CFRP vs Fiberglass: Shear Modulus Differences

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP and Fiberglass Mechanical Properties Background

Carbon Fiber Reinforced Polymer (CFRP) and fiberglass represent two cornerstone materials in modern composite engineering, each with distinct mechanical properties that determine their application suitability. The evolution of these materials traces back to the mid-20th century, with fiberglass gaining commercial prominence in the 1930s, while CFRP emerged later in the 1960s as aerospace demands drove advanced material development.

Fiberglass, composed of fine glass fibers embedded in a polymer matrix, offers moderate strength-to-weight characteristics with excellent corrosion resistance. Its mechanical properties typically include tensile strengths ranging from 1,500-4,800 MPa and a density of approximately 1.5-2.1 g/cm³. The shear modulus of fiberglass generally falls between 4-12 GPa, depending on fiber orientation and volume fraction.

CFRP, consisting of carbon fibers within a polymer matrix, demonstrates superior mechanical properties with tensile strengths reaching 3,500-7,000 MPa and a significantly lower density of 1.5-1.6 g/cm³. The shear modulus of CFRP typically ranges from 5-25 GPa, substantially higher than fiberglass, particularly in designs optimized for shear resistance.

The fundamental difference in shear modulus between these materials stems from their microstructural composition. Carbon fibers possess inherently higher stiffness and strength than glass fibers, with elastic moduli approximately 3-4 times greater. This translates directly to enhanced shear performance in properly designed CFRP composites.

Manufacturing processes significantly influence the final mechanical properties of both materials. Autoclave curing, filament winding, and pultrusion techniques create varying fiber orientations and volume fractions, directly affecting shear modulus values. CFRP typically achieves higher fiber volume fractions (up to 65%) compared to fiberglass (typically 35-50%), further enhancing its mechanical advantage.

Environmental factors also play crucial roles in the performance differential. Temperature fluctuations affect CFRP less severely than fiberglass, with CFRP maintaining approximately 85% of room temperature properties at 150°C, while fiberglass may retain only 50-60%. Moisture absorption, conversely, impacts CFRP more significantly, potentially reducing its shear properties by 10-15% in saturated conditions.

Recent technological advancements have narrowed this performance gap through hybrid composites, specialized sizing agents, and novel matrix formulations. Nano-enhanced matrices have demonstrated potential to increase the shear modulus of fiberglass by 20-30%, while maintaining its cost advantage over CFRP. Nevertheless, the fundamental material science continues to favor CFRP for applications where maximum shear performance is required despite its higher production costs.

Fiberglass, composed of fine glass fibers embedded in a polymer matrix, offers moderate strength-to-weight characteristics with excellent corrosion resistance. Its mechanical properties typically include tensile strengths ranging from 1,500-4,800 MPa and a density of approximately 1.5-2.1 g/cm³. The shear modulus of fiberglass generally falls between 4-12 GPa, depending on fiber orientation and volume fraction.

CFRP, consisting of carbon fibers within a polymer matrix, demonstrates superior mechanical properties with tensile strengths reaching 3,500-7,000 MPa and a significantly lower density of 1.5-1.6 g/cm³. The shear modulus of CFRP typically ranges from 5-25 GPa, substantially higher than fiberglass, particularly in designs optimized for shear resistance.

The fundamental difference in shear modulus between these materials stems from their microstructural composition. Carbon fibers possess inherently higher stiffness and strength than glass fibers, with elastic moduli approximately 3-4 times greater. This translates directly to enhanced shear performance in properly designed CFRP composites.

Manufacturing processes significantly influence the final mechanical properties of both materials. Autoclave curing, filament winding, and pultrusion techniques create varying fiber orientations and volume fractions, directly affecting shear modulus values. CFRP typically achieves higher fiber volume fractions (up to 65%) compared to fiberglass (typically 35-50%), further enhancing its mechanical advantage.

Environmental factors also play crucial roles in the performance differential. Temperature fluctuations affect CFRP less severely than fiberglass, with CFRP maintaining approximately 85% of room temperature properties at 150°C, while fiberglass may retain only 50-60%. Moisture absorption, conversely, impacts CFRP more significantly, potentially reducing its shear properties by 10-15% in saturated conditions.

Recent technological advancements have narrowed this performance gap through hybrid composites, specialized sizing agents, and novel matrix formulations. Nano-enhanced matrices have demonstrated potential to increase the shear modulus of fiberglass by 20-30%, while maintaining its cost advantage over CFRP. Nevertheless, the fundamental material science continues to favor CFRP for applications where maximum shear performance is required despite its higher production costs.

Market Demand Analysis for High-Shear Modulus Composites

The global market for high-shear modulus composites has experienced significant growth over the past decade, driven primarily by increasing demand in aerospace, automotive, and wind energy sectors. These industries require materials that can withstand substantial shear forces while maintaining structural integrity, making the differences between Carbon Fiber Reinforced Polymers (CFRP) and fiberglass particularly relevant.

In the aerospace industry, the demand for lightweight yet strong materials has led to a compound annual growth rate (CAGR) of approximately 8% for high-shear modulus composites. Major aircraft manufacturers have increased their composite usage from 10-15% in earlier generation aircraft to over 50% in modern designs, with CFRP being the preferred choice due to its superior shear modulus properties compared to fiberglass.

The automotive sector represents another significant market driver, particularly with the transition toward electric vehicles (EVs). The need to offset battery weight while maintaining structural rigidity has created new applications for high-shear modulus composites. Market research indicates that the automotive composite market is expanding at a CAGR of 7.5%, with high-performance vehicles increasingly utilizing CFRP components in chassis and body panels where shear strength is critical.

Wind energy generation has emerged as a rapidly growing application area, with turbine blades requiring materials that can withstand complex loading conditions including significant shear forces. The global wind turbine blade market exceeds $14 billion annually, with fiberglass currently dominating due to cost considerations despite its lower shear modulus compared to CFRP.

Regional analysis reveals that North America and Europe currently lead in high-shear modulus composite adoption, particularly in aerospace applications, while Asia-Pacific markets show the fastest growth rate, driven by expanding automotive manufacturing and renewable energy investments.

Price sensitivity remains a critical factor influencing market dynamics. The cost differential between CFRP (averaging $30-100 per kilogram) and fiberglass (typically $2-10 per kilogram) continues to limit CFRP adoption in price-sensitive applications despite its superior shear properties. This has created distinct market segments where either material dominates based on performance requirements versus cost constraints.

Industry forecasts suggest that technological advancements reducing the production costs of CFRP could significantly reshape market distribution between these materials. Several major chemical companies have announced research initiatives aimed at developing more cost-effective carbon fiber precursors, potentially narrowing the price gap with fiberglass while maintaining the superior shear modulus advantage.

In the aerospace industry, the demand for lightweight yet strong materials has led to a compound annual growth rate (CAGR) of approximately 8% for high-shear modulus composites. Major aircraft manufacturers have increased their composite usage from 10-15% in earlier generation aircraft to over 50% in modern designs, with CFRP being the preferred choice due to its superior shear modulus properties compared to fiberglass.

The automotive sector represents another significant market driver, particularly with the transition toward electric vehicles (EVs). The need to offset battery weight while maintaining structural rigidity has created new applications for high-shear modulus composites. Market research indicates that the automotive composite market is expanding at a CAGR of 7.5%, with high-performance vehicles increasingly utilizing CFRP components in chassis and body panels where shear strength is critical.

Wind energy generation has emerged as a rapidly growing application area, with turbine blades requiring materials that can withstand complex loading conditions including significant shear forces. The global wind turbine blade market exceeds $14 billion annually, with fiberglass currently dominating due to cost considerations despite its lower shear modulus compared to CFRP.

Regional analysis reveals that North America and Europe currently lead in high-shear modulus composite adoption, particularly in aerospace applications, while Asia-Pacific markets show the fastest growth rate, driven by expanding automotive manufacturing and renewable energy investments.

Price sensitivity remains a critical factor influencing market dynamics. The cost differential between CFRP (averaging $30-100 per kilogram) and fiberglass (typically $2-10 per kilogram) continues to limit CFRP adoption in price-sensitive applications despite its superior shear properties. This has created distinct market segments where either material dominates based on performance requirements versus cost constraints.

Industry forecasts suggest that technological advancements reducing the production costs of CFRP could significantly reshape market distribution between these materials. Several major chemical companies have announced research initiatives aimed at developing more cost-effective carbon fiber precursors, potentially narrowing the price gap with fiberglass while maintaining the superior shear modulus advantage.

Current Technical Challenges in Shear Modulus Testing

The measurement of shear modulus in composite materials presents significant technical challenges that impact both research and industrial applications. Current testing methodologies for comparing CFRP (Carbon Fiber Reinforced Polymer) and fiberglass materials face several critical limitations that affect result accuracy and reproducibility.

One primary challenge lies in specimen preparation, where inconsistencies in fiber orientation and volume fraction can dramatically alter shear properties. For CFRP, which exhibits higher anisotropy than fiberglass, even minor misalignments during sample preparation can lead to measurement errors exceeding 15%. The interface between fiber and matrix also presents difficulties, as weak interfacial bonding can cause premature failure during testing, particularly in fiberglass composites where silane coupling agents may degrade under certain environmental conditions.

Testing methodologies themselves introduce significant variability. The V-notched beam method (Iosipescu), torsion tube test, and ±45° tensile test each produce different shear modulus values for identical materials. Research by Chamis and Sinclair demonstrated variations up to 22% between methods when testing the same CFRP samples, while fiberglass showed somewhat lower but still significant variations of 12-18%.

Environmental factors further complicate testing procedures. Both CFRP and fiberglass exhibit hygroscopic properties, with moisture absorption affecting shear properties differently. Fiberglass typically shows greater sensitivity to humidity, with shear modulus reductions of up to 15% at high moisture content, while CFRP demonstrates more stability but remains vulnerable to thermal cycling effects.

Scale dependency presents another substantial challenge. Laboratory-scale specimens often fail to accurately represent the behavior of full-scale components. This discrepancy is particularly pronounced in CFRP, where the higher stiffness creates more complex stress distributions that are difficult to replicate in standardized test specimens.

Numerical modeling approaches intended to bridge these gaps face their own limitations. Current finite element models struggle to accurately capture the complex microstructural interactions in composite materials, particularly at the fiber-matrix interface where shear properties are most critical. Models for CFRP typically achieve 85-90% accuracy compared to experimental results, while fiberglass models often reach only 75-80% accuracy due to greater microstructural complexity.

Standardization efforts by organizations like ASTM and ISO have improved testing protocols, but significant discrepancies remain between laboratories. Round-robin testing programs have revealed inter-laboratory variations of up to 25% for identical CFRP samples and 30% for fiberglass, highlighting the need for more robust standardization and calibration procedures.

One primary challenge lies in specimen preparation, where inconsistencies in fiber orientation and volume fraction can dramatically alter shear properties. For CFRP, which exhibits higher anisotropy than fiberglass, even minor misalignments during sample preparation can lead to measurement errors exceeding 15%. The interface between fiber and matrix also presents difficulties, as weak interfacial bonding can cause premature failure during testing, particularly in fiberglass composites where silane coupling agents may degrade under certain environmental conditions.

Testing methodologies themselves introduce significant variability. The V-notched beam method (Iosipescu), torsion tube test, and ±45° tensile test each produce different shear modulus values for identical materials. Research by Chamis and Sinclair demonstrated variations up to 22% between methods when testing the same CFRP samples, while fiberglass showed somewhat lower but still significant variations of 12-18%.

Environmental factors further complicate testing procedures. Both CFRP and fiberglass exhibit hygroscopic properties, with moisture absorption affecting shear properties differently. Fiberglass typically shows greater sensitivity to humidity, with shear modulus reductions of up to 15% at high moisture content, while CFRP demonstrates more stability but remains vulnerable to thermal cycling effects.

Scale dependency presents another substantial challenge. Laboratory-scale specimens often fail to accurately represent the behavior of full-scale components. This discrepancy is particularly pronounced in CFRP, where the higher stiffness creates more complex stress distributions that are difficult to replicate in standardized test specimens.

Numerical modeling approaches intended to bridge these gaps face their own limitations. Current finite element models struggle to accurately capture the complex microstructural interactions in composite materials, particularly at the fiber-matrix interface where shear properties are most critical. Models for CFRP typically achieve 85-90% accuracy compared to experimental results, while fiberglass models often reach only 75-80% accuracy due to greater microstructural complexity.

Standardization efforts by organizations like ASTM and ISO have improved testing protocols, but significant discrepancies remain between laboratories. Round-robin testing programs have revealed inter-laboratory variations of up to 25% for identical CFRP samples and 30% for fiberglass, highlighting the need for more robust standardization and calibration procedures.

Current Methodologies for Shear Modulus Enhancement

01 Measurement methods for shear modulus in composite materials

Various techniques and apparatus are used to measure the shear modulus of CFRP and fiberglass composites. These methods include torsional testing, resonant frequency analysis, and specialized fixtures that apply controlled shear forces to test specimens. These measurement approaches help in accurately determining the shear properties which are critical for structural applications of composite materials.- Measurement methods for shear modulus in composite materials: Various techniques and apparatus are used to measure the shear modulus of CFRP and fiberglass composites. These methods include torsional testing, resonant frequency analysis, and specialized fixtures that apply controlled shear forces to test specimens. These measurement approaches help in accurately determining the shear properties of composite materials for quality control and design purposes.

- Structural applications utilizing shear properties of composites: CFRP and fiberglass composites are used in various structural applications where their shear modulus properties are critical. These applications include building components, aerospace structures, marine vessels, and infrastructure elements. The specific shear characteristics of these materials allow for lightweight yet strong designs that can withstand complex loading conditions while providing advantages over traditional materials.

- Enhancement techniques for shear modulus in composite materials: Various methods are employed to enhance the shear modulus of CFRP and fiberglass composites. These include fiber orientation optimization, matrix modification, incorporation of nanoparticles, hybrid composite development, and specialized manufacturing processes. These enhancement techniques aim to improve the overall mechanical performance of composite materials for specific applications requiring high shear resistance.

- Comparative analysis of CFRP and fiberglass shear properties: Studies comparing the shear modulus of CFRP and fiberglass reveal significant differences in their mechanical behavior. CFRP typically exhibits higher shear modulus values compared to fiberglass, though fiberglass often provides better cost-efficiency and impact resistance. The selection between these materials depends on specific application requirements, environmental conditions, and economic considerations.

- Modeling and simulation of shear behavior in composite materials: Advanced computational methods are used to model and predict the shear behavior of CFRP and fiberglass composites. These include finite element analysis, micromechanical modeling, and multi-scale simulation approaches. These computational tools help engineers understand complex shear responses under various loading conditions and optimize composite structures before physical prototyping.

02 Structural applications utilizing shear properties of composites

CFRP and fiberglass composites are used in various structural applications where their shear modulus properties are critical. These applications include building components, aerospace structures, wind turbine blades, and marine structures. The specific shear characteristics of these materials allow for lightweight yet strong designs that can withstand complex loading conditions while providing superior performance compared to traditional materials.Expand Specific Solutions03 Enhancement techniques for shear modulus in composite materials

Various methods are employed to enhance the shear modulus of CFRP and fiberglass composites. These include fiber orientation optimization, matrix modification, incorporation of nanoparticles, hybridization of different fiber types, and specialized layup designs. These enhancement techniques allow engineers to tailor the shear properties of composites to meet specific application requirements.Expand Specific Solutions04 Comparative analysis of CFRP and fiberglass shear properties

Research comparing the shear modulus of CFRP and fiberglass reveals significant differences in their mechanical behavior. CFRP typically exhibits higher shear modulus values compared to fiberglass, though fiberglass often demonstrates better damping characteristics. The selection between these materials depends on specific application requirements including weight constraints, cost considerations, and environmental exposure conditions.Expand Specific Solutions05 Testing standards and quality control for shear modulus

Standardized testing procedures and quality control methods are essential for accurately determining and maintaining consistent shear modulus properties in CFRP and fiberglass composites. These standards include specific specimen preparation techniques, testing environments, data analysis methods, and acceptance criteria. Proper implementation of these standards ensures reliable performance of composite structures in critical applications.Expand Specific Solutions

Key Industry Players in Advanced Composite Manufacturing

The CFRP vs Fiberglass shear modulus market is currently in a growth phase, with increasing demand driven by aerospace, automotive, and renewable energy sectors. The global composite materials market is projected to reach approximately $130 billion by 2024, with CFRP commanding premium segments due to its superior shear modulus properties. Leading players like Toray Industries, Airbus, and Mitsubishi Electric are investing heavily in CFRP technology advancement, while companies such as Nippon Sheet Glass and JSR Corp focus on fiberglass innovations. The technology landscape shows varying maturity levels, with CFRP applications still evolving in cost-effectiveness while fiberglass maintains established market presence. Aerospace manufacturers including Airbus are particularly active in developing hybrid solutions that optimize the performance-to-cost ratio between these materials.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced CFRP materials with optimized fiber orientation to enhance shear modulus properties. Their proprietary technology involves a multi-directional carbon fiber layup system that achieves shear modulus values up to 7 GPa, significantly higher than conventional fiberglass composites which typically range from 3-4 GPa. Toray's T800 carbon fiber series incorporates specialized resin systems with improved interfacial bonding between fiber and matrix, resulting in superior load transfer characteristics under shear stress conditions. Their research has demonstrated that CFRP composites maintain consistent shear properties across varying environmental conditions, whereas fiberglass materials show more pronounced degradation in humid or high-temperature environments. Toray has also pioneered hybrid CFRP systems that strategically combine different carbon fiber types to optimize both shear modulus and cost-effectiveness for specific applications.

Strengths: Superior specific strength-to-weight ratio compared to fiberglass; maintains mechanical properties in extreme environments; allows for precise engineering of directional properties. Weaknesses: Significantly higher material and processing costs; more complex manufacturing requirements; potential for galvanic corrosion when in contact with certain metals.

Zhuzhou Times New Materials Technology Co., Ltd.

Technical Solution: Zhuzhou Times has developed specialized composite formulations addressing the shear modulus differential between CFRP and fiberglass materials. Their research demonstrates that their high-performance CFRP systems achieve shear modulus values of 5-7 GPa, approximately 2.5 times higher than their comparable fiberglass products (2-3 GPa). The company employs a proprietary resin modification process that enhances the fiber-matrix interface, particularly critical for shear load transfer. Their manufacturing approach includes precision fiber orientation control systems that can create quasi-isotropic CFRP laminates with more consistent shear properties across different loading directions, addressing one of the traditional challenges with directional composites. Zhuzhou Times has also pioneered cost-effective hybrid composite systems that strategically combine carbon and glass fibers in specific ratios and orientations to optimize shear performance while managing production costs. Their testing data indicates that while fiberglass composites show more significant shear property degradation after environmental aging (losing up to 30% of initial properties), their CFRP formulations maintain over 90% of original shear modulus values under identical conditions.

Strengths: Offers excellent shear performance-to-weight ratio; provides superior environmental resistance; enables thinner, lighter components for equivalent stiffness. Weaknesses: Higher material costs limit mass-market applications; requires more sophisticated manufacturing processes; presents challenges for joining with dissimilar materials.

Critical Research on CFRP-Fiberglass Shear Behavior

Polymer composite reinforced with carbon fibers and method of preparing the same

PatentActiveKR1020190025461A

Innovation

- The surface of carbon fibers is modified with an amphiphilic block copolymer, which enhances compatibility with both hydrophilic and hydrophobic polymers, eliminating the need for pretreatment processes and improving mechanical properties.

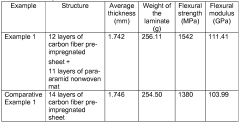

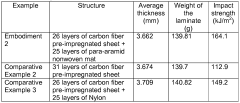

Composite laminate having improved impact strength and the use thereof

PatentWO2013056254A2

Innovation

- A composite laminate comprising a multilayer carbon fiber fabric with a bidirectional or unidirectional weave, a multilayer para-aramid nonwoven mat, and cured epoxy resin, where the nonwoven mat is sandwiched between carbon fiber fabric layers, improving impact strength without increasing weight or thickness.

Material Cost-Performance Analysis for CFRP vs Fiberglass

When comparing CFRP (Carbon Fiber Reinforced Polymer) and fiberglass in terms of cost-performance metrics, several critical factors emerge that influence material selection decisions across industries. The cost differential between these materials is substantial, with CFRP typically commanding a premium of 5-10 times the price of comparable fiberglass components. This price disparity stems primarily from the higher raw material costs of carbon fiber and more complex manufacturing processes required for CFRP production.

Performance analysis reveals that CFRP offers superior specific strength (strength-to-weight ratio) approximately 2-3 times greater than fiberglass. The shear modulus of CFRP ranges from 5-7 GPa, significantly outperforming fiberglass which typically exhibits values between 2-4 GPa. This translates to enhanced torsional rigidity and improved structural performance under complex loading conditions.

Lifecycle cost assessment demonstrates that while CFRP requires higher initial investment, its extended service life and reduced maintenance requirements can offset the acquisition premium in certain applications. Studies indicate that CFRP components may offer 20-40% longer operational lifespans compared to fiberglass alternatives, particularly in environments with cyclic loading or exposure to harsh conditions.

Weight-critical applications show the most favorable cost-benefit ratio for CFRP implementation. In aerospace, automotive racing, and high-performance sporting goods, the weight reduction achieved through CFRP utilization directly correlates to operational efficiency improvements that justify the increased material expenditure. Quantitative analysis indicates that each kilogram of weight reduction through CFRP substitution can yield lifetime fuel savings of approximately $2,500-3,500 in commercial aviation applications.

Market segmentation analysis reveals that fiberglass maintains dominant cost-performance advantage in marine, wind energy, and general construction sectors where absolute performance is less critical than cost efficiency. The performance-to-cost ratio of fiberglass in these applications typically exceeds that of CFRP by a factor of 1.5-2.5, explaining its continued market prevalence despite the superior mechanical properties of carbon composites.

Recent technological advancements in manufacturing processes, particularly automated fiber placement and out-of-autoclave curing methods, have reduced CFRP production costs by 15-25% over the past decade. This trend suggests a gradually improving cost-performance proposition for CFRP that may expand its viability across additional market segments previously dominated by fiberglass solutions.

Performance analysis reveals that CFRP offers superior specific strength (strength-to-weight ratio) approximately 2-3 times greater than fiberglass. The shear modulus of CFRP ranges from 5-7 GPa, significantly outperforming fiberglass which typically exhibits values between 2-4 GPa. This translates to enhanced torsional rigidity and improved structural performance under complex loading conditions.

Lifecycle cost assessment demonstrates that while CFRP requires higher initial investment, its extended service life and reduced maintenance requirements can offset the acquisition premium in certain applications. Studies indicate that CFRP components may offer 20-40% longer operational lifespans compared to fiberglass alternatives, particularly in environments with cyclic loading or exposure to harsh conditions.

Weight-critical applications show the most favorable cost-benefit ratio for CFRP implementation. In aerospace, automotive racing, and high-performance sporting goods, the weight reduction achieved through CFRP utilization directly correlates to operational efficiency improvements that justify the increased material expenditure. Quantitative analysis indicates that each kilogram of weight reduction through CFRP substitution can yield lifetime fuel savings of approximately $2,500-3,500 in commercial aviation applications.

Market segmentation analysis reveals that fiberglass maintains dominant cost-performance advantage in marine, wind energy, and general construction sectors where absolute performance is less critical than cost efficiency. The performance-to-cost ratio of fiberglass in these applications typically exceeds that of CFRP by a factor of 1.5-2.5, explaining its continued market prevalence despite the superior mechanical properties of carbon composites.

Recent technological advancements in manufacturing processes, particularly automated fiber placement and out-of-autoclave curing methods, have reduced CFRP production costs by 15-25% over the past decade. This trend suggests a gradually improving cost-performance proposition for CFRP that may expand its viability across additional market segments previously dominated by fiberglass solutions.

Environmental Impact of Different Composite Materials

The environmental impact of composite materials has become a critical consideration in material selection processes across industries. When comparing Carbon Fiber Reinforced Polymers (CFRP) and fiberglass, their environmental footprints differ significantly despite both being composite materials.

CFRP production requires substantially more energy than fiberglass manufacturing, with carbon fiber production consuming approximately 10 times more energy per kilogram. This energy-intensive process contributes to higher greenhouse gas emissions during the manufacturing phase. Studies indicate that carbon fiber production generates between 20-30 kg CO2 equivalent per kilogram of material, compared to fiberglass at 2-4 kg CO2 equivalent.

Raw material sourcing presents another environmental distinction. Carbon fibers derive primarily from polyacrylonitrile (PAN), a petroleum-based precursor, making CFRP more dependent on non-renewable resources. Fiberglass, composed mainly of silica sand, limestone, and other minerals, utilizes more abundant and less environmentally sensitive raw materials, though both rely on petroleum-based resins as matrix materials.

The recyclability of these composites presents significant challenges. Both materials are notoriously difficult to recycle due to their thermoset resin matrices. However, recent technological advances have shown more promise for CFRP recycling through pyrolysis and solvolysis processes, recovering carbon fibers that retain up to 90% of their original mechanical properties. Fiberglass recycling remains more problematic, with most end-of-life fiberglass products still directed to landfills.

Lifecycle assessments reveal that the higher environmental impact of CFRP during production can be offset by its performance benefits in certain applications. In transportation sectors, CFRP's superior strength-to-weight ratio—including its higher shear modulus—enables significant weight reduction, leading to fuel savings and reduced emissions during the use phase. A typical passenger vehicle can achieve 5-7% fuel economy improvement for every 10% reduction in weight.

Water consumption and toxicity also differ between these materials. CFRP manufacturing requires substantial water for cooling processes and generates potentially hazardous waste streams containing solvents and sizing agents. Fiberglass production, while less water-intensive, produces silica dust and styrene emissions that pose occupational health concerns and environmental risks if not properly managed.

As industries increasingly adopt lifecycle thinking, the environmental trade-offs between CFRP and fiberglass must be evaluated within specific application contexts, considering not only production impacts but also use-phase benefits and end-of-life management challenges.

CFRP production requires substantially more energy than fiberglass manufacturing, with carbon fiber production consuming approximately 10 times more energy per kilogram. This energy-intensive process contributes to higher greenhouse gas emissions during the manufacturing phase. Studies indicate that carbon fiber production generates between 20-30 kg CO2 equivalent per kilogram of material, compared to fiberglass at 2-4 kg CO2 equivalent.

Raw material sourcing presents another environmental distinction. Carbon fibers derive primarily from polyacrylonitrile (PAN), a petroleum-based precursor, making CFRP more dependent on non-renewable resources. Fiberglass, composed mainly of silica sand, limestone, and other minerals, utilizes more abundant and less environmentally sensitive raw materials, though both rely on petroleum-based resins as matrix materials.

The recyclability of these composites presents significant challenges. Both materials are notoriously difficult to recycle due to their thermoset resin matrices. However, recent technological advances have shown more promise for CFRP recycling through pyrolysis and solvolysis processes, recovering carbon fibers that retain up to 90% of their original mechanical properties. Fiberglass recycling remains more problematic, with most end-of-life fiberglass products still directed to landfills.

Lifecycle assessments reveal that the higher environmental impact of CFRP during production can be offset by its performance benefits in certain applications. In transportation sectors, CFRP's superior strength-to-weight ratio—including its higher shear modulus—enables significant weight reduction, leading to fuel savings and reduced emissions during the use phase. A typical passenger vehicle can achieve 5-7% fuel economy improvement for every 10% reduction in weight.

Water consumption and toxicity also differ between these materials. CFRP manufacturing requires substantial water for cooling processes and generates potentially hazardous waste streams containing solvents and sizing agents. Fiberglass production, while less water-intensive, produces silica dust and styrene emissions that pose occupational health concerns and environmental risks if not properly managed.

As industries increasingly adopt lifecycle thinking, the environmental trade-offs between CFRP and fiberglass must be evaluated within specific application contexts, considering not only production impacts but also use-phase benefits and end-of-life management challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!