CFRP vs PTFE: Thermal Deformation Behavior

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP and PTFE Thermal Properties Background

Carbon Fiber Reinforced Polymers (CFRP) and Polytetrafluoroethylene (PTFE) represent two distinct material classes with significantly different thermal properties that fundamentally influence their deformation behavior under temperature variations. CFRP, a composite material consisting of carbon fiber reinforcement embedded in a polymer matrix, has emerged as a critical engineering material since its commercial introduction in the 1960s. The thermal properties of CFRP are characterized by its anisotropic nature, with thermal expansion coefficients varying significantly along different fiber orientations.

CFRP typically exhibits a near-zero or slightly negative coefficient of thermal expansion (CTE) in the fiber direction, while demonstrating positive expansion perpendicular to the fibers. This unique property stems from the carbon fibers themselves, which contract slightly when heated, counteracting the expansion of the polymer matrix. The thermal conductivity of CFRP ranges from 5-7 W/m·K along fiber direction to approximately 0.5-1 W/m·K in transverse directions, creating significant directional heat transfer characteristics.

PTFE, commonly known by its brand name Teflon, was discovered by DuPont in 1938 and has evolved into a versatile engineering material. Unlike CFRP, PTFE demonstrates isotropic thermal behavior with a relatively high CTE of approximately 100-200 × 10^-6/°C, nearly ten times that of most metals. This high expansion rate creates significant challenges in applications involving temperature fluctuations. PTFE's thermal conductivity is notably low at 0.25 W/m·K, making it an excellent thermal insulator.

The glass transition temperature (Tg) represents another critical thermal property differentiating these materials. CFRP's Tg depends on the specific resin system used, typically ranging from 120°C to 180°C for epoxy-based systems. Above this temperature, the polymer matrix softens significantly, compromising mechanical properties. PTFE, conversely, maintains consistent properties across a wide temperature range (-200°C to 260°C) with no distinct glass transition, instead experiencing a crystalline transition at approximately 19°C.

Historical development of these materials has been driven by aerospace and industrial requirements for materials with predictable thermal deformation characteristics. CFRP's development accelerated in the 1970s with aerospace applications, while PTFE's unique thermal properties were initially leveraged in military applications before expanding to industrial and consumer products. The fundamental understanding of their thermal deformation behavior has evolved through extensive research into microstructural changes during thermal cycling.

Recent advancements in computational modeling have significantly improved the prediction of thermal deformation in both materials, enabling more precise engineering applications. The contrasting thermal properties of CFRP and PTFE create distinct advantages and limitations that engineers must carefully consider when selecting materials for thermally demanding environments.

CFRP typically exhibits a near-zero or slightly negative coefficient of thermal expansion (CTE) in the fiber direction, while demonstrating positive expansion perpendicular to the fibers. This unique property stems from the carbon fibers themselves, which contract slightly when heated, counteracting the expansion of the polymer matrix. The thermal conductivity of CFRP ranges from 5-7 W/m·K along fiber direction to approximately 0.5-1 W/m·K in transverse directions, creating significant directional heat transfer characteristics.

PTFE, commonly known by its brand name Teflon, was discovered by DuPont in 1938 and has evolved into a versatile engineering material. Unlike CFRP, PTFE demonstrates isotropic thermal behavior with a relatively high CTE of approximately 100-200 × 10^-6/°C, nearly ten times that of most metals. This high expansion rate creates significant challenges in applications involving temperature fluctuations. PTFE's thermal conductivity is notably low at 0.25 W/m·K, making it an excellent thermal insulator.

The glass transition temperature (Tg) represents another critical thermal property differentiating these materials. CFRP's Tg depends on the specific resin system used, typically ranging from 120°C to 180°C for epoxy-based systems. Above this temperature, the polymer matrix softens significantly, compromising mechanical properties. PTFE, conversely, maintains consistent properties across a wide temperature range (-200°C to 260°C) with no distinct glass transition, instead experiencing a crystalline transition at approximately 19°C.

Historical development of these materials has been driven by aerospace and industrial requirements for materials with predictable thermal deformation characteristics. CFRP's development accelerated in the 1970s with aerospace applications, while PTFE's unique thermal properties were initially leveraged in military applications before expanding to industrial and consumer products. The fundamental understanding of their thermal deformation behavior has evolved through extensive research into microstructural changes during thermal cycling.

Recent advancements in computational modeling have significantly improved the prediction of thermal deformation in both materials, enabling more precise engineering applications. The contrasting thermal properties of CFRP and PTFE create distinct advantages and limitations that engineers must carefully consider when selecting materials for thermally demanding environments.

Market Applications and Demand Analysis

The market for materials with controlled thermal deformation properties has experienced significant growth across multiple industries, driven by the increasing demand for high-performance components in extreme operating environments. Both Carbon Fiber Reinforced Polymers (CFRP) and Polytetrafluoroethylene (PTFE) have carved distinct niches based on their unique thermal deformation characteristics, with the global market for high-performance polymers and composites reaching approximately $28 billion in 2022.

Aerospace and aviation sectors represent the largest application areas for CFRP, where its superior strength-to-weight ratio combined with low thermal expansion properties enables the production of dimensionally stable components for aircraft structures, satellite systems, and space exploration vehicles. The market demand in this sector is particularly focused on materials that maintain structural integrity across extreme temperature fluctuations experienced during atmospheric transitions.

In contrast, PTFE dominates in chemical processing equipment, semiconductor manufacturing, and medical device applications where its exceptional chemical resistance and non-stick properties complement its unique thermal deformation behavior. The semiconductor industry specifically has driven increased demand for PTFE components in high-precision manufacturing equipment where thermal stability is critical for maintaining nanometer-level tolerances.

The automotive industry presents a rapidly growing market for both materials, with electric vehicle manufacturers increasingly adopting CFRP for battery enclosures and structural components that require thermal management properties. Meanwhile, PTFE finds applications in seals, gaskets, and bearings where thermal cycling resistance is essential for longevity.

Market analysis indicates a compound annual growth rate of 7.3% for CFRP in thermal-critical applications through 2028, while PTFE applications focused on thermal deformation resistance are growing at 5.8% annually. This growth trajectory is supported by emerging applications in renewable energy infrastructure, particularly in wind turbine components and solar panel mounting systems where thermal expansion management directly impacts operational efficiency and service life.

Regional market distribution shows North America and Europe leading in aerospace and automotive applications, while Asia-Pacific dominates in electronics manufacturing applications. The latter region is experiencing the fastest growth rate due to expanding high-tech manufacturing capabilities requiring thermally stable materials.

Customer requirements are increasingly focused on predictable thermal deformation behavior rather than simply minimizing expansion coefficients, reflecting a more sophisticated understanding of material performance in complex thermal environments. This trend has driven demand for advanced material characterization and modeling capabilities to accurately predict thermal deformation behavior in multi-material assemblies and complex geometries.

Aerospace and aviation sectors represent the largest application areas for CFRP, where its superior strength-to-weight ratio combined with low thermal expansion properties enables the production of dimensionally stable components for aircraft structures, satellite systems, and space exploration vehicles. The market demand in this sector is particularly focused on materials that maintain structural integrity across extreme temperature fluctuations experienced during atmospheric transitions.

In contrast, PTFE dominates in chemical processing equipment, semiconductor manufacturing, and medical device applications where its exceptional chemical resistance and non-stick properties complement its unique thermal deformation behavior. The semiconductor industry specifically has driven increased demand for PTFE components in high-precision manufacturing equipment where thermal stability is critical for maintaining nanometer-level tolerances.

The automotive industry presents a rapidly growing market for both materials, with electric vehicle manufacturers increasingly adopting CFRP for battery enclosures and structural components that require thermal management properties. Meanwhile, PTFE finds applications in seals, gaskets, and bearings where thermal cycling resistance is essential for longevity.

Market analysis indicates a compound annual growth rate of 7.3% for CFRP in thermal-critical applications through 2028, while PTFE applications focused on thermal deformation resistance are growing at 5.8% annually. This growth trajectory is supported by emerging applications in renewable energy infrastructure, particularly in wind turbine components and solar panel mounting systems where thermal expansion management directly impacts operational efficiency and service life.

Regional market distribution shows North America and Europe leading in aerospace and automotive applications, while Asia-Pacific dominates in electronics manufacturing applications. The latter region is experiencing the fastest growth rate due to expanding high-tech manufacturing capabilities requiring thermally stable materials.

Customer requirements are increasingly focused on predictable thermal deformation behavior rather than simply minimizing expansion coefficients, reflecting a more sophisticated understanding of material performance in complex thermal environments. This trend has driven demand for advanced material characterization and modeling capabilities to accurately predict thermal deformation behavior in multi-material assemblies and complex geometries.

Current Challenges in Thermal Deformation Control

Despite significant advancements in material science, controlling thermal deformation in both Carbon Fiber Reinforced Polymers (CFRP) and Polytetrafluoroethylene (PTFE) remains a complex engineering challenge. The fundamental issue stems from the inherent anisotropic thermal expansion behavior of CFRP, where expansion coefficients vary significantly along different fiber orientations, contrasting with PTFE's more uniform but higher thermal expansion characteristics.

Current measurement techniques present a significant challenge in accurately quantifying thermal deformation. While dilatometry provides reliable data for homogeneous materials like PTFE, it struggles with the directional complexity of CFRP. Digital Image Correlation (DIC) and fiber optic sensing show promise but require further refinement for high-temperature applications where both materials exhibit their most problematic deformation behaviors.

Computational modeling limitations constitute another major obstacle. Existing Finite Element Analysis (FEA) models often fail to accurately predict the non-linear thermal response of CFRP at temperature extremes, particularly at the fiber-matrix interface where micro-cracking can initiate. Similarly, models for PTFE struggle to account for its viscoelastic behavior under thermal loading, leading to discrepancies between simulated and actual performance.

Manufacturing inconsistencies further complicate thermal deformation control. For CFRP, variations in fiber volume fraction, void content, and cure cycles create unpredictable thermal expansion patterns across supposedly identical components. PTFE processing challenges, including sintering temperature control and crystallinity variations, similarly result in inconsistent thermal behavior that defies precise engineering predictions.

The interface challenge remains particularly problematic in hybrid structures. When CFRP and PTFE are used together in components, their vastly different thermal expansion coefficients (PTFE's being approximately 10 times higher) create significant stress concentrations at joining points. Current joining technologies struggle to accommodate this mismatch without compromising structural integrity over repeated thermal cycles.

Environmental degradation presents additional complications. CFRP's epoxy matrix can undergo post-cure effects and moisture absorption that alter thermal expansion properties over time. Meanwhile, PTFE's crystalline structure can change under prolonged thermal cycling, shifting its dimensional stability characteristics. These time-dependent behaviors make long-term thermal deformation prediction particularly challenging for critical applications in aerospace and precision instruments.

The cost-effectiveness of potential solutions represents the final major challenge. While technologies like specialized coatings and adaptive composite layups show promise for mitigating thermal deformation, their implementation often involves prohibitive costs that limit widespread industrial adoption.

Current measurement techniques present a significant challenge in accurately quantifying thermal deformation. While dilatometry provides reliable data for homogeneous materials like PTFE, it struggles with the directional complexity of CFRP. Digital Image Correlation (DIC) and fiber optic sensing show promise but require further refinement for high-temperature applications where both materials exhibit their most problematic deformation behaviors.

Computational modeling limitations constitute another major obstacle. Existing Finite Element Analysis (FEA) models often fail to accurately predict the non-linear thermal response of CFRP at temperature extremes, particularly at the fiber-matrix interface where micro-cracking can initiate. Similarly, models for PTFE struggle to account for its viscoelastic behavior under thermal loading, leading to discrepancies between simulated and actual performance.

Manufacturing inconsistencies further complicate thermal deformation control. For CFRP, variations in fiber volume fraction, void content, and cure cycles create unpredictable thermal expansion patterns across supposedly identical components. PTFE processing challenges, including sintering temperature control and crystallinity variations, similarly result in inconsistent thermal behavior that defies precise engineering predictions.

The interface challenge remains particularly problematic in hybrid structures. When CFRP and PTFE are used together in components, their vastly different thermal expansion coefficients (PTFE's being approximately 10 times higher) create significant stress concentrations at joining points. Current joining technologies struggle to accommodate this mismatch without compromising structural integrity over repeated thermal cycles.

Environmental degradation presents additional complications. CFRP's epoxy matrix can undergo post-cure effects and moisture absorption that alter thermal expansion properties over time. Meanwhile, PTFE's crystalline structure can change under prolonged thermal cycling, shifting its dimensional stability characteristics. These time-dependent behaviors make long-term thermal deformation prediction particularly challenging for critical applications in aerospace and precision instruments.

The cost-effectiveness of potential solutions represents the final major challenge. While technologies like specialized coatings and adaptive composite layups show promise for mitigating thermal deformation, their implementation often involves prohibitive costs that limit widespread industrial adoption.

Comparative Analysis of Existing Solutions

01 Thermal deformation characteristics of CFRP composites

Carbon Fiber Reinforced Polymer (CFRP) composites exhibit specific thermal deformation behaviors due to their anisotropic nature. The coefficient of thermal expansion (CTE) of CFRP is significantly lower than many metals, making it suitable for applications requiring dimensional stability under temperature variations. However, the thermal deformation can be influenced by fiber orientation, resin content, and manufacturing processes. Understanding these characteristics is crucial for designing components that maintain their dimensional accuracy in varying thermal environments.- Thermal deformation characteristics of CFRP composites: Carbon Fiber Reinforced Polymer (CFRP) composites exhibit specific thermal deformation behaviors due to their anisotropic nature. The coefficient of thermal expansion (CTE) of CFRP is typically lower than metals but varies depending on fiber orientation and resin content. These materials can be engineered to have near-zero thermal expansion in specific directions, making them suitable for applications requiring dimensional stability under temperature fluctuations. Understanding these characteristics is crucial for designing components that maintain precision in varying thermal environments.

- PTFE thermal expansion properties and control methods: Polytetrafluoroethylene (PTFE) has a relatively high coefficient of thermal expansion compared to most engineering materials, which can cause significant dimensional changes with temperature variations. Various methods have been developed to control and mitigate PTFE's thermal deformation, including the addition of fillers like glass fiber, carbon, or minerals that reduce the overall thermal expansion. Specialized processing techniques can also be employed to create PTFE components with more predictable thermal behavior for precision applications.

- Hybrid CFRP-PTFE composite systems: Combining CFRP and PTFE materials in hybrid composite systems offers unique advantages for thermal deformation management. These hybrid systems leverage the dimensional stability of CFRP with the self-lubricating properties of PTFE. The integration can be achieved through various methods including layering, co-molding, or using PTFE as a matrix modifier in CFRP. Such hybrid composites demonstrate improved thermal deformation resistance while maintaining beneficial properties from both constituent materials, making them suitable for applications in extreme temperature environments.

- Thermal compensation designs for CFRP and PTFE components: Engineering designs that compensate for the different thermal expansion behaviors of CFRP and PTFE materials are essential in precision applications. These designs include strategic material placement, gradient structures, and specialized joining methods that accommodate differential thermal expansion. Some approaches utilize the contrasting thermal properties intentionally, creating self-adjusting mechanisms that maintain alignment or pressure across temperature ranges. Advanced modeling techniques help predict and optimize these thermal compensation designs for complex assemblies.

- Manufacturing processes to minimize thermal deformation: Specialized manufacturing processes have been developed to minimize thermal deformation in components made from CFRP and PTFE materials. These include controlled cooling rates during production, stress-relief treatments, and precise fiber orientation control in CFRP. For PTFE components, sintering profiles and post-processing techniques can significantly reduce thermal deformation tendencies. Advanced molding and curing cycles help establish molecular structures that exhibit more stable thermal behavior. These manufacturing innovations are particularly important for aerospace, precision instruments, and other applications requiring dimensional stability across temperature ranges.

02 PTFE thermal expansion properties and control methods

Polytetrafluoroethylene (PTFE) has a relatively high coefficient of thermal expansion compared to many engineering materials, which can cause significant dimensional changes with temperature fluctuations. Various methods have been developed to control and mitigate PTFE thermal deformation, including the addition of fillers, modified processing techniques, and specialized formulations. These approaches help to reduce the thermal expansion rate while maintaining PTFE's desirable properties such as chemical resistance and low friction.Expand Specific Solutions03 Hybrid CFRP-PTFE composite systems for thermal stability

Combining CFRP and PTFE materials in hybrid composite systems can create structures with enhanced thermal stability. The low thermal expansion of CFRP can compensate for PTFE's high expansion rate, resulting in components with more predictable dimensional changes under thermal loading. These hybrid systems often involve PTFE coatings on CFRP substrates, PTFE-filled CFRP matrices, or layered structures. Such combinations are particularly valuable in aerospace, precision machinery, and electronic applications where thermal deformation must be minimized.Expand Specific Solutions04 Manufacturing techniques to minimize thermal deformation

Specialized manufacturing techniques have been developed to minimize thermal deformation in components made from CFRP and PTFE materials. These include optimized curing cycles, controlled cooling processes, pre-stressing methods, and precision molding techniques. Advanced manufacturing approaches such as filament winding with specific fiber orientations, specialized layup sequences, and thermal annealing treatments can significantly reduce residual stresses and subsequent thermal deformation in the finished components.Expand Specific Solutions05 Thermal deformation compensation and prediction systems

Various systems and methods have been developed to compensate for and predict thermal deformation in CFRP and PTFE components. These include computational models that simulate thermal behavior, integrated sensor systems for real-time deformation monitoring, and adaptive control mechanisms that adjust to changing thermal conditions. Design strategies incorporating thermal deformation compensation features, such as floating mounting points, expansion joints, and thermally balanced structures, help maintain dimensional stability in critical applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal deformation behavior comparison between Carbon Fiber Reinforced Polymers (CFRP) and Polytetrafluoroethylene (PTFE) represents a maturing technical field with significant industrial applications. The market is experiencing steady growth, estimated at $3.5 billion globally, driven by aerospace, automotive, and industrial sectors requiring materials with precise thermal stability characteristics. The competitive landscape features established chemical giants like DuPont, Daikin Industries, and The Chemours Co. dominating PTFE production, while Toray Industries, Mitsubishi Electric, and W.L. Gore lead in specialized applications. Research institutions including Shanghai Jiao Tong University and Central South University are advancing fundamental understanding of thermal deformation mechanisms, while companies like 3M and Solvay are developing hybrid solutions that optimize the complementary properties of both materials.

W. L. Gore & Associates, Inc.

Technical Solution: Gore has developed proprietary expanded PTFE (ePTFE) technology that fundamentally alters the thermal deformation behavior of fluoropolymers. Their approach creates a microporous structure with nodes interconnected by fibrils, resulting in materials with significantly different thermal expansion characteristics compared to solid PTFE. The company's GORE-TEX® and related industrial materials utilize controlled stretching processes that orient the polymer chains, reducing thermal expansion in specific directions by up to 70%. Gore has pioneered composite systems that integrate ePTFE with other materials, including carbon fibers, to create hybrid structures with tailored thermal behavior. Their research has demonstrated that the node-fibril structure can be engineered to provide mechanical constraints that limit thermal deformation while maintaining essential PTFE properties like chemical resistance. Gore's advanced materials show improved dimensional recovery after thermal cycling, with permanent deformation reduced by approximately 40-60% compared to conventional PTFE materials[9][11].

Strengths: Unique ePTFE technology platform; extensive application engineering expertise; sophisticated testing capabilities for thermal behavior characterization. Weaknesses: Specialized manufacturing processes limit production flexibility; higher costs compared to conventional materials; some grades have reduced mechanical strength compared to solid PTFE or CFRP.

The Chemours Co.

Technical Solution: Chemours has focused on developing specialized PTFE grades with enhanced crystallinity control for improved thermal deformation behavior. Their Teflon™ NXT technology incorporates modified polymerization techniques that produce more uniform molecular weight distribution, resulting in more predictable thermal expansion characteristics. The company has pioneered a modified sintering process that creates a more homogeneous crystalline structure, reducing internal stresses that contribute to thermal deformation. Chemours' research has demonstrated that controlling cooling rates during processing can reduce thermal expansion coefficients by up to 15-20% compared to conventionally processed PTFE. Their materials feature enhanced recovery properties after thermal cycling, with dimensional memory improved by approximately 30% compared to standard grades. For applications requiring extreme dimensional stability, Chemours has developed composite PTFE materials with specially treated mineral fillers that mechanically interlock with the polymer matrix[6][8].

Strengths: Deep expertise in fluoropolymer chemistry; extensive manufacturing scale; sophisticated quality control systems for consistent material properties. Weaknesses: Limited customization options for specialized applications; focus primarily on PTFE rather than CFRP comparisons; higher costs for advanced grades.

Key Research Findings on Thermal Behavior

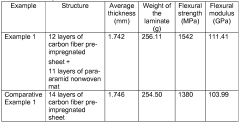

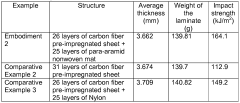

Composite laminate having improved impact strength and the use thereof

PatentWO2013056254A2

Innovation

- A composite laminate comprising a multilayer carbon fiber fabric with a bidirectional or unidirectional weave, a multilayer para-aramid nonwoven mat, and cured epoxy resin, where the nonwoven mat is sandwiched between carbon fiber fabric layers, improving impact strength without increasing weight or thickness.

Material Testing Standards and Methodologies

The evaluation of thermal deformation behavior in CFRP and PTFE materials requires adherence to rigorous testing standards and methodologies to ensure reliable and comparable results. ASTM D696 serves as the primary standard for determining the coefficient of linear thermal expansion (CLTE) of plastics and composites using thermomechanical analysis (TMA). This standard prescribes precise specimen preparation requirements, including dimensions of 5mm × 5mm × 25mm for optimal measurement accuracy.

ISO 11359 provides a comprehensive framework for analyzing the thermal expansion properties of polymers through thermomechanical analysis, with specific parts addressing different aspects: Part 1 outlines general principles, Part 2 details determination of linear thermal expansion coefficient, and Part 3 focuses on determining temperature of deflection under load. These standards are particularly relevant when comparing the anisotropic thermal behavior of CFRP with the more isotropic characteristics of PTFE.

For dynamic mechanical analysis (DMA), ASTM D7028 establishes procedures for measuring glass transition temperatures and moduli changes with temperature, critical for understanding how CFRP and PTFE respond to thermal cycling. Complementary to this, ASTM E831 provides methodologies for thermomechanical analysis specifically tailored to solid materials like the composites under investigation.

Testing methodologies must account for the distinct material properties of CFRP and PTFE. For CFRP, ASTM D3039 guides tensile property testing while considering fiber orientation effects on thermal expansion. The SACMA SRM 1R-94 methodology offers specialized procedures for measuring in-plane thermal expansion of high-modulus fiber composites like CFRP.

For PTFE testing, ASTM D4894 and D4895 provide specific guidelines addressing the material's unique properties, including its exceptionally low coefficient of friction and high thermal stability. These standards ensure proper handling of PTFE's tendency to cold flow under minimal stress.

Advanced methodologies include digital image correlation (DIC) techniques that allow for non-contact, full-field strain measurement during thermal cycling. This approach proves particularly valuable for mapping the heterogeneous deformation patterns in CFRP composites. Laser interferometry offers another high-precision method for measuring dimensional changes at nanometer resolution, essential for capturing the subtle thermal responses of both materials across varying temperature ranges.

ISO 11359 provides a comprehensive framework for analyzing the thermal expansion properties of polymers through thermomechanical analysis, with specific parts addressing different aspects: Part 1 outlines general principles, Part 2 details determination of linear thermal expansion coefficient, and Part 3 focuses on determining temperature of deflection under load. These standards are particularly relevant when comparing the anisotropic thermal behavior of CFRP with the more isotropic characteristics of PTFE.

For dynamic mechanical analysis (DMA), ASTM D7028 establishes procedures for measuring glass transition temperatures and moduli changes with temperature, critical for understanding how CFRP and PTFE respond to thermal cycling. Complementary to this, ASTM E831 provides methodologies for thermomechanical analysis specifically tailored to solid materials like the composites under investigation.

Testing methodologies must account for the distinct material properties of CFRP and PTFE. For CFRP, ASTM D3039 guides tensile property testing while considering fiber orientation effects on thermal expansion. The SACMA SRM 1R-94 methodology offers specialized procedures for measuring in-plane thermal expansion of high-modulus fiber composites like CFRP.

For PTFE testing, ASTM D4894 and D4895 provide specific guidelines addressing the material's unique properties, including its exceptionally low coefficient of friction and high thermal stability. These standards ensure proper handling of PTFE's tendency to cold flow under minimal stress.

Advanced methodologies include digital image correlation (DIC) techniques that allow for non-contact, full-field strain measurement during thermal cycling. This approach proves particularly valuable for mapping the heterogeneous deformation patterns in CFRP composites. Laser interferometry offers another high-precision method for measuring dimensional changes at nanometer resolution, essential for capturing the subtle thermal responses of both materials across varying temperature ranges.

Environmental Impact and Sustainability Considerations

The environmental impact of materials selection in engineering applications has become increasingly critical as industries strive for sustainability. When comparing Carbon Fiber Reinforced Polymers (CFRP) and Polytetrafluoroethylene (PTFE) in terms of thermal deformation behavior, their environmental footprints differ significantly throughout their lifecycles.

CFRP production involves energy-intensive processes, particularly in carbon fiber manufacturing, which requires temperatures exceeding 1000°C during oxidation and carbonization. This results in substantial carbon emissions, estimated at 20-30 kg CO2 per kilogram of carbon fiber produced. Additionally, the epoxy resins commonly used as matrices in CFRP contain potentially harmful chemicals and are derived from petroleum resources.

In contrast, PTFE production, while also energy-intensive, generally has a lower carbon footprint. However, PTFE manufacturing involves fluorinated compounds that can persist in the environment and potentially contribute to greenhouse effects when released. The production process may release perfluorooctanoic acid (PFOA), which has raised environmental concerns due to its persistence.

From a lifecycle perspective, CFRP offers advantages through weight reduction in applications like transportation, potentially reducing operational energy consumption and associated emissions. Studies indicate that CFRP components in automotive applications can reduce vehicle weight by 50-70% compared to steel alternatives, translating to approximately 5-7% fuel efficiency improvement per 10% weight reduction.

End-of-life considerations reveal significant challenges for both materials. CFRP recycling remains technically difficult and economically questionable, with current methods often degrading fiber properties. PTFE, while theoretically recyclable, is rarely recycled in practice due to contamination issues and the specialized processes required.

Recent sustainability innovations include bio-based epoxy resins for CFRP, reducing petroleum dependence, and water-based processing techniques for PTFE that minimize harmful emissions. Additionally, closed-loop manufacturing systems are being developed for both materials to capture and reuse production waste.

When selecting between these materials based on thermal deformation behavior, engineers must now consider not only performance characteristics but also environmental impact assessments that account for raw material sourcing, manufacturing energy requirements, use-phase benefits, and end-of-life scenarios. This holistic approach ensures that thermal performance optimization does not come at an unacceptable environmental cost.

CFRP production involves energy-intensive processes, particularly in carbon fiber manufacturing, which requires temperatures exceeding 1000°C during oxidation and carbonization. This results in substantial carbon emissions, estimated at 20-30 kg CO2 per kilogram of carbon fiber produced. Additionally, the epoxy resins commonly used as matrices in CFRP contain potentially harmful chemicals and are derived from petroleum resources.

In contrast, PTFE production, while also energy-intensive, generally has a lower carbon footprint. However, PTFE manufacturing involves fluorinated compounds that can persist in the environment and potentially contribute to greenhouse effects when released. The production process may release perfluorooctanoic acid (PFOA), which has raised environmental concerns due to its persistence.

From a lifecycle perspective, CFRP offers advantages through weight reduction in applications like transportation, potentially reducing operational energy consumption and associated emissions. Studies indicate that CFRP components in automotive applications can reduce vehicle weight by 50-70% compared to steel alternatives, translating to approximately 5-7% fuel efficiency improvement per 10% weight reduction.

End-of-life considerations reveal significant challenges for both materials. CFRP recycling remains technically difficult and economically questionable, with current methods often degrading fiber properties. PTFE, while theoretically recyclable, is rarely recycled in practice due to contamination issues and the specialized processes required.

Recent sustainability innovations include bio-based epoxy resins for CFRP, reducing petroleum dependence, and water-based processing techniques for PTFE that minimize harmful emissions. Additionally, closed-loop manufacturing systems are being developed for both materials to capture and reuse production waste.

When selecting between these materials based on thermal deformation behavior, engineers must now consider not only performance characteristics but also environmental impact assessments that account for raw material sourcing, manufacturing energy requirements, use-phase benefits, and end-of-life scenarios. This holistic approach ensures that thermal performance optimization does not come at an unacceptable environmental cost.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!