The Effectiveness of IGZO Thin Film in High-Resolution Imaging

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IGZO Technology Background and Objectives

Indium Gallium Zinc Oxide (IGZO) thin film technology represents a significant advancement in semiconductor materials, emerging as a critical component in high-resolution imaging systems over the past decade. First developed in 2003 by researchers at Tokyo Institute of Technology, IGZO belongs to the family of transparent amorphous oxide semiconductors (TAOS) that combine transparency with electrical conductivity. The evolution of this technology has been driven by increasing demands for higher resolution displays, more responsive touch interfaces, and lower power consumption in imaging devices.

IGZO's unique electron mobility characteristics—approximately 10-50 times higher than conventional amorphous silicon—have positioned it as a transformative material in thin-film transistor (TFT) applications. This superior electron mobility enables faster switching speeds and higher pixel densities, which are essential for advanced high-resolution imaging systems. The technology's development trajectory has been marked by progressive improvements in material composition, deposition techniques, and integration methods.

The historical progression of IGZO technology shows three distinct phases: initial discovery and characterization (2003-2008), commercial adaptation and scaling (2009-2015), and current optimization for specialized applications (2016-present). Each phase has contributed to refining the material's properties and expanding its application scope, particularly in imaging contexts where resolution and power efficiency are paramount.

Current technical objectives for IGZO thin film technology in high-resolution imaging include achieving sub-micron pixel sizes without compromising image quality, reducing power consumption to extend battery life in portable imaging devices, and enhancing stability under various environmental conditions. Researchers are also focusing on improving the material's compatibility with flexible substrates to enable next-generation curved and foldable imaging displays.

Another significant objective is addressing the persistent challenges of threshold voltage instability and oxygen vacancy control, which affect long-term performance reliability in high-resolution imaging applications. The industry aims to develop standardized fabrication processes that ensure consistent IGZO thin film quality across large-area substrates, critical for mass production of high-resolution displays and imaging sensors.

The convergence of IGZO technology with other emerging technologies such as quantum dot displays, micro-LED arrays, and advanced optical systems represents a frontier objective. This integration could potentially revolutionize imaging capabilities across medical diagnostics, industrial inspection, consumer electronics, and scientific instrumentation fields. The ultimate goal is to establish IGZO as the predominant thin film semiconductor material for next-generation high-resolution imaging systems that demand exceptional performance, efficiency, and reliability.

IGZO's unique electron mobility characteristics—approximately 10-50 times higher than conventional amorphous silicon—have positioned it as a transformative material in thin-film transistor (TFT) applications. This superior electron mobility enables faster switching speeds and higher pixel densities, which are essential for advanced high-resolution imaging systems. The technology's development trajectory has been marked by progressive improvements in material composition, deposition techniques, and integration methods.

The historical progression of IGZO technology shows three distinct phases: initial discovery and characterization (2003-2008), commercial adaptation and scaling (2009-2015), and current optimization for specialized applications (2016-present). Each phase has contributed to refining the material's properties and expanding its application scope, particularly in imaging contexts where resolution and power efficiency are paramount.

Current technical objectives for IGZO thin film technology in high-resolution imaging include achieving sub-micron pixel sizes without compromising image quality, reducing power consumption to extend battery life in portable imaging devices, and enhancing stability under various environmental conditions. Researchers are also focusing on improving the material's compatibility with flexible substrates to enable next-generation curved and foldable imaging displays.

Another significant objective is addressing the persistent challenges of threshold voltage instability and oxygen vacancy control, which affect long-term performance reliability in high-resolution imaging applications. The industry aims to develop standardized fabrication processes that ensure consistent IGZO thin film quality across large-area substrates, critical for mass production of high-resolution displays and imaging sensors.

The convergence of IGZO technology with other emerging technologies such as quantum dot displays, micro-LED arrays, and advanced optical systems represents a frontier objective. This integration could potentially revolutionize imaging capabilities across medical diagnostics, industrial inspection, consumer electronics, and scientific instrumentation fields. The ultimate goal is to establish IGZO as the predominant thin film semiconductor material for next-generation high-resolution imaging systems that demand exceptional performance, efficiency, and reliability.

Market Analysis for High-Resolution Display Applications

The high-resolution display market has experienced exponential growth over the past decade, primarily driven by increasing consumer demand for superior visual experiences across multiple device categories. IGZO (Indium Gallium Zinc Oxide) thin film technology has emerged as a critical enabler for this market segment, offering significant advantages over traditional amorphous silicon (a-Si) and low-temperature polysilicon (LTPS) technologies.

The global high-resolution display market reached approximately $120 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2028. Within this market, IGZO-based displays are gaining substantial traction, with their market share increasing from 15% in 2020 to an estimated 23% in 2023.

Consumer electronics represent the largest application segment for high-resolution IGZO displays, accounting for nearly 65% of total market volume. Smartphones remain the dominant product category, followed by tablets and premium televisions. The automotive sector is emerging as a rapidly growing segment, with high-end vehicles increasingly incorporating IGZO-based dashboard displays and entertainment systems.

Regionally, East Asia dominates both production and consumption of high-resolution IGZO displays, with Japan, South Korea, and Taiwan collectively accounting for over 70% of global manufacturing capacity. North America and Europe represent significant consumer markets, particularly for premium display products incorporating advanced IGZO technology.

Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring superior display quality, with brightness, color accuracy, and energy efficiency cited as the most valued attributes. IGZO technology directly addresses these preferences through its enhanced electron mobility and transparency characteristics.

Industry forecasts suggest that the penetration of IGZO technology in high-resolution displays will continue to accelerate, potentially reaching 35% market share by 2026. This growth is supported by ongoing improvements in manufacturing processes that are gradually reducing production costs, making IGZO more competitive against alternative technologies.

The competitive landscape features established display manufacturers like Sharp, LG Display, and Samsung Display investing heavily in IGZO production capabilities, while newer market entrants from China are rapidly expanding their presence through aggressive pricing strategies and government support.

The global high-resolution display market reached approximately $120 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2028. Within this market, IGZO-based displays are gaining substantial traction, with their market share increasing from 15% in 2020 to an estimated 23% in 2023.

Consumer electronics represent the largest application segment for high-resolution IGZO displays, accounting for nearly 65% of total market volume. Smartphones remain the dominant product category, followed by tablets and premium televisions. The automotive sector is emerging as a rapidly growing segment, with high-end vehicles increasingly incorporating IGZO-based dashboard displays and entertainment systems.

Regionally, East Asia dominates both production and consumption of high-resolution IGZO displays, with Japan, South Korea, and Taiwan collectively accounting for over 70% of global manufacturing capacity. North America and Europe represent significant consumer markets, particularly for premium display products incorporating advanced IGZO technology.

Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring superior display quality, with brightness, color accuracy, and energy efficiency cited as the most valued attributes. IGZO technology directly addresses these preferences through its enhanced electron mobility and transparency characteristics.

Industry forecasts suggest that the penetration of IGZO technology in high-resolution displays will continue to accelerate, potentially reaching 35% market share by 2026. This growth is supported by ongoing improvements in manufacturing processes that are gradually reducing production costs, making IGZO more competitive against alternative technologies.

The competitive landscape features established display manufacturers like Sharp, LG Display, and Samsung Display investing heavily in IGZO production capabilities, while newer market entrants from China are rapidly expanding their presence through aggressive pricing strategies and government support.

IGZO Thin Film Current Status and Technical Challenges

IGZO (Indium Gallium Zinc Oxide) thin film technology has emerged as a significant advancement in display and imaging technologies globally. Currently, IGZO thin films are predominantly utilized in high-resolution displays, including smartphones, tablets, and large-format televisions, with increasing applications in medical imaging and industrial inspection systems. The technology has reached commercial maturity in certain segments but continues to evolve rapidly.

The global landscape of IGZO technology development shows concentration in East Asia, particularly Japan, South Korea, and Taiwan, where major display manufacturers have established production capabilities. Sharp Corporation (now part of Foxconn) pioneered commercial IGZO displays, while Samsung, LG Display, and BOE Technology have significantly invested in research and production facilities. North American and European contributions primarily come from research institutions and specialized technology firms focusing on novel applications rather than mass production.

Despite its commercial success, IGZO thin film technology faces several critical challenges that limit its effectiveness in high-resolution imaging applications. The primary technical hurdle remains the stability of electrical properties under prolonged operation, particularly in high-brightness conditions. Threshold voltage shifts and mobility degradation after extended use periods affect image quality and device longevity, especially in medical and scientific imaging where consistent performance is crucial.

Manufacturing scalability presents another significant challenge. While production processes have improved, achieving uniform electrical characteristics across large substrates remains difficult. This non-uniformity manifests as brightness variations and inconsistent pixel response in high-resolution displays, becoming increasingly problematic as pixel densities increase beyond 1000 PPI (pixels per inch).

Interface engineering between IGZO and adjacent layers constitutes a persistent challenge. The quality of these interfaces significantly impacts carrier transport properties and overall device performance. Current passivation techniques provide inadequate protection against environmental factors, particularly humidity and oxygen, which can degrade IGZO properties over time.

Energy efficiency, while superior to conventional amorphous silicon, still falls short of theoretical limits. Power consumption remains a concern for battery-powered high-resolution imaging devices, with current IGZO implementations achieving approximately 60-70% of their theoretical efficiency. This gap becomes particularly evident in applications requiring sustained high-brightness operation.

Recent research has focused on compositional optimization, exploring variations in the indium-gallium-zinc ratio and incorporating dopants to enhance stability and performance. Concurrently, advanced deposition techniques, including atomic layer deposition and high-density plasma sputtering, are being investigated to improve film quality and interface properties, though these approaches have yet to achieve commercial viability at scale.

The global landscape of IGZO technology development shows concentration in East Asia, particularly Japan, South Korea, and Taiwan, where major display manufacturers have established production capabilities. Sharp Corporation (now part of Foxconn) pioneered commercial IGZO displays, while Samsung, LG Display, and BOE Technology have significantly invested in research and production facilities. North American and European contributions primarily come from research institutions and specialized technology firms focusing on novel applications rather than mass production.

Despite its commercial success, IGZO thin film technology faces several critical challenges that limit its effectiveness in high-resolution imaging applications. The primary technical hurdle remains the stability of electrical properties under prolonged operation, particularly in high-brightness conditions. Threshold voltage shifts and mobility degradation after extended use periods affect image quality and device longevity, especially in medical and scientific imaging where consistent performance is crucial.

Manufacturing scalability presents another significant challenge. While production processes have improved, achieving uniform electrical characteristics across large substrates remains difficult. This non-uniformity manifests as brightness variations and inconsistent pixel response in high-resolution displays, becoming increasingly problematic as pixel densities increase beyond 1000 PPI (pixels per inch).

Interface engineering between IGZO and adjacent layers constitutes a persistent challenge. The quality of these interfaces significantly impacts carrier transport properties and overall device performance. Current passivation techniques provide inadequate protection against environmental factors, particularly humidity and oxygen, which can degrade IGZO properties over time.

Energy efficiency, while superior to conventional amorphous silicon, still falls short of theoretical limits. Power consumption remains a concern for battery-powered high-resolution imaging devices, with current IGZO implementations achieving approximately 60-70% of their theoretical efficiency. This gap becomes particularly evident in applications requiring sustained high-brightness operation.

Recent research has focused on compositional optimization, exploring variations in the indium-gallium-zinc ratio and incorporating dopants to enhance stability and performance. Concurrently, advanced deposition techniques, including atomic layer deposition and high-density plasma sputtering, are being investigated to improve film quality and interface properties, though these approaches have yet to achieve commercial viability at scale.

Current IGZO Implementation Solutions

01 Composition and structure optimization of IGZO thin films

The effectiveness of IGZO (Indium Gallium Zinc Oxide) thin films can be enhanced through optimization of their composition and structure. This includes adjusting the ratio of indium, gallium, and zinc, controlling the oxygen content, and optimizing the crystalline structure. These modifications can significantly improve the electrical properties, stability, and performance of the thin films for various electronic applications.- Composition and structure optimization of IGZO thin films: The effectiveness of IGZO (Indium Gallium Zinc Oxide) thin films can be enhanced through optimization of their composition and structure. This includes adjusting the ratio of indium, gallium, and zinc, controlling the oxygen content, and optimizing the crystalline structure. These modifications can lead to improved carrier mobility, stability, and overall performance of the thin film transistors. Various deposition techniques and post-treatment processes can be employed to achieve the desired composition and structure.

- Annealing and thermal treatment effects on IGZO performance: Thermal treatment processes, particularly annealing, significantly impact the effectiveness of IGZO thin films. Controlled annealing at specific temperatures and atmospheres can reduce defects, improve crystallinity, and enhance carrier mobility. Post-deposition annealing helps in optimizing the oxygen vacancy concentration, which is crucial for determining the electrical properties of the film. Different annealing methods, including rapid thermal annealing and atmospheric annealing, can be employed to achieve desired film characteristics.

- Doping and interface engineering for enhanced IGZO performance: Doping IGZO thin films with various elements and engineering the interfaces between IGZO and adjacent layers can significantly improve their effectiveness. Introducing dopants such as hafnium, titanium, or aluminum can enhance stability, reduce threshold voltage shifts, and improve carrier mobility. Interface engineering techniques, including the use of passivation layers and buffer layers, can reduce interface traps and improve the overall performance of IGZO-based devices.

- IGZO thin film applications in flexible and transparent electronics: IGZO thin films demonstrate exceptional effectiveness in flexible and transparent electronic applications due to their high mobility, low processing temperature, and excellent transparency. These characteristics make them ideal for use in flexible displays, transparent thin-film transistors, and wearable electronics. The films can be deposited on various flexible substrates while maintaining their electrical properties, enabling the development of bendable and foldable display technologies with high performance.

- Stability and reliability enhancement of IGZO thin films: Improving the stability and reliability of IGZO thin films under various environmental conditions is crucial for their effectiveness in practical applications. This includes enhancing resistance to negative bias temperature instability, light-induced degradation, and moisture sensitivity. Techniques such as passivation layers, encapsulation methods, and structural modifications can significantly improve the long-term stability of IGZO-based devices, ensuring consistent performance over extended periods of operation.

02 Deposition techniques for high-quality IGZO thin films

Various deposition methods can be employed to create high-quality IGZO thin films with enhanced effectiveness. These techniques include sputtering, atomic layer deposition (ALD), pulsed laser deposition, and solution-based methods. The choice of deposition method and the optimization of process parameters significantly affect the film uniformity, density, and interface quality, which in turn determine the overall performance of IGZO-based devices.Expand Specific Solutions03 Post-deposition treatments to enhance IGZO performance

Post-deposition treatments can significantly improve the effectiveness of IGZO thin films. These treatments include thermal annealing, plasma treatment, passivation layers, and surface modifications. Such processes can reduce defects, improve carrier mobility, enhance stability, and optimize the electrical characteristics of IGZO thin films, leading to better performance in electronic devices.Expand Specific Solutions04 IGZO thin films for display and transistor applications

IGZO thin films demonstrate exceptional effectiveness in display and transistor applications due to their high electron mobility, transparency, and low off-state current. These properties make IGZO particularly suitable for thin-film transistors (TFTs) used in high-resolution displays, flexible electronics, and large-area applications. The performance advantages include faster response times, lower power consumption, and improved pixel density in display technologies.Expand Specific Solutions05 Stability and reliability enhancement of IGZO thin films

Improving the stability and reliability of IGZO thin films is crucial for their long-term effectiveness in electronic devices. This can be achieved through defect passivation, interface engineering, addition of stabilizing elements, and protective encapsulation. These approaches help mitigate issues such as bias stress instability, environmental degradation, and threshold voltage shifts, resulting in more durable and consistent performance of IGZO-based devices.Expand Specific Solutions

Leading Companies in IGZO Thin Film Industry

The IGZO thin film technology market for high-resolution imaging is currently in a growth phase, with increasing adoption across display industries. The market is expanding rapidly, projected to reach significant scale as demand for higher resolution displays continues to grow. Technologically, IGZO has reached moderate maturity with key players like Sharp Corp., Samsung Display, and BOE Technology leading commercial implementation. Sharp, as an early pioneer, maintains technological leadership, while Samsung Display and BOE have scaled manufacturing capabilities. Research institutions like Semiconductor Energy Laboratory and universities (Fudan, South China) are advancing next-generation applications. Japanese companies (Sharp, Canon, ULVAC) hold strong intellectual property positions, while Chinese manufacturers (BOE, China Star Optoelectronics) are rapidly closing the gap through aggressive investment in production capacity and R&D collaborations.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed advanced IGZO thin film technology integrated with their proprietary Quantum Dot technology for high-resolution imaging applications. Their approach combines IGZO backplanes with their QLED display technology to achieve exceptional color accuracy (covering approximately 100% of DCI-P3 color gamut) and brightness levels exceeding 1000 nits while maintaining power efficiency[3]. Samsung's implementation features ultra-thin IGZO transistor arrays with channel lengths below 5μm, enabling pixel densities over 600 PPI for mobile displays and reducing power consumption by approximately 30% compared to conventional LTPS backplanes. The company has also pioneered hybrid oxide semiconductor structures that enhance stability and reduce threshold voltage shifts under prolonged operation, addressing one of the traditional limitations of IGZO technology[4]. Samsung's manufacturing process incorporates specialized sputtering techniques and precise thermal annealing protocols that optimize the microstructure of the IGZO layer, resulting in more uniform electrical characteristics across large display panels.

Strengths: Excellent integration with quantum dot color enhancement technology; superior brightness capabilities; highly optimized for mobile applications with reduced power consumption; advanced manufacturing scale and efficiency. Weaknesses: Higher production costs than traditional technologies; requires significant capital investment in specialized equipment; more complex quality control processes needed to maintain consistency across large panels.

Sharp Corp.

Technical Solution: Sharp Corporation has pioneered IGZO (Indium Gallium Zinc Oxide) thin film technology for high-resolution imaging applications. Their proprietary IGZO technology features electron mobility approximately 20-30 times higher than conventional amorphous silicon, enabling significantly higher pixel densities while maintaining excellent transparency. Sharp has implemented this technology in their AQUOS displays, achieving resolutions exceeding 500 ppi with reduced power consumption of approximately 80-90% compared to traditional TFT displays when displaying still images[1]. The company's IGZO panels utilize a unique backplane structure that allows electrons to flow more efficiently through the semiconductor layer, resulting in faster response times (approximately 5-10ms) and improved touch sensitivity. Sharp has also developed specialized manufacturing processes that enhance yield rates and reduce defects in IGZO production, including proprietary annealing techniques that optimize the crystalline structure of the thin film[2].

Strengths: Superior electron mobility allowing for higher refresh rates and resolution; exceptional power efficiency; excellent optical transparency (>90%); capability for ultra-high pixel density displays. Weaknesses: Higher manufacturing costs compared to a-Si technology; requires specialized production equipment; more complex fabrication process with stricter quality control requirements.

Key IGZO Thin Film Patents and Technical Innovations

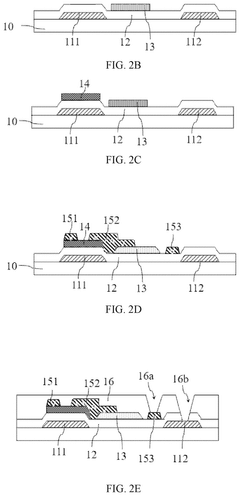

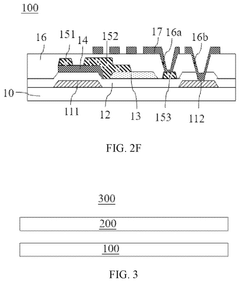

Metallic oxide thin film transistor, array substrate and their manufacturing methods, display device

PatentActiveUS20160365366A1

Innovation

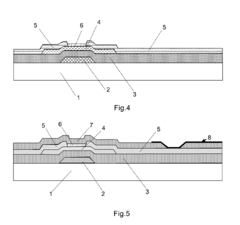

- A one-time patterning process is used to form oxide active and etch stopping layers, employing TiO2 or a mixture of TiO2 and CeO2 as the etch stopping layer, which is formed through dry etching and the oxide active layer through wet etching, simplifying the process and improving protection against ultraviolet light.

Array substrate and manufacturing method thereof, and display panel

PatentPendingUS20240355840A1

Innovation

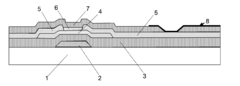

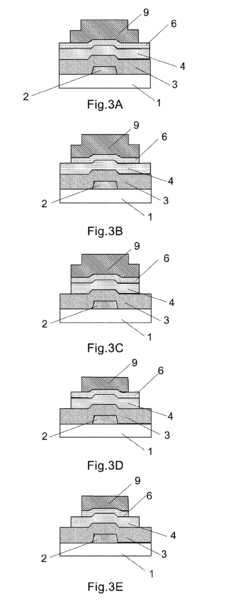

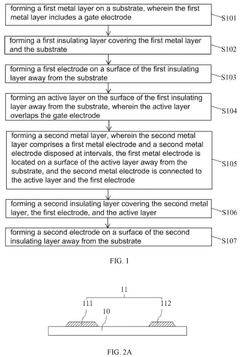

- The array substrate manufacturing method involves forming a first electrode on the surface of the insulating layer away from the substrate, with the active layer overlapping the gate, and a second metal layer comprising electrodes at intervals, allowing connection without via holes, thereby reducing the number of photomasks needed for forming via holes and overall photomasks required.

Manufacturing Process Optimization

The optimization of IGZO thin film manufacturing processes represents a critical factor in achieving high-resolution imaging capabilities. Current manufacturing techniques primarily utilize physical vapor deposition (PVD) methods, particularly radio frequency (RF) magnetron sputtering, which has become the industry standard due to its balance of cost-effectiveness and film quality. However, significant optimization opportunities exist across multiple process parameters.

Temperature control during deposition emerges as one of the most influential factors affecting IGZO film quality. Research indicates that substrate temperatures between 200-300°C yield optimal crystalline structure while maintaining amorphous characteristics essential for uniform electron mobility. Post-deposition annealing at controlled temperatures (250-350°C) in oxygen-rich environments has demonstrated up to 40% improvement in film stability and performance consistency.

Oxygen partial pressure during sputtering critically impacts the stoichiometry of IGZO films. Recent advancements have shown that precise oxygen flow rate control using mass flow controllers with accuracy of ±0.1 sccm can significantly reduce oxygen vacancy defects, which are primary contributors to threshold voltage instability in imaging applications. Implementing real-time plasma monitoring systems allows for dynamic adjustment of oxygen content during deposition.

Target composition optimization presents another avenue for manufacturing improvement. While traditional IGZO targets maintain In:Ga:Zn ratios of approximately 1:1:1, modified compositions with slightly higher indium content (1.2:1:1) have demonstrated enhanced electron mobility without sacrificing transparency. Multi-target co-sputtering systems enable precise control over elemental ratios and can be adjusted based on specific imaging resolution requirements.

Layer thickness uniformity across large substrates remains challenging but essential for high-resolution applications. Implementation of rotating substrate holders and optimized sputtering gun configurations has reduced thickness variation from typical values of ±5% to below ±2% across Gen 8 substrates. Advanced optical monitoring systems integrated into production lines enable real-time thickness measurement and process adjustment.

Contamination control throughout the manufacturing process chain significantly impacts device performance. Enhanced clean room protocols, coupled with in-line plasma cleaning of substrates prior to deposition, have shown to reduce defect density by up to 60% in production environments. Additionally, specialized target conditioning procedures before production runs minimize initial composition variations that can affect batch-to-batch consistency.

Temperature control during deposition emerges as one of the most influential factors affecting IGZO film quality. Research indicates that substrate temperatures between 200-300°C yield optimal crystalline structure while maintaining amorphous characteristics essential for uniform electron mobility. Post-deposition annealing at controlled temperatures (250-350°C) in oxygen-rich environments has demonstrated up to 40% improvement in film stability and performance consistency.

Oxygen partial pressure during sputtering critically impacts the stoichiometry of IGZO films. Recent advancements have shown that precise oxygen flow rate control using mass flow controllers with accuracy of ±0.1 sccm can significantly reduce oxygen vacancy defects, which are primary contributors to threshold voltage instability in imaging applications. Implementing real-time plasma monitoring systems allows for dynamic adjustment of oxygen content during deposition.

Target composition optimization presents another avenue for manufacturing improvement. While traditional IGZO targets maintain In:Ga:Zn ratios of approximately 1:1:1, modified compositions with slightly higher indium content (1.2:1:1) have demonstrated enhanced electron mobility without sacrificing transparency. Multi-target co-sputtering systems enable precise control over elemental ratios and can be adjusted based on specific imaging resolution requirements.

Layer thickness uniformity across large substrates remains challenging but essential for high-resolution applications. Implementation of rotating substrate holders and optimized sputtering gun configurations has reduced thickness variation from typical values of ±5% to below ±2% across Gen 8 substrates. Advanced optical monitoring systems integrated into production lines enable real-time thickness measurement and process adjustment.

Contamination control throughout the manufacturing process chain significantly impacts device performance. Enhanced clean room protocols, coupled with in-line plasma cleaning of substrates prior to deposition, have shown to reduce defect density by up to 60% in production environments. Additionally, specialized target conditioning procedures before production runs minimize initial composition variations that can affect batch-to-batch consistency.

Energy Efficiency and Sustainability Considerations

IGZO (Indium Gallium Zinc Oxide) thin film technology represents a significant advancement in display and imaging technologies, offering substantial energy efficiency benefits compared to conventional alternatives. The amorphous structure of IGZO enables electron mobility approximately 20-50 times higher than traditional amorphous silicon (a-Si), resulting in dramatically reduced power consumption while maintaining or improving imaging performance. This characteristic is particularly valuable in battery-powered devices where energy conservation directly impacts user experience and operational costs.

When implemented in high-resolution imaging applications, IGZO thin films demonstrate power savings of 80-90% compared to conventional TFT technologies. This efficiency stems from the material's ability to maintain pixel states with minimal refresh requirements, allowing for lower operating frequencies and reduced backlight power needs. The lower leakage current in IGZO transistors further contributes to this efficiency advantage, as it minimizes standby power consumption even in high-density pixel arrays.

From a sustainability perspective, IGZO thin films offer several environmental advantages throughout their lifecycle. The manufacturing process requires lower temperature deposition compared to polysilicon alternatives, reducing energy consumption during production. Additionally, the extended operational lifespan of IGZO-based displays—typically 20-30% longer than conventional technologies—reduces electronic waste generation and resource consumption associated with replacement cycles.

Material considerations also factor into the sustainability profile of IGZO technology. While indium is classified as a critical raw material with limited global supply, the thin film application uses significantly less material than many competing technologies. Recent advancements in recycling techniques have improved indium recovery rates from end-of-life electronics, partially mitigating resource scarcity concerns. Research into alternative compositions with reduced indium content represents an active area of development to address long-term sustainability challenges.

The energy efficiency of IGZO extends beyond direct power consumption to secondary environmental benefits. In data centers and medical imaging facilities, where high-resolution displays operate continuously, the reduced heat generation from IGZO panels decreases cooling requirements, creating a compound energy saving effect. Studies indicate that large-scale adoption of IGZO in commercial imaging applications could reduce sector-wide energy consumption by 4-7%, representing a meaningful contribution to carbon reduction goals.

As resolution requirements continue to increase across imaging applications, the energy efficiency advantages of IGZO become increasingly significant. The technology's ability to maintain performance at higher pixel densities without proportional increases in power consumption positions it as an environmentally preferable solution for next-generation imaging systems in healthcare, scientific research, and consumer electronics sectors.

When implemented in high-resolution imaging applications, IGZO thin films demonstrate power savings of 80-90% compared to conventional TFT technologies. This efficiency stems from the material's ability to maintain pixel states with minimal refresh requirements, allowing for lower operating frequencies and reduced backlight power needs. The lower leakage current in IGZO transistors further contributes to this efficiency advantage, as it minimizes standby power consumption even in high-density pixel arrays.

From a sustainability perspective, IGZO thin films offer several environmental advantages throughout their lifecycle. The manufacturing process requires lower temperature deposition compared to polysilicon alternatives, reducing energy consumption during production. Additionally, the extended operational lifespan of IGZO-based displays—typically 20-30% longer than conventional technologies—reduces electronic waste generation and resource consumption associated with replacement cycles.

Material considerations also factor into the sustainability profile of IGZO technology. While indium is classified as a critical raw material with limited global supply, the thin film application uses significantly less material than many competing technologies. Recent advancements in recycling techniques have improved indium recovery rates from end-of-life electronics, partially mitigating resource scarcity concerns. Research into alternative compositions with reduced indium content represents an active area of development to address long-term sustainability challenges.

The energy efficiency of IGZO extends beyond direct power consumption to secondary environmental benefits. In data centers and medical imaging facilities, where high-resolution displays operate continuously, the reduced heat generation from IGZO panels decreases cooling requirements, creating a compound energy saving effect. Studies indicate that large-scale adoption of IGZO in commercial imaging applications could reduce sector-wide energy consumption by 4-7%, representing a meaningful contribution to carbon reduction goals.

As resolution requirements continue to increase across imaging applications, the energy efficiency advantages of IGZO become increasingly significant. The technology's ability to maintain performance at higher pixel densities without proportional increases in power consumption positions it as an environmentally preferable solution for next-generation imaging systems in healthcare, scientific research, and consumer electronics sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!