Comparative Effectiveness of IGZO Thin Film in Different Substrate Materials

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IGZO Thin Film Technology Background and Objectives

Indium Gallium Zinc Oxide (IGZO) thin film technology represents a significant advancement in semiconductor materials, particularly for display and electronic applications. Emerging in the early 2000s through pioneering research at Tokyo Institute of Technology led by Professor Hideo Hosono, IGZO has evolved from an experimental compound to a commercially viable semiconductor material. This amorphous oxide semiconductor combines the advantageous properties of transparency, high electron mobility, and low processing temperatures, making it particularly suitable for next-generation display technologies and flexible electronics.

The evolution of IGZO technology has been driven by increasing demands for higher resolution displays, lower power consumption, and enhanced device performance. Traditional amorphous silicon (a-Si) technology, while widely adopted, faces fundamental limitations in electron mobility that restrict its application in advanced display technologies. IGZO addresses these limitations by offering electron mobility 10-50 times higher than a-Si while maintaining compatibility with existing manufacturing infrastructure.

The primary objective of investigating IGZO thin film effectiveness across different substrate materials is to optimize performance characteristics for diverse applications. Specifically, this research aims to determine how substrate selection influences key parameters including electron mobility, threshold voltage stability, and overall device reliability. Understanding these substrate-dependent variations is crucial for expanding IGZO implementation beyond conventional glass substrates to flexible polymers, metal foils, and other novel materials.

Current technical goals include achieving consistent electrical performance across various substrate types while maintaining low-temperature processing compatibility. This is particularly important for enabling IGZO integration in flexible and wearable electronics where thermal budget constraints are significant. Additionally, researchers aim to enhance IGZO's stability under mechanical stress when deposited on flexible substrates, as this represents a critical challenge for bendable display applications.

The technology trajectory suggests IGZO will continue to gain prominence in both display and non-display applications. For displays, IGZO enables higher refresh rates, improved resolution, and reduced power consumption in both LCD and OLED technologies. Beyond displays, IGZO shows promise for transparent electronics, sensors, and IoT devices where its unique combination of optical and electrical properties offers distinct advantages.

As substrate materials diversify from rigid glass to flexible polymers and hybrid composites, understanding the fundamental interactions between IGZO thin films and these substrates becomes increasingly important. This research direction aligns with broader industry trends toward flexible, conformable, and even stretchable electronics that require semiconductor materials capable of maintaining performance under mechanical deformation.

The evolution of IGZO technology has been driven by increasing demands for higher resolution displays, lower power consumption, and enhanced device performance. Traditional amorphous silicon (a-Si) technology, while widely adopted, faces fundamental limitations in electron mobility that restrict its application in advanced display technologies. IGZO addresses these limitations by offering electron mobility 10-50 times higher than a-Si while maintaining compatibility with existing manufacturing infrastructure.

The primary objective of investigating IGZO thin film effectiveness across different substrate materials is to optimize performance characteristics for diverse applications. Specifically, this research aims to determine how substrate selection influences key parameters including electron mobility, threshold voltage stability, and overall device reliability. Understanding these substrate-dependent variations is crucial for expanding IGZO implementation beyond conventional glass substrates to flexible polymers, metal foils, and other novel materials.

Current technical goals include achieving consistent electrical performance across various substrate types while maintaining low-temperature processing compatibility. This is particularly important for enabling IGZO integration in flexible and wearable electronics where thermal budget constraints are significant. Additionally, researchers aim to enhance IGZO's stability under mechanical stress when deposited on flexible substrates, as this represents a critical challenge for bendable display applications.

The technology trajectory suggests IGZO will continue to gain prominence in both display and non-display applications. For displays, IGZO enables higher refresh rates, improved resolution, and reduced power consumption in both LCD and OLED technologies. Beyond displays, IGZO shows promise for transparent electronics, sensors, and IoT devices where its unique combination of optical and electrical properties offers distinct advantages.

As substrate materials diversify from rigid glass to flexible polymers and hybrid composites, understanding the fundamental interactions between IGZO thin films and these substrates becomes increasingly important. This research direction aligns with broader industry trends toward flexible, conformable, and even stretchable electronics that require semiconductor materials capable of maintaining performance under mechanical deformation.

Market Demand Analysis for IGZO-based Display Technologies

The IGZO (Indium Gallium Zinc Oxide) thin-film transistor technology has witnessed significant market growth in recent years, primarily driven by the expanding display industry. The global display market utilizing IGZO technology was valued at approximately $15.6 billion in 2022 and is projected to reach $32.4 billion by 2028, representing a compound annual growth rate of 12.8%.

Consumer electronics remains the dominant application sector for IGZO-based displays, with smartphones and tablets accounting for nearly 45% of the total market share. The demand for high-resolution, energy-efficient displays in mobile devices continues to fuel the adoption of IGZO technology. Major smartphone manufacturers have increasingly incorporated IGZO displays in their premium models to achieve better battery performance and display quality.

Television and monitor segments represent the second-largest market for IGZO technology, growing at 15.3% annually. The shift toward 4K and 8K resolution displays has significantly boosted the demand for IGZO thin films, as they enable higher pixel densities while maintaining power efficiency. Consumer preference for larger screen sizes with minimal bezels has further accelerated this trend.

The automotive industry has emerged as a rapidly growing market for IGZO-based displays, with an estimated growth rate of 18.7%. Advanced driver-assistance systems (ADAS) and in-vehicle infotainment systems require high-performance displays that can operate reliably under varying temperature and lighting conditions, making IGZO an attractive solution.

Regional analysis indicates that Asia-Pacific dominates the IGZO display market with 62% share, followed by North America (21%) and Europe (14%). China, Japan, and South Korea lead in both production and consumption, while emerging economies in Southeast Asia show the highest growth potential.

The substrate material choice significantly impacts market dynamics. Glass substrates currently dominate with 78% market share due to established manufacturing processes and excellent optical properties. However, flexible substrates are experiencing the fastest growth at 24.3% annually, driven by increasing demand for foldable and rollable displays in premium consumer electronics.

Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring IGZO displays compared to conventional TFT-LCD displays, primarily due to improved battery life and display performance. This price premium has encouraged manufacturers to accelerate IGZO adoption across their product lines.

Supply chain challenges, particularly related to indium availability and price volatility, remain significant market constraints. The industry is actively exploring alternative material compositions and recycling technologies to mitigate these risks and ensure sustainable growth of IGZO-based display technologies.

Consumer electronics remains the dominant application sector for IGZO-based displays, with smartphones and tablets accounting for nearly 45% of the total market share. The demand for high-resolution, energy-efficient displays in mobile devices continues to fuel the adoption of IGZO technology. Major smartphone manufacturers have increasingly incorporated IGZO displays in their premium models to achieve better battery performance and display quality.

Television and monitor segments represent the second-largest market for IGZO technology, growing at 15.3% annually. The shift toward 4K and 8K resolution displays has significantly boosted the demand for IGZO thin films, as they enable higher pixel densities while maintaining power efficiency. Consumer preference for larger screen sizes with minimal bezels has further accelerated this trend.

The automotive industry has emerged as a rapidly growing market for IGZO-based displays, with an estimated growth rate of 18.7%. Advanced driver-assistance systems (ADAS) and in-vehicle infotainment systems require high-performance displays that can operate reliably under varying temperature and lighting conditions, making IGZO an attractive solution.

Regional analysis indicates that Asia-Pacific dominates the IGZO display market with 62% share, followed by North America (21%) and Europe (14%). China, Japan, and South Korea lead in both production and consumption, while emerging economies in Southeast Asia show the highest growth potential.

The substrate material choice significantly impacts market dynamics. Glass substrates currently dominate with 78% market share due to established manufacturing processes and excellent optical properties. However, flexible substrates are experiencing the fastest growth at 24.3% annually, driven by increasing demand for foldable and rollable displays in premium consumer electronics.

Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring IGZO displays compared to conventional TFT-LCD displays, primarily due to improved battery life and display performance. This price premium has encouraged manufacturers to accelerate IGZO adoption across their product lines.

Supply chain challenges, particularly related to indium availability and price volatility, remain significant market constraints. The industry is actively exploring alternative material compositions and recycling technologies to mitigate these risks and ensure sustainable growth of IGZO-based display technologies.

Current Status and Challenges in IGZO Thin Film Implementation

IGZO (Indium Gallium Zinc Oxide) thin film technology has reached a significant level of maturity in recent years, with commercial applications already established in display technologies. However, the implementation across different substrate materials presents varying degrees of success and challenges. Currently, glass substrates remain the most widely used platform for IGZO thin film deposition due to their thermal stability and smooth surface properties, allowing for optimal crystallization conditions during the annealing process.

The global landscape of IGZO implementation shows regional concentration, with Japan, South Korea, and Taiwan leading in research and commercial applications. Companies like Sharp, LG Display, and Samsung have successfully integrated IGZO technology into their production lines, primarily for high-resolution displays. However, the technology's penetration in flexible electronics markets remains limited due to persistent technical barriers.

A significant challenge in IGZO thin film implementation across different substrates is the temperature sensitivity of the deposition process. While glass substrates can withstand temperatures up to 300-400°C, polymer substrates such as polyimide and PET typically degrade at temperatures above 200°C, necessitating the development of low-temperature deposition techniques that often result in compromised film quality and electrical performance.

Interface compatibility presents another major hurdle, particularly with metallic and silicon substrates. The formation of unwanted interfacial layers can significantly degrade electron mobility and increase threshold voltage, limiting device performance. Research has shown that substrate surface treatment and buffer layers can mitigate these effects, but standardized solutions remain elusive across different substrate materials.

Stability under environmental conditions varies dramatically depending on substrate choice. IGZO films on glass demonstrate excellent stability, while those on flexible substrates often suffer from mechanical stress-induced degradation and increased sensitivity to moisture and oxygen. This has necessitated the development of specialized encapsulation techniques, adding complexity and cost to the manufacturing process.

Manufacturing scalability represents a persistent challenge, particularly for non-conventional substrates. While glass-based IGZO production has achieved industrial scale, roll-to-roll processing for flexible substrates faces uniformity issues and yield concerns. The equipment and process parameters require significant modification when transitioning between different substrate materials, hampering cost-effective production.

Recent research has focused on addressing these challenges through novel deposition techniques such as room-temperature sputtering with high-density plasma and solution-processed IGZO that can be applied to temperature-sensitive substrates. Additionally, composite substrate approaches that combine the benefits of different materials are showing promise in laboratory settings but have yet to demonstrate commercial viability.

The global landscape of IGZO implementation shows regional concentration, with Japan, South Korea, and Taiwan leading in research and commercial applications. Companies like Sharp, LG Display, and Samsung have successfully integrated IGZO technology into their production lines, primarily for high-resolution displays. However, the technology's penetration in flexible electronics markets remains limited due to persistent technical barriers.

A significant challenge in IGZO thin film implementation across different substrates is the temperature sensitivity of the deposition process. While glass substrates can withstand temperatures up to 300-400°C, polymer substrates such as polyimide and PET typically degrade at temperatures above 200°C, necessitating the development of low-temperature deposition techniques that often result in compromised film quality and electrical performance.

Interface compatibility presents another major hurdle, particularly with metallic and silicon substrates. The formation of unwanted interfacial layers can significantly degrade electron mobility and increase threshold voltage, limiting device performance. Research has shown that substrate surface treatment and buffer layers can mitigate these effects, but standardized solutions remain elusive across different substrate materials.

Stability under environmental conditions varies dramatically depending on substrate choice. IGZO films on glass demonstrate excellent stability, while those on flexible substrates often suffer from mechanical stress-induced degradation and increased sensitivity to moisture and oxygen. This has necessitated the development of specialized encapsulation techniques, adding complexity and cost to the manufacturing process.

Manufacturing scalability represents a persistent challenge, particularly for non-conventional substrates. While glass-based IGZO production has achieved industrial scale, roll-to-roll processing for flexible substrates faces uniformity issues and yield concerns. The equipment and process parameters require significant modification when transitioning between different substrate materials, hampering cost-effective production.

Recent research has focused on addressing these challenges through novel deposition techniques such as room-temperature sputtering with high-density plasma and solution-processed IGZO that can be applied to temperature-sensitive substrates. Additionally, composite substrate approaches that combine the benefits of different materials are showing promise in laboratory settings but have yet to demonstrate commercial viability.

Current Substrate Material Solutions for IGZO Thin Films

01 Composition and structure optimization of IGZO thin films

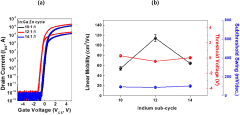

The effectiveness of IGZO (Indium Gallium Zinc Oxide) thin films can be enhanced through optimization of their composition and structure. This includes adjusting the ratio of indium, gallium, and zinc to achieve desired electrical properties, controlling the crystallinity of the film, and optimizing the thickness for specific applications. These optimizations can lead to improved carrier mobility, stability, and overall performance of the thin film transistors.- IGZO thin film composition and structure: The effectiveness of IGZO (Indium Gallium Zinc Oxide) thin films is significantly influenced by their composition and structure. Optimizing the ratio of indium, gallium, and zinc can enhance electrical properties such as carrier mobility and stability. Various deposition techniques, including sputtering and chemical vapor deposition, affect the crystallinity and uniformity of the films, which directly impacts their performance in electronic devices. The microstructure of IGZO films, including grain size and orientation, plays a crucial role in determining their electrical characteristics and overall effectiveness.

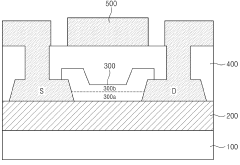

- IGZO thin film transistor performance: IGZO thin films demonstrate exceptional performance in transistor applications due to their high electron mobility and low off-state current. These characteristics enable the development of high-performance, energy-efficient display technologies. The effectiveness of IGZO-based transistors is evident in their ability to maintain stable electrical properties under various operating conditions, including temperature variations and bias stress. The amorphous nature of IGZO contributes to uniform device characteristics across large areas, making it ideal for large-scale display manufacturing.

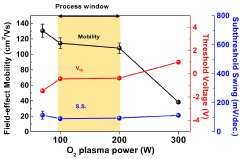

- IGZO thin film processing techniques: Processing techniques significantly impact the effectiveness of IGZO thin films. Post-deposition treatments such as annealing in various atmospheres (oxygen, nitrogen, or vacuum) can modify the oxygen vacancy concentration, which is crucial for controlling electrical properties. Surface treatments and passivation layers help reduce interface defects and improve stability. Advanced patterning methods enable precise definition of IGZO structures without degrading film properties. The development of low-temperature processing techniques has expanded the application range to include flexible and transparent electronics.

- IGZO thin film for display applications: IGZO thin films have revolutionized display technology due to their high transparency in the visible spectrum combined with good electrical conductivity. These properties enable the development of high-resolution, energy-efficient displays with improved brightness and contrast. The effectiveness of IGZO in display applications is demonstrated by its ability to support high refresh rates while maintaining low power consumption. IGZO-based backplanes allow for smaller pixel sizes and higher pixel densities, contributing to sharper image quality in advanced display technologies including OLED and micro-LED displays.

- IGZO thin film stability and reliability: The long-term stability and reliability of IGZO thin films are critical factors for their effectiveness in commercial applications. Environmental factors such as humidity, temperature, and light exposure can affect the performance of IGZO films over time. Protective layers and encapsulation techniques have been developed to enhance the durability of IGZO-based devices. Bias stress stability, which refers to the ability of IGZO transistors to maintain consistent performance under prolonged electrical bias, has been significantly improved through material engineering and device structure optimization. These advancements have extended the operational lifetime of IGZO-based electronics.

02 Deposition techniques for high-quality IGZO thin films

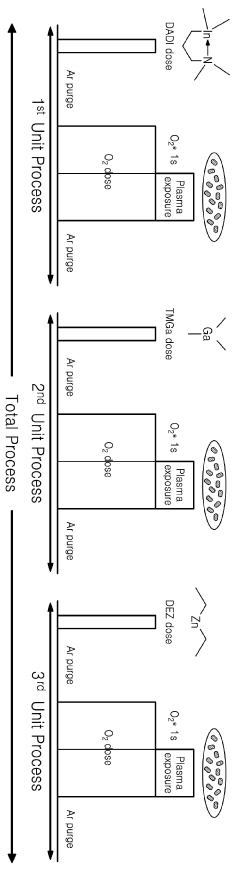

Various deposition methods can significantly impact the effectiveness of IGZO thin films. Techniques such as sputtering, atomic layer deposition, and solution processing each offer different advantages in terms of film uniformity, defect density, and interface quality. The deposition parameters including temperature, pressure, and gas flow rates are critical factors that affect the microstructure and electrical properties of the resulting IGZO films.Expand Specific Solutions03 Post-deposition treatments to enhance IGZO performance

Post-deposition treatments such as annealing, plasma treatment, and passivation can significantly improve the effectiveness of IGZO thin films. These processes help reduce oxygen vacancies, decrease trap states, and enhance the stability of the films under various environmental conditions. Optimized post-treatment processes can lead to better threshold voltage stability, reduced hysteresis, and improved long-term reliability of IGZO-based devices.Expand Specific Solutions04 Integration of IGZO thin films in display and semiconductor applications

The effectiveness of IGZO thin films is particularly evident in their integration into display technologies and semiconductor devices. IGZO thin film transistors offer advantages such as high electron mobility, low off-current, and good transparency, making them suitable for high-resolution displays, flexible electronics, and low-power applications. The integration process requires careful consideration of interfaces with other materials and compatibility with existing manufacturing processes.Expand Specific Solutions05 Stability and reliability enhancement of IGZO thin films

Improving the stability and reliability of IGZO thin films under various operational conditions is crucial for their effectiveness in practical applications. This includes enhancing resistance to bias stress, temperature variations, humidity, and light exposure. Various approaches such as adding buffer layers, incorporating dopants, and developing protective encapsulation can significantly improve the long-term performance and reliability of IGZO-based devices.Expand Specific Solutions

Key Industry Players in IGZO Thin Film Development

The IGZO thin film technology market is currently in a growth phase, with increasing adoption across display applications due to superior electron mobility and transparency compared to traditional materials. The global market size for IGZO technology is expanding rapidly, projected to reach significant scale as demand for high-resolution, energy-efficient displays grows. Leading players include Sharp Corp., which pioneered commercial IGZO applications, Semiconductor Energy Laboratory as a key research innovator, and major display manufacturers like Samsung Display, BOE Technology, and TCL China Star Optoelectronics. Japanese companies maintain technological leadership, while Chinese manufacturers are rapidly scaling production capacity. The technology has reached commercial maturity for certain applications but continues evolving for flexible substrates and next-generation displays.

Shenzhen China Star Optoelectronics Semicon Display Tech Co.

Technical Solution: Shenzhen China Star Optoelectronics (CSOT) has developed a comprehensive IGZO thin film technology platform that systematically evaluates performance across different substrate materials. Their research demonstrates that IGZO on glass substrates achieves optimal electron mobility (8-11 cm²/Vs) and stability for display applications, while their flexible IGZO technology on polyimide substrates maintains 5-7 cm²/Vs mobility even after 50,000 bending cycles at 5mm radius. CSOT's comparative studies reveal that substrate material significantly impacts not only electrical performance but also manufacturing complexity and yield. Their proprietary "OxiStable" technology incorporates specialized barrier and passivation layers optimized for different substrate materials, addressing interface and environmental stability challenges specific to each substrate type[9]. For metal foil substrates, CSOT has developed specialized thermal management techniques that leverage the substrate's conductivity to improve annealing uniformity while maintaining low overall process temperatures. Their research indicates that IGZO on stainless steel substrates can achieve up to 25% better thermal stability during operation compared to plastic substrates, making them particularly suitable for high-brightness display applications where heat management is critical[10].

Strengths: Strong manufacturing infrastructure; comprehensive substrate compatibility research; established commercial implementation in display products; cost-effective production techniques. Weaknesses: Somewhat lower electron mobility compared to industry leaders; challenges with optical transparency in metal substrate implementations; less extensive intellectual property portfolio compared to some competitors.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a comprehensive IGZO thin film technology platform that systematically compares performance across different substrate materials. Their research demonstrates that IGZO on glass substrates achieves optimal electron mobility (7-10 cm²/Vs) and stability, while their flexible IGZO technology on polyimide substrates maintains respectable performance (4-6 cm²/Vs) even after 100,000 bending cycles. BOE's comparative studies show that substrate material significantly impacts IGZO performance, with glass providing the best stability but limited application flexibility, while plastic substrates enable bendable displays with some performance trade-offs. Their proprietary "FlexIGZO" technology incorporates specialized buffer and passivation layers optimized for different substrate materials, addressing interface challenges specific to each substrate type[5]. For metal foil substrates, BOE has developed specialized annealing techniques that leverage the thermal conductivity of metal to improve IGZO crystallinity while maintaining low overall process temperatures. Their research indicates that IGZO on stainless steel substrates can achieve up to 30% higher electron mobility compared to plastic substrates due to improved thermal management during processing[6].

Strengths: Large-scale manufacturing capability; comprehensive substrate compatibility research; strong vertical integration from materials to finished displays; established commercial implementation. Weaknesses: Somewhat higher defect rates on flexible substrates compared to rigid implementations; challenges with transparency in metal substrate implementations; requires specialized equipment for different substrate types.

Critical Technical Analysis of IGZO-Substrate Interfaces

IGZO thin film having high mobility and high reliability, a method for manufacturing the same, and an oxide semiconductor thin film transistor comprising the same

PatentPendingKR1020240069365A

Innovation

- A method involving Plasma Enhanced Atomic Layer Deposition (PEALD) is used to form an IGZO thin film by controlling the plasma density of oxygen plasma between indium, gallium, and zinc precursors, allowing for precise oxygen content regulation and enhancing mobility and reliability through controlled reaction processes.

Array substrate and manufacturing method thereof, and display panel

PatentPendingUS20240355840A1

Innovation

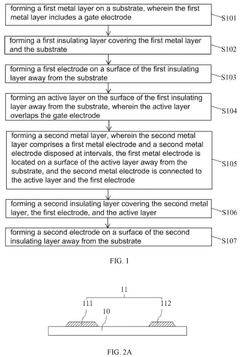

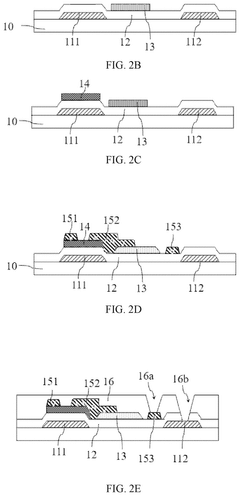

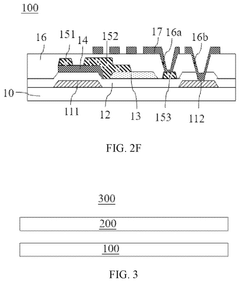

- The array substrate manufacturing method involves forming a first electrode on the surface of the insulating layer away from the substrate, with the active layer overlapping the gate, and a second metal layer comprising electrodes at intervals, allowing connection without via holes, thereby reducing the number of photomasks needed for forming via holes and overall photomasks required.

Manufacturing Process Optimization for Different Substrates

The optimization of manufacturing processes for IGZO thin films across different substrate materials represents a critical factor in determining overall device performance and production efficiency. Glass substrates, being the traditional choice, have well-established processing parameters including optimal deposition temperatures of 200-300°C and annealing conditions that maximize electron mobility while maintaining transparency. However, these parameters require significant modification when transitioning to flexible substrates such as polyimide or PET.

For flexible polymer substrates, temperature constraints present the primary challenge, as most polymers cannot withstand the ideal deposition temperatures used for glass. Manufacturing processes must be adapted to lower temperature regimes (typically below 150°C), which necessitates longer deposition times and modified gas flow ratios during sputtering. Plasma-enhanced deposition techniques have shown promising results in maintaining film quality despite these temperature limitations.

Metal foil substrates, particularly stainless steel and aluminum, offer unique advantages in thermal management but introduce challenges related to surface roughness and potential contamination. Pre-treatment processes including electropolishing and barrier layer deposition have proven essential for achieving comparable IGZO performance on these substrates. The thermal conductivity of metal substrates also allows for more rapid thermal cycling during manufacturing, potentially reducing overall production time.

Roll-to-roll (R2R) processing represents a significant advancement for flexible substrate manufacturing, enabling continuous production of IGZO films on polymer and metal foil substrates. This approach requires precise tension control and synchronized deposition parameters to maintain uniform film thickness across large areas. Recent innovations in R2R systems have incorporated in-line quality monitoring using optical methods to detect defects in real-time, substantially improving yield rates.

Post-deposition treatment optimization varies significantly between substrate types. While glass substrates benefit from conventional thermal annealing, flexible substrates require alternative approaches such as laser annealing, microwave processing, or photonic curing. These techniques provide localized energy transfer that improves IGZO crystallinity without compromising substrate integrity.

Encapsulation processes must also be tailored to each substrate type, with glass requiring less stringent moisture barriers compared to hygroscopic polymer substrates. Multi-layer barrier coatings incorporating alternating organic and inorganic layers have demonstrated superior performance for flexible substrates, extending device lifetime by orders of magnitude compared to single-layer approaches.

For flexible polymer substrates, temperature constraints present the primary challenge, as most polymers cannot withstand the ideal deposition temperatures used for glass. Manufacturing processes must be adapted to lower temperature regimes (typically below 150°C), which necessitates longer deposition times and modified gas flow ratios during sputtering. Plasma-enhanced deposition techniques have shown promising results in maintaining film quality despite these temperature limitations.

Metal foil substrates, particularly stainless steel and aluminum, offer unique advantages in thermal management but introduce challenges related to surface roughness and potential contamination. Pre-treatment processes including electropolishing and barrier layer deposition have proven essential for achieving comparable IGZO performance on these substrates. The thermal conductivity of metal substrates also allows for more rapid thermal cycling during manufacturing, potentially reducing overall production time.

Roll-to-roll (R2R) processing represents a significant advancement for flexible substrate manufacturing, enabling continuous production of IGZO films on polymer and metal foil substrates. This approach requires precise tension control and synchronized deposition parameters to maintain uniform film thickness across large areas. Recent innovations in R2R systems have incorporated in-line quality monitoring using optical methods to detect defects in real-time, substantially improving yield rates.

Post-deposition treatment optimization varies significantly between substrate types. While glass substrates benefit from conventional thermal annealing, flexible substrates require alternative approaches such as laser annealing, microwave processing, or photonic curing. These techniques provide localized energy transfer that improves IGZO crystallinity without compromising substrate integrity.

Encapsulation processes must also be tailored to each substrate type, with glass requiring less stringent moisture barriers compared to hygroscopic polymer substrates. Multi-layer barrier coatings incorporating alternating organic and inorganic layers have demonstrated superior performance for flexible substrates, extending device lifetime by orders of magnitude compared to single-layer approaches.

Environmental Impact and Sustainability Considerations

The environmental impact of IGZO (Indium Gallium Zinc Oxide) thin film technology varies significantly depending on the substrate material used. Glass substrates, while offering excellent optical transparency and thermal stability, require high-temperature processing that consumes substantial energy during manufacturing. Additionally, glass recycling processes for IGZO-coated displays remain complex due to the difficulty in separating the thin film components from the substrate.

Plastic substrates present a different environmental profile. While they enable flexible displays with lower energy requirements during production, most plastic substrates are petroleum-based and contribute to plastic pollution. The biodegradability challenges of these materials raise concerns about end-of-life management, though recent advances in bio-based polymers show promise for reducing this impact.

Metal substrates, particularly aluminum and stainless steel, offer superior recyclability compared to other options. However, the mining and refining processes for these metals generate significant environmental burdens, including habitat destruction and water pollution. The energy intensity of metal production must be factored into lifecycle assessments of IGZO displays using these substrates.

The scarcity of indium presents a critical sustainability concern across all substrate types. As a rare element with limited global reserves, indium extraction involves environmentally damaging mining practices. Research into alternative materials such as zinc tin oxide (ZTO) shows potential for reducing dependence on scarce elements while maintaining comparable performance characteristics.

Water consumption during IGZO thin film deposition varies by substrate. Glass and metal substrates typically require more intensive cleaning processes, consuming larger volumes of ultra-pure water compared to plastic substrates. Implementing closed-loop water recycling systems in manufacturing facilities has demonstrated significant reductions in water footprint across substrate types.

Energy efficiency during device operation represents another important environmental consideration. IGZO thin films on glass substrates generally demonstrate longer operational lifespans, reducing replacement frequency and associated waste. Conversely, IGZO on flexible substrates enables new device architectures that can potentially reduce overall material consumption through multifunctional designs.

Carbon footprint analyses reveal that transportation impacts differ substantially between substrate materials. The lighter weight of plastic substrates reduces transportation emissions compared to glass or metal alternatives, though this advantage must be balanced against their shorter functional lifespan in many applications.

Plastic substrates present a different environmental profile. While they enable flexible displays with lower energy requirements during production, most plastic substrates are petroleum-based and contribute to plastic pollution. The biodegradability challenges of these materials raise concerns about end-of-life management, though recent advances in bio-based polymers show promise for reducing this impact.

Metal substrates, particularly aluminum and stainless steel, offer superior recyclability compared to other options. However, the mining and refining processes for these metals generate significant environmental burdens, including habitat destruction and water pollution. The energy intensity of metal production must be factored into lifecycle assessments of IGZO displays using these substrates.

The scarcity of indium presents a critical sustainability concern across all substrate types. As a rare element with limited global reserves, indium extraction involves environmentally damaging mining practices. Research into alternative materials such as zinc tin oxide (ZTO) shows potential for reducing dependence on scarce elements while maintaining comparable performance characteristics.

Water consumption during IGZO thin film deposition varies by substrate. Glass and metal substrates typically require more intensive cleaning processes, consuming larger volumes of ultra-pure water compared to plastic substrates. Implementing closed-loop water recycling systems in manufacturing facilities has demonstrated significant reductions in water footprint across substrate types.

Energy efficiency during device operation represents another important environmental consideration. IGZO thin films on glass substrates generally demonstrate longer operational lifespans, reducing replacement frequency and associated waste. Conversely, IGZO on flexible substrates enables new device architectures that can potentially reduce overall material consumption through multifunctional designs.

Carbon footprint analyses reveal that transportation impacts differ substantially between substrate materials. The lighter weight of plastic substrates reduces transportation emissions compared to glass or metal alternatives, though this advantage must be balanced against their shorter functional lifespan in many applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!