The Role of IGZO Thin Film in Battery Electrode Design

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IGZO Thin Film Technology Evolution and Objectives

Indium Gallium Zinc Oxide (IGZO) thin film technology has evolved significantly since its initial development in the early 2000s. Originally pioneered by Japanese researchers at Tokyo Institute of Technology, IGZO emerged as a promising semiconductor material for transparent electronics and display technologies. The evolution of IGZO thin films has been characterized by continuous improvements in deposition techniques, material composition optimization, and expanding application domains beyond displays.

The fundamental breakthrough in IGZO technology came with the recognition of its unique electronic properties, combining high electron mobility (10-50 cm²/Vs) with excellent transparency and low processing temperatures. These characteristics positioned IGZO as superior to conventional amorphous silicon in various applications. The technology evolution accelerated around 2012 when Sharp Corporation commercialized the first IGZO-based displays, demonstrating the material's industrial viability.

Subsequent technological developments focused on enhancing stability, reducing defect density, and improving carrier concentration control. Researchers achieved significant milestones in refining sputtering techniques, post-deposition treatments, and composition ratios to optimize electrical performance while maintaining optical transparency. The period between 2015-2020 saw particular advancement in low-temperature processing methods, enabling IGZO integration with flexible substrates and expanding its potential applications.

The technology trajectory has recently pivoted toward energy applications, particularly battery technologies. This shift represents a natural evolution as researchers recognized IGZO's potential beyond traditional electronics. The material's high surface area, controllable nanostructure, and excellent electron transport properties make it particularly suitable for electrode applications in next-generation energy storage devices.

The primary technical objectives for IGZO thin films in battery electrode design include enhancing energy density, improving charge-discharge cycling stability, and facilitating faster ion transport. Researchers aim to leverage IGZO's unique electronic structure to create electrodes with superior electron conductivity while maintaining structural integrity during repeated charging cycles. Additional objectives include developing scalable manufacturing processes for IGZO-based battery components and optimizing the interface between IGZO and electrolyte materials.

Looking forward, the technology roadmap for IGZO in battery applications focuses on several key objectives: achieving precise control over film morphology at nanoscale dimensions, developing composite structures that combine IGZO with other active materials, and establishing industry-compatible production methods. The ultimate goal is to create battery electrodes that significantly outperform current technologies in terms of energy density, charging speed, and operational lifetime.

The fundamental breakthrough in IGZO technology came with the recognition of its unique electronic properties, combining high electron mobility (10-50 cm²/Vs) with excellent transparency and low processing temperatures. These characteristics positioned IGZO as superior to conventional amorphous silicon in various applications. The technology evolution accelerated around 2012 when Sharp Corporation commercialized the first IGZO-based displays, demonstrating the material's industrial viability.

Subsequent technological developments focused on enhancing stability, reducing defect density, and improving carrier concentration control. Researchers achieved significant milestones in refining sputtering techniques, post-deposition treatments, and composition ratios to optimize electrical performance while maintaining optical transparency. The period between 2015-2020 saw particular advancement in low-temperature processing methods, enabling IGZO integration with flexible substrates and expanding its potential applications.

The technology trajectory has recently pivoted toward energy applications, particularly battery technologies. This shift represents a natural evolution as researchers recognized IGZO's potential beyond traditional electronics. The material's high surface area, controllable nanostructure, and excellent electron transport properties make it particularly suitable for electrode applications in next-generation energy storage devices.

The primary technical objectives for IGZO thin films in battery electrode design include enhancing energy density, improving charge-discharge cycling stability, and facilitating faster ion transport. Researchers aim to leverage IGZO's unique electronic structure to create electrodes with superior electron conductivity while maintaining structural integrity during repeated charging cycles. Additional objectives include developing scalable manufacturing processes for IGZO-based battery components and optimizing the interface between IGZO and electrolyte materials.

Looking forward, the technology roadmap for IGZO in battery applications focuses on several key objectives: achieving precise control over film morphology at nanoscale dimensions, developing composite structures that combine IGZO with other active materials, and establishing industry-compatible production methods. The ultimate goal is to create battery electrodes that significantly outperform current technologies in terms of energy density, charging speed, and operational lifetime.

Market Analysis for Advanced Battery Electrode Materials

The advanced battery electrode materials market is experiencing significant growth, driven by the increasing demand for high-performance energy storage solutions across multiple industries. Currently valued at approximately $7.5 billion, this market is projected to reach $15.3 billion by 2028, representing a compound annual growth rate (CAGR) of 12.6%. This robust growth is primarily fueled by the expanding electric vehicle (EV) sector, which requires batteries with higher energy density, faster charging capabilities, and longer lifespans.

IGZO (Indium Gallium Zinc Oxide) thin films, traditionally known for their application in display technologies, are emerging as promising materials for next-generation battery electrode designs. The unique properties of IGZO, including high electron mobility, excellent stability, and transparency, position it as a valuable component in enhancing battery performance metrics.

Consumer electronics represent another substantial market segment driving demand for advanced electrode materials. With portable devices requiring increasingly compact yet powerful batteries, IGZO thin films offer advantages in terms of reduced thickness while maintaining electrical conductivity. The healthcare sector is also showing interest in these materials for medical devices that require reliable, long-lasting power sources.

Regional analysis indicates that Asia-Pacific dominates the market, accounting for 45% of global production and consumption, with China, South Korea, and Japan leading in manufacturing capacity. North America and Europe follow with 28% and 22% market share respectively, with significant investments in research and development of novel electrode materials.

The integration of IGZO thin films in battery electrodes aligns with the market's demand for sustainable and environmentally friendly solutions. The reduced reliance on cobalt and other critical materials addresses supply chain concerns and environmental impacts associated with traditional battery production.

Key market drivers include stringent government regulations promoting clean energy technologies, substantial investments in renewable energy storage solutions, and increasing consumer awareness regarding sustainable products. These factors collectively contribute to the accelerated adoption of advanced materials like IGZO in battery systems.

Market challenges include high initial production costs, technical complexities in scaling manufacturing processes, and competition from alternative electrode materials. However, ongoing research and development efforts are focused on addressing these barriers, with several breakthrough technologies expected to reach commercial viability within the next 3-5 years.

IGZO (Indium Gallium Zinc Oxide) thin films, traditionally known for their application in display technologies, are emerging as promising materials for next-generation battery electrode designs. The unique properties of IGZO, including high electron mobility, excellent stability, and transparency, position it as a valuable component in enhancing battery performance metrics.

Consumer electronics represent another substantial market segment driving demand for advanced electrode materials. With portable devices requiring increasingly compact yet powerful batteries, IGZO thin films offer advantages in terms of reduced thickness while maintaining electrical conductivity. The healthcare sector is also showing interest in these materials for medical devices that require reliable, long-lasting power sources.

Regional analysis indicates that Asia-Pacific dominates the market, accounting for 45% of global production and consumption, with China, South Korea, and Japan leading in manufacturing capacity. North America and Europe follow with 28% and 22% market share respectively, with significant investments in research and development of novel electrode materials.

The integration of IGZO thin films in battery electrodes aligns with the market's demand for sustainable and environmentally friendly solutions. The reduced reliance on cobalt and other critical materials addresses supply chain concerns and environmental impacts associated with traditional battery production.

Key market drivers include stringent government regulations promoting clean energy technologies, substantial investments in renewable energy storage solutions, and increasing consumer awareness regarding sustainable products. These factors collectively contribute to the accelerated adoption of advanced materials like IGZO in battery systems.

Market challenges include high initial production costs, technical complexities in scaling manufacturing processes, and competition from alternative electrode materials. However, ongoing research and development efforts are focused on addressing these barriers, with several breakthrough technologies expected to reach commercial viability within the next 3-5 years.

IGZO Implementation Challenges in Battery Applications

Despite the promising theoretical advantages of IGZO thin films in battery electrode design, several significant implementation challenges must be addressed before widespread commercial adoption becomes viable. The primary obstacle lies in the integration of IGZO with existing battery manufacturing processes, which typically involve high-temperature sintering and aggressive chemical environments that can degrade IGZO's electrical properties. Current production methods for IGZO thin films, such as RF sputtering and pulsed laser deposition, require precise control of oxygen partial pressure and substrate temperature, making them difficult to scale for mass battery production.

Material compatibility presents another substantial hurdle. When IGZO interfaces with common battery electrolytes, particularly those containing fluorinated compounds, chemical reactions can occur that alter the semiconductor's band structure and carrier concentration. Long-term stability testing has revealed that repeated lithium intercalation/deintercalation cycles can induce structural changes in IGZO films, potentially compromising their electronic conductivity over hundreds of charge-discharge cycles.

Cost considerations also significantly impact implementation feasibility. The primary constituents of IGZO (indium and gallium) are relatively expensive and supply-constrained compared to traditional battery electrode materials like graphite or lithium iron phosphate. Economic analyses indicate that IGZO-enhanced electrodes currently cost 3-5 times more per kWh than conventional alternatives, necessitating either dramatic performance improvements or substantial cost reductions to achieve commercial viability.

Technical limitations in thickness control and uniformity further complicate implementation. While laboratory demonstrations have achieved excellent results with precisely controlled nanometer-thick IGZO layers, translating these to industrial-scale coating processes introduces variability that can significantly impact performance. Defect density and film homogeneity become increasingly problematic as production scales increase.

Environmental and regulatory challenges must also be considered. Indium extraction and processing carry environmental concerns, and end-of-life recycling protocols for IGZO-containing batteries remain underdeveloped. Several jurisdictions are implementing stricter regulations on battery material composition that may impact IGZO adoption timelines.

Finally, knowledge gaps in fundamental understanding of IGZO behavior in battery environments persist. The complex interactions between IGZO's amorphous structure, its carrier transport mechanisms, and the electrochemical processes occurring during battery operation are not fully characterized, making predictive modeling and optimization difficult. These gaps necessitate further basic research before optimal implementation strategies can be developed.

Material compatibility presents another substantial hurdle. When IGZO interfaces with common battery electrolytes, particularly those containing fluorinated compounds, chemical reactions can occur that alter the semiconductor's band structure and carrier concentration. Long-term stability testing has revealed that repeated lithium intercalation/deintercalation cycles can induce structural changes in IGZO films, potentially compromising their electronic conductivity over hundreds of charge-discharge cycles.

Cost considerations also significantly impact implementation feasibility. The primary constituents of IGZO (indium and gallium) are relatively expensive and supply-constrained compared to traditional battery electrode materials like graphite or lithium iron phosphate. Economic analyses indicate that IGZO-enhanced electrodes currently cost 3-5 times more per kWh than conventional alternatives, necessitating either dramatic performance improvements or substantial cost reductions to achieve commercial viability.

Technical limitations in thickness control and uniformity further complicate implementation. While laboratory demonstrations have achieved excellent results with precisely controlled nanometer-thick IGZO layers, translating these to industrial-scale coating processes introduces variability that can significantly impact performance. Defect density and film homogeneity become increasingly problematic as production scales increase.

Environmental and regulatory challenges must also be considered. Indium extraction and processing carry environmental concerns, and end-of-life recycling protocols for IGZO-containing batteries remain underdeveloped. Several jurisdictions are implementing stricter regulations on battery material composition that may impact IGZO adoption timelines.

Finally, knowledge gaps in fundamental understanding of IGZO behavior in battery environments persist. The complex interactions between IGZO's amorphous structure, its carrier transport mechanisms, and the electrochemical processes occurring during battery operation are not fully characterized, making predictive modeling and optimization difficult. These gaps necessitate further basic research before optimal implementation strategies can be developed.

Current IGZO Electrode Design Methodologies

01 IGZO thin film fabrication methods

Various methods for fabricating IGZO (Indium Gallium Zinc Oxide) thin films are disclosed, including sputtering, chemical vapor deposition, and solution processing techniques. These methods control the composition, crystallinity, and microstructure of the IGZO films to achieve desired electrical properties. Process parameters such as temperature, pressure, and gas flow rates are optimized to produce high-quality IGZO thin films with uniform thickness and composition.- IGZO thin film fabrication methods: Various methods for fabricating IGZO (Indium Gallium Zinc Oxide) thin films have been developed to optimize their electrical and physical properties. These methods include sputtering, solution processing, and atomic layer deposition techniques. The fabrication parameters such as temperature, pressure, and gas flow rates significantly affect the crystallinity, density, and performance of the resulting IGZO films. Advanced deposition techniques can produce high-quality IGZO films with controlled thickness and composition for semiconductor applications.

- IGZO thin film transistor structures: IGZO thin film transistors (TFTs) feature various structural designs to enhance performance characteristics. These structures include bottom-gate, top-gate, and dual-gate configurations with different electrode materials and arrangements. The channel layer composition and thickness are optimized to achieve desired mobility, threshold voltage, and stability. Novel TFT architectures incorporate additional functional layers such as passivation films and buffer layers to protect the IGZO channel and improve device reliability under various operating conditions.

- IGZO thin film doping and composition optimization: The electrical properties of IGZO thin films can be significantly enhanced through doping and composition optimization. By adjusting the ratio of indium, gallium, and zinc, or introducing dopants such as hafnium, titanium, or aluminum, the carrier concentration, mobility, and stability of IGZO films can be controlled. Composition engineering addresses issues such as oxygen vacancy formation and enables customization of IGZO properties for specific applications. These modifications improve the performance and reliability of IGZO-based electronic devices.

- IGZO thin film for display applications: IGZO thin films are widely used in display technologies due to their high electron mobility and transparency. In display applications, IGZO serves as the active channel layer in TFTs that drive pixels in LCD and OLED displays. The low off-current and high mobility of IGZO enable high-resolution, low-power displays with improved refresh rates. Integration techniques for IGZO in display backplanes include specialized patterning methods and interface engineering to ensure compatibility with other display components and manufacturing processes.

- IGZO thin film stability and passivation: Enhancing the stability of IGZO thin films under various environmental conditions is crucial for reliable device operation. Passivation techniques using materials such as silicon oxide, silicon nitride, or aluminum oxide protect IGZO films from moisture, oxygen, and temperature variations. Post-deposition treatments including annealing processes and plasma treatments help reduce defects and stabilize the electrical properties of IGZO films. These approaches mitigate negative bias illumination stress effects and threshold voltage shifts, extending the operational lifetime of IGZO-based devices.

02 IGZO thin film transistor structures

Different structural designs of thin film transistors (TFTs) using IGZO as the semiconductor layer are presented. These structures include bottom-gate, top-gate, and dual-gate configurations with various electrode materials and dielectric layers. The designs aim to improve electrical performance metrics such as mobility, on/off ratio, threshold voltage stability, and subthreshold swing. Novel channel structures and contact engineering approaches are also described to enhance TFT performance.Expand Specific Solutions03 IGZO composition and doping strategies

The composition of IGZO thin films can be modified by adjusting the ratio of indium, gallium, and zinc, or by incorporating dopants to enhance specific properties. Doping elements such as hafnium, aluminum, or nitrogen can improve stability, carrier concentration, and mobility. Post-deposition treatments including annealing in different atmospheres (oxygen, nitrogen, hydrogen) are used to control oxygen vacancies and optimize electrical characteristics of the IGZO films.Expand Specific Solutions04 IGZO thin film applications in display technology

IGZO thin films are widely applied in display technologies such as OLED, LCD, and flexible displays. The high electron mobility and transparency of IGZO make it suitable for backplane transistors in high-resolution displays. Implementation strategies for integrating IGZO TFTs into display panels are described, including pixel circuit designs, addressing schemes, and compensation methods for display uniformity. The low off-current of IGZO TFTs enables low power consumption in display applications.Expand Specific Solutions05 IGZO thin film reliability and stability enhancement

Methods to improve the reliability and stability of IGZO thin films under various stress conditions are presented. These include passivation layers, buffer layers, and interface engineering techniques to reduce defects and prevent degradation. Approaches to mitigate negative bias temperature instability, light-induced instability, and moisture sensitivity are described. Encapsulation technologies and protective structures are employed to extend the operational lifetime of IGZO-based devices in different environmental conditions.Expand Specific Solutions

Leading Companies in IGZO Thin Film Battery Technology

The IGZO thin film battery electrode technology market is in an early growth phase, characterized by increasing research activities and emerging commercial applications. The market size remains relatively modest but shows promising expansion potential due to IGZO's unique properties for energy storage applications. From a technical maturity perspective, the landscape is dominated by established display technology companies leveraging their IGZO expertise into battery applications. Sharp Corp., Samsung Display, and BOE Technology Group lead commercial development, while Semiconductor Energy Laboratory maintains strong research positions. Japanese companies like ULVAC and Nissan Chemical provide critical manufacturing equipment and materials. Academic-industry collaborations with MIT, ETH Zurich, and South China University of Technology are accelerating innovation, suggesting the technology is transitioning from research to early commercialization phases.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has leveraged its extensive experience in thin-film transistor manufacturing to develop IGZO-enhanced battery electrodes with superior performance characteristics. Their approach incorporates IGZO thin films as a functional interface layer between active materials and current collectors, creating a stable electron transport pathway that minimizes contact resistance and enhances rate capability. BOE's technology utilizes a modified sputtering process that enables precise control over IGZO film composition and microstructure, with the ability to tune the oxygen vacancy concentration to optimize electronic conductivity while maintaining electrochemical stability. The company has developed composite electrodes where IGZO thin films (typically 10-30 nm thick) are integrated with conventional active materials, resulting in a synergistic structure that facilitates both electron and ion transport. BOE has demonstrated that their IGZO-enhanced electrodes exhibit up to 40% higher rate performance at 5C discharge rates compared to conventional electrodes, while maintaining similar capacity at lower rates. The technology has been particularly effective in improving the performance of silicon-based anodes, where the IGZO layer helps accommodate volume changes during cycling.

Strengths: Significant improvement in high-rate performance, excellent compatibility with silicon-based electrode materials, leverages existing manufacturing expertise from display industry. Weaknesses: More complex manufacturing process compared to conventional electrodes, potential challenges in ensuring uniform IGZO coverage in high-volume production, higher cost structure.

Semiconductor Energy Laboratory Co., Ltd.

Technical Solution: Semiconductor Energy Laboratory (SEL) has pioneered IGZO thin film technology for battery electrode applications by leveraging their expertise in oxide semiconductor materials. Their approach involves using IGZO (Indium Gallium Zinc Oxide) as a functional layer in lithium-ion battery electrodes to enhance electron transport and stability. SEL's technology utilizes IGZO's high electron mobility (typically 10-20 cm²/Vs) and excellent uniformity to create ultra-thin conductive layers that facilitate faster ion transport while maintaining structural integrity during charge-discharge cycles. The company has developed proprietary deposition techniques that allow for precise control of IGZO film thickness (down to several nanometers) and composition, optimizing the ratio of In:Ga:Zn to achieve desired electrical properties for specific battery chemistries. SEL has demonstrated that IGZO-enhanced electrodes can improve capacity retention by up to 30% after 1000 cycles compared to conventional electrodes.

Strengths: Superior electron mobility compared to traditional materials, excellent uniformity and stability under electrochemical conditions, compatibility with existing manufacturing processes. Weaknesses: Higher production costs due to indium content, potential supply chain concerns for indium, requires specialized deposition equipment for optimal performance.

Critical Patents and Research on IGZO Battery Integration

NMOS PTAT generator and voltage reference

PatentActiveUS20210286395A1

Innovation

- A voltage reference circuit using area-mismatched NMOS transistors with a voltage divider circuit and an operational amplifier to provide a reference output signal proportional to the temperature of the transistors, combining PTAT and CTAT circuits to achieve stability across temperature variations.

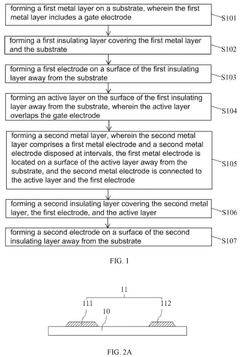

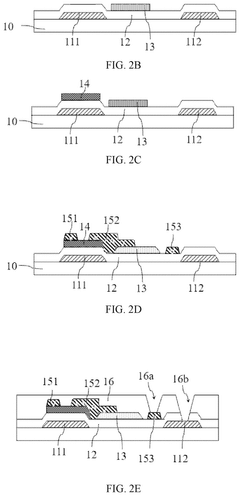

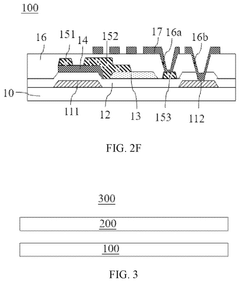

Array substrate and manufacturing method thereof, and display panel

PatentPendingUS20240355840A1

Innovation

- The array substrate manufacturing method involves forming a first electrode on the surface of the insulating layer away from the substrate, with the active layer overlapping the gate, and a second metal layer comprising electrodes at intervals, allowing connection without via holes, thereby reducing the number of photomasks needed for forming via holes and overall photomasks required.

Environmental Impact of IGZO in Battery Manufacturing

The environmental implications of IGZO (Indium Gallium Zinc Oxide) thin film technology in battery manufacturing represent a critical consideration for sustainable energy storage development. IGZO materials introduce both advantages and challenges from an ecological perspective when integrated into battery electrode designs.

The extraction and processing of IGZO's constituent elements—particularly indium and gallium—present significant environmental concerns. These rare metals require energy-intensive mining operations that contribute to habitat disruption, soil degradation, and water pollution. Current extraction methods for indium, primarily obtained as a byproduct of zinc processing, generate substantial carbon emissions and toxic waste streams that require careful management and remediation.

However, IGZO thin films offer notable environmental benefits in the manufacturing phase compared to conventional electrode materials. The low-temperature deposition processes used for IGZO films consume significantly less energy than traditional high-temperature sintering methods required for many battery components. Studies indicate that IGZO manufacturing can reduce energy consumption by approximately 30-40% compared to alternative thin-film technologies, resulting in a smaller carbon footprint during production.

Water usage represents another important environmental dimension. IGZO manufacturing typically requires less water than conventional electrode production processes, potentially reducing freshwater consumption by 25-35% according to recent industry assessments. This advantage becomes particularly significant in regions facing water scarcity challenges.

The chemical composition of IGZO raises toxicity concerns that warrant careful consideration. While zinc oxide is generally recognized as environmentally benign, indium and gallium compounds may present ecological risks if improperly handled or disposed of. Manufacturers implementing IGZO technology must establish robust waste management protocols to prevent environmental contamination and ensure worker safety throughout the production lifecycle.

From a product lifecycle perspective, IGZO-enhanced batteries demonstrate promising environmental characteristics. The improved efficiency and extended lifespan of batteries incorporating IGZO thin films translate to reduced replacement frequency and decreased electronic waste generation. Additionally, the enhanced performance characteristics may enable more efficient energy storage systems that support renewable energy integration, indirectly contributing to reduced fossil fuel dependence.

Recycling capabilities represent a crucial environmental factor for IGZO implementation. Current recycling technologies for recovering indium and gallium from electronic components remain limited and inefficient. Industry stakeholders must prioritize the development of effective recovery methods to establish a circular economy approach for these valuable materials, thereby mitigating supply constraints and reducing environmental impacts associated with primary extraction.

The extraction and processing of IGZO's constituent elements—particularly indium and gallium—present significant environmental concerns. These rare metals require energy-intensive mining operations that contribute to habitat disruption, soil degradation, and water pollution. Current extraction methods for indium, primarily obtained as a byproduct of zinc processing, generate substantial carbon emissions and toxic waste streams that require careful management and remediation.

However, IGZO thin films offer notable environmental benefits in the manufacturing phase compared to conventional electrode materials. The low-temperature deposition processes used for IGZO films consume significantly less energy than traditional high-temperature sintering methods required for many battery components. Studies indicate that IGZO manufacturing can reduce energy consumption by approximately 30-40% compared to alternative thin-film technologies, resulting in a smaller carbon footprint during production.

Water usage represents another important environmental dimension. IGZO manufacturing typically requires less water than conventional electrode production processes, potentially reducing freshwater consumption by 25-35% according to recent industry assessments. This advantage becomes particularly significant in regions facing water scarcity challenges.

The chemical composition of IGZO raises toxicity concerns that warrant careful consideration. While zinc oxide is generally recognized as environmentally benign, indium and gallium compounds may present ecological risks if improperly handled or disposed of. Manufacturers implementing IGZO technology must establish robust waste management protocols to prevent environmental contamination and ensure worker safety throughout the production lifecycle.

From a product lifecycle perspective, IGZO-enhanced batteries demonstrate promising environmental characteristics. The improved efficiency and extended lifespan of batteries incorporating IGZO thin films translate to reduced replacement frequency and decreased electronic waste generation. Additionally, the enhanced performance characteristics may enable more efficient energy storage systems that support renewable energy integration, indirectly contributing to reduced fossil fuel dependence.

Recycling capabilities represent a crucial environmental factor for IGZO implementation. Current recycling technologies for recovering indium and gallium from electronic components remain limited and inefficient. Industry stakeholders must prioritize the development of effective recovery methods to establish a circular economy approach for these valuable materials, thereby mitigating supply constraints and reducing environmental impacts associated with primary extraction.

Performance Metrics and Testing Standards for IGZO Electrodes

The evaluation of IGZO (Indium Gallium Zinc Oxide) thin films for battery electrode applications requires standardized performance metrics and testing protocols to ensure reliable comparison across different research efforts and commercial developments. Currently, the battery industry employs several key performance indicators that have been adapted specifically for IGZO-based electrodes.

Capacity retention represents one of the most critical metrics for IGZO electrodes, typically measured through galvanostatic charge-discharge cycling at various C-rates. Standard testing protocols require a minimum of 500 cycles at 1C rate, with premium applications demanding 1000+ cycles with less than 20% capacity degradation. The unique amorphous structure of IGZO contributes to exceptional cycling stability compared to conventional electrode materials, necessitating extended testing periods to fully characterize long-term performance.

Coulombic efficiency measurements for IGZO electrodes follow modified protocols that account for the semiconductor properties of the material. Industry standards now require efficiency values exceeding 99.5% after the initial formation cycles, with measurements conducted at controlled temperatures ranging from -20°C to 60°C to assess thermal stability characteristics unique to metal oxide thin films.

Rate capability testing for IGZO electrodes employs standardized step protocols, typically progressing from 0.1C to 10C rates in predefined increments. The semiconductor nature of IGZO necessitates additional attention to electronic conductivity measurements, with four-point probe testing being the preferred method for thin film configurations. Standard resistivity values for optimized IGZO electrodes should fall below 10^-3 Ω·cm to ensure adequate electron transport during high-rate operation.

Adhesion strength between IGZO thin films and current collectors represents a specialized metric not commonly prioritized for conventional electrode materials. The industry has adopted modified tape tests and scratch tests with quantitative force measurements, establishing minimum adhesion strength requirements of 5-7 N/mm² for automotive applications.

Electrochemical impedance spectroscopy (EIS) protocols for IGZO electrodes have been standardized to capture the unique interfacial properties of these semiconductor materials. Testing standards require measurements across frequencies from 100 kHz to 10 mHz, with particular attention to charge transfer resistance values, which should remain below 50 Ω·cm² throughout the battery lifetime.

Environmental testing standards for IGZO electrodes have evolved to include accelerated aging protocols under high humidity (85% RH) and elevated temperature (85°C) conditions, reflecting the growing importance of stability in diverse operating environments. These specialized tests address the potential sensitivity of metal oxide thin films to environmental factors that may not significantly impact conventional electrode materials.

Capacity retention represents one of the most critical metrics for IGZO electrodes, typically measured through galvanostatic charge-discharge cycling at various C-rates. Standard testing protocols require a minimum of 500 cycles at 1C rate, with premium applications demanding 1000+ cycles with less than 20% capacity degradation. The unique amorphous structure of IGZO contributes to exceptional cycling stability compared to conventional electrode materials, necessitating extended testing periods to fully characterize long-term performance.

Coulombic efficiency measurements for IGZO electrodes follow modified protocols that account for the semiconductor properties of the material. Industry standards now require efficiency values exceeding 99.5% after the initial formation cycles, with measurements conducted at controlled temperatures ranging from -20°C to 60°C to assess thermal stability characteristics unique to metal oxide thin films.

Rate capability testing for IGZO electrodes employs standardized step protocols, typically progressing from 0.1C to 10C rates in predefined increments. The semiconductor nature of IGZO necessitates additional attention to electronic conductivity measurements, with four-point probe testing being the preferred method for thin film configurations. Standard resistivity values for optimized IGZO electrodes should fall below 10^-3 Ω·cm to ensure adequate electron transport during high-rate operation.

Adhesion strength between IGZO thin films and current collectors represents a specialized metric not commonly prioritized for conventional electrode materials. The industry has adopted modified tape tests and scratch tests with quantitative force measurements, establishing minimum adhesion strength requirements of 5-7 N/mm² for automotive applications.

Electrochemical impedance spectroscopy (EIS) protocols for IGZO electrodes have been standardized to capture the unique interfacial properties of these semiconductor materials. Testing standards require measurements across frequencies from 100 kHz to 10 mHz, with particular attention to charge transfer resistance values, which should remain below 50 Ω·cm² throughout the battery lifetime.

Environmental testing standards for IGZO electrodes have evolved to include accelerated aging protocols under high humidity (85% RH) and elevated temperature (85°C) conditions, reflecting the growing importance of stability in diverse operating environments. These specialized tests address the potential sensitivity of metal oxide thin films to environmental factors that may not significantly impact conventional electrode materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!