How IGZO Thin Film Enables Ultra-High Definition Video Displays

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IGZO Technology Evolution and Display Enhancement Goals

Indium Gallium Zinc Oxide (IGZO) technology represents a significant breakthrough in display technology, evolving from traditional amorphous silicon (a-Si) thin-film transistors (TFTs) that dominated the industry for decades. The evolution of IGZO began in the early 2000s when researchers at Tokyo Institute of Technology, led by Professor Hideo Hosono, first demonstrated the semiconductor properties of this transparent oxide. This innovation addressed fundamental limitations of a-Si technology, particularly electron mobility constraints that restricted display resolution and performance.

The technological trajectory of IGZO has been characterized by continuous refinement of material composition and manufacturing processes. Initial implementations achieved electron mobility of approximately 10 cm²/Vs, representing a tenfold improvement over a-Si. Subsequent generations have pushed this boundary further, with current advanced IGZO formulations reaching mobility values of 20-30 cm²/Vs, enabling increasingly sophisticated display applications.

A pivotal milestone in IGZO evolution occurred in 2012 when Sharp Corporation commercialized the first IGZO displays, demonstrating the technology's viability for mass production. This catalyzed industry-wide adoption, with companies including LG Display, Samsung, and BOE Technology subsequently incorporating IGZO into their product roadmaps and manufacturing capabilities.

The primary enhancement goals driving IGZO development center on enabling ultra-high definition displays while simultaneously reducing power consumption. With 4K and 8K resolution displays becoming standard in premium market segments, IGZO's superior electron mobility allows for smaller transistors that can be packed more densely, supporting the pixel density requirements of these advanced display formats without compromising refresh rates or response times.

Energy efficiency represents another critical enhancement objective. IGZO's unique electronic structure allows transistors to maintain their state with minimal power when displaying static images, resulting in power consumption reductions of up to 80-90% compared to conventional TFT technologies. This characteristic has positioned IGZO as an enabling technology for mobile devices where battery life is paramount.

Looking forward, the technology roadmap for IGZO includes further refinements in material composition to achieve even higher electron mobility, potentially exceeding 50 cm²/Vs. Research is also focused on improving manufacturing yield rates and reducing production costs to extend IGZO benefits across broader market segments. Additionally, integration with emerging display technologies such as microLED and quantum dot displays represents a frontier where IGZO's capabilities may unlock new performance thresholds.

The ultimate goal for IGZO technology evolution is to establish a semiconductor foundation capable of supporting next-generation display requirements, including higher refresh rates (120Hz+), increased brightness, enhanced color accuracy, and reduced motion blur, all while maintaining or improving energy efficiency profiles.

The technological trajectory of IGZO has been characterized by continuous refinement of material composition and manufacturing processes. Initial implementations achieved electron mobility of approximately 10 cm²/Vs, representing a tenfold improvement over a-Si. Subsequent generations have pushed this boundary further, with current advanced IGZO formulations reaching mobility values of 20-30 cm²/Vs, enabling increasingly sophisticated display applications.

A pivotal milestone in IGZO evolution occurred in 2012 when Sharp Corporation commercialized the first IGZO displays, demonstrating the technology's viability for mass production. This catalyzed industry-wide adoption, with companies including LG Display, Samsung, and BOE Technology subsequently incorporating IGZO into their product roadmaps and manufacturing capabilities.

The primary enhancement goals driving IGZO development center on enabling ultra-high definition displays while simultaneously reducing power consumption. With 4K and 8K resolution displays becoming standard in premium market segments, IGZO's superior electron mobility allows for smaller transistors that can be packed more densely, supporting the pixel density requirements of these advanced display formats without compromising refresh rates or response times.

Energy efficiency represents another critical enhancement objective. IGZO's unique electronic structure allows transistors to maintain their state with minimal power when displaying static images, resulting in power consumption reductions of up to 80-90% compared to conventional TFT technologies. This characteristic has positioned IGZO as an enabling technology for mobile devices where battery life is paramount.

Looking forward, the technology roadmap for IGZO includes further refinements in material composition to achieve even higher electron mobility, potentially exceeding 50 cm²/Vs. Research is also focused on improving manufacturing yield rates and reducing production costs to extend IGZO benefits across broader market segments. Additionally, integration with emerging display technologies such as microLED and quantum dot displays represents a frontier where IGZO's capabilities may unlock new performance thresholds.

The ultimate goal for IGZO technology evolution is to establish a semiconductor foundation capable of supporting next-generation display requirements, including higher refresh rates (120Hz+), increased brightness, enhanced color accuracy, and reduced motion blur, all while maintaining or improving energy efficiency profiles.

Market Demand Analysis for Ultra-High Definition Displays

The global market for ultra-high definition (UHD) displays has experienced exponential growth over the past decade, driven primarily by consumer demand for superior visual experiences across various platforms. The transition from standard definition to high definition, and now to ultra-high definition formats (4K and 8K), represents a significant shift in display technology requirements and market dynamics.

Consumer electronics retailers report that UHD televisions now account for over 60% of all TV sales in developed markets, with particularly strong adoption rates in North America, Western Europe, and East Asia. This trend is expected to continue as content providers increasingly produce native 4K and 8K content, creating a positive feedback loop that further drives demand for compatible display technologies.

The commercial sector has also emerged as a major driver for UHD display adoption. Digital signage, professional video production, medical imaging, and industrial visualization applications all benefit from the enhanced detail and color accuracy offered by ultra-high definition displays. The healthcare segment specifically has shown remarkable growth, with high-resolution displays becoming essential for advanced diagnostic imaging and surgical visualization systems.

Mobile device manufacturers have similarly recognized the market potential for higher resolution displays in smartphones and tablets. Premium mobile devices now routinely feature display resolutions that exceed 400 pixels per inch, creating additional demand for thin-film transistor technologies like IGZO that can efficiently drive such high-resolution panels while maintaining reasonable power consumption profiles.

Market research indicates that consumers are willing to pay premium prices for displays with superior visual quality, with picture clarity and color accuracy consistently ranking among the top purchasing considerations. This premium positioning has allowed manufacturers to maintain healthy profit margins despite increasing competition and manufacturing complexity.

The gaming and virtual reality segments represent particularly promising growth vectors for UHD display technologies. Gamers demand high refresh rates alongside high resolution, while VR applications require extremely high pixel densities to create convincing immersive experiences. Both use cases benefit significantly from the performance characteristics of IGZO thin-film transistor technology.

Content ecosystem development remains a critical factor influencing market adoption. Streaming platforms have invested heavily in 4K content libraries, while next-generation gaming consoles now support 4K output as standard. The gradual expansion of 8K content, though still limited, is beginning to create early demand for compatible display technologies in premium market segments.

Supply chain considerations also impact market dynamics, with panel manufacturing capacity and yield rates directly affecting product availability and pricing. The specialized nature of advanced display manufacturing creates significant barriers to entry, allowing established players to maintain competitive advantages in the high-end display market.

Consumer electronics retailers report that UHD televisions now account for over 60% of all TV sales in developed markets, with particularly strong adoption rates in North America, Western Europe, and East Asia. This trend is expected to continue as content providers increasingly produce native 4K and 8K content, creating a positive feedback loop that further drives demand for compatible display technologies.

The commercial sector has also emerged as a major driver for UHD display adoption. Digital signage, professional video production, medical imaging, and industrial visualization applications all benefit from the enhanced detail and color accuracy offered by ultra-high definition displays. The healthcare segment specifically has shown remarkable growth, with high-resolution displays becoming essential for advanced diagnostic imaging and surgical visualization systems.

Mobile device manufacturers have similarly recognized the market potential for higher resolution displays in smartphones and tablets. Premium mobile devices now routinely feature display resolutions that exceed 400 pixels per inch, creating additional demand for thin-film transistor technologies like IGZO that can efficiently drive such high-resolution panels while maintaining reasonable power consumption profiles.

Market research indicates that consumers are willing to pay premium prices for displays with superior visual quality, with picture clarity and color accuracy consistently ranking among the top purchasing considerations. This premium positioning has allowed manufacturers to maintain healthy profit margins despite increasing competition and manufacturing complexity.

The gaming and virtual reality segments represent particularly promising growth vectors for UHD display technologies. Gamers demand high refresh rates alongside high resolution, while VR applications require extremely high pixel densities to create convincing immersive experiences. Both use cases benefit significantly from the performance characteristics of IGZO thin-film transistor technology.

Content ecosystem development remains a critical factor influencing market adoption. Streaming platforms have invested heavily in 4K content libraries, while next-generation gaming consoles now support 4K output as standard. The gradual expansion of 8K content, though still limited, is beginning to create early demand for compatible display technologies in premium market segments.

Supply chain considerations also impact market dynamics, with panel manufacturing capacity and yield rates directly affecting product availability and pricing. The specialized nature of advanced display manufacturing creates significant barriers to entry, allowing established players to maintain competitive advantages in the high-end display market.

IGZO Thin Film Technical Challenges and Global Development Status

IGZO (Indium Gallium Zinc Oxide) thin film technology represents a significant advancement in display technology, currently facing several technical challenges despite its promising capabilities. The fabrication process of IGZO thin films requires precise control of oxygen vacancies, which directly impacts carrier concentration and mobility. Variations in oxygen content during deposition can lead to inconsistent electrical properties across the substrate, affecting display uniformity. Additionally, IGZO exhibits sensitivity to environmental factors such as humidity and temperature, which can degrade performance over time if not properly encapsulated.

The threshold voltage instability under prolonged bias stress remains a critical challenge, particularly for applications requiring continuous operation. This instability manifests as shifts in the transfer characteristics of thin-film transistors (TFTs), potentially causing pixel non-uniformity in displays. Furthermore, achieving ultra-high electron mobility while maintaining low off-state current presents a fundamental trade-off that researchers continue to address through material composition optimization and novel device architectures.

From a global development perspective, Japan has established itself as the pioneer in IGZO technology, with Sharp Corporation (now part of Foxconn) leading commercial implementation since 2012. Their early patents and manufacturing expertise have created a significant competitive advantage in the high-end display market. South Korean companies, particularly Samsung and LG Display, have invested heavily in alternative oxide semiconductor technologies while also developing their own IGZO implementations for specific applications.

Taiwan has positioned itself as a manufacturing hub for IGZO panels, with companies like AU Optronics and Innolux Corporation focusing on mass production capabilities. Chinese display manufacturers have rapidly expanded their IGZO production capacity in recent years, benefiting from government support and substantial investments in advanced display technologies. This has shifted the global manufacturing landscape, with China now accounting for an increasing percentage of global IGZO panel production.

European and North American contributions have primarily focused on fundamental research and specialized applications rather than mass production. Research institutions in these regions have made significant advances in understanding the material science aspects of IGZO and developing novel device architectures. Companies like Applied Materials and Ulvac have developed specialized deposition equipment for IGZO manufacturing, creating another competitive dimension in the ecosystem.

The technical maturity of IGZO varies significantly across different applications. While it has achieved commercial success in large-format displays and some mobile devices, challenges remain in achieving the reliability and performance required for next-generation applications such as foldable displays, transparent electronics, and ultra-high refresh rate panels for virtual reality applications.

The threshold voltage instability under prolonged bias stress remains a critical challenge, particularly for applications requiring continuous operation. This instability manifests as shifts in the transfer characteristics of thin-film transistors (TFTs), potentially causing pixel non-uniformity in displays. Furthermore, achieving ultra-high electron mobility while maintaining low off-state current presents a fundamental trade-off that researchers continue to address through material composition optimization and novel device architectures.

From a global development perspective, Japan has established itself as the pioneer in IGZO technology, with Sharp Corporation (now part of Foxconn) leading commercial implementation since 2012. Their early patents and manufacturing expertise have created a significant competitive advantage in the high-end display market. South Korean companies, particularly Samsung and LG Display, have invested heavily in alternative oxide semiconductor technologies while also developing their own IGZO implementations for specific applications.

Taiwan has positioned itself as a manufacturing hub for IGZO panels, with companies like AU Optronics and Innolux Corporation focusing on mass production capabilities. Chinese display manufacturers have rapidly expanded their IGZO production capacity in recent years, benefiting from government support and substantial investments in advanced display technologies. This has shifted the global manufacturing landscape, with China now accounting for an increasing percentage of global IGZO panel production.

European and North American contributions have primarily focused on fundamental research and specialized applications rather than mass production. Research institutions in these regions have made significant advances in understanding the material science aspects of IGZO and developing novel device architectures. Companies like Applied Materials and Ulvac have developed specialized deposition equipment for IGZO manufacturing, creating another competitive dimension in the ecosystem.

The technical maturity of IGZO varies significantly across different applications. While it has achieved commercial success in large-format displays and some mobile devices, challenges remain in achieving the reliability and performance required for next-generation applications such as foldable displays, transparent electronics, and ultra-high refresh rate panels for virtual reality applications.

Current IGZO Implementation Approaches for UHD Displays

01 IGZO thin film transistor fabrication for UHD displays

Indium Gallium Zinc Oxide (IGZO) thin film transistors are fabricated using specific deposition techniques to achieve high electron mobility and stability required for ultra-high definition displays. These fabrication methods include optimized sputtering conditions, annealing processes, and precise control of oxygen content to enhance the semiconductor properties of IGZO, resulting in improved display performance with higher resolution and refresh rates.- IGZO thin film transistor fabrication for UHD displays: Indium Gallium Zinc Oxide (IGZO) thin film transistors provide superior electron mobility and stability compared to conventional amorphous silicon, making them ideal for ultra-high definition displays. The fabrication process involves specialized deposition techniques to create uniform IGZO layers with optimized composition ratios of indium, gallium, and zinc to achieve the desired electrical properties. These transistors enable higher resolution, faster refresh rates, and improved power efficiency in UHD display panels.

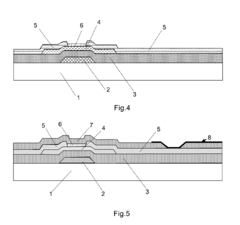

- IGZO-based display panel structures for UHD applications: Advanced panel structures incorporating IGZO technology are designed specifically for ultra-high definition applications. These structures feature optimized pixel arrangements, specialized electrode configurations, and integrated circuit designs that leverage IGZO's unique properties. The panel architectures include innovations in backplane design, pixel density optimization, and signal processing to support the increased data throughput required for UHD content while maintaining image quality and reducing power consumption.

- IGZO material composition and treatment methods: The performance of IGZO thin films for UHD displays depends significantly on material composition and post-deposition treatments. Various techniques are employed to optimize the oxide semiconductor properties, including precise control of oxygen content, annealing processes, and surface treatments. These methods aim to reduce defects, improve carrier concentration, and enhance stability under operational stress. Advanced doping strategies and multi-layer structures are also implemented to tailor the electrical characteristics for specific UHD display requirements.

- IGZO integration with driving circuits for UHD displays: Effective integration of IGZO thin film transistors with driving circuits is crucial for UHD display performance. This involves specialized circuit designs that accommodate IGZO's electrical characteristics while supporting the high data rates required for ultra-high definition content. Advanced gate driver circuits, data line configurations, and signal processing architectures are implemented to minimize response time and reduce power consumption. These integrated systems enable the full potential of IGZO technology in delivering superior image quality at UHD resolutions.

- IGZO technology for flexible and transparent UHD displays: IGZO thin film technology enables the development of flexible and transparent ultra-high definition displays. The low-temperature processing capability of IGZO allows for deposition on flexible substrates without degradation. Special manufacturing techniques are employed to maintain the electrical performance of IGZO transistors under mechanical stress during bending or folding. These advances support next-generation display applications including foldable smartphones, rollable televisions, and transparent display panels while maintaining UHD resolution and image quality.

02 IGZO-based display panel structures for UHD applications

Advanced panel structures incorporating IGZO technology are designed specifically for ultra-high definition applications. These structures feature optimized pixel arrangements, improved backplane architectures, and enhanced electrode configurations that leverage IGZO's superior electrical characteristics. The resulting display panels offer higher pixel density, better uniformity, and improved optical performance necessary for UHD content reproduction.Expand Specific Solutions03 Signal processing techniques for IGZO UHD displays

Specialized signal processing methods are developed to fully utilize IGZO capabilities in ultra-high definition displays. These techniques include advanced driving schemes, compensation algorithms for TFT variations, and optimized data compression methods for handling the massive data throughput required by UHD resolutions. The implementation of these signal processing techniques enables smoother motion rendering, better color accuracy, and reduced power consumption in IGZO-based UHD displays.Expand Specific Solutions04 IGZO material composition optimization for UHD performance

The composition of IGZO materials is carefully optimized to enhance performance in ultra-high definition applications. This involves precise control of the indium, gallium, and zinc ratios, along with strategic doping with additional elements to improve electrical properties. Modified IGZO compositions demonstrate superior electron mobility, better threshold voltage stability, and enhanced resistance to environmental factors, all critical for maintaining consistent performance in demanding UHD display applications.Expand Specific Solutions05 Integration of IGZO technology with advanced display architectures

IGZO technology is integrated with other advanced display architectures to create next-generation ultra-high definition displays. These integrations include combining IGZO backplanes with OLED or micro-LED frontplanes, implementing novel pixel circuits, and incorporating flexible or transparent substrates. Such hybrid approaches leverage the strengths of IGZO while addressing its limitations, resulting in UHD displays with exceptional image quality, flexibility, and form factors suitable for various applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in IGZO Display Industry

IGZO thin film technology for ultra-high definition displays is currently in a growth phase, with the market expanding rapidly due to increasing demand for high-resolution displays in consumer electronics and professional applications. The global market size for IGZO displays is projected to reach significant scale as manufacturers adopt this technology for its superior electron mobility and power efficiency advantages. From a technological maturity perspective, companies like Sharp Corp. (pioneer in IGZO commercialization), Samsung Display, LG Display, and BOE Technology are leading implementation with production-ready solutions. Semiconductor Energy Laboratory remains a key research contributor, while TCL China Star Optoelectronics and Japan's ULVAC are advancing manufacturing processes. The competitive landscape shows Asian manufacturers dominating, with Japanese companies focusing on innovation and Chinese firms scaling production capacity.

BOE Technology Group Co., Ltd.

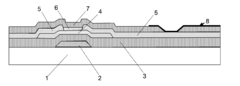

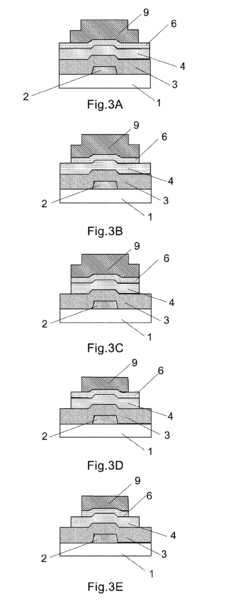

Technical Solution: BOE Technology has developed a comprehensive IGZO technology platform branded as "BOE-IGZO" specifically optimized for ultra-high definition displays across multiple size categories. Their implementation features a unique four-metal-layer (4M1G) backplane design that enables higher integration density and improved aperture ratio compared to conventional TFT structures[1]. BOE's IGZO transistors achieve electron mobility of approximately 15-35 cm²/Vs through carefully controlled deposition parameters and post-processing treatments. Their manufacturing process incorporates specialized plasma-enhanced chemical vapor deposition (PECVD) techniques for gate insulator layers that minimize interface traps and improve carrier transport[3]. BOE has developed proprietary compensation algorithms that address threshold voltage shifts in IGZO transistors, ensuring consistent performance over the display lifetime. Their IGZO displays support refresh rates up to 144Hz in consumer products and up to 360Hz in specialized gaming displays, with response times as low as 1ms. BOE's implementation enables power savings of approximately 40-60% compared to conventional a-Si TFT displays[5]. The company has also pioneered the integration of IGZO backplanes with advanced frontplane technologies including OLED, mini-LED, and micro-LED, creating hybrid display solutions that leverage the advantages of each technology. BOE's latest IGZO displays feature pixel densities exceeding 500 PPI while maintaining excellent uniformity across panel sizes ranging from smartphone displays to large-format professional monitors[7].

Strengths: Strong vertical integration from material development to panel manufacturing; excellent scalability across different display sizes and applications; good balance of performance and cost-effectiveness; compatibility with multiple frontplane technologies. Weaknesses: Moderate electron mobility compared to crystalline IGZO variants; requires careful process control to maintain consistency across large production volumes; higher manufacturing complexity than conventional a-Si technology; some challenges with yield rates in early production phases.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed a hybrid approach to IGZO implementation, combining it with their proprietary metal oxide semiconductor technologies. Their Oxide TFT technology incorporates IGZO as one of several metal oxide semiconductors used in different display products. Samsung's implementation features a unique multi-layer structure with carefully engineered interfaces between the semiconductor, gate insulator, and electrodes to optimize carrier transport and stability[2]. Their IGZO-based displays achieve electron mobility of approximately 10-30 cm²/Vs, supporting ultra-high definition resolutions exceeding 8K (7680×4320) in their premium product lines[4]. Samsung has developed specialized etching and patterning techniques that enable fine-pitch TFT arrays with channel lengths below 3μm, supporting pixel densities over 600 PPI. Their manufacturing process incorporates advanced annealing methods that reduce defect states and carrier trapping, improving long-term reliability. Samsung's IGZO displays feature proprietary compensation circuits that mitigate image sticking and threshold voltage drift, common challenges in oxide semiconductor displays[6]. Their technology supports variable refresh rates from 1Hz to 120Hz, dynamically adjusting based on content to optimize power consumption while maintaining smooth motion rendering. Samsung has also pioneered the integration of IGZO with quantum dot color conversion layers, achieving expanded color gamut coverage exceeding 90% of Rec.2020[8].

Strengths: Excellent integration with Samsung's ecosystem of display technologies; good balance of performance and manufacturing scalability; advanced compensation techniques for improved reliability; compatibility with quantum dot enhancement films for superior color performance. Weaknesses: Somewhat lower electron mobility than leading IGZO implementations; complex manufacturing process requiring tight quality control; higher initial investment costs; requires specialized driver ICs optimized for oxide TFT characteristics.

Key IGZO Innovations Enabling Higher Pixel Density

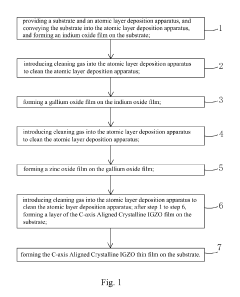

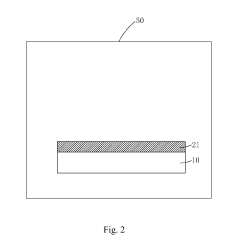

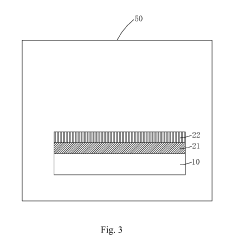

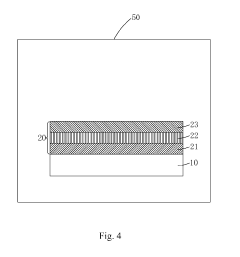

C-axis aligned crystalline IGZO thin film and manufacture method thereof

PatentInactiveUS20190153595A1

Innovation

- A method using atomic layer deposition to form C-axis Aligned Crystalline IGZO thin films by sequentially depositing indium oxide, gallium oxide, and zinc oxide layers on a substrate with controlled temperature, oxygen concentration, and deposition power, resulting in a larger crystalline area with reduced oxygen defects.

Metallic oxide thin film transistor, array substrate and their manufacturing methods, display device

PatentActiveUS20160365366A1

Innovation

- A one-time patterning process is used to form oxide active and etch stopping layers, employing TiO2 or a mixture of TiO2 and CeO2 as the etch stopping layer, which is formed through dry etching and the oxide active layer through wet etching, simplifying the process and improving protection against ultraviolet light.

Power Efficiency and Battery Life Considerations

Power efficiency represents one of the most significant advantages of IGZO (Indium Gallium Zinc Oxide) thin film technology in ultra-high definition displays. The electron mobility in IGZO is approximately 20-50 times higher than in conventional amorphous silicon (a-Si), allowing transistors to switch faster while consuming substantially less power. This characteristic is particularly crucial for battery-powered devices such as smartphones, tablets, and laptops where energy consumption directly impacts user experience.

IGZO's unique atomic structure enables electrons to move more freely through the material, resulting in lower resistance and reduced power requirements. When implemented in display backplanes, this translates to approximately 80-90% less power consumption compared to traditional TFT technologies when displaying static images. This efficiency stems from IGZO's ability to maintain pixel states with minimal refresh requirements.

The technology's low leakage current is another critical factor contributing to power efficiency. IGZO transistors can maintain their state with significantly less frequent refresh cycles than conventional technologies. While standard displays typically require refreshing 60 times per second regardless of content changes, IGZO-based displays can reduce refresh rates to as low as once per second for static content, dramatically reducing power consumption during typical usage scenarios.

For mobile devices, these power efficiency improvements directly translate to extended battery life. Field tests have demonstrated that devices utilizing IGZO display technology can achieve 20-40% longer battery life compared to equivalent devices with conventional display technologies. This extension becomes even more pronounced when displaying predominantly static content such as e-books or documents.

The power savings become increasingly significant as display resolutions increase. With 4K and 8K displays requiring four and sixteen times the pixel count of Full HD respectively, the energy demands would be prohibitive without advanced technologies like IGZO. The technology enables these ultra-high-definition displays to operate within reasonable power envelopes, making portable UHD devices commercially viable.

Temperature management also benefits from IGZO's power efficiency. Lower power consumption results in reduced heat generation, which in turn decreases the need for active cooling solutions. This creates a virtuous cycle where less energy is required for both display operation and thermal management, further extending battery life in portable devices.

As battery technology advances relatively slowly compared to other components, IGZO's efficiency gains represent a critical enabling factor for next-generation mobile devices with increasingly demanding display specifications. Manufacturers can either maintain current battery life while implementing higher resolution displays, or significantly extend usage time between charges while maintaining current display specifications.

IGZO's unique atomic structure enables electrons to move more freely through the material, resulting in lower resistance and reduced power requirements. When implemented in display backplanes, this translates to approximately 80-90% less power consumption compared to traditional TFT technologies when displaying static images. This efficiency stems from IGZO's ability to maintain pixel states with minimal refresh requirements.

The technology's low leakage current is another critical factor contributing to power efficiency. IGZO transistors can maintain their state with significantly less frequent refresh cycles than conventional technologies. While standard displays typically require refreshing 60 times per second regardless of content changes, IGZO-based displays can reduce refresh rates to as low as once per second for static content, dramatically reducing power consumption during typical usage scenarios.

For mobile devices, these power efficiency improvements directly translate to extended battery life. Field tests have demonstrated that devices utilizing IGZO display technology can achieve 20-40% longer battery life compared to equivalent devices with conventional display technologies. This extension becomes even more pronounced when displaying predominantly static content such as e-books or documents.

The power savings become increasingly significant as display resolutions increase. With 4K and 8K displays requiring four and sixteen times the pixel count of Full HD respectively, the energy demands would be prohibitive without advanced technologies like IGZO. The technology enables these ultra-high-definition displays to operate within reasonable power envelopes, making portable UHD devices commercially viable.

Temperature management also benefits from IGZO's power efficiency. Lower power consumption results in reduced heat generation, which in turn decreases the need for active cooling solutions. This creates a virtuous cycle where less energy is required for both display operation and thermal management, further extending battery life in portable devices.

As battery technology advances relatively slowly compared to other components, IGZO's efficiency gains represent a critical enabling factor for next-generation mobile devices with increasingly demanding display specifications. Manufacturers can either maintain current battery life while implementing higher resolution displays, or significantly extend usage time between charges while maintaining current display specifications.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of IGZO (Indium Gallium Zinc Oxide) thin film technology represents a critical factor in its widespread adoption for ultra-high definition displays. Current production methodologies have evolved significantly since the technology's initial commercialization, with major improvements in yield rates and production efficiency. The sputtering deposition process, which remains the primary manufacturing technique for IGZO thin films, has been optimized to accommodate larger substrate sizes, enabling the production of displays exceeding 100 inches diagonally.

Cost analysis reveals that IGZO manufacturing has experienced a steady decline in production expenses, with an estimated 35% reduction in manufacturing costs over the past five years. This cost reduction trajectory has been driven by several factors, including improved material utilization efficiency, reduced energy consumption during the deposition process, and enhanced automation in fabrication facilities. The material cost component, particularly the indium content, remains a significant consideration due to indium's status as a relatively scarce element, though recycling initiatives have helped mitigate supply constraints.

When comparing IGZO with competing technologies such as LTPS (Low-Temperature Polysilicon), IGZO demonstrates superior scalability advantages for large-area displays. While LTPS offers higher electron mobility, its manufacturing complexity increases disproportionately with panel size, creating a distinct economic advantage for IGZO in the ultra-large display segment. This scalability differential has positioned IGZO as the preferred technology for premium television displays exceeding 65 inches.

Production capacity analysis indicates that global IGZO manufacturing capability has expanded at approximately 22% annually over the past three years, with major investments concentrated in East Asia. Japanese, Korean, and Taiwanese manufacturers have established dedicated production lines, with Chinese manufacturers rapidly expanding their capabilities. This geographic concentration presents both supply chain efficiencies and potential vulnerabilities in terms of geopolitical considerations.

The economic viability threshold for IGZO implementation varies by application, with current cost structures making it economically advantageous for premium displays above certain size thresholds. Industry projections suggest that continued manufacturing refinements will further reduce the cost differential between IGZO and conventional a-Si TFT technology, potentially expanding IGZO's market penetration into mid-range display products within the next 2-3 years. This cost trajectory will likely accelerate as production volumes increase, creating a positive feedback loop that enhances the technology's competitive position.

Cost analysis reveals that IGZO manufacturing has experienced a steady decline in production expenses, with an estimated 35% reduction in manufacturing costs over the past five years. This cost reduction trajectory has been driven by several factors, including improved material utilization efficiency, reduced energy consumption during the deposition process, and enhanced automation in fabrication facilities. The material cost component, particularly the indium content, remains a significant consideration due to indium's status as a relatively scarce element, though recycling initiatives have helped mitigate supply constraints.

When comparing IGZO with competing technologies such as LTPS (Low-Temperature Polysilicon), IGZO demonstrates superior scalability advantages for large-area displays. While LTPS offers higher electron mobility, its manufacturing complexity increases disproportionately with panel size, creating a distinct economic advantage for IGZO in the ultra-large display segment. This scalability differential has positioned IGZO as the preferred technology for premium television displays exceeding 65 inches.

Production capacity analysis indicates that global IGZO manufacturing capability has expanded at approximately 22% annually over the past three years, with major investments concentrated in East Asia. Japanese, Korean, and Taiwanese manufacturers have established dedicated production lines, with Chinese manufacturers rapidly expanding their capabilities. This geographic concentration presents both supply chain efficiencies and potential vulnerabilities in terms of geopolitical considerations.

The economic viability threshold for IGZO implementation varies by application, with current cost structures making it economically advantageous for premium displays above certain size thresholds. Industry projections suggest that continued manufacturing refinements will further reduce the cost differential between IGZO and conventional a-Si TFT technology, potentially expanding IGZO's market penetration into mid-range display products within the next 2-3 years. This cost trajectory will likely accelerate as production volumes increase, creating a positive feedback loop that enhances the technology's competitive position.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!