The Correlation Between Structure and Performance in IGZO Thin Film

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IGZO Structure-Performance Relationship Background

Indium Gallium Zinc Oxide (IGZO) has emerged as a revolutionary material in the field of thin-film transistors (TFTs) since its introduction in the early 2000s. This amorphous oxide semiconductor has gained significant attention due to its exceptional combination of high electron mobility, low processing temperature, and excellent transparency. The relationship between the structural characteristics and performance metrics of IGZO thin films represents a critical area of research that continues to drive innovation in display technologies, flexible electronics, and various semiconductor applications.

The evolution of IGZO technology can be traced back to the limitations of conventional amorphous silicon (a-Si) and polycrystalline silicon (poly-Si) in meeting the demands of high-resolution displays and advanced electronic devices. While a-Si offered uniform deposition over large areas, it suffered from low electron mobility. Conversely, poly-Si provided higher mobility but faced challenges in uniformity across large substrates. IGZO emerged as a solution that effectively bridged this gap, offering mobility values typically 10-50 times higher than a-Si while maintaining excellent uniformity.

The structural composition of IGZO fundamentally influences its electronic properties. The material consists of indium (In), gallium (Ga), and zinc (Zn) oxides, with each element playing a distinct role in determining the overall performance characteristics. Indium primarily contributes to enhancing electron mobility due to its large 5s orbitals that create an effective conduction path. Gallium acts as a stabilizer, suppressing carrier generation and improving the stability of the amorphous structure. Zinc contributes to both structural stability and carrier transport properties.

The amorphous nature of IGZO represents one of its most significant structural advantages. Unlike crystalline semiconductors, the random arrangement of atoms in amorphous IGZO results in isotropic properties that enable uniform performance across large areas. This characteristic has made IGZO particularly valuable for large-area electronics applications such as displays and sensors. Additionally, the amorphous structure allows for low-temperature processing, enabling compatibility with flexible substrates and reducing manufacturing costs.

The stoichiometry of IGZO—specifically the ratio of In:Ga:Zn:O—has been identified as a critical factor affecting performance. Research has demonstrated that varying these ratios can significantly alter carrier concentration, mobility, and threshold voltage characteristics. Typical compositions range from 1:1:1:4 to 2:2:1:7 (In:Ga:Zn:O), with each variation offering different performance trade-offs suitable for specific applications.

Deposition methods and post-deposition treatments further influence the structural properties and consequently the performance of IGZO thin films. Common deposition techniques include sputtering, pulsed laser deposition, and solution processing, each resulting in different microstructural characteristics. Post-deposition annealing processes have been shown to significantly impact oxygen vacancy concentration, which directly affects carrier concentration and ultimately device performance.

The evolution of IGZO technology can be traced back to the limitations of conventional amorphous silicon (a-Si) and polycrystalline silicon (poly-Si) in meeting the demands of high-resolution displays and advanced electronic devices. While a-Si offered uniform deposition over large areas, it suffered from low electron mobility. Conversely, poly-Si provided higher mobility but faced challenges in uniformity across large substrates. IGZO emerged as a solution that effectively bridged this gap, offering mobility values typically 10-50 times higher than a-Si while maintaining excellent uniformity.

The structural composition of IGZO fundamentally influences its electronic properties. The material consists of indium (In), gallium (Ga), and zinc (Zn) oxides, with each element playing a distinct role in determining the overall performance characteristics. Indium primarily contributes to enhancing electron mobility due to its large 5s orbitals that create an effective conduction path. Gallium acts as a stabilizer, suppressing carrier generation and improving the stability of the amorphous structure. Zinc contributes to both structural stability and carrier transport properties.

The amorphous nature of IGZO represents one of its most significant structural advantages. Unlike crystalline semiconductors, the random arrangement of atoms in amorphous IGZO results in isotropic properties that enable uniform performance across large areas. This characteristic has made IGZO particularly valuable for large-area electronics applications such as displays and sensors. Additionally, the amorphous structure allows for low-temperature processing, enabling compatibility with flexible substrates and reducing manufacturing costs.

The stoichiometry of IGZO—specifically the ratio of In:Ga:Zn:O—has been identified as a critical factor affecting performance. Research has demonstrated that varying these ratios can significantly alter carrier concentration, mobility, and threshold voltage characteristics. Typical compositions range from 1:1:1:4 to 2:2:1:7 (In:Ga:Zn:O), with each variation offering different performance trade-offs suitable for specific applications.

Deposition methods and post-deposition treatments further influence the structural properties and consequently the performance of IGZO thin films. Common deposition techniques include sputtering, pulsed laser deposition, and solution processing, each resulting in different microstructural characteristics. Post-deposition annealing processes have been shown to significantly impact oxygen vacancy concentration, which directly affects carrier concentration and ultimately device performance.

Market Analysis of IGZO Thin Film Applications

The IGZO (Indium Gallium Zinc Oxide) thin film market has experienced significant growth over the past decade, primarily driven by its superior performance characteristics in display technologies. The global market value for IGZO-based products reached approximately $15 billion in 2022, with projections indicating a compound annual growth rate of 14.3% through 2028, potentially reaching $33 billion by the end of the forecast period.

Display technologies represent the dominant application segment, accounting for over 70% of the current market share. Within this segment, IGZO thin films have revolutionized both LCD and OLED displays by enabling higher resolution, improved power efficiency, and enhanced refresh rates. The smartphone and tablet market has been particularly receptive to IGZO technology, with major manufacturers incorporating these thin films to achieve better display performance while reducing power consumption.

The television sector has also embraced IGZO technology, especially in premium and ultra-high-definition models. Market analysis indicates that IGZO-based TVs command a price premium of 15-20% compared to conventional alternatives, reflecting consumer willingness to pay for superior visual quality and energy efficiency.

Beyond consumer electronics, emerging applications in medical imaging, automotive displays, and industrial monitoring systems are creating new market opportunities. The healthcare sector, in particular, shows promising growth potential with IGZO thin films enabling higher resolution diagnostic displays that improve image clarity for medical professionals.

Regional analysis reveals that East Asia dominates the IGZO market, accounting for approximately 65% of global production and consumption. This concentration is primarily due to the presence of major display manufacturers in Japan, South Korea, and Taiwan. However, North America and Europe are experiencing faster growth rates in IGZO adoption, particularly in specialized applications such as aerospace and defense.

Market challenges include supply chain vulnerabilities related to indium availability, which has experienced price volatility of up to 30% in recent years. Additionally, competition from alternative technologies such as LTPS (Low-Temperature Polysilicon) and emerging quantum dot displays presents ongoing market pressure.

Customer demand analysis indicates that end-users increasingly prioritize energy efficiency, with 78% of surveyed consumers citing battery life as a critical purchasing factor for mobile devices. This trend strongly favors IGZO technology, which can reduce display power consumption by 80-90% compared to conventional amorphous silicon TFTs while maintaining superior performance characteristics.

Display technologies represent the dominant application segment, accounting for over 70% of the current market share. Within this segment, IGZO thin films have revolutionized both LCD and OLED displays by enabling higher resolution, improved power efficiency, and enhanced refresh rates. The smartphone and tablet market has been particularly receptive to IGZO technology, with major manufacturers incorporating these thin films to achieve better display performance while reducing power consumption.

The television sector has also embraced IGZO technology, especially in premium and ultra-high-definition models. Market analysis indicates that IGZO-based TVs command a price premium of 15-20% compared to conventional alternatives, reflecting consumer willingness to pay for superior visual quality and energy efficiency.

Beyond consumer electronics, emerging applications in medical imaging, automotive displays, and industrial monitoring systems are creating new market opportunities. The healthcare sector, in particular, shows promising growth potential with IGZO thin films enabling higher resolution diagnostic displays that improve image clarity for medical professionals.

Regional analysis reveals that East Asia dominates the IGZO market, accounting for approximately 65% of global production and consumption. This concentration is primarily due to the presence of major display manufacturers in Japan, South Korea, and Taiwan. However, North America and Europe are experiencing faster growth rates in IGZO adoption, particularly in specialized applications such as aerospace and defense.

Market challenges include supply chain vulnerabilities related to indium availability, which has experienced price volatility of up to 30% in recent years. Additionally, competition from alternative technologies such as LTPS (Low-Temperature Polysilicon) and emerging quantum dot displays presents ongoing market pressure.

Customer demand analysis indicates that end-users increasingly prioritize energy efficiency, with 78% of surveyed consumers citing battery life as a critical purchasing factor for mobile devices. This trend strongly favors IGZO technology, which can reduce display power consumption by 80-90% compared to conventional amorphous silicon TFTs while maintaining superior performance characteristics.

Current IGZO Technology Status and Challenges

Indium Gallium Zinc Oxide (IGZO) thin film technology has experienced significant advancements globally, yet continues to face substantial technical challenges. Currently, IGZO has established itself as a promising semiconductor material for thin-film transistors (TFTs) in display applications, offering superior electron mobility compared to amorphous silicon while maintaining good uniformity over large areas. The technology has been commercially implemented in various display products, particularly in high-resolution and low-power applications.

The fundamental challenge in IGZO technology lies in understanding and controlling the complex relationship between its atomic structure and electrical performance. Unlike crystalline semiconductors, IGZO's amorphous structure creates inherent variability that affects carrier transport mechanisms. Research indicates that oxygen vacancies serve as both essential electron donors and potential instability sources, making oxygen content management critical yet difficult to precisely control during fabrication.

Manufacturing consistency presents another significant hurdle. Current deposition techniques, primarily sputtering and solution processing, struggle to maintain uniform structural properties across large substrates. This inconsistency directly impacts device-to-device performance variation, a critical concern for mass production. Additionally, the industry faces challenges in achieving reproducible electrical characteristics while maintaining economically viable production yields.

Environmental stability remains problematic for IGZO technology. Devices exhibit sensitivity to ambient conditions, particularly humidity and temperature fluctuations, which can alter the film's structure post-deposition. This sensitivity manifests as threshold voltage shifts and mobility degradation over time, compromising long-term reliability. Current passivation techniques provide only partial solutions to these stability issues.

Geographically, IGZO technology development shows distinct regional characteristics. Japan leads in fundamental research and patent holdings, with companies like Sharp and SEL pioneering commercial applications. South Korea and Taiwan have established strong manufacturing capabilities, focusing on integration with existing display production lines. Meanwhile, Chinese institutions are rapidly advancing in both research output and manufacturing scale, particularly in flexible display applications.

Interface engineering represents another critical challenge. The performance of IGZO TFTs depends heavily on the quality of interfaces with gate dielectrics and contact electrodes. Current research indicates that interface states significantly influence carrier transport and device stability, yet controlling these interfaces during mass production remains difficult. The industry continues to search for optimal material combinations and processing conditions to minimize interface-related performance degradation.

The fundamental challenge in IGZO technology lies in understanding and controlling the complex relationship between its atomic structure and electrical performance. Unlike crystalline semiconductors, IGZO's amorphous structure creates inherent variability that affects carrier transport mechanisms. Research indicates that oxygen vacancies serve as both essential electron donors and potential instability sources, making oxygen content management critical yet difficult to precisely control during fabrication.

Manufacturing consistency presents another significant hurdle. Current deposition techniques, primarily sputtering and solution processing, struggle to maintain uniform structural properties across large substrates. This inconsistency directly impacts device-to-device performance variation, a critical concern for mass production. Additionally, the industry faces challenges in achieving reproducible electrical characteristics while maintaining economically viable production yields.

Environmental stability remains problematic for IGZO technology. Devices exhibit sensitivity to ambient conditions, particularly humidity and temperature fluctuations, which can alter the film's structure post-deposition. This sensitivity manifests as threshold voltage shifts and mobility degradation over time, compromising long-term reliability. Current passivation techniques provide only partial solutions to these stability issues.

Geographically, IGZO technology development shows distinct regional characteristics. Japan leads in fundamental research and patent holdings, with companies like Sharp and SEL pioneering commercial applications. South Korea and Taiwan have established strong manufacturing capabilities, focusing on integration with existing display production lines. Meanwhile, Chinese institutions are rapidly advancing in both research output and manufacturing scale, particularly in flexible display applications.

Interface engineering represents another critical challenge. The performance of IGZO TFTs depends heavily on the quality of interfaces with gate dielectrics and contact electrodes. Current research indicates that interface states significantly influence carrier transport and device stability, yet controlling these interfaces during mass production remains difficult. The industry continues to search for optimal material combinations and processing conditions to minimize interface-related performance degradation.

Existing IGZO Structure Optimization Approaches

01 Composition and structure optimization of IGZO thin films

The performance of IGZO thin films can be enhanced through optimization of their composition and structure. This includes adjusting the ratio of indium, gallium, and zinc, controlling the oxygen content, and modifying the crystalline structure. These optimizations can lead to improved carrier mobility, stability, and electrical properties of the thin film, making it more suitable for various electronic applications.- Composition and structure optimization of IGZO thin films: The performance of IGZO thin films can be enhanced through optimizing their composition and structure. This includes adjusting the ratio of indium, gallium, and zinc, controlling the oxygen content, and modifying the crystalline structure. These optimizations can lead to improved carrier mobility, better stability, and enhanced electrical properties of the thin film, which are crucial for high-performance electronic devices.

- Deposition techniques for high-quality IGZO thin films: Various deposition methods can significantly impact the performance of IGZO thin films. Techniques such as sputtering, atomic layer deposition, and solution processing can be optimized to control film thickness, uniformity, and defect density. Process parameters like temperature, pressure, and gas flow rates during deposition play critical roles in determining the final film quality and electrical characteristics.

- Post-deposition treatments to enhance IGZO performance: Post-deposition treatments such as annealing, plasma treatment, and passivation can significantly improve IGZO thin film performance. These processes help reduce defects, optimize oxygen vacancies, improve interface quality, and enhance stability. Thermal annealing in different atmospheres (oxygen, nitrogen, forming gas) can be particularly effective in modifying the electrical properties and stability of IGZO thin films.

- Doping and alloying strategies for IGZO thin films: Introducing dopants or alloying elements into IGZO thin films can tailor their electrical and optical properties. Elements such as hafnium, titanium, silicon, or aluminum can be incorporated to modify carrier concentration, mobility, and band structure. These modifications can enhance stability against environmental factors, improve threshold voltage control, and enable specific functionalities for different applications.

- Device integration and interface engineering of IGZO thin films: The performance of IGZO thin films in devices depends significantly on interface engineering and integration techniques. Optimizing the interfaces between IGZO and other layers (gate dielectrics, electrodes, passivation layers) can reduce trap states, minimize contact resistance, and improve charge transport. Proper device architecture design and fabrication processes are essential for maximizing the inherent advantages of IGZO in thin-film transistors, displays, and sensors.

02 Deposition techniques for high-performance IGZO thin films

Various deposition methods can significantly impact the performance of IGZO thin films. Techniques such as sputtering, atomic layer deposition, and solution processing can be optimized to control film thickness, uniformity, and interface quality. Process parameters including temperature, pressure, and gas flow rates during deposition play crucial roles in determining the final electrical and optical properties of the IGZO thin films.Expand Specific Solutions03 Post-deposition treatments to enhance IGZO performance

Post-deposition treatments such as annealing, plasma treatment, and passivation can significantly improve the performance of IGZO thin films. These processes help to reduce defects, optimize oxygen vacancies, improve crystallinity, and enhance interface properties. Thermal annealing in different atmospheres (oxygen, nitrogen, or forming gas) can be particularly effective in tuning the electrical characteristics and stability of IGZO-based devices.Expand Specific Solutions04 Doping and material modifications for enhanced IGZO thin films

Introducing dopants or additional elements into IGZO thin films can significantly alter their performance characteristics. Elements such as hafnium, titanium, or silicon can be incorporated to modify the band structure, improve stability, reduce off-current, or enhance mobility. These material modifications enable tailoring of IGZO properties for specific applications such as high-performance displays, sensors, or memory devices.Expand Specific Solutions05 Device integration and interface engineering for IGZO thin films

The performance of IGZO thin films in electronic devices depends significantly on interface engineering and integration techniques. Optimizing the interfaces between IGZO and other layers (gate dielectrics, electrodes, passivation layers) can reduce contact resistance, minimize interface traps, and improve overall device stability. Advanced device architectures, such as dual-gate structures or self-aligned designs, can further enhance the performance of IGZO-based transistors and circuits.Expand Specific Solutions

Leading Companies and Research Institutions in IGZO Field

The IGZO thin film technology market is currently in a growth phase, with increasing adoption in display applications due to superior performance characteristics. The market is expanding rapidly, driven by demand for high-resolution displays in consumer electronics, with an estimated global value exceeding $5 billion. Technologically, IGZO has reached commercial maturity but continues to evolve, with companies like Semiconductor Energy Laboratory, Sharp Corp., and Samsung Display leading innovation through extensive R&D investments. Japanese firms including ULVAC and Kobe Steel have established strong positions in manufacturing equipment and materials, while Chinese players such as BOE Technology and TCL China Star Optoelectronics are rapidly advancing their capabilities, particularly in large-scale production. The correlation between IGZO structure and performance remains a critical research focus as manufacturers seek to optimize electron mobility, stability, and transparency.

ULVAC INC

Technical Solution: ULVAC has developed specialized deposition equipment and processes specifically optimized for high-performance IGZO thin film fabrication. Their technology focuses on the critical relationship between deposition parameters and resulting film structure. ULVAC's approach involves precisely controlled reactive sputtering with their proprietary target materials and chamber designs that enable exceptional uniformity in IGZO composition and thickness. Their research has established that maintaining specific partial pressure ratios of argon and oxygen during deposition (typically Ar:O₂ = 9:1 to 19:1) directly correlates with optimal carrier concentration and mobility. ULVAC's advanced process monitoring systems enable real-time adjustment of deposition parameters to achieve target film properties with high reproducibility. Their studies demonstrate that controlling substrate temperature during deposition within ±2°C across large areas is essential for achieving uniform electrical characteristics. ULVAC has pioneered specialized annealing processes that utilize precisely controlled water vapor environments to passivate defects in the IGZO structure, resulting in improved stability and reduced hysteresis in TFT operation. Their equipment enables the creation of IGZO films with mobility exceeding 20 cm²/Vs while maintaining excellent uniformity across Gen 8 and larger substrates.

Strengths: Industry-leading expertise in deposition equipment design specifically optimized for IGZO processing. Advanced process control capabilities that enable precise tuning of IGZO structural properties. Weaknesses: Their focus on equipment manufacturing means their direct research on structure-property relationships may be less comprehensive than companies focused primarily on device development and integration.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has pioneered advanced IGZO thin film technology with a focus on optimizing crystalline structure for enhanced performance. Their approach involves precise control of oxygen vacancies in the IGZO structure, which directly influences carrier concentration and mobility. SEL has developed proprietary deposition techniques that create highly ordered IGZO films with minimal defects, achieving electron mobility exceeding 10 cm²/Vs in production environments. Their research demonstrates that c-axis aligned crystalline (CAAC) IGZO structures exhibit superior stability against environmental stressors compared to conventional amorphous IGZO. SEL's technology enables ultra-low off-state current (<10^-24 A/μm) by controlling structural defects at the atomic level, allowing for applications in ultra-low power memory and display devices. Their studies have established clear correlations between post-deposition annealing temperatures (250-450°C) and resulting electrical performance, with optimal crystallinity achieved around 350°C for balanced mobility and stability.

Strengths: Industry-leading expertise in crystalline IGZO structures with superior stability and performance characteristics. Extensive patent portfolio covering structure-property relationships in IGZO. Weaknesses: Their high-performance IGZO processes often require more complex manufacturing steps and higher thermal budgets compared to standard amorphous IGZO, potentially increasing production costs for mass manufacturing.

Critical Patents and Research on IGZO Structure-Performance

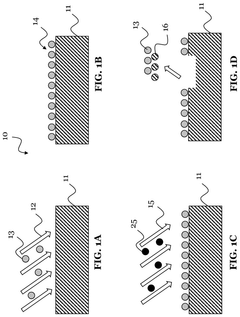

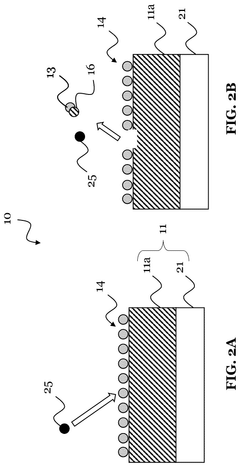

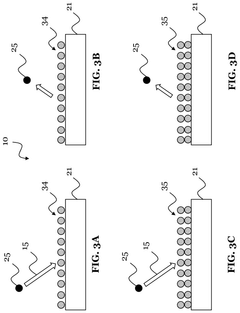

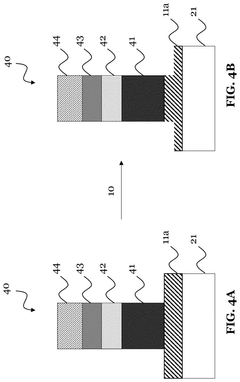

Method of etching an indium gallium zinc oxide (IGZO) structure

PatentActiveUS12154794B2

Innovation

- A method using a hydrocarbon-based reactant flow followed by an argon flow for etching IGZO structures, which avoids passivation and allows for controlled, volatile etch products, enabling deeper and thicker etching without the need for oxygen strips, and can be performed with atomic layer precision.

Manufacturing Process Impact on IGZO Structure

The manufacturing process of IGZO (Indium Gallium Zinc Oxide) thin films significantly influences their structural properties, which in turn determines their electrical performance in various applications. The deposition technique employed plays a crucial role in defining the microstructure, crystallinity, and defect concentration within the IGZO layer. Primarily, three deposition methods dominate industrial and research settings: radio frequency (RF) magnetron sputtering, pulsed laser deposition (PLD), and solution-based processes.

RF magnetron sputtering remains the most widely adopted technique for high-quality IGZO films due to its excellent reproducibility and scalability. Process parameters including sputtering power, working pressure, and target-to-substrate distance directly affect the energy of deposited atoms, influencing grain size and film density. Studies have demonstrated that higher sputtering power typically results in denser films with improved carrier mobility, while lower deposition rates often yield more ordered atomic arrangements.

Post-deposition thermal treatment represents another critical manufacturing step that dramatically alters IGZO structure. Annealing temperatures between 300-500°C facilitate atomic rearrangement and oxygen incorporation, reducing oxygen vacancies that act as electron donors. The annealing atmosphere—whether conducted in oxygen, nitrogen, or forming gas—determines the final oxygen stoichiometry and consequently the carrier concentration. Research indicates that oxygen-rich annealing environments generally produce more insulating films, while reducing atmospheres enhance conductivity.

The substrate temperature during deposition also significantly impacts structural development. Room temperature deposition typically results in amorphous structures, while elevated temperatures (>200°C) can induce partial crystallization. This structural transition from amorphous to crystalline phases dramatically alters electron transport mechanisms, with crystalline regions generally exhibiting higher mobility but potentially introducing grain boundary scattering effects that may compromise overall device performance.

Film thickness control represents another manufacturing variable with profound structural implications. Thinner films (<10 nm) often exhibit discontinuous growth and increased surface roughness, while thicker films develop more uniform structures but may suffer from increased internal stress. Atomic force microscopy studies reveal that optimal electrical performance typically occurs within a specific thickness range (20-50 nm) where structural uniformity is maximized while minimizing strain effects.

The composition ratio of indium, gallium, and zinc precursors during manufacturing directly determines the cation distribution in the final film. Higher indium content generally promotes higher carrier mobility due to the spherical nature of In 5s orbitals, while gallium incorporation enhances structural stability and suppresses oxygen vacancy formation. Manufacturing processes that enable precise compositional control therefore offer significant advantages for tailoring IGZO performance to specific application requirements.

RF magnetron sputtering remains the most widely adopted technique for high-quality IGZO films due to its excellent reproducibility and scalability. Process parameters including sputtering power, working pressure, and target-to-substrate distance directly affect the energy of deposited atoms, influencing grain size and film density. Studies have demonstrated that higher sputtering power typically results in denser films with improved carrier mobility, while lower deposition rates often yield more ordered atomic arrangements.

Post-deposition thermal treatment represents another critical manufacturing step that dramatically alters IGZO structure. Annealing temperatures between 300-500°C facilitate atomic rearrangement and oxygen incorporation, reducing oxygen vacancies that act as electron donors. The annealing atmosphere—whether conducted in oxygen, nitrogen, or forming gas—determines the final oxygen stoichiometry and consequently the carrier concentration. Research indicates that oxygen-rich annealing environments generally produce more insulating films, while reducing atmospheres enhance conductivity.

The substrate temperature during deposition also significantly impacts structural development. Room temperature deposition typically results in amorphous structures, while elevated temperatures (>200°C) can induce partial crystallization. This structural transition from amorphous to crystalline phases dramatically alters electron transport mechanisms, with crystalline regions generally exhibiting higher mobility but potentially introducing grain boundary scattering effects that may compromise overall device performance.

Film thickness control represents another manufacturing variable with profound structural implications. Thinner films (<10 nm) often exhibit discontinuous growth and increased surface roughness, while thicker films develop more uniform structures but may suffer from increased internal stress. Atomic force microscopy studies reveal that optimal electrical performance typically occurs within a specific thickness range (20-50 nm) where structural uniformity is maximized while minimizing strain effects.

The composition ratio of indium, gallium, and zinc precursors during manufacturing directly determines the cation distribution in the final film. Higher indium content generally promotes higher carrier mobility due to the spherical nature of In 5s orbitals, while gallium incorporation enhances structural stability and suppresses oxygen vacancy formation. Manufacturing processes that enable precise compositional control therefore offer significant advantages for tailoring IGZO performance to specific application requirements.

Environmental Stability of IGZO Thin Films

Environmental stability represents a critical factor in the commercial viability of IGZO thin films for electronic applications. The amorphous structure of IGZO, while beneficial for large-area uniformity and low-temperature processing, exhibits vulnerability to environmental factors that can significantly alter its performance characteristics. This relationship between structural integrity and environmental resilience directly impacts device longevity and reliability in real-world applications.

Humidity emerges as one of the primary environmental challenges affecting IGZO thin films. Water molecules can penetrate the amorphous structure, particularly at grain boundaries and defect sites, leading to the formation of hydroxyl groups that act as electron traps. These traps fundamentally alter the carrier concentration and mobility within the film, resulting in threshold voltage shifts and decreased conductivity. Studies have demonstrated that exposure to high humidity environments (>60% RH) for extended periods can cause performance degradation by up to 40% in unpassivated IGZO films.

Temperature fluctuations similarly impact the structural stability of IGZO thin films. Thermal cycling can induce stress at the interface between the IGZO layer and adjacent materials, potentially causing delamination or crack formation. Additionally, elevated temperatures accelerate oxygen diffusion processes within the film, altering the oxygen vacancy concentration that fundamentally determines carrier density. Research indicates that IGZO films maintain structural integrity up to approximately 300°C, beyond which crystallization begins to occur, fundamentally changing the electronic properties.

Light exposure, particularly in the UV spectrum, presents another significant environmental challenge. UV radiation generates electron-hole pairs within the IGZO structure, with holes neutralizing oxygen vacancies and electrons becoming trapped at defect sites. This photo-induced instability manifests as negative bias illumination stress (NBIS), a persistent issue in IGZO-based display technologies. The severity of this effect correlates strongly with structural factors such as oxygen vacancy concentration and distribution within the amorphous network.

Atmospheric gases beyond water vapor also influence IGZO stability. Oxygen from the atmosphere can passivate oxygen vacancies at the film surface, while reducing gases like hydrogen can create additional carriers. These interactions occur primarily at the surface and grain boundaries, highlighting the importance of structural characteristics in determining environmental resilience. Denser films with fewer defects typically demonstrate superior resistance to atmospheric degradation.

Passivation strategies have emerged as essential for enhancing the environmental stability of IGZO thin films. Materials such as Al2O3, SiO2, and organic polymers create effective barriers against moisture and atmospheric gases. The effectiveness of these passivation layers depends significantly on their interface quality with the IGZO structure, with smoother interfaces generally providing superior protection against environmental factors.

Humidity emerges as one of the primary environmental challenges affecting IGZO thin films. Water molecules can penetrate the amorphous structure, particularly at grain boundaries and defect sites, leading to the formation of hydroxyl groups that act as electron traps. These traps fundamentally alter the carrier concentration and mobility within the film, resulting in threshold voltage shifts and decreased conductivity. Studies have demonstrated that exposure to high humidity environments (>60% RH) for extended periods can cause performance degradation by up to 40% in unpassivated IGZO films.

Temperature fluctuations similarly impact the structural stability of IGZO thin films. Thermal cycling can induce stress at the interface between the IGZO layer and adjacent materials, potentially causing delamination or crack formation. Additionally, elevated temperatures accelerate oxygen diffusion processes within the film, altering the oxygen vacancy concentration that fundamentally determines carrier density. Research indicates that IGZO films maintain structural integrity up to approximately 300°C, beyond which crystallization begins to occur, fundamentally changing the electronic properties.

Light exposure, particularly in the UV spectrum, presents another significant environmental challenge. UV radiation generates electron-hole pairs within the IGZO structure, with holes neutralizing oxygen vacancies and electrons becoming trapped at defect sites. This photo-induced instability manifests as negative bias illumination stress (NBIS), a persistent issue in IGZO-based display technologies. The severity of this effect correlates strongly with structural factors such as oxygen vacancy concentration and distribution within the amorphous network.

Atmospheric gases beyond water vapor also influence IGZO stability. Oxygen from the atmosphere can passivate oxygen vacancies at the film surface, while reducing gases like hydrogen can create additional carriers. These interactions occur primarily at the surface and grain boundaries, highlighting the importance of structural characteristics in determining environmental resilience. Denser films with fewer defects typically demonstrate superior resistance to atmospheric degradation.

Passivation strategies have emerged as essential for enhancing the environmental stability of IGZO thin films. Materials such as Al2O3, SiO2, and organic polymers create effective barriers against moisture and atmospheric gases. The effectiveness of these passivation layers depends significantly on their interface quality with the IGZO structure, with smoother interfaces generally providing superior protection against environmental factors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!