CFRP vs Metal Foam Composites: Structural Performance Under Load

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP and Metal Foam Evolution and Objectives

Carbon Fiber Reinforced Polymers (CFRP) emerged in the 1960s as advanced composite materials, initially developed for aerospace applications where high strength-to-weight ratios were critical. The evolution of CFRP technology has been marked by significant improvements in manufacturing processes, from hand lay-up methods to automated fiber placement and resin transfer molding, enabling more consistent quality and reduced production costs.

Metal foams, particularly aluminum-based variants, gained prominence in the 1990s as lightweight structural materials with unique energy absorption capabilities. Their development trajectory has focused on overcoming production challenges related to cell size consistency, density control, and structural integrity. The integration of metal foams with traditional materials represents a relatively recent innovation aimed at combining the beneficial properties of both material systems.

The convergence of CFRP and metal foam technologies has accelerated in the past decade, driven by demands from automotive, aerospace, and defense sectors for materials that offer superior mechanical performance while meeting increasingly stringent weight reduction targets. This technological intersection aims to address the inherent limitations of each material system when used independently.

Current research objectives in this field focus on optimizing the structural performance of CFRP-metal foam composites under various loading conditions, including static, dynamic, and impact scenarios. Specific goals include enhancing load distribution mechanisms, improving energy absorption capabilities, and developing predictive models for composite behavior under complex stress states.

A critical technical objective involves understanding and controlling the interface properties between CFRP layers and metal foam cores, as these interfaces often represent potential failure points under load. Researchers are exploring various bonding techniques, surface treatments, and interlayer materials to optimize this critical aspect of composite performance.

Another significant goal is the development of cost-effective manufacturing processes that can reliably produce these hybrid composites at industrial scales. This includes addressing challenges related to joining dissimilar materials, managing thermal expansion differences, and ensuring consistent quality across large structural components.

The evolution of these materials is increasingly being guided by sustainability considerations, with objectives to develop recyclable variants, reduce energy consumption in manufacturing, and extend service life through improved durability and damage tolerance. These environmental factors are becoming as important as mechanical performance in defining the trajectory of CFRP-metal foam composite development.

Metal foams, particularly aluminum-based variants, gained prominence in the 1990s as lightweight structural materials with unique energy absorption capabilities. Their development trajectory has focused on overcoming production challenges related to cell size consistency, density control, and structural integrity. The integration of metal foams with traditional materials represents a relatively recent innovation aimed at combining the beneficial properties of both material systems.

The convergence of CFRP and metal foam technologies has accelerated in the past decade, driven by demands from automotive, aerospace, and defense sectors for materials that offer superior mechanical performance while meeting increasingly stringent weight reduction targets. This technological intersection aims to address the inherent limitations of each material system when used independently.

Current research objectives in this field focus on optimizing the structural performance of CFRP-metal foam composites under various loading conditions, including static, dynamic, and impact scenarios. Specific goals include enhancing load distribution mechanisms, improving energy absorption capabilities, and developing predictive models for composite behavior under complex stress states.

A critical technical objective involves understanding and controlling the interface properties between CFRP layers and metal foam cores, as these interfaces often represent potential failure points under load. Researchers are exploring various bonding techniques, surface treatments, and interlayer materials to optimize this critical aspect of composite performance.

Another significant goal is the development of cost-effective manufacturing processes that can reliably produce these hybrid composites at industrial scales. This includes addressing challenges related to joining dissimilar materials, managing thermal expansion differences, and ensuring consistent quality across large structural components.

The evolution of these materials is increasingly being guided by sustainability considerations, with objectives to develop recyclable variants, reduce energy consumption in manufacturing, and extend service life through improved durability and damage tolerance. These environmental factors are becoming as important as mechanical performance in defining the trajectory of CFRP-metal foam composite development.

Market Applications and Demand Analysis

The market for advanced structural materials is experiencing significant growth, driven by industries seeking optimal performance-to-weight ratios in their applications. Carbon Fiber Reinforced Polymers (CFRP) currently dominate the high-performance composites market, valued at approximately $38 billion globally, with annual growth rates consistently above 10%. This strong market position stems from CFRP's established presence in aerospace, automotive, and sporting goods sectors where weight reduction directly translates to performance gains and energy efficiency.

Metal foam composites represent an emerging segment within the structural materials market, currently smaller but growing at 15-18% annually. This accelerated growth reflects increasing recognition of metal foams' unique combination of properties, particularly their superior energy absorption capabilities and thermal management characteristics that CFRP cannot match.

Aerospace remains the primary demand driver for both materials, accounting for 35% of high-performance composite consumption. In this sector, CFRP maintains dominance in primary structures, while metal foam composites are gaining traction in impact zones and thermal management applications. The automotive industry represents the fastest-growing application sector, with premium manufacturers increasingly adopting both materials to meet stringent emissions standards through vehicle lightweighting.

Construction and infrastructure sectors are emerging as significant new markets, particularly for metal foam composites. Their superior fire resistance and energy absorption properties address critical safety requirements that CFRP struggles to meet. This sector is projected to grow at 20% annually for metal foam applications, compared to 8% for CFRP.

Defense applications represent a premium market segment where performance requirements often outweigh cost considerations. Both materials are seeing increased adoption in ballistic protection systems, with metal foams showing particular promise in blast mitigation applications due to their superior energy absorption under dynamic loading conditions.

Market analysis indicates a shift toward hybrid solutions that combine both materials to leverage their complementary properties. This trend is particularly evident in transportation applications where designers seek to optimize structural performance across multiple load conditions while managing costs effectively.

Regional market distribution shows North America and Europe leading in adoption of both materials, with Asia-Pacific representing the fastest-growing market. China's strategic investments in advanced materials manufacturing capacity are reshaping global supply chains, potentially reducing the significant cost premium that has historically limited wider adoption of these materials.

Metal foam composites represent an emerging segment within the structural materials market, currently smaller but growing at 15-18% annually. This accelerated growth reflects increasing recognition of metal foams' unique combination of properties, particularly their superior energy absorption capabilities and thermal management characteristics that CFRP cannot match.

Aerospace remains the primary demand driver for both materials, accounting for 35% of high-performance composite consumption. In this sector, CFRP maintains dominance in primary structures, while metal foam composites are gaining traction in impact zones and thermal management applications. The automotive industry represents the fastest-growing application sector, with premium manufacturers increasingly adopting both materials to meet stringent emissions standards through vehicle lightweighting.

Construction and infrastructure sectors are emerging as significant new markets, particularly for metal foam composites. Their superior fire resistance and energy absorption properties address critical safety requirements that CFRP struggles to meet. This sector is projected to grow at 20% annually for metal foam applications, compared to 8% for CFRP.

Defense applications represent a premium market segment where performance requirements often outweigh cost considerations. Both materials are seeing increased adoption in ballistic protection systems, with metal foams showing particular promise in blast mitigation applications due to their superior energy absorption under dynamic loading conditions.

Market analysis indicates a shift toward hybrid solutions that combine both materials to leverage their complementary properties. This trend is particularly evident in transportation applications where designers seek to optimize structural performance across multiple load conditions while managing costs effectively.

Regional market distribution shows North America and Europe leading in adoption of both materials, with Asia-Pacific representing the fastest-growing market. China's strategic investments in advanced materials manufacturing capacity are reshaping global supply chains, potentially reducing the significant cost premium that has historically limited wider adoption of these materials.

Current Capabilities and Technical Limitations

Carbon Fiber Reinforced Polymers (CFRP) have established themselves as premier lightweight structural materials in aerospace, automotive, and high-performance applications. Current CFRP manufacturing capabilities allow for tensile strengths exceeding 3,500 MPa and modulus values up to 230 GPa, while maintaining densities around 1.6 g/cm³. This exceptional strength-to-weight ratio enables weight reductions of 50-70% compared to steel structures while maintaining equivalent performance under load.

Despite these advantages, CFRP exhibits several technical limitations. The material demonstrates relatively poor compression properties compared to its tensile performance, with compression strengths typically 30-40% lower than tensile values. Additionally, CFRP shows vulnerability to impact damage and delamination, with poor through-thickness properties due to its laminar structure. Manufacturing costs remain 5-10 times higher than traditional metals, limiting widespread adoption in cost-sensitive applications.

Metal foam composites represent an emerging alternative with unique capabilities. Current aluminum foam composites achieve densities as low as 0.4-0.8 g/cm³ while maintaining compressive strengths of 1.5-10 MPa and elastic moduli of 0.7-3 GPa. Their primary advantage lies in exceptional energy absorption capabilities, absorbing 80-90% of impact energy through controlled deformation, significantly outperforming solid metals and many composite materials in this regard.

The technical limitations of metal foam composites include relatively low absolute strength compared to solid metals or CFRP, with yield strengths typically 10-20% of their solid metal counterparts. Manufacturing consistency remains challenging, with cell size and distribution variations of 15-30% common in production environments, leading to performance variability. Joining and fastening these materials presents significant engineering challenges due to their porous structure.

When comparing structural performance under load, CFRP excels in applications requiring high specific strength and stiffness under predictable loading conditions, particularly in tension. Metal foam composites demonstrate superior performance in applications requiring energy absorption, thermal management, and acoustic damping, with exceptional performance under compression and impact loading.

The integration of these materials as hybrid structures represents a promising frontier, combining CFRP's tensile properties with metal foam's compression and energy absorption capabilities. Current research indicates potential weight savings of 30-40% compared to traditional structures while improving impact resistance by 50-70%. However, interface bonding between these dissimilar materials remains a significant technical challenge, with delamination at the interface occurring at 40-60% lower loads than would be predicted by the properties of either material independently.

Despite these advantages, CFRP exhibits several technical limitations. The material demonstrates relatively poor compression properties compared to its tensile performance, with compression strengths typically 30-40% lower than tensile values. Additionally, CFRP shows vulnerability to impact damage and delamination, with poor through-thickness properties due to its laminar structure. Manufacturing costs remain 5-10 times higher than traditional metals, limiting widespread adoption in cost-sensitive applications.

Metal foam composites represent an emerging alternative with unique capabilities. Current aluminum foam composites achieve densities as low as 0.4-0.8 g/cm³ while maintaining compressive strengths of 1.5-10 MPa and elastic moduli of 0.7-3 GPa. Their primary advantage lies in exceptional energy absorption capabilities, absorbing 80-90% of impact energy through controlled deformation, significantly outperforming solid metals and many composite materials in this regard.

The technical limitations of metal foam composites include relatively low absolute strength compared to solid metals or CFRP, with yield strengths typically 10-20% of their solid metal counterparts. Manufacturing consistency remains challenging, with cell size and distribution variations of 15-30% common in production environments, leading to performance variability. Joining and fastening these materials presents significant engineering challenges due to their porous structure.

When comparing structural performance under load, CFRP excels in applications requiring high specific strength and stiffness under predictable loading conditions, particularly in tension. Metal foam composites demonstrate superior performance in applications requiring energy absorption, thermal management, and acoustic damping, with exceptional performance under compression and impact loading.

The integration of these materials as hybrid structures represents a promising frontier, combining CFRP's tensile properties with metal foam's compression and energy absorption capabilities. Current research indicates potential weight savings of 30-40% compared to traditional structures while improving impact resistance by 50-70%. However, interface bonding between these dissimilar materials remains a significant technical challenge, with delamination at the interface occurring at 40-60% lower loads than would be predicted by the properties of either material independently.

Comparative Structural Performance Solutions

01 Structural performance enhancement of CFRP-metal foam composites

Carbon fiber reinforced polymer (CFRP) combined with metal foam creates composites with enhanced structural performance. These composites exhibit improved strength-to-weight ratios, impact resistance, and energy absorption capabilities. The integration of metal foam with CFRP provides synergistic effects, resulting in superior mechanical properties compared to traditional materials. These composites are engineered to maintain structural integrity under various loading conditions while reducing overall weight.- Structural performance enhancement of CFRP-metal foam sandwich composites: Carbon fiber reinforced polymer (CFRP) combined with metal foam cores creates sandwich structures with superior mechanical properties. These composites demonstrate enhanced load-bearing capacity, impact resistance, and energy absorption while maintaining lightweight characteristics. The metal foam core provides compression strength and damage tolerance, while the CFRP skins offer tensile strength and stiffness, resulting in structures with excellent strength-to-weight ratios for aerospace and automotive applications.

- Manufacturing methods for CFRP-metal foam hybrid structures: Various manufacturing techniques have been developed to create CFRP-metal foam composite structures with optimal structural performance. These include adhesive bonding, co-curing processes, and innovative joining methods that ensure strong interfacial bonding between the dissimilar materials. Advanced fabrication approaches like selective laser melting for metal foams and automated fiber placement for CFRP components enable precise control over structural properties and performance characteristics of the resulting composites.

- Impact and energy absorption properties of CFRP-metal foam composites: CFRP-metal foam composites exhibit exceptional energy absorption capabilities during impact events. The metal foam core deforms progressively under compression, absorbing significant energy while the CFRP layers maintain structural integrity. This combination provides superior crash protection and blast resistance compared to traditional materials. The energy dissipation mechanisms include foam cell collapse, plastic deformation of cell walls, and controlled failure modes in the composite structure, making these materials ideal for safety-critical applications.

- Thermal and environmental performance of CFRP-metal foam structures: CFRP-metal foam composites demonstrate advantageous thermal management properties alongside their structural performance. The metal foam provides effective heat dissipation and fire resistance, while the CFRP components maintain strength at elevated temperatures. These composites also show resistance to environmental degradation, including moisture absorption and corrosion, through specialized surface treatments and protective coatings. The thermal expansion compatibility between components is engineered to prevent delamination and maintain structural integrity across wide temperature ranges.

- Multifunctional aspects of CFRP-metal foam composite structures: Beyond mechanical performance, CFRP-metal foam composites offer multifunctional capabilities that enhance their structural utility. These include electromagnetic shielding, vibration damping, acoustic insulation, and ballistic protection. The cellular structure of metal foams combined with the electrical properties of carbon fibers creates composites that can serve multiple engineering functions simultaneously. Additionally, these materials can be designed with self-monitoring capabilities through embedded sensors that detect damage and structural changes, enabling predictive maintenance and enhanced safety in critical applications.

02 Manufacturing methods for CFRP-metal foam hybrid structures

Various manufacturing techniques are employed to produce CFRP-metal foam hybrid structures with optimal structural performance. These methods include infiltration processes, adhesive bonding, co-curing, and innovative layup techniques. Advanced manufacturing approaches ensure proper interfacial bonding between the metal foam and CFRP components, which is critical for structural integrity. Process parameters are carefully controlled to minimize defects and enhance the mechanical properties of the resulting composites.Expand Specific Solutions03 Impact and energy absorption characteristics

CFRP-metal foam composites demonstrate exceptional impact resistance and energy absorption capabilities. The metal foam component provides progressive crushing behavior and energy dissipation, while the CFRP layers contribute high strength and stiffness. This combination results in structures that can withstand high-energy impacts while maintaining structural integrity. These composites are particularly valuable in applications requiring crash protection and blast resistance, as they can absorb significant amounts of energy during impact events.Expand Specific Solutions04 Lightweight structural applications in transportation

CFRP-metal foam composites are increasingly utilized in transportation applications where weight reduction and structural performance are critical. These materials offer significant weight savings compared to traditional metal structures while maintaining or improving mechanical properties. In automotive and aerospace applications, these composites contribute to improved fuel efficiency, increased payload capacity, and enhanced vehicle performance. The tailored properties of these hybrid materials make them suitable for specific structural components in various transportation systems.Expand Specific Solutions05 Thermal and acoustic performance of CFRP-metal foam structures

Beyond mechanical properties, CFRP-metal foam composites offer enhanced thermal and acoustic performance. The cellular structure of metal foams provides excellent thermal insulation and sound dampening characteristics. When combined with CFRP, these composites can be engineered to manage heat transfer and reduce noise transmission while maintaining structural integrity. This multifunctional performance makes these materials valuable in applications where thermal management and noise reduction are important alongside structural requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The CFRP vs Metal Foam Composites market is currently in a growth phase, with increasing adoption across aerospace, automotive, and defense sectors. The global market size for advanced composite materials is expanding at approximately 8-10% annually, driven by demand for lightweight structural solutions. In terms of technical maturity, aerospace leaders like Airbus Operations GmbH, Boeing Co., and Sikorsky Aircraft have achieved high TRL levels with CFRP implementation, while automotive manufacturers including BMW, Honda, and Nissan are advancing metal foam composite applications. Research collaborations between industry players like Toray Industries and academic institutions such as Shenzhen University are accelerating innovation in hybrid composite systems that combine the high strength-to-weight ratio of CFRP with the energy absorption capabilities of metal foams for next-generation structural applications.

Airbus Operations GmbH

Technical Solution: Airbus has developed sophisticated CFRP implementation strategies for aerospace structures, with a particular focus on large-scale components like wing spars and fuselage sections. Their technical approach involves advanced automated fiber placement (AFP) technology that enables precise fiber orientation control for optimized load paths. Airbus's A350 XWB incorporates approximately 53% composite materials by weight, representing one of the highest percentages in commercial aircraft. The company has pioneered vacuum-assisted resin transfer molding (VARTM) techniques for large structures, reducing manufacturing costs while maintaining structural integrity. Airbus has conducted extensive research comparing CFRP performance to metal alternatives under various loading conditions, demonstrating weight savings of 15-20% while achieving equivalent or superior mechanical properties. Their research also extends to hybrid structures that strategically combine CFRP with metal components in areas requiring specific performance characteristics.

Strengths: Extensive experience with large-scale CFRP structures; sophisticated design methodologies for complex load cases; advanced manufacturing capabilities for consistent quality. Weaknesses: High initial tooling and equipment costs; longer production cycles for some components compared to metal alternatives; complex certification requirements for primary structures.

Bayerische Motoren Werke AG

Technical Solution: BMW has pioneered the integration of CFRP in automotive mass production, particularly through their BMW i series vehicles. Their technical approach involves a proprietary resin transfer molding (RTM) process that allows for faster production cycles compared to traditional aerospace CFRP manufacturing. BMW's carbon fiber components are designed with a focus on crash energy absorption and structural integrity. The company has developed a hybrid construction approach that strategically combines CFRP with aluminum and high-strength steel in what they call their "Carbon Core" technology. This allows for weight reductions of up to 30% compared to conventional steel structures while maintaining or improving crash performance. BMW has also invested in recycling technologies for CFRP components, addressing one of the material's key sustainability challenges.

Strengths: Significant weight reduction leading to improved fuel efficiency and performance; excellent crash energy absorption properties; ability to create complex geometries in single components. Weaknesses: Higher production costs despite innovations in manufacturing; limited repairability in collision scenarios; requires specialized joining techniques with other materials.

Key Patents and Research Breakthroughs

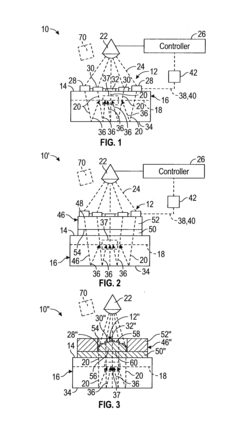

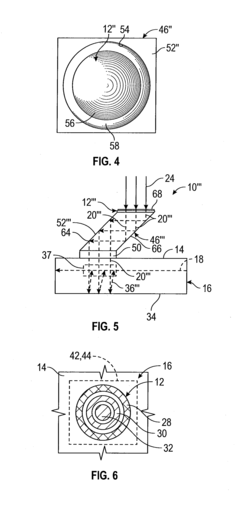

Bond Inspection System and Method

PatentActiveUS20160320350A1

Innovation

- A compact bond inspection system using a reactive material that creates compression waves when activated by a lower-energy source, such as a 10 joule laser, positioned in a predetermined pattern to generate tension waves that reflect and combine simultaneously at the bondline, reducing the need for high-power equipment and enabling on-site inspections.

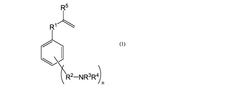

Composition and molded object

PatentWO2017038528A1

Innovation

- A composition comprising a polymer with an amino group, carbon fibers, and a thermoplastic resin, where the carbon fibers are aligned under tension and the polymer is used to enhance adhesion between the fibers and the resin, improving mechanical strength.

Weight-to-Strength Ratio Optimization Strategies

Optimizing the weight-to-strength ratio represents a critical engineering challenge when comparing Carbon Fiber Reinforced Polymers (CFRP) and Metal Foam Composites for structural applications. Current optimization strategies focus on leveraging the inherent advantages of each material while mitigating their respective limitations through innovative design approaches and manufacturing techniques.

For CFRP structures, fiber orientation optimization stands as the primary method for enhancing weight-to-strength performance. Advanced algorithms now enable precise fiber placement along principal stress trajectories, resulting in up to 30% improvement in specific strength compared to conventional layup patterns. Variable stiffness design, where fiber orientation gradually changes across components, has demonstrated particular effectiveness in complex loading scenarios.

Topology optimization techniques have revolutionized both CFRP and metal foam design paradigms. By systematically removing material from low-stress regions while maintaining structural integrity in high-stress zones, engineers can achieve weight reductions of 40-60% compared to traditional designs. When applied to metal foams, this approach creates gradient density structures that concentrate material precisely where mechanical performance demands it most.

Hybrid material systems represent another promising frontier. Strategic integration of CFRP with selective metal foam reinforcement at critical stress concentration points combines the lightweight properties of composites with the energy absorption capabilities of metal foams. Recent studies demonstrate that such hybrids can achieve 25% higher specific strength than pure CFRP while maintaining comparable weight profiles.

Manufacturing innovations have significantly expanded optimization possibilities. Additive manufacturing enables the production of metal foams with precisely controlled cell structures, allowing engineers to tailor density, pore size, and distribution according to specific loading requirements. Similarly, automated fiber placement technologies permit the creation of variable-thickness CFRP components that allocate material exclusively where needed for load-bearing capacity.

Multiscale optimization approaches are gaining traction, addressing material performance across nano, micro, and macro scales simultaneously. For metal foams, controlling cell wall thickness and cell geometry at the microscale while optimizing overall component geometry yields synergistic benefits. In CFRP, manipulating fiber-matrix interfaces at the microscale while optimizing laminate sequences at the component level has demonstrated exceptional weight-to-strength improvements.

Computational methods, particularly machine learning algorithms trained on extensive material testing datasets, now enable rapid exploration of design spaces previously considered intractable. These tools can identify non-intuitive material distributions and structural configurations that human engineers might overlook, further pushing the boundaries of weight-to-strength optimization.

For CFRP structures, fiber orientation optimization stands as the primary method for enhancing weight-to-strength performance. Advanced algorithms now enable precise fiber placement along principal stress trajectories, resulting in up to 30% improvement in specific strength compared to conventional layup patterns. Variable stiffness design, where fiber orientation gradually changes across components, has demonstrated particular effectiveness in complex loading scenarios.

Topology optimization techniques have revolutionized both CFRP and metal foam design paradigms. By systematically removing material from low-stress regions while maintaining structural integrity in high-stress zones, engineers can achieve weight reductions of 40-60% compared to traditional designs. When applied to metal foams, this approach creates gradient density structures that concentrate material precisely where mechanical performance demands it most.

Hybrid material systems represent another promising frontier. Strategic integration of CFRP with selective metal foam reinforcement at critical stress concentration points combines the lightweight properties of composites with the energy absorption capabilities of metal foams. Recent studies demonstrate that such hybrids can achieve 25% higher specific strength than pure CFRP while maintaining comparable weight profiles.

Manufacturing innovations have significantly expanded optimization possibilities. Additive manufacturing enables the production of metal foams with precisely controlled cell structures, allowing engineers to tailor density, pore size, and distribution according to specific loading requirements. Similarly, automated fiber placement technologies permit the creation of variable-thickness CFRP components that allocate material exclusively where needed for load-bearing capacity.

Multiscale optimization approaches are gaining traction, addressing material performance across nano, micro, and macro scales simultaneously. For metal foams, controlling cell wall thickness and cell geometry at the microscale while optimizing overall component geometry yields synergistic benefits. In CFRP, manipulating fiber-matrix interfaces at the microscale while optimizing laminate sequences at the component level has demonstrated exceptional weight-to-strength improvements.

Computational methods, particularly machine learning algorithms trained on extensive material testing datasets, now enable rapid exploration of design spaces previously considered intractable. These tools can identify non-intuitive material distributions and structural configurations that human engineers might overlook, further pushing the boundaries of weight-to-strength optimization.

Environmental Impact and Lifecycle Assessment

The environmental footprint of materials used in structural applications has become increasingly critical in engineering decisions. When comparing Carbon Fiber Reinforced Polymers (CFRP) and Metal Foam Composites, their environmental impacts differ significantly throughout their lifecycles.

CFRP production involves energy-intensive processes, particularly during carbon fiber manufacturing, which requires temperatures exceeding 1000°C during oxidation and carbonization. Studies indicate that producing 1kg of carbon fiber generates approximately 20-25kg of CO2 equivalent emissions. The epoxy resins used as matrices in CFRP also contribute to environmental concerns, as they typically derive from petroleum-based sources and contain potentially harmful compounds like bisphenol A.

Metal foam composites, particularly aluminum-based foams, demonstrate different environmental characteristics. While aluminum production is energy-intensive initially, requiring about 14 kWh/kg, these materials offer significant advantages in recyclability. Unlike CFRP, which presents considerable challenges in end-of-life separation and recovery, metal foams can be recycled through conventional metallurgical processes with relatively minor property degradation.

Lifecycle assessment (LCA) studies reveal that the environmental impact of CFRP is front-loaded, with 80-90% of emissions occurring during raw material extraction and manufacturing. In contrast, metal foams distribute their environmental impact more evenly across production and use phases, with significant potential for impact reduction through recycling.

The use phase presents another critical distinction. CFRP's lightweight properties contribute to fuel efficiency in transportation applications, potentially offsetting initial production impacts over the material's lifetime. Research indicates that in automotive applications, each 10% weight reduction can improve fuel economy by 6-8%. Metal foams, while heavier than CFRP, offer multifunctional benefits including thermal insulation and sound dampening that may reduce overall system complexity and associated environmental impacts.

End-of-life management remains particularly challenging for CFRP, with limited commercial-scale recycling options available. Current technologies like pyrolysis and solvolysis recover only portions of the original fiber properties. Metal foams, conversely, can be reintegrated into standard metal recycling streams, though the presence of stabilizing particles may require additional separation processes.

Recent innovations in bio-based carbon fibers and environmentally friendly core materials for metal foams suggest potential pathways for reducing the environmental footprint of both material systems, though these technologies remain at relatively early stages of commercial development.

CFRP production involves energy-intensive processes, particularly during carbon fiber manufacturing, which requires temperatures exceeding 1000°C during oxidation and carbonization. Studies indicate that producing 1kg of carbon fiber generates approximately 20-25kg of CO2 equivalent emissions. The epoxy resins used as matrices in CFRP also contribute to environmental concerns, as they typically derive from petroleum-based sources and contain potentially harmful compounds like bisphenol A.

Metal foam composites, particularly aluminum-based foams, demonstrate different environmental characteristics. While aluminum production is energy-intensive initially, requiring about 14 kWh/kg, these materials offer significant advantages in recyclability. Unlike CFRP, which presents considerable challenges in end-of-life separation and recovery, metal foams can be recycled through conventional metallurgical processes with relatively minor property degradation.

Lifecycle assessment (LCA) studies reveal that the environmental impact of CFRP is front-loaded, with 80-90% of emissions occurring during raw material extraction and manufacturing. In contrast, metal foams distribute their environmental impact more evenly across production and use phases, with significant potential for impact reduction through recycling.

The use phase presents another critical distinction. CFRP's lightweight properties contribute to fuel efficiency in transportation applications, potentially offsetting initial production impacts over the material's lifetime. Research indicates that in automotive applications, each 10% weight reduction can improve fuel economy by 6-8%. Metal foams, while heavier than CFRP, offer multifunctional benefits including thermal insulation and sound dampening that may reduce overall system complexity and associated environmental impacts.

End-of-life management remains particularly challenging for CFRP, with limited commercial-scale recycling options available. Current technologies like pyrolysis and solvolysis recover only portions of the original fiber properties. Metal foams, conversely, can be reintegrated into standard metal recycling streams, though the presence of stabilizing particles may require additional separation processes.

Recent innovations in bio-based carbon fibers and environmentally friendly core materials for metal foams suggest potential pathways for reducing the environmental footprint of both material systems, though these technologies remain at relatively early stages of commercial development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!