The Role of IGZO Thin Film as a Catalyst in Chemical Sensors

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IGZO Thin Film Evolution and Sensing Objectives

Indium Gallium Zinc Oxide (IGZO) thin film technology has evolved significantly since its initial development in the early 2000s. Originally conceived as a semiconductor material for display technologies, IGZO has undergone substantial transformation in its composition, fabrication methods, and application domains. The evolution trajectory began with Hosono's groundbreaking research at Tokyo Institute of Technology, which demonstrated IGZO's unique combination of high electron mobility and optical transparency even in amorphous state.

The material's evolution has been characterized by progressive refinements in stoichiometric ratios, with the typical In:Ga:Zn:O ratio evolving from initial 1:1:1:4 configurations to more specialized compositions tailored for specific applications. Fabrication techniques have similarly advanced from basic sputtering methods to sophisticated atomic layer deposition (ALD) and solution-processing approaches, enabling precise control over film thickness down to nanometer scale with enhanced uniformity.

In the context of chemical sensing applications, IGZO thin films have demonstrated remarkable potential due to their unique electronic structure. The material features oxygen vacancies that serve as active sites for gas molecule adsorption, making it inherently sensitive to environmental changes. This characteristic has driven research toward leveraging IGZO not merely as a transducing element but as an active catalyst in chemical detection systems.

The primary sensing objectives for IGZO thin films in chemical detection encompass several dimensions. First, achieving enhanced selectivity toward specific target analytes while minimizing cross-sensitivity to interfering species remains a fundamental goal. Second, researchers aim to lower detection limits to sub-ppm or even ppb levels for critical applications in environmental monitoring and medical diagnostics. Third, improving response and recovery times is essential for real-time monitoring applications.

Another critical objective involves enhancing long-term stability and reliability under varying environmental conditions, particularly in high humidity or fluctuating temperature scenarios. The development of self-calibrating or self-recovering sensor architectures represents an ambitious goal to address drift issues that plague many existing chemical sensor technologies.

From an integration perspective, research efforts are focused on developing IGZO-based sensing platforms compatible with flexible substrates and low-power operation for incorporation into wearable devices and IoT networks. The ultimate vision encompasses creating multifunctional IGZO-based sensors capable of simultaneous detection of multiple analytes with minimal power consumption and form factor.

These evolutionary trends and objectives collectively frame the research landscape for IGZO thin films as catalytic elements in next-generation chemical sensing technologies, positioning this material at the intersection of materials science, electronics, and analytical chemistry.

The material's evolution has been characterized by progressive refinements in stoichiometric ratios, with the typical In:Ga:Zn:O ratio evolving from initial 1:1:1:4 configurations to more specialized compositions tailored for specific applications. Fabrication techniques have similarly advanced from basic sputtering methods to sophisticated atomic layer deposition (ALD) and solution-processing approaches, enabling precise control over film thickness down to nanometer scale with enhanced uniformity.

In the context of chemical sensing applications, IGZO thin films have demonstrated remarkable potential due to their unique electronic structure. The material features oxygen vacancies that serve as active sites for gas molecule adsorption, making it inherently sensitive to environmental changes. This characteristic has driven research toward leveraging IGZO not merely as a transducing element but as an active catalyst in chemical detection systems.

The primary sensing objectives for IGZO thin films in chemical detection encompass several dimensions. First, achieving enhanced selectivity toward specific target analytes while minimizing cross-sensitivity to interfering species remains a fundamental goal. Second, researchers aim to lower detection limits to sub-ppm or even ppb levels for critical applications in environmental monitoring and medical diagnostics. Third, improving response and recovery times is essential for real-time monitoring applications.

Another critical objective involves enhancing long-term stability and reliability under varying environmental conditions, particularly in high humidity or fluctuating temperature scenarios. The development of self-calibrating or self-recovering sensor architectures represents an ambitious goal to address drift issues that plague many existing chemical sensor technologies.

From an integration perspective, research efforts are focused on developing IGZO-based sensing platforms compatible with flexible substrates and low-power operation for incorporation into wearable devices and IoT networks. The ultimate vision encompasses creating multifunctional IGZO-based sensors capable of simultaneous detection of multiple analytes with minimal power consumption and form factor.

These evolutionary trends and objectives collectively frame the research landscape for IGZO thin films as catalytic elements in next-generation chemical sensing technologies, positioning this material at the intersection of materials science, electronics, and analytical chemistry.

Chemical Sensor Market Demand Analysis

The chemical sensor market has been experiencing robust growth, driven by increasing applications across various industries including healthcare, environmental monitoring, automotive, and industrial processes. The global chemical sensor market was valued at approximately 20 billion USD in 2020 and is projected to reach 32 billion USD by 2027, growing at a CAGR of around 7% during the forecast period. This growth trajectory underscores the expanding demand for advanced sensing technologies.

Within this broader market, gas sensors represent a significant segment, accounting for nearly 40% of the total chemical sensor market. The demand for gas sensors is particularly strong in environmental monitoring applications, where detection of harmful gases such as CO, CO2, NOx, and volatile organic compounds (VOCs) is critical for ensuring public safety and regulatory compliance.

IGZO (Indium Gallium Zinc Oxide) thin film-based chemical sensors are positioned at the intersection of two rapidly evolving markets: semiconductor materials and sensing technologies. The unique properties of IGZO, including high electron mobility, excellent stability, and low-temperature processability, make it an attractive material for next-generation chemical sensing applications.

Market research indicates a growing demand for chemical sensors with enhanced sensitivity, selectivity, and stability - attributes that IGZO thin films can potentially deliver. The healthcare sector, in particular, shows significant interest in IGZO-based sensors for breath analysis and disease diagnosis, with an estimated market potential of 3.5 billion USD by 2025.

Industrial applications represent another substantial market segment, where IGZO-based sensors could address the need for real-time monitoring of chemical processes and emissions. The industrial sensor market is expected to grow at 8.2% annually, creating opportunities for innovative sensing technologies.

Consumer electronics manufacturers are also exploring IGZO-based chemical sensors for integration into smartphones and wearable devices, potentially enabling personal environmental monitoring and health tracking functionalities. This segment is projected to be the fastest-growing application area, with an anticipated growth rate exceeding 12% annually.

Regionally, Asia-Pacific dominates the chemical sensor market, accounting for approximately 45% of global demand, followed by North America and Europe. China and Japan, in particular, are investing heavily in advanced sensing technologies, creating favorable conditions for the development and commercialization of IGZO-based chemical sensors.

The market demand analysis suggests that IGZO thin films as catalysts in chemical sensors could address several unmet needs in the current market, particularly in applications requiring high sensitivity, low power consumption, and compatibility with flexible substrates.

Within this broader market, gas sensors represent a significant segment, accounting for nearly 40% of the total chemical sensor market. The demand for gas sensors is particularly strong in environmental monitoring applications, where detection of harmful gases such as CO, CO2, NOx, and volatile organic compounds (VOCs) is critical for ensuring public safety and regulatory compliance.

IGZO (Indium Gallium Zinc Oxide) thin film-based chemical sensors are positioned at the intersection of two rapidly evolving markets: semiconductor materials and sensing technologies. The unique properties of IGZO, including high electron mobility, excellent stability, and low-temperature processability, make it an attractive material for next-generation chemical sensing applications.

Market research indicates a growing demand for chemical sensors with enhanced sensitivity, selectivity, and stability - attributes that IGZO thin films can potentially deliver. The healthcare sector, in particular, shows significant interest in IGZO-based sensors for breath analysis and disease diagnosis, with an estimated market potential of 3.5 billion USD by 2025.

Industrial applications represent another substantial market segment, where IGZO-based sensors could address the need for real-time monitoring of chemical processes and emissions. The industrial sensor market is expected to grow at 8.2% annually, creating opportunities for innovative sensing technologies.

Consumer electronics manufacturers are also exploring IGZO-based chemical sensors for integration into smartphones and wearable devices, potentially enabling personal environmental monitoring and health tracking functionalities. This segment is projected to be the fastest-growing application area, with an anticipated growth rate exceeding 12% annually.

Regionally, Asia-Pacific dominates the chemical sensor market, accounting for approximately 45% of global demand, followed by North America and Europe. China and Japan, in particular, are investing heavily in advanced sensing technologies, creating favorable conditions for the development and commercialization of IGZO-based chemical sensors.

The market demand analysis suggests that IGZO thin films as catalysts in chemical sensors could address several unmet needs in the current market, particularly in applications requiring high sensitivity, low power consumption, and compatibility with flexible substrates.

IGZO Catalyst Technology Status and Barriers

The global landscape of IGZO (Indium Gallium Zinc Oxide) thin film technology as a catalyst in chemical sensing applications presents a complex picture of advancement and limitation. Currently, IGZO thin films have demonstrated promising catalytic properties for gas detection, particularly for volatile organic compounds (VOCs), nitrogen oxides, and hydrogen sulfide. The amorphous structure of IGZO provides unique advantages including high electron mobility, excellent uniformity, and stability at room temperature, making it particularly suitable for portable and low-power sensing devices.

Despite these advantages, several significant technical barriers impede widespread commercial adoption. The primary challenge remains the sensitivity to environmental factors, particularly humidity and temperature fluctuations, which can cause signal drift and reduce reliability in real-world applications. This environmental susceptibility necessitates complex calibration algorithms or protective layers that increase manufacturing complexity and cost.

Another substantial barrier is the selectivity limitation of IGZO-based sensors. Current implementations struggle to differentiate between chemically similar compounds, resulting in cross-sensitivity issues that compromise accuracy in mixed-gas environments. This represents a critical challenge for applications requiring precise identification of specific analytes within complex mixtures.

Manufacturing scalability presents additional challenges. While IGZO deposition techniques like sputtering and solution processing are well-established, achieving consistent catalytic performance across large-area substrates remains difficult. Variations in film thickness, composition, and microstructure can significantly affect catalytic efficiency and sensor response characteristics.

The stability and longevity of IGZO catalytic surfaces constitute another major concern. Degradation mechanisms including surface poisoning, oxidation state changes, and structural reorganization under repeated exposure to target gases limit sensor lifetime. Current research indicates performance deterioration after 3-6 months of continuous operation in industrial environments, falling short of the 2-5 year lifespan required for commercial viability.

From a geographical perspective, IGZO catalyst technology development shows distinct regional patterns. Japan and South Korea lead in fundamental research and patent filings, with significant contributions from research institutions in the United States and Germany. China has recently emerged as a major player, particularly in manufacturing process optimization and cost reduction strategies.

The economic barrier of indium scarcity cannot be overlooked. As a relatively rare element, indium's limited availability and fluctuating costs impact the long-term sustainability of IGZO-based sensing technologies. This has prompted research into alternative compositions with reduced indium content, though these alternatives typically demonstrate inferior catalytic performance.

Despite these advantages, several significant technical barriers impede widespread commercial adoption. The primary challenge remains the sensitivity to environmental factors, particularly humidity and temperature fluctuations, which can cause signal drift and reduce reliability in real-world applications. This environmental susceptibility necessitates complex calibration algorithms or protective layers that increase manufacturing complexity and cost.

Another substantial barrier is the selectivity limitation of IGZO-based sensors. Current implementations struggle to differentiate between chemically similar compounds, resulting in cross-sensitivity issues that compromise accuracy in mixed-gas environments. This represents a critical challenge for applications requiring precise identification of specific analytes within complex mixtures.

Manufacturing scalability presents additional challenges. While IGZO deposition techniques like sputtering and solution processing are well-established, achieving consistent catalytic performance across large-area substrates remains difficult. Variations in film thickness, composition, and microstructure can significantly affect catalytic efficiency and sensor response characteristics.

The stability and longevity of IGZO catalytic surfaces constitute another major concern. Degradation mechanisms including surface poisoning, oxidation state changes, and structural reorganization under repeated exposure to target gases limit sensor lifetime. Current research indicates performance deterioration after 3-6 months of continuous operation in industrial environments, falling short of the 2-5 year lifespan required for commercial viability.

From a geographical perspective, IGZO catalyst technology development shows distinct regional patterns. Japan and South Korea lead in fundamental research and patent filings, with significant contributions from research institutions in the United States and Germany. China has recently emerged as a major player, particularly in manufacturing process optimization and cost reduction strategies.

The economic barrier of indium scarcity cannot be overlooked. As a relatively rare element, indium's limited availability and fluctuating costs impact the long-term sustainability of IGZO-based sensing technologies. This has prompted research into alternative compositions with reduced indium content, though these alternatives typically demonstrate inferior catalytic performance.

Current IGZO Catalyst Integration Approaches

01 IGZO thin film composition and structure for catalytic applications

Indium Gallium Zinc Oxide (IGZO) thin films can be formulated with specific compositions and structures to enhance their catalytic performance. The ratio of indium, gallium, and zinc can be optimized to create active sites for catalytic reactions. Additionally, the crystalline structure, thickness, and surface morphology of the IGZO films play crucial roles in determining their catalytic efficiency. These films can be designed with high surface area and controlled porosity to maximize the exposure of catalytic sites.- IGZO thin film composition and structure for catalytic applications: Indium Gallium Zinc Oxide (IGZO) thin films can be formulated with specific compositions and structures to enhance their catalytic performance. The ratio of indium, gallium, and zinc can be optimized to create active sites for catalytic reactions. Additionally, the crystalline structure, thickness, and surface morphology of the IGZO films significantly impact their catalytic efficiency. These films can be designed with high surface area and controlled porosity to maximize the exposure of catalytic sites.

- Deposition methods for catalytically active IGZO thin films: Various deposition techniques can be employed to create IGZO thin films with enhanced catalytic properties. These methods include sputtering, atomic layer deposition, chemical vapor deposition, and solution-based processes. The deposition parameters such as temperature, pressure, and gas flow rates significantly influence the film's microstructure, composition uniformity, and catalytic activity. Post-deposition treatments like annealing in specific atmospheres can further optimize the catalytic performance by modifying the film's electronic structure and surface properties.

- Doping and modification of IGZO for enhanced catalytic performance: Doping IGZO thin films with additional elements or compounds can significantly enhance their catalytic performance. Common dopants include transition metals, noble metals, and rare earth elements that create active sites for specific catalytic reactions. Surface modification techniques, such as plasma treatment or functionalization with specific chemical groups, can also improve the catalytic activity by altering the surface energy and adsorption properties. These modifications enable IGZO films to catalyze a wider range of chemical reactions with improved efficiency and selectivity.

- IGZO thin film integration with other materials for synergistic catalysis: IGZO thin films can be integrated with other catalytic materials to create composite structures with synergistic catalytic effects. These hybrid systems may combine IGZO with other metal oxides, noble metal nanoparticles, or carbon-based materials. The resulting composites often exhibit enhanced catalytic performance due to complementary reaction pathways, improved charge transfer, or stabilization of reactive intermediates. Such integrated systems can be designed as multilayer structures, core-shell particles, or heterojunctions to optimize the catalytic performance for specific applications.

- Applications of IGZO thin films as catalysts in various processes: IGZO thin films demonstrate catalytic activity in various applications including photocatalysis, electrocatalysis, and heterogeneous catalysis for organic transformations. In photocatalytic applications, IGZO films can harness light energy to drive chemical reactions such as water splitting or degradation of pollutants. As electrocatalysts, they facilitate electrochemical reactions in fuel cells, batteries, or electrochemical sensors. The unique electronic properties and tunable band structure of IGZO make it suitable for selective catalysis in chemical synthesis and environmental remediation processes.

02 Doping and modification of IGZO thin films for enhanced catalytic activity

The catalytic performance of IGZO thin films can be significantly improved through doping with various elements or functional groups. Common dopants include transition metals, noble metals, and non-metal elements that create active sites or modify the electronic structure of the film. Surface modification techniques, such as plasma treatment or functionalization with specific chemical groups, can also enhance the catalytic properties by increasing the number of active sites or improving the adsorption of reactants on the film surface.Expand Specific Solutions03 Fabrication methods for catalytically active IGZO thin films

Various deposition and fabrication techniques can be employed to create IGZO thin films with enhanced catalytic properties. These include sputtering, chemical vapor deposition, sol-gel processing, and atomic layer deposition. Post-deposition treatments such as annealing, plasma treatment, or chemical etching can further optimize the catalytic performance by modifying the film's crystallinity, defect structure, or surface properties. The processing parameters significantly influence the resulting catalytic activity of the IGZO films.Expand Specific Solutions04 IGZO thin film-based composite catalysts and hybrid structures

IGZO thin films can be combined with other materials to form composite or hybrid catalytic structures with enhanced performance. These composites may include IGZO films deposited on various substrates, multilayer structures with other metal oxides, or hybrid systems incorporating nanoparticles, carbon materials, or polymers. The synergistic effects between IGZO and the complementary materials can significantly improve catalytic activity, selectivity, and stability under reaction conditions.Expand Specific Solutions05 Applications of IGZO thin films as catalysts in various reactions

IGZO thin films demonstrate catalytic activity in various chemical reactions and processes. These include photocatalytic degradation of pollutants, water splitting for hydrogen production, CO2 reduction, and organic transformation reactions. The films can also serve as supports for other catalytic materials or as components in electrochemical catalytic systems. The unique electronic properties of IGZO, combined with their stability and tunable composition, make them versatile catalytic materials for diverse applications.Expand Specific Solutions

Leading IGZO Thin Film and Sensor Manufacturers

The IGZO thin film catalyst market for chemical sensors is in an early growth phase, characterized by increasing research activities and emerging commercial applications. The market size is expanding as demand for high-performance, energy-efficient sensors grows across healthcare, environmental monitoring, and industrial sectors. Technologically, IGZO catalysts are advancing rapidly with key players demonstrating varying levels of maturity. Companies like BOE Technology, Samsung Display, and ULVAC are leading with established manufacturing capabilities, while research institutions such as King Abdullah University and Interuniversitair Micro-Electronica Centrum are driving fundamental innovations. Japanese firms including AGC and Air Liquide are developing specialized materials and processes, positioning themselves strategically in this evolving ecosystem that bridges semiconductor technology with chemical sensing applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered a comprehensive IGZO thin film technology platform for chemical sensing applications that leverages their expertise in display manufacturing. Their approach incorporates IGZO films with controlled defect structures, specifically engineered oxygen vacancy concentrations that serve as catalytic sites for gas-surface interactions. BOE's proprietary deposition process combines pulsed laser deposition with precise control of oxygen partial pressure (typically 0.1-1 Pa) to achieve optimal catalytic performance. The company has developed multi-layered sensor structures where IGZO serves dual functions: as a semiconductor channel for signal transduction and as a catalytic layer for target analyte interaction. Their sensors demonstrate particular sensitivity toward oxidizing gases like NO2 and O3, with detection limits below 10 ppb. BOE has integrated these sensors into their smart home and environmental monitoring product lines, utilizing the same manufacturing infrastructure used for their display panels.

Strengths: Excellent compatibility with existing TFT manufacturing processes; high uniformity across large substrates; good stability under varying humidity conditions. Weaknesses: Relatively slower response time compared to some competing technologies; sensitivity affected by temperature fluctuations requiring additional compensation circuitry.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed advanced IGZO (Indium Gallium Zinc Oxide) thin film technology specifically engineered for chemical sensing applications. Their approach utilizes precisely controlled IGZO stoichiometry with optimized In:Ga:Zn ratios (typically 1:1:1 or 2:2:1) to enhance catalytic properties. Samsung's process involves RF magnetron sputtering deposition at controlled oxygen partial pressures, followed by post-deposition annealing at 300-400°C to create oxygen vacancies that serve as active catalytic sites. The company has implemented this technology in flexible sensor arrays where IGZO functions both as the semiconductor channel and catalytic layer, enabling detection of gases like NO2, NH3, and VOCs at parts-per-billion levels. Their sensors demonstrate enhanced selectivity through surface functionalization techniques and pattern recognition algorithms integrated with the sensing elements.

Strengths: Superior stability in various environmental conditions; excellent integration with existing display manufacturing infrastructure; high sensitivity due to optimized oxygen vacancy concentration. Weaknesses: Higher production costs compared to conventional metal oxide sensors; requires complex calibration algorithms to compensate for drift over extended operation periods.

Key IGZO Thin Film Catalyst Mechanisms

Array substrate and manufacturing method thereof, and display panel

PatentPendingUS20240355840A1

Innovation

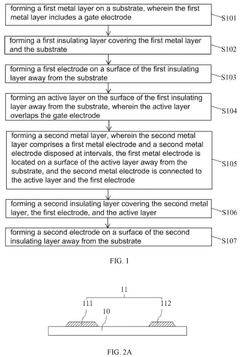

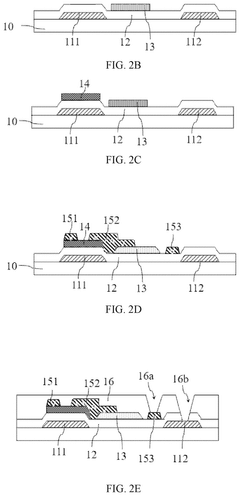

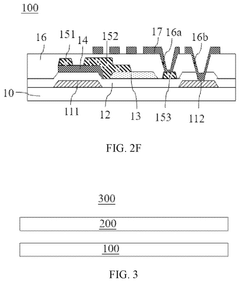

- The array substrate manufacturing method involves forming a first electrode on the surface of the insulating layer away from the substrate, with the active layer overlapping the gate, and a second metal layer comprising electrodes at intervals, allowing connection without via holes, thereby reducing the number of photomasks needed for forming via holes and overall photomasks required.

Material Sustainability and Environmental Impact

The sustainability profile of IGZO (Indium Gallium Zinc Oxide) thin films represents a critical consideration in their application as catalysts for chemical sensors. The material composition raises several environmental concerns, primarily due to the scarcity of indium, which is classified as a critical raw material with limited global reserves. Current extraction processes for indium are energy-intensive and often generate significant environmental pollution, including acid mine drainage and heavy metal contamination.

Manufacturing processes for IGZO thin films typically involve vacuum deposition techniques such as sputtering or pulsed laser deposition, which consume substantial energy. The environmental footprint of these processes includes high electricity consumption and the use of specialized gases that may have significant global warming potential. However, compared to traditional silicon-based technologies, IGZO fabrication generally requires lower processing temperatures, potentially reducing overall energy requirements by 30-40%.

Life cycle assessment studies indicate that IGZO-based sensors demonstrate favorable sustainability metrics when operational efficiency is considered. The material's high electron mobility and low off-state current enable sensors that consume significantly less power during operation, extending battery life and reducing the environmental impact associated with frequent battery replacement or recharging.

End-of-life considerations for IGZO thin films present both challenges and opportunities. The presence of indium necessitates specialized recycling processes to recover this valuable element. Current recycling rates for indium remain below 1% globally, highlighting a significant area for improvement in circular economy approaches. Research into recovery methods specific to IGZO from electronic waste shows promising results, with potential recovery rates of up to 80% under optimized conditions.

Alternative material compositions are being actively investigated to address sustainability concerns. Approaches include partial substitution of indium with more abundant elements such as aluminum or tin, and exploration of entirely different material systems based on earth-abundant elements. These alternatives must maintain the exceptional sensing properties of IGZO while improving environmental compatibility.

Recent advances in deposition techniques, including solution processing methods, offer pathways to reduce the environmental impact of manufacturing. These approaches operate at ambient conditions, eliminating the need for energy-intensive vacuum systems and potentially enabling roll-to-roll processing for large-scale, energy-efficient production of chemical sensors.

Manufacturing processes for IGZO thin films typically involve vacuum deposition techniques such as sputtering or pulsed laser deposition, which consume substantial energy. The environmental footprint of these processes includes high electricity consumption and the use of specialized gases that may have significant global warming potential. However, compared to traditional silicon-based technologies, IGZO fabrication generally requires lower processing temperatures, potentially reducing overall energy requirements by 30-40%.

Life cycle assessment studies indicate that IGZO-based sensors demonstrate favorable sustainability metrics when operational efficiency is considered. The material's high electron mobility and low off-state current enable sensors that consume significantly less power during operation, extending battery life and reducing the environmental impact associated with frequent battery replacement or recharging.

End-of-life considerations for IGZO thin films present both challenges and opportunities. The presence of indium necessitates specialized recycling processes to recover this valuable element. Current recycling rates for indium remain below 1% globally, highlighting a significant area for improvement in circular economy approaches. Research into recovery methods specific to IGZO from electronic waste shows promising results, with potential recovery rates of up to 80% under optimized conditions.

Alternative material compositions are being actively investigated to address sustainability concerns. Approaches include partial substitution of indium with more abundant elements such as aluminum or tin, and exploration of entirely different material systems based on earth-abundant elements. These alternatives must maintain the exceptional sensing properties of IGZO while improving environmental compatibility.

Recent advances in deposition techniques, including solution processing methods, offer pathways to reduce the environmental impact of manufacturing. These approaches operate at ambient conditions, eliminating the need for energy-intensive vacuum systems and potentially enabling roll-to-roll processing for large-scale, energy-efficient production of chemical sensors.

Cross-Industry Applications and Integration Potential

IGZO thin film technology, initially developed for display applications, demonstrates remarkable versatility across multiple industries beyond its established role in chemical sensing. In healthcare, IGZO-based chemical sensors are being integrated into wearable health monitoring devices, enabling continuous tracking of biomarkers in sweat, tears, and interstitial fluids. These applications extend to early disease detection systems and personalized medicine platforms, where the high sensitivity and stability of IGZO catalysts provide reliable biochemical measurements under varying physiological conditions.

The environmental monitoring sector represents another significant integration opportunity, with IGZO sensors being deployed in air quality monitoring networks, water contamination detection systems, and industrial emission control equipment. The low power consumption characteristics of IGZO make these sensors particularly suitable for remote and distributed sensing applications where energy efficiency is paramount.

In the automotive industry, IGZO-based gas sensors are finding applications in cabin air quality monitoring, engine performance optimization, and battery management systems for electric vehicles. The thermal stability and resistance to harsh environments make IGZO catalysts particularly valuable in these demanding applications, where traditional sensing materials often degrade rapidly.

Smart agriculture represents an emerging application domain, with IGZO sensors being integrated into precision farming systems for soil composition analysis, crop health monitoring, and optimized fertilizer application. These integrations enable data-driven farming practices that maximize yield while minimizing environmental impact.

The industrial Internet of Things (IIoT) sector is leveraging IGZO sensor technology for predictive maintenance systems, process optimization, and safety monitoring in manufacturing environments. The ability to detect minute changes in gas composition allows early identification of equipment failures or process deviations before they escalate into costly problems.

Cross-platform integration potential is further enhanced by the compatibility of IGZO with existing semiconductor manufacturing processes, enabling cost-effective integration with microprocessors, wireless communication modules, and power management systems. This compatibility facilitates the development of complete sensing solutions rather than isolated components, significantly expanding market potential.

The convergence of IGZO sensor technology with artificial intelligence and edge computing represents perhaps the most promising integration pathway, enabling intelligent, autonomous sensing systems capable of real-time data analysis and decision-making without constant cloud connectivity. This integration direction aligns with broader industry trends toward distributed intelligence and autonomous operation in sensing networks.

The environmental monitoring sector represents another significant integration opportunity, with IGZO sensors being deployed in air quality monitoring networks, water contamination detection systems, and industrial emission control equipment. The low power consumption characteristics of IGZO make these sensors particularly suitable for remote and distributed sensing applications where energy efficiency is paramount.

In the automotive industry, IGZO-based gas sensors are finding applications in cabin air quality monitoring, engine performance optimization, and battery management systems for electric vehicles. The thermal stability and resistance to harsh environments make IGZO catalysts particularly valuable in these demanding applications, where traditional sensing materials often degrade rapidly.

Smart agriculture represents an emerging application domain, with IGZO sensors being integrated into precision farming systems for soil composition analysis, crop health monitoring, and optimized fertilizer application. These integrations enable data-driven farming practices that maximize yield while minimizing environmental impact.

The industrial Internet of Things (IIoT) sector is leveraging IGZO sensor technology for predictive maintenance systems, process optimization, and safety monitoring in manufacturing environments. The ability to detect minute changes in gas composition allows early identification of equipment failures or process deviations before they escalate into costly problems.

Cross-platform integration potential is further enhanced by the compatibility of IGZO with existing semiconductor manufacturing processes, enabling cost-effective integration with microprocessors, wireless communication modules, and power management systems. This compatibility facilitates the development of complete sensing solutions rather than isolated components, significantly expanding market potential.

The convergence of IGZO sensor technology with artificial intelligence and edge computing represents perhaps the most promising integration pathway, enabling intelligent, autonomous sensing systems capable of real-time data analysis and decision-making without constant cloud connectivity. This integration direction aligns with broader industry trends toward distributed intelligence and autonomous operation in sensing networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!