. This premium positioning is supported by lifecycle cost analyses demonstrating that despite higher initial investment, weather-resistant CFRP offers superior long-term value through reduced maintenance requirements and extended service life.

Regional market analysis reveals that demand is strongest in regions with extreme or highly variable climate conditions. Countries with coastal areas, regions experiencing freeze-thaw cycles, and locations with high UV exposure show particularly strong market potential for weather-resistant CFRP solutions.

The renewable energy sector, particularly wind energy, represents an emerging market with substantial growth potential. Wind turbine blades manufactured from weather-resistant CFRP can withstand harsh offshore conditions, including salt spray, UV radiation, and temperature variations, while maintaining optimal aerodynamic properties throughout their operational lifespan.

In the aerospace industry, the demand for weather-resistant CFRP has been particularly strong, with an annual growth rate exceeding the overall composites market. Aircraft manufacturers are increasingly replacing traditional materials with CFRP components that can withstand extreme temperature variations, UV radiation, and moisture exposure during flight operations. This transition is motivated by the need for fuel efficiency through weight reduction while ensuring durability in diverse operating environments.

The automotive sector represents another substantial market for weather-resistant CFRP, especially in premium and electric vehicle segments. Manufacturers are incorporating these materials in exterior body panels, chassis components, and structural elements that are exposed to varying weather conditions. The market is responding to consumer expectations for vehicles that maintain aesthetic and structural properties despite prolonged exposure to environmental factors such as acid rain, road salt, and temperature fluctuations.

Construction and infrastructure applications constitute a rapidly expanding market segment for weather-resistant CFRP. Bridge rehabilitation, building reinforcement, and marine structures benefit from CFRP's corrosion resistance and durability under cyclic weather conditions. The infrastructure rehabilitation market in North America and Europe has shown particular interest in these materials as aging structures require reinforcement solutions that can withstand seasonal weather variations.

Market research indicates that customers across industries are willing to pay premium prices for CFRP materials with proven weather resistance capabilities. This premium positioning is supported by lifecycle cost analyses demonstrating that despite higher initial investment, weather-resistant CFRP offers superior long-term value through reduced maintenance requirements and extended service life.

Regional market analysis reveals that demand is strongest in regions with extreme or highly variable climate conditions. Countries with coastal areas, regions experiencing freeze-thaw cycles, and locations with high UV exposure show particularly strong market potential for weather-resistant CFRP solutions.

The renewable energy sector, particularly wind energy, represents an emerging market with substantial growth potential. Wind turbine blades manufactured from weather-resistant CFRP can withstand harsh offshore conditions, including salt spray, UV radiation, and temperature variations, while maintaining optimal aerodynamic properties throughout their operational lifespan.

Current Testing Challenges and Limitations

The current testing methodologies for Carbon Fiber Reinforced Polymers (CFRP) under cyclic weather conditions face significant challenges that limit their effectiveness in predicting real-world performance. Traditional accelerated aging tests often fail to accurately replicate the complex interactions between temperature fluctuations, moisture cycles, UV radiation, and mechanical loading that CFRPs experience in actual service environments. This disconnect between laboratory testing and field performance creates substantial uncertainty in durability predictions.

One major limitation is the inability to simultaneously apply multiple environmental stressors in a realistic sequence. Most existing test chambers can control temperature and humidity but struggle to incorporate UV exposure and mechanical loading concurrently. This segregated approach to testing fails to capture the synergistic degradation mechanisms that occur when these factors interact, potentially leading to underestimation of material degradation rates.

Time compression remains another significant challenge. Accelerated testing protocols must compress decades of environmental exposure into manageable test durations, but current acceleration factors often lack validation against real-world aging data. The absence of standardized correlation methods between accelerated test results and actual service life predictions undermines confidence in durability assessments for long-term applications in aerospace, automotive, and renewable energy sectors.

The heterogeneous nature of CFRP composites further complicates testing procedures. Different fiber orientations, matrix systems, and manufacturing processes result in varying degradation mechanisms under identical environmental conditions. Current testing standards inadequately address this variability, leading to inconsistent results across different material configurations and manufacturing techniques.

Data interpretation presents additional challenges. The complex failure modes of CFRPs under cyclic weather conditions—including matrix cracking, fiber-matrix debonding, and interlaminar delamination—are difficult to quantify using conventional metrics. Non-destructive evaluation techniques often lack the sensitivity to detect early-stage degradation, while destructive testing provides only point-in-time snapshots rather than continuous degradation profiles.

Scale effects represent another critical limitation. Laboratory specimens typically differ significantly in size and geometry from actual components, creating uncertainty when extrapolating test results to full-scale structures. Edge effects, thickness variations, and geometric complexities present in real components are rarely accounted for in standardized coupon tests, potentially masking critical failure mechanisms.

Finally, there is a notable absence of comprehensive databases correlating accelerated test results with field performance across diverse environmental conditions. This knowledge gap hampers the development of reliable predictive models and forces engineers to incorporate excessive safety factors, resulting in overdesigned and economically inefficient CFRP applications.

One major limitation is the inability to simultaneously apply multiple environmental stressors in a realistic sequence. Most existing test chambers can control temperature and humidity but struggle to incorporate UV exposure and mechanical loading concurrently. This segregated approach to testing fails to capture the synergistic degradation mechanisms that occur when these factors interact, potentially leading to underestimation of material degradation rates.

Time compression remains another significant challenge. Accelerated testing protocols must compress decades of environmental exposure into manageable test durations, but current acceleration factors often lack validation against real-world aging data. The absence of standardized correlation methods between accelerated test results and actual service life predictions undermines confidence in durability assessments for long-term applications in aerospace, automotive, and renewable energy sectors.

The heterogeneous nature of CFRP composites further complicates testing procedures. Different fiber orientations, matrix systems, and manufacturing processes result in varying degradation mechanisms under identical environmental conditions. Current testing standards inadequately address this variability, leading to inconsistent results across different material configurations and manufacturing techniques.

Data interpretation presents additional challenges. The complex failure modes of CFRPs under cyclic weather conditions—including matrix cracking, fiber-matrix debonding, and interlaminar delamination—are difficult to quantify using conventional metrics. Non-destructive evaluation techniques often lack the sensitivity to detect early-stage degradation, while destructive testing provides only point-in-time snapshots rather than continuous degradation profiles.

Scale effects represent another critical limitation. Laboratory specimens typically differ significantly in size and geometry from actual components, creating uncertainty when extrapolating test results to full-scale structures. Edge effects, thickness variations, and geometric complexities present in real components are rarely accounted for in standardized coupon tests, potentially masking critical failure mechanisms.

Finally, there is a notable absence of comprehensive databases correlating accelerated test results with field performance across diverse environmental conditions. This knowledge gap hampers the development of reliable predictive models and forces engineers to incorporate excessive safety factors, resulting in overdesigned and economically inefficient CFRP applications.

Current Cyclic Weather Testing Protocols

01 Environmental protection and durability enhancement of CFRP

Various methods are employed to enhance the durability of Carbon Fiber Reinforced Polymer (CFRP) against environmental factors. These include specialized coatings, surface treatments, and additives that protect against UV radiation, moisture, and chemical exposure. These protective measures significantly extend the service life of CFRP components in harsh environments while maintaining their mechanical properties and structural integrity.- Environmental resistance and protection methods: CFRP materials can be vulnerable to environmental factors such as UV radiation, moisture, and chemical exposure. Various protection methods have been developed to enhance durability, including specialized coatings, sealants, and surface treatments that create barriers against environmental degradation. These protective layers help maintain the structural integrity of CFRP components over extended periods, particularly in harsh environments where exposure to elements could otherwise lead to material deterioration.

- Impact and damage resistance enhancement: Improving CFRP's resistance to impact damage is crucial for applications in automotive, aerospace, and construction industries. Techniques include incorporating energy-absorbing materials, optimizing fiber orientation, and developing multi-layer composite structures that can withstand mechanical stress without compromising structural integrity. These enhancements significantly improve the durability of CFRP components under dynamic loading conditions and extend their service life in high-stress applications.

- Manufacturing processes for durability optimization: Advanced manufacturing techniques significantly influence CFRP durability. Processes such as automated fiber placement, resin transfer molding, and controlled curing cycles help minimize defects like voids, resin-rich areas, and fiber misalignment that could compromise long-term performance. Optimized manufacturing parameters ensure consistent quality and enhanced durability properties in the final composite structure, leading to more reliable components with predictable service life characteristics.

- Fatigue resistance and cyclic loading performance: CFRP materials are subject to performance degradation under cyclic loading conditions. Research focuses on improving fatigue resistance through matrix modification, fiber-matrix interface enhancement, and structural design optimization. These approaches help prevent microcrack propagation and delamination under repeated stress, extending the operational lifespan of CFRP components in applications where vibration and cyclic loading are common, such as in aerospace structures, wind turbine blades, and automotive components.

- Repair and maintenance technologies: Effective repair methods are essential for maintaining CFRP durability throughout the service life. Advanced repair technologies include patch bonding, resin injection, and localized heat treatment to restore damaged areas without compromising the overall structural integrity. Non-destructive testing methods are employed to detect internal damage before it becomes critical, allowing for timely maintenance interventions that extend the useful life of CFRP structures and components in various industrial applications.

02 Impact resistance and damage tolerance improvements

Techniques to improve the impact resistance and damage tolerance of CFRP materials involve matrix modifications, fiber architecture optimization, and incorporation of energy-absorbing elements. These approaches help prevent delamination, crack propagation, and catastrophic failure under impact loads. Enhanced impact resistance is crucial for applications in automotive, aerospace, and other industries where CFRP components may be subjected to sudden forces.Expand Specific Solutions03 Manufacturing processes for durable CFRP structures

Advanced manufacturing processes significantly influence the durability of CFRP structures. Techniques such as optimized curing cycles, controlled fiber alignment, and innovative molding methods reduce internal stresses and defects that could lead to premature failure. These manufacturing innovations result in more homogeneous composites with improved long-term performance and resistance to fatigue and environmental degradation.Expand Specific Solutions04 Fatigue resistance and cyclic loading performance

Enhancing the fatigue resistance of CFRP involves fiber-matrix interface optimization, strategic fiber orientation, and incorporation of nano-reinforcements. These approaches help CFRP structures withstand repeated loading cycles without significant degradation in mechanical properties. Improved fatigue performance is essential for applications where components are subjected to cyclic stresses, such as in wind turbine blades, bridges, and aerospace structures.Expand Specific Solutions05 Repair and maintenance techniques for CFRP durability

Effective repair and maintenance techniques are crucial for extending the service life of CFRP structures. These include non-destructive testing methods for damage detection, patch repair systems, and in-situ restoration techniques. Advanced repair methodologies allow for cost-effective maintenance of CFRP components, avoiding complete replacement and ensuring continued structural integrity throughout the intended service life.Expand Specific Solutions

Key Industry Players and Research Institutions

The CFRP durability testing market under cyclic weather conditions is in a growth phase, driven by increasing adoption of carbon fiber reinforced polymers in automotive, aerospace, and renewable energy sectors. The global market size is estimated to exceed $500 million, expanding at 8-10% CAGR. Leading players include established materials manufacturers like Toray Industries and Mitsubishi Cable Industries, who possess advanced testing capabilities, alongside specialized research institutions such as Southwest Research Institute and Xi'an Jiaotong University. The technology maturity varies significantly, with companies like GE and Toyota demonstrating sophisticated weathering simulation technologies, while newer entrants like Zhejiang Fengli focus on application-specific testing protocols. Academic-industrial partnerships are accelerating standardization efforts in this technically challenging field.

Toray Industries, Inc.

Technical Solution: Toray has developed an advanced multi-environmental cyclic testing protocol for CFRP durability assessment that simulates real-world weather conditions. Their approach combines temperature cycling (-40°C to 80°C), humidity variation (10-95% RH), and UV radiation exposure in an integrated testing chamber. The company employs proprietary fiber surface treatments that enhance the fiber-matrix interface stability under cyclic weather conditions. Their testing methodology incorporates accelerated aging protocols that can compress 10+ years of environmental exposure into months of laboratory testing. Toray's system includes real-time monitoring of mechanical property degradation through embedded sensors and non-destructive evaluation techniques, allowing for continuous assessment without test interruption. The company has established correlation models between accelerated laboratory tests and field performance data collected from various climate zones worldwide.

Strengths: Industry-leading expertise in CFRP manufacturing provides deep understanding of material behavior; extensive global field data for validation; proprietary surface treatments enhance durability. Weaknesses: Testing protocols may be optimized primarily for aerospace applications; high cost of comprehensive testing infrastructure limits accessibility for smaller projects.

Southwest Research Institute

Technical Solution: Southwest Research Institute (SwRI) has developed a comprehensive CFRP durability testing platform specifically designed for cyclic weather conditions. Their system integrates multiple environmental stressors including temperature cycling (-60°C to 120°C), controlled humidity (0-100% RH), salt spray exposure, and calibrated UV radiation that matches solar spectral distribution. SwRI employs a unique "Environmental Stress Multiplier" approach that identifies synergistic effects between different environmental factors, allowing for more accurate prediction of long-term performance. Their testing protocols incorporate mechanical loading during environmental exposure, simulating real-world conditions where components experience both environmental and mechanical stresses simultaneously. The institute has developed specialized imaging techniques including infrared thermography and digital image correlation to detect subsurface damage progression during cyclic weather testing without test interruption.

Strengths: Multidisciplinary expertise allows for comprehensive testing approaches; strong correlation between laboratory and field results; advanced non-destructive evaluation capabilities. Weaknesses: Testing services may be cost-prohibitive for smaller organizations; standardized protocols may require customization for specific applications.

Critical Research on CFRP Environmental Degradation

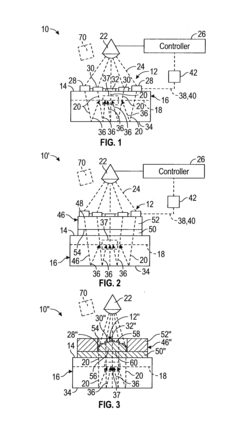

Bond Inspection System and Method

PatentActiveUS20160320350A1

Innovation

- A compact bond inspection system using a reactive material that creates compression waves when activated by a lower-energy source, such as a 10 joule laser, positioned in a predetermined pattern to generate tension waves that reflect and combine simultaneously at the bondline, reducing the need for high-power equipment and enabling on-site inspections.

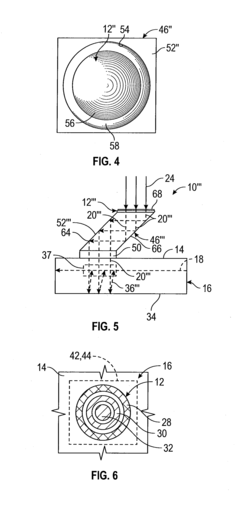

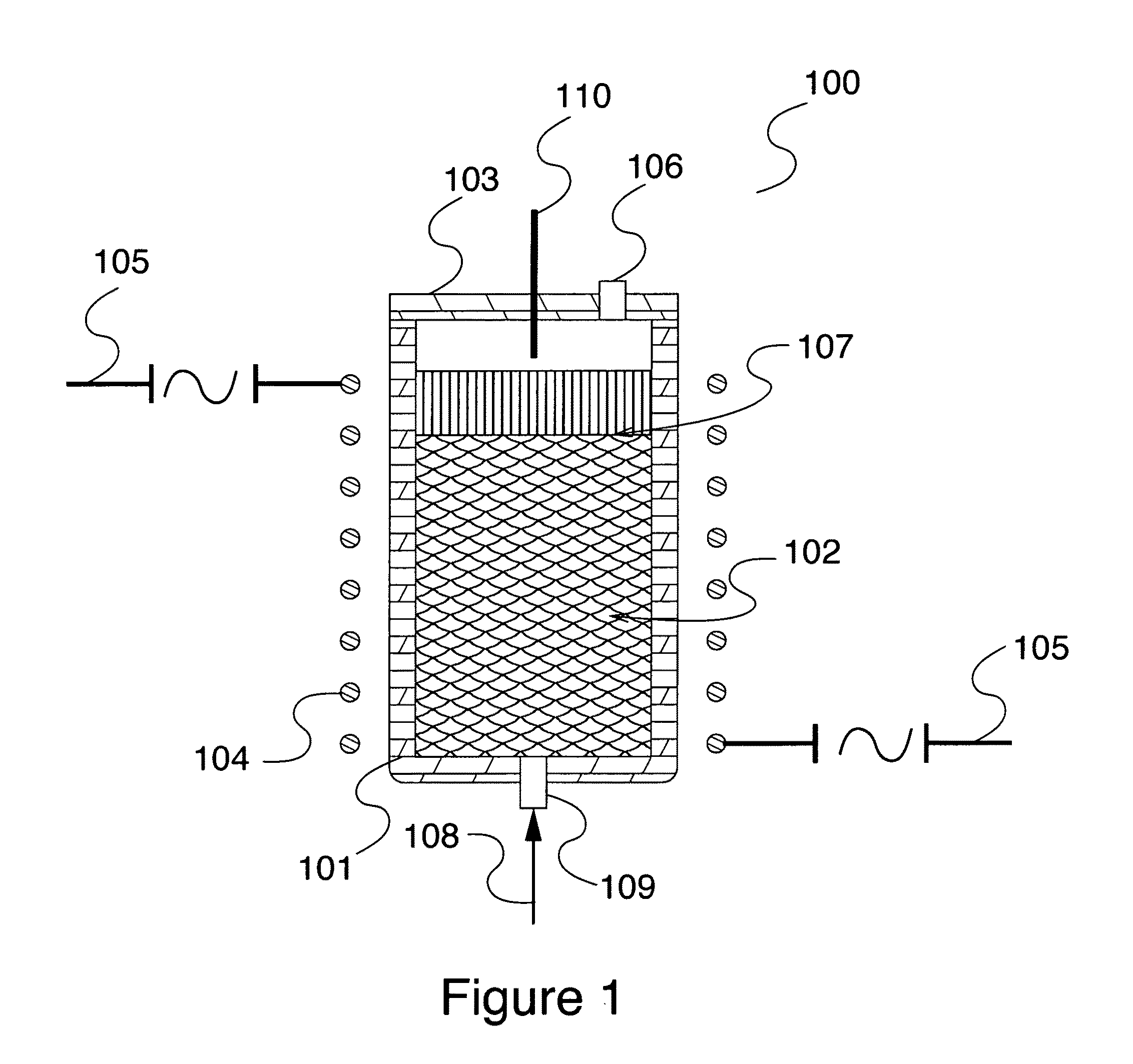

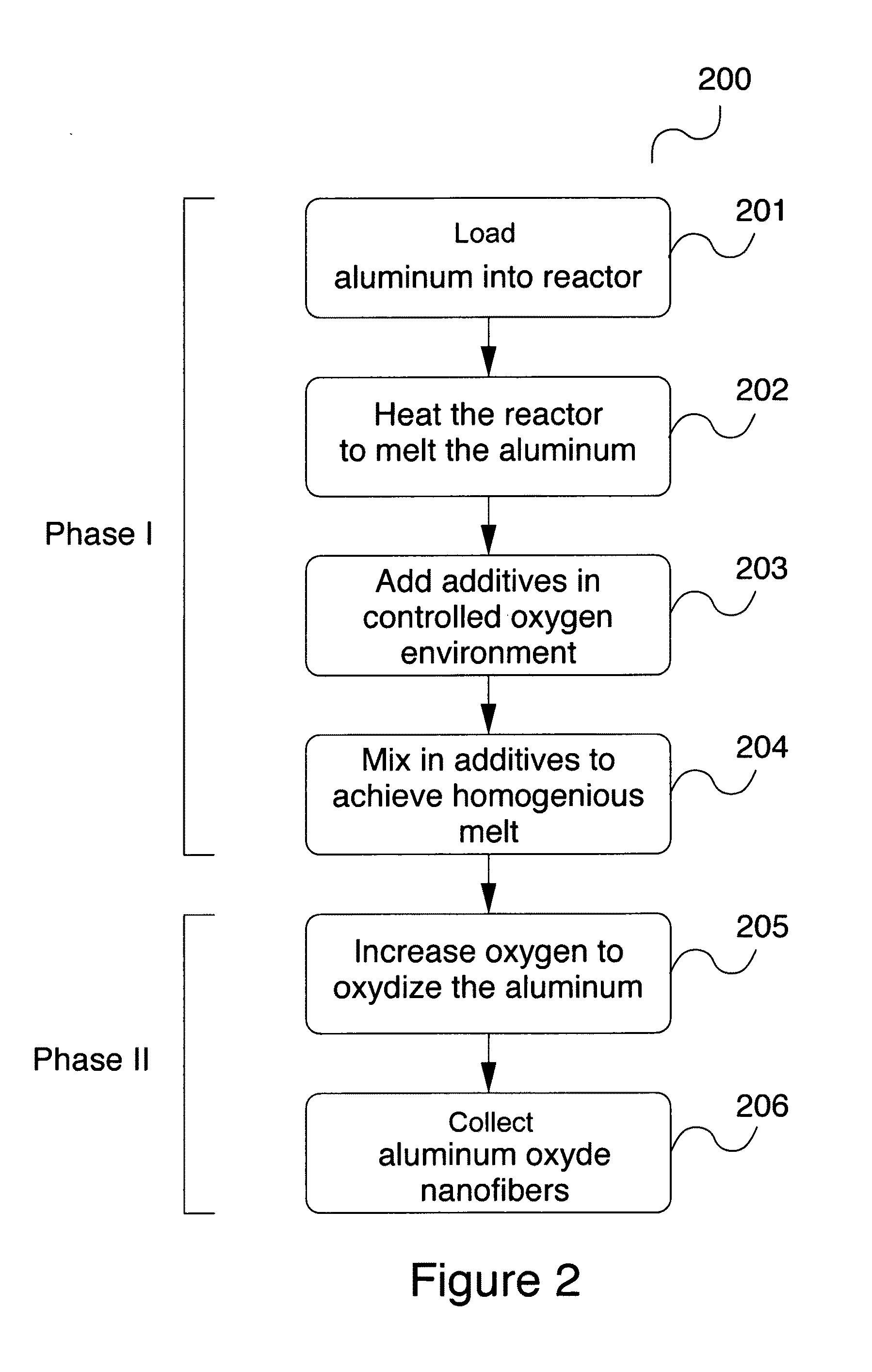

Method and apparatus for producing a carbon-fiber-reinforced polymers additiuonally reinforced by alumina nanofibers

PatentInactiveUS20160114500A1

Innovation

- The method involves saturating a structure of co-oriented pre-dispersed alumina Al2O3 nanofibers with a polymer matrix and facilitating polymerization, which includes pre-heating, cooling, exposure to ultraviolet light or electron beams, adding chemical hardeners, and applying ultrasound or hydrodynamic stress to enhance the dispersion and properties of the nanocomposite material.

Standardization and Certification Requirements

The standardization and certification landscape for CFRP durability testing under cyclic weather conditions remains fragmented, with various international bodies establishing different requirements. ASTM D7264 and ISO 14125 provide foundational frameworks for flexural testing, while ASTM D2247 and ISO 9142 address humidity resistance testing parameters. However, these standards often lack specific provisions for the complex cyclic weather patterns that composite materials encounter in real-world applications.

Certification requirements typically mandate comprehensive documentation of test procedures, equipment calibration records, and detailed analysis of results. Organizations seeking certification must demonstrate adherence to prescribed methodologies and maintain traceability throughout the testing process. The aerospace industry, through standards like RTCA DO-160 and MIL-STD-810, has established more rigorous requirements specifically addressing environmental cycling effects on composite materials used in aircraft structures.

Automotive industry standards, including SAE J2380 and ISO 20653, have begun incorporating cyclic weather testing requirements for CFRP components, though these remain less comprehensive than aerospace counterparts. The divergence in standards across industries creates challenges for manufacturers producing CFRP components for multiple sectors, often necessitating redundant testing to satisfy different certification requirements.

Recent developments in standardization include efforts to harmonize testing methodologies across regions and industries. The European Committee for Standardization (CEN) has initiated working groups focused specifically on developing unified standards for environmental durability testing of composite materials. Similarly, China's GB/T standards are evolving to address the growing domestic CFRP manufacturing sector, with increasing alignment to international norms.

Certification bodies are increasingly requiring accelerated aging tests that simulate multiple environmental factors simultaneously, moving beyond single-factor testing approaches. This shift reflects growing recognition that the interaction between different environmental stressors often produces more severe degradation than individual factors tested in isolation. Test duration requirements have also expanded, with some certification processes now demanding 5,000+ hours of cyclic exposure to validate long-term durability claims.

Digital certification frameworks are emerging as a significant trend, with requirements for data logging, real-time monitoring, and statistical analysis of test results becoming standard in advanced certification processes. These developments aim to enhance the reliability and reproducibility of durability assessments while reducing the time and resources required for certification.

Certification requirements typically mandate comprehensive documentation of test procedures, equipment calibration records, and detailed analysis of results. Organizations seeking certification must demonstrate adherence to prescribed methodologies and maintain traceability throughout the testing process. The aerospace industry, through standards like RTCA DO-160 and MIL-STD-810, has established more rigorous requirements specifically addressing environmental cycling effects on composite materials used in aircraft structures.

Automotive industry standards, including SAE J2380 and ISO 20653, have begun incorporating cyclic weather testing requirements for CFRP components, though these remain less comprehensive than aerospace counterparts. The divergence in standards across industries creates challenges for manufacturers producing CFRP components for multiple sectors, often necessitating redundant testing to satisfy different certification requirements.

Recent developments in standardization include efforts to harmonize testing methodologies across regions and industries. The European Committee for Standardization (CEN) has initiated working groups focused specifically on developing unified standards for environmental durability testing of composite materials. Similarly, China's GB/T standards are evolving to address the growing domestic CFRP manufacturing sector, with increasing alignment to international norms.

Certification bodies are increasingly requiring accelerated aging tests that simulate multiple environmental factors simultaneously, moving beyond single-factor testing approaches. This shift reflects growing recognition that the interaction between different environmental stressors often produces more severe degradation than individual factors tested in isolation. Test duration requirements have also expanded, with some certification processes now demanding 5,000+ hours of cyclic exposure to validate long-term durability claims.

Digital certification frameworks are emerging as a significant trend, with requirements for data logging, real-time monitoring, and statistical analysis of test results becoming standard in advanced certification processes. These developments aim to enhance the reliability and reproducibility of durability assessments while reducing the time and resources required for certification.

Lifecycle Assessment of Weather-Exposed CFRP

The lifecycle assessment of weather-exposed Carbon Fiber Reinforced Polymers (CFRP) represents a critical dimension in understanding the long-term performance and environmental impact of these advanced composite materials. When subjected to varying weather conditions over extended periods, CFRP materials undergo complex degradation processes that significantly affect their structural integrity, mechanical properties, and overall service life.

Environmental exposure factors including UV radiation, moisture, temperature fluctuations, and chemical contaminants interact synergistically to accelerate the degradation mechanisms in CFRP structures. Research indicates that moisture absorption can lead to matrix plasticization and fiber-matrix interface weakening, while UV radiation primarily affects the polymer matrix through photo-oxidation processes, resulting in surface embrittlement and microcracking.

Comprehensive lifecycle assessment methodologies for weather-exposed CFRP typically incorporate accelerated aging protocols that simulate decades of environmental exposure within compressed timeframes. These protocols often employ cyclic exposure to UV radiation, moisture, temperature variations, and salt spray to replicate real-world conditions. Advanced monitoring techniques including acoustic emission, thermography, and digital image correlation enable the non-destructive evaluation of progressive damage accumulation throughout the material's lifecycle.

The environmental footprint of CFRP materials presents another crucial aspect of lifecycle assessment. While the production phase of CFRP is energy-intensive, the extended service life and lightweight properties often result in significant operational energy savings in transportation applications. End-of-life considerations remain challenging, as conventional recycling methods struggle to effectively separate and recover carbon fibers from the thermoset matrix without compromising their mechanical properties.

Predictive modeling approaches have evolved to incorporate multi-physics simulations that account for coupled hygrothermal-mechanical behavior under cyclic weather conditions. These models integrate empirical degradation data with theoretical frameworks to forecast remaining useful life and establish maintenance intervals. Machine learning algorithms are increasingly being employed to process the complex datasets generated during long-term exposure testing, enabling more accurate prediction of degradation rates across diverse environmental conditions.

Recent advancements in protective systems, including specialized coatings, surface treatments, and matrix modifications, have demonstrated promising results in extending the service life of weather-exposed CFRP. These innovations aim to mitigate the primary degradation mechanisms while maintaining the mechanical advantages that make CFRP attractive for high-performance applications.

Environmental exposure factors including UV radiation, moisture, temperature fluctuations, and chemical contaminants interact synergistically to accelerate the degradation mechanisms in CFRP structures. Research indicates that moisture absorption can lead to matrix plasticization and fiber-matrix interface weakening, while UV radiation primarily affects the polymer matrix through photo-oxidation processes, resulting in surface embrittlement and microcracking.

Comprehensive lifecycle assessment methodologies for weather-exposed CFRP typically incorporate accelerated aging protocols that simulate decades of environmental exposure within compressed timeframes. These protocols often employ cyclic exposure to UV radiation, moisture, temperature variations, and salt spray to replicate real-world conditions. Advanced monitoring techniques including acoustic emission, thermography, and digital image correlation enable the non-destructive evaluation of progressive damage accumulation throughout the material's lifecycle.

The environmental footprint of CFRP materials presents another crucial aspect of lifecycle assessment. While the production phase of CFRP is energy-intensive, the extended service life and lightweight properties often result in significant operational energy savings in transportation applications. End-of-life considerations remain challenging, as conventional recycling methods struggle to effectively separate and recover carbon fibers from the thermoset matrix without compromising their mechanical properties.

Predictive modeling approaches have evolved to incorporate multi-physics simulations that account for coupled hygrothermal-mechanical behavior under cyclic weather conditions. These models integrate empirical degradation data with theoretical frameworks to forecast remaining useful life and establish maintenance intervals. Machine learning algorithms are increasingly being employed to process the complex datasets generated during long-term exposure testing, enabling more accurate prediction of degradation rates across diverse environmental conditions.

Recent advancements in protective systems, including specialized coatings, surface treatments, and matrix modifications, have demonstrated promising results in extending the service life of weather-exposed CFRP. These innovations aim to mitigate the primary degradation mechanisms while maintaining the mechanical advantages that make CFRP attractive for high-performance applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!