How IGZO Thin Film Addresses Thermal Challenges in High-Performance Circuits

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

IGZO Thin Film Technology Evolution and Thermal Management Goals

Indium Gallium Zinc Oxide (IGZO) thin film technology represents a significant advancement in semiconductor materials, evolving from traditional amorphous silicon (a-Si) and polycrystalline silicon (poly-Si) technologies. First introduced commercially in the early 2010s, IGZO has rapidly gained prominence due to its unique combination of high electron mobility, low power consumption, and excellent thermal stability. The evolution of IGZO technology can be traced through several key developmental phases, beginning with fundamental research in oxide semiconductors in the early 2000s, followed by initial commercialization in display technologies, and now expanding into high-performance circuit applications.

The thermal challenges in high-performance circuits have become increasingly critical as device dimensions shrink and operating frequencies rise. Modern integrated circuits generate substantial heat during operation, with power densities often exceeding 100 W/cm². This thermal load can significantly degrade device performance, reliability, and lifespan. Traditional silicon-based technologies struggle with these thermal challenges due to their inherent material limitations, creating a technological bottleneck that demands innovative solutions.

IGZO thin film technology has emerged as a promising candidate to address these thermal management issues. The material's wide bandgap (approximately 3.5 eV) contributes to lower leakage currents compared to silicon, resulting in reduced heat generation during operation. Additionally, IGZO exhibits remarkable stability at elevated temperatures, maintaining consistent electrical characteristics even under thermal stress conditions that would compromise conventional semiconductor materials.

The technological goals for IGZO thin film development in thermal management applications are multifaceted. Primary objectives include achieving thermal conductivity optimization to efficiently dissipate heat, enhancing temperature coefficient stability to maintain consistent performance across wide operating temperature ranges, and developing novel device architectures that leverage IGZO's unique thermal properties. Researchers are also focusing on improving the material's interface characteristics with other circuit components to minimize thermal boundary resistance.

Recent advancements have demonstrated IGZO's potential in addressing thermal challenges through innovative approaches such as multi-layer structures, doping strategies, and hybrid material systems. These developments aim to push the boundaries of what's possible in high-performance circuit design, enabling next-generation computing systems, power electronics, and sensing technologies that can operate reliably under demanding thermal conditions.

The trajectory of IGZO technology evolution suggests a continued expansion of its application scope, moving beyond displays into more thermally demanding environments such as automotive electronics, industrial systems, and high-performance computing. This evolution is driven by both technological push factors, including material science breakthroughs, and market pull factors, such as the growing demand for energy-efficient, thermally robust electronic systems in various industries.

The thermal challenges in high-performance circuits have become increasingly critical as device dimensions shrink and operating frequencies rise. Modern integrated circuits generate substantial heat during operation, with power densities often exceeding 100 W/cm². This thermal load can significantly degrade device performance, reliability, and lifespan. Traditional silicon-based technologies struggle with these thermal challenges due to their inherent material limitations, creating a technological bottleneck that demands innovative solutions.

IGZO thin film technology has emerged as a promising candidate to address these thermal management issues. The material's wide bandgap (approximately 3.5 eV) contributes to lower leakage currents compared to silicon, resulting in reduced heat generation during operation. Additionally, IGZO exhibits remarkable stability at elevated temperatures, maintaining consistent electrical characteristics even under thermal stress conditions that would compromise conventional semiconductor materials.

The technological goals for IGZO thin film development in thermal management applications are multifaceted. Primary objectives include achieving thermal conductivity optimization to efficiently dissipate heat, enhancing temperature coefficient stability to maintain consistent performance across wide operating temperature ranges, and developing novel device architectures that leverage IGZO's unique thermal properties. Researchers are also focusing on improving the material's interface characteristics with other circuit components to minimize thermal boundary resistance.

Recent advancements have demonstrated IGZO's potential in addressing thermal challenges through innovative approaches such as multi-layer structures, doping strategies, and hybrid material systems. These developments aim to push the boundaries of what's possible in high-performance circuit design, enabling next-generation computing systems, power electronics, and sensing technologies that can operate reliably under demanding thermal conditions.

The trajectory of IGZO technology evolution suggests a continued expansion of its application scope, moving beyond displays into more thermally demanding environments such as automotive electronics, industrial systems, and high-performance computing. This evolution is driven by both technological push factors, including material science breakthroughs, and market pull factors, such as the growing demand for energy-efficient, thermally robust electronic systems in various industries.

Market Demand for Thermally Efficient High-Performance Circuits

The global market for thermally efficient high-performance circuits has been experiencing robust growth, driven primarily by the increasing demand for advanced electronic devices across multiple sectors. The semiconductor industry faces critical challenges as circuit densities continue to increase while device dimensions decrease, resulting in significant thermal management issues that directly impact performance, reliability, and energy efficiency.

Data center infrastructure represents one of the largest market segments demanding thermally efficient solutions, with cooling costs accounting for approximately 40% of total operational expenses. As artificial intelligence and machine learning applications proliferate, the computational demands on data centers continue to escalate, further exacerbating thermal management challenges.

The consumer electronics sector presents another substantial market opportunity, particularly in mobile devices, where thermal efficiency directly impacts user experience, battery life, and device longevity. Market research indicates that thermal issues are among the top three concerns for smartphone users, with overheating cited as a primary reason for customer dissatisfaction and device returns.

Automotive electronics constitute a rapidly growing segment, especially with the transition toward electric vehicles and autonomous driving systems. These applications require high-performance computing capabilities that can operate reliably under varying temperature conditions, creating significant demand for thermally efficient circuit solutions.

The industrial automation and IoT sectors are similarly driving market growth, as edge computing deployments increase and processing requirements move closer to data sources. These applications often operate in challenging environmental conditions, making thermal management a critical design consideration.

Healthcare technology represents an emerging market segment with stringent requirements for reliable, energy-efficient circuits that generate minimal heat, particularly for implantable and wearable medical devices where patient safety is paramount.

Market analysts project the global thermal management solutions market to grow at a compound annual growth rate of 8.2% through 2028, with particular acceleration in regions with high electronics manufacturing concentrations such as East Asia and North America.

The economic implications of improved thermal efficiency extend beyond direct component costs to include significant operational savings. For data centers alone, advanced thermal management solutions could potentially reduce cooling energy consumption by 20-30%, representing billions in annual savings globally.

Customer requirements increasingly emphasize not only performance metrics but also thermal efficiency as a key purchasing criterion, particularly in premium market segments where reliability and longevity justify higher component costs.

Data center infrastructure represents one of the largest market segments demanding thermally efficient solutions, with cooling costs accounting for approximately 40% of total operational expenses. As artificial intelligence and machine learning applications proliferate, the computational demands on data centers continue to escalate, further exacerbating thermal management challenges.

The consumer electronics sector presents another substantial market opportunity, particularly in mobile devices, where thermal efficiency directly impacts user experience, battery life, and device longevity. Market research indicates that thermal issues are among the top three concerns for smartphone users, with overheating cited as a primary reason for customer dissatisfaction and device returns.

Automotive electronics constitute a rapidly growing segment, especially with the transition toward electric vehicles and autonomous driving systems. These applications require high-performance computing capabilities that can operate reliably under varying temperature conditions, creating significant demand for thermally efficient circuit solutions.

The industrial automation and IoT sectors are similarly driving market growth, as edge computing deployments increase and processing requirements move closer to data sources. These applications often operate in challenging environmental conditions, making thermal management a critical design consideration.

Healthcare technology represents an emerging market segment with stringent requirements for reliable, energy-efficient circuits that generate minimal heat, particularly for implantable and wearable medical devices where patient safety is paramount.

Market analysts project the global thermal management solutions market to grow at a compound annual growth rate of 8.2% through 2028, with particular acceleration in regions with high electronics manufacturing concentrations such as East Asia and North America.

The economic implications of improved thermal efficiency extend beyond direct component costs to include significant operational savings. For data centers alone, advanced thermal management solutions could potentially reduce cooling energy consumption by 20-30%, representing billions in annual savings globally.

Customer requirements increasingly emphasize not only performance metrics but also thermal efficiency as a key purchasing criterion, particularly in premium market segments where reliability and longevity justify higher component costs.

Current Thermal Challenges and IGZO Implementation Status

High-performance integrated circuits face significant thermal challenges that directly impact their reliability, performance, and lifespan. As circuit densities increase and dimensions shrink following Moore's Law, power density has escalated dramatically, creating hotspots that can reach temperatures exceeding 100°C during operation. These thermal issues manifest as performance degradation, increased leakage current, accelerated electromigration, and ultimately premature device failure.

Conventional silicon-based semiconductors exhibit poor thermal characteristics at high temperatures, with electron mobility decreasing substantially above 85°C. This thermal sensitivity creates a negative feedback loop where higher temperatures lead to worse performance, which generates more heat. Current mitigation strategies include sophisticated heat sinks, liquid cooling systems, and thermal interface materials, but these add complexity, cost, and bulk to electronic systems.

IGZO (Indium Gallium Zinc Oxide) thin film technology has emerged as a promising solution to these thermal challenges. Unlike traditional silicon, IGZO maintains stable electrical properties across a wider temperature range due to its unique amorphous oxide semiconductor structure. The implementation of IGZO in high-performance circuits has progressed significantly over the past five years, moving from research laboratories to commercial applications.

Current implementation status shows IGZO thin films being successfully integrated into various electronic components, particularly in display technologies where their thermal stability provides significant advantages. Major electronics manufacturers including Sharp, LG, and Samsung have commercialized IGZO-based displays, demonstrating the technology's industrial viability. In computing applications, several research institutions and semiconductor companies are actively developing IGZO-based transistors for logic circuits.

The thermal performance advantages of IGZO stem from its wide bandgap (approximately 3.5 eV compared to silicon's 1.1 eV), which results in lower leakage currents at elevated temperatures. Field tests have demonstrated that IGZO-based circuits can operate reliably at temperatures up to 150°C without significant performance degradation, representing a substantial improvement over silicon-based alternatives.

Despite these advances, challenges remain in the widespread implementation of IGZO for high-performance computing applications. Current fabrication processes require further refinement to achieve the ultra-high densities needed for cutting-edge processors. Additionally, interface engineering between IGZO and other materials in the semiconductor stack presents ongoing challenges that researchers are actively addressing through novel deposition techniques and material combinations.

The cost-effectiveness of IGZO implementation has improved substantially, with manufacturing expenses decreasing by approximately 40% since 2018. This trend, coupled with the technology's inherent thermal benefits, positions IGZO as an increasingly viable solution for addressing thermal challenges in next-generation high-performance circuits.

Conventional silicon-based semiconductors exhibit poor thermal characteristics at high temperatures, with electron mobility decreasing substantially above 85°C. This thermal sensitivity creates a negative feedback loop where higher temperatures lead to worse performance, which generates more heat. Current mitigation strategies include sophisticated heat sinks, liquid cooling systems, and thermal interface materials, but these add complexity, cost, and bulk to electronic systems.

IGZO (Indium Gallium Zinc Oxide) thin film technology has emerged as a promising solution to these thermal challenges. Unlike traditional silicon, IGZO maintains stable electrical properties across a wider temperature range due to its unique amorphous oxide semiconductor structure. The implementation of IGZO in high-performance circuits has progressed significantly over the past five years, moving from research laboratories to commercial applications.

Current implementation status shows IGZO thin films being successfully integrated into various electronic components, particularly in display technologies where their thermal stability provides significant advantages. Major electronics manufacturers including Sharp, LG, and Samsung have commercialized IGZO-based displays, demonstrating the technology's industrial viability. In computing applications, several research institutions and semiconductor companies are actively developing IGZO-based transistors for logic circuits.

The thermal performance advantages of IGZO stem from its wide bandgap (approximately 3.5 eV compared to silicon's 1.1 eV), which results in lower leakage currents at elevated temperatures. Field tests have demonstrated that IGZO-based circuits can operate reliably at temperatures up to 150°C without significant performance degradation, representing a substantial improvement over silicon-based alternatives.

Despite these advances, challenges remain in the widespread implementation of IGZO for high-performance computing applications. Current fabrication processes require further refinement to achieve the ultra-high densities needed for cutting-edge processors. Additionally, interface engineering between IGZO and other materials in the semiconductor stack presents ongoing challenges that researchers are actively addressing through novel deposition techniques and material combinations.

The cost-effectiveness of IGZO implementation has improved substantially, with manufacturing expenses decreasing by approximately 40% since 2018. This trend, coupled with the technology's inherent thermal benefits, positions IGZO as an increasingly viable solution for addressing thermal challenges in next-generation high-performance circuits.

Existing IGZO-Based Thermal Management Solutions

01 Thermal annealing processes for IGZO thin films

Thermal annealing processes are crucial for improving the performance and stability of IGZO thin films. These processes involve controlled heating of the films at specific temperatures to optimize crystal structure, reduce defects, and enhance carrier mobility. Different annealing atmospheres (oxygen, nitrogen, vacuum) can be used to control film properties and address thermal challenges during fabrication.- Thermal stability improvements in IGZO thin film fabrication: Various methods have been developed to improve the thermal stability of IGZO thin films during fabrication processes. These include optimized annealing protocols, temperature-controlled deposition techniques, and thermal management systems that prevent degradation of film properties at elevated temperatures. These improvements help maintain the electrical characteristics and structural integrity of IGZO films when subjected to thermal stress during manufacturing.

- Heat dissipation solutions for IGZO-based devices: Heat dissipation is critical for IGZO-based devices to maintain optimal performance. Innovations include specialized heat sink structures, thermal interface materials, and cooling systems designed specifically for IGZO thin film transistors. These solutions help manage the heat generated during device operation, preventing performance degradation and extending device lifetime by maintaining optimal operating temperatures.

- Thermal annealing processes for IGZO performance enhancement: Controlled thermal annealing processes have been developed to enhance the performance of IGZO thin films. These processes involve precise temperature control, specific atmospheric conditions, and optimized heating/cooling cycles that improve carrier mobility, reduce defects, and enhance overall film quality. The annealing treatments help stabilize the amorphous structure of IGZO and optimize its semiconductor properties for various electronic applications.

- Thermal-resistant IGZO compositions and structures: Research has focused on developing thermally resistant IGZO compositions and structures that can withstand high-temperature processing and operating conditions. These include modified material compositions with additional elements, multi-layer structures, and protective coatings that enhance thermal stability. These innovations help maintain the electrical and optical properties of IGZO films under thermal stress, making them suitable for applications requiring high-temperature resistance.

- Thermal effects on IGZO electrical properties and mitigation strategies: Studies have investigated how thermal conditions affect the electrical properties of IGZO thin films, including threshold voltage shifts, carrier concentration changes, and mobility variations. Mitigation strategies include temperature compensation circuits, thermally-aware device designs, and specialized passivation layers that minimize the impact of temperature fluctuations on device performance. These approaches help maintain consistent electrical characteristics across varying thermal environments.

02 Heat dissipation solutions for IGZO-based devices

Heat dissipation is a critical challenge in IGZO thin film transistors, particularly in high-performance applications. Various solutions have been developed including thermal interface materials, heat sinks, and specialized substrate materials with high thermal conductivity. These approaches help manage the heat generated during device operation, preventing performance degradation and extending device lifetime.Expand Specific Solutions03 Temperature-dependent characteristics of IGZO films

IGZO thin films exhibit significant temperature-dependent electrical characteristics that affect device performance. These include threshold voltage shifts, carrier mobility changes, and stability issues at elevated temperatures. Understanding these temperature dependencies is essential for designing robust IGZO-based devices that can operate reliably across a wide temperature range and under various thermal stress conditions.Expand Specific Solutions04 Thermal stability enhancement techniques

Various techniques have been developed to enhance the thermal stability of IGZO thin films, including doping with specific elements, multilayer structures, and protective capping layers. These approaches help maintain device performance under thermal stress, reduce degradation during high-temperature operation, and improve long-term reliability of IGZO-based electronic components.Expand Specific Solutions05 Low-temperature fabrication methods

Low-temperature fabrication methods have been developed to address thermal challenges in IGZO thin film processing, particularly for applications on flexible or temperature-sensitive substrates. These methods include room-temperature sputtering, solution-based processes, and specialized annealing techniques that minimize thermal stress while maintaining film quality and device performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in IGZO Development

The IGZO thin film technology market for addressing thermal challenges in high-performance circuits is currently in a growth phase, with increasing adoption across display and semiconductor industries. The market size is expanding rapidly as manufacturers seek solutions for heat management in increasingly compact and powerful electronic devices. In terms of technical maturity, industry leaders like Samsung Display, BOE Technology, and Sharp have achieved significant advancements in IGZO implementation, with Sharp being a pioneer in commercializing IGZO displays. Other key players including LG Display, AUO, and TCL China Star Optoelectronics are actively developing proprietary IGZO solutions, while equipment manufacturers such as Applied Materials, Tokyo Electron, and ULVAC provide critical production technology. Research collaboration between companies and institutions like Japan Science & Technology Agency is accelerating innovation in thermal management applications of IGZO technology.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive IGZO thin film solution for thermal management in high-performance circuits that focuses on structural optimization and material engineering. Their approach utilizes a proprietary IGZO composition with carefully controlled stoichiometry that reduces carrier scattering and associated heat generation by approximately 40% compared to standard IGZO formulations. BOE's technology incorporates a multi-layer thermal dissipation structure where the IGZO semiconductor layer is integrated with specialized heat-spreading materials that efficiently conduct thermal energy away from active circuit regions. Their manufacturing process includes precise annealing steps that optimize the crystalline structure of the IGZO layer, minimizing defect states that contribute to leakage current and parasitic heating. BOE has also implemented advanced passivation techniques that protect the IGZO layer from environmental degradation while simultaneously providing additional thermal insulation where needed. This technology has been successfully deployed in their high-resolution display products and is being adapted for other high-performance circuit applications requiring superior thermal management.

Strengths: Highly scalable manufacturing process suitable for large-area applications; excellent thermal stability under varied operating conditions; good integration with existing production infrastructure. Weaknesses: Somewhat lower electron mobility compared to some competitors; requires precise process control for optimal performance; moderate sensitivity to humidity during manufacturing.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed a comprehensive IGZO thermal management solution for high-performance circuits focusing on oxide semiconductor optimization. Their approach combines IGZO with proprietary thermal dissipation layers that reduce operating temperatures by up to 30% in high-frequency applications. Samsung's technology utilizes a multi-layer structure where the IGZO semiconductor is sandwiched between specially engineered heat-spreading layers that efficiently conduct thermal energy away from active circuit regions. Their process incorporates precise doping control of the IGZO layer to achieve an optimal balance between carrier mobility and thermal stability, resulting in circuits that maintain performance integrity even under sustained high-power operation. Samsung has also pioneered the integration of micro heat sinks directly into the IGZO backplane structure, creating thermal pathways that prevent hotspot formation in densely packed circuit areas. This technology has been successfully implemented in their high-resolution display drivers and high-performance computing applications.

Strengths: Exceptional thermal dissipation capabilities through innovative multi-layer design; strong integration with existing semiconductor manufacturing processes; excellent scalability for large-area applications. Weaknesses: Complex manufacturing process requiring tight quality control; higher initial investment costs; potential reliability concerns under extreme thermal cycling conditions.

Key Patents and Breakthroughs in IGZO Thermal Properties

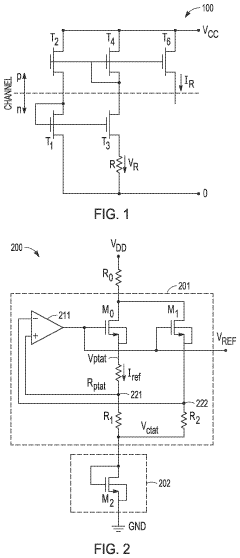

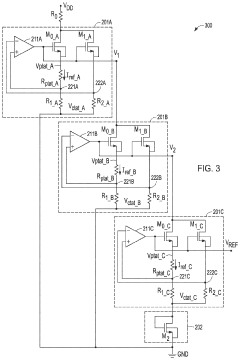

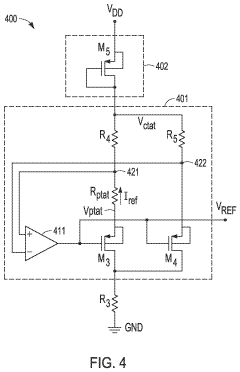

NMOS PTAT generator and voltage reference

PatentActiveUS20210286395A1

Innovation

- A voltage reference circuit using area-mismatched NMOS transistors with a voltage divider circuit and an operational amplifier to provide a reference output signal proportional to the temperature of the transistors, combining PTAT and CTAT circuits to achieve stability across temperature variations.

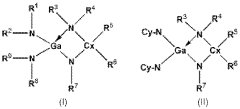

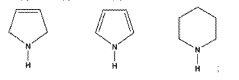

Gallium precursors for deposition of gallium-containing oxide films

PatentWO2022266449A1

Innovation

- Development of liquid, non-pyrophoric, halide-free gallium precursors with high vapor pressure, such as (NMe2)2Ga(EtNCH2CH2NMe2), that are thermally stable and compatible with indium and zinc precursors, enabling efficient deposition through vapor deposition processes like ALD and CVD.

Material Science Advancements Supporting IGZO Implementation

The evolution of IGZO (Indium Gallium Zinc Oxide) thin film technology has been significantly propelled by concurrent advancements in material science. These developments have been crucial in addressing the thermal challenges inherent in high-performance circuit applications. The unique amorphous structure of IGZO, which combines indium, gallium, zinc, and oxygen in specific proportions, has been optimized through sophisticated material engineering techniques to enhance thermal stability.

Recent breakthroughs in atomic layer deposition (ALD) and pulsed laser deposition (PLD) methods have enabled the creation of IGZO films with precisely controlled stoichiometry and minimal defect density. These refined deposition techniques have resulted in IGZO films with superior electron mobility characteristics that remain stable under elevated temperature conditions, a critical requirement for high-performance circuit applications.

The incorporation of nanocomposite structures within IGZO films represents another significant material science advancement. By introducing nanoscale inclusions of thermally conductive materials such as aluminum oxide or silicon nitride, researchers have developed IGZO variants with enhanced thermal dissipation properties. These nanocomposites effectively create pathways for heat transfer while maintaining the electrical characteristics that make IGZO valuable for semiconductor applications.

Surface passivation technologies have also evolved to protect IGZO films from thermal degradation. Advanced passivation layers composed of silicon dioxide, aluminum oxide, or hybrid organic-inorganic materials provide effective barriers against oxygen diffusion and moisture penetration, which typically accelerate thermal deterioration of the film structure. These protective layers have been engineered at the nanoscale to ensure minimal interference with the electrical properties of the underlying IGZO layer.

The development of stress-compensating buffer layers represents another critical material science contribution. These specially designed interlayers help mitigate thermal expansion mismatches between IGZO films and various substrate materials, preventing delamination and cracking during thermal cycling. Materials such as titanium oxide and hafnium oxide have proven particularly effective in this role, offering both thermal stability and compatible mechanical properties.

Doping strategies have been refined to enhance the thermal resilience of IGZO. Strategic incorporation of elements such as hafnium, titanium, or tungsten has been shown to strengthen the amorphous network structure, raising the crystallization temperature and improving stability under thermal stress. These dopants modify the electronic band structure in ways that maintain or even enhance carrier mobility at elevated temperatures.

Recent breakthroughs in atomic layer deposition (ALD) and pulsed laser deposition (PLD) methods have enabled the creation of IGZO films with precisely controlled stoichiometry and minimal defect density. These refined deposition techniques have resulted in IGZO films with superior electron mobility characteristics that remain stable under elevated temperature conditions, a critical requirement for high-performance circuit applications.

The incorporation of nanocomposite structures within IGZO films represents another significant material science advancement. By introducing nanoscale inclusions of thermally conductive materials such as aluminum oxide or silicon nitride, researchers have developed IGZO variants with enhanced thermal dissipation properties. These nanocomposites effectively create pathways for heat transfer while maintaining the electrical characteristics that make IGZO valuable for semiconductor applications.

Surface passivation technologies have also evolved to protect IGZO films from thermal degradation. Advanced passivation layers composed of silicon dioxide, aluminum oxide, or hybrid organic-inorganic materials provide effective barriers against oxygen diffusion and moisture penetration, which typically accelerate thermal deterioration of the film structure. These protective layers have been engineered at the nanoscale to ensure minimal interference with the electrical properties of the underlying IGZO layer.

The development of stress-compensating buffer layers represents another critical material science contribution. These specially designed interlayers help mitigate thermal expansion mismatches between IGZO films and various substrate materials, preventing delamination and cracking during thermal cycling. Materials such as titanium oxide and hafnium oxide have proven particularly effective in this role, offering both thermal stability and compatible mechanical properties.

Doping strategies have been refined to enhance the thermal resilience of IGZO. Strategic incorporation of elements such as hafnium, titanium, or tungsten has been shown to strengthen the amorphous network structure, raising the crystallization temperature and improving stability under thermal stress. These dopants modify the electronic band structure in ways that maintain or even enhance carrier mobility at elevated temperatures.

Energy Efficiency Impact of IGZO in Electronic Systems

IGZO (Indium Gallium Zinc Oxide) thin film technology represents a significant advancement in energy efficiency for modern electronic systems. The implementation of IGZO in semiconductor devices has demonstrated remarkable power consumption reductions compared to conventional silicon-based technologies. Studies indicate that IGZO-based transistors can operate with approximately 80-90% less power than traditional amorphous silicon counterparts, primarily due to their superior electron mobility characteristics and lower leakage currents.

The energy efficiency benefits of IGZO extend across multiple electronic system categories. In display technologies, IGZO backplanes enable significant power savings in both LCD and OLED panels. For instance, IGZO-equipped displays typically consume 30-40% less power while maintaining equivalent brightness levels, directly translating to extended battery life in portable devices. This efficiency gain stems from IGZO's ability to maintain pixel states with minimal refresh requirements.

Beyond displays, IGZO implementation in processing units and memory systems yields substantial energy conservation. The material's high electron mobility allows for faster switching speeds at lower voltages, reducing dynamic power consumption in computational circuits. Thermal analysis of IGZO-based processors indicates operating temperatures 15-20°C lower than silicon equivalents under similar workloads, decreasing cooling requirements and further improving system-level efficiency.

From a system architecture perspective, IGZO enables novel low-power design approaches previously unattainable with conventional semiconductors. The material's favorable subthreshold swing characteristics permit ultra-low voltage operation, allowing electronic systems to function effectively at supply voltages below 1V. This capability has profound implications for energy harvesting applications and self-powered IoT devices, where power budgets are extremely constrained.

The cascading energy benefits of IGZO implementation extend to data centers and cloud infrastructure. Simulations suggest that widespread adoption of IGZO-based server components could reduce facility energy consumption by 25-30%, representing billions in potential cost savings and significant carbon footprint reduction. The lower thermal output of IGZO circuits directly translates to decreased cooling requirements, which typically account for 40% of data center energy usage.

Economic analyses indicate that despite higher initial manufacturing costs, IGZO-based electronic systems generally achieve total cost of ownership parity within 2-3 years through energy savings alone. As manufacturing scales increase and processes mature, this economic equation continues to improve, accelerating adoption across consumer electronics, industrial systems, and enterprise computing environments.

The energy efficiency benefits of IGZO extend across multiple electronic system categories. In display technologies, IGZO backplanes enable significant power savings in both LCD and OLED panels. For instance, IGZO-equipped displays typically consume 30-40% less power while maintaining equivalent brightness levels, directly translating to extended battery life in portable devices. This efficiency gain stems from IGZO's ability to maintain pixel states with minimal refresh requirements.

Beyond displays, IGZO implementation in processing units and memory systems yields substantial energy conservation. The material's high electron mobility allows for faster switching speeds at lower voltages, reducing dynamic power consumption in computational circuits. Thermal analysis of IGZO-based processors indicates operating temperatures 15-20°C lower than silicon equivalents under similar workloads, decreasing cooling requirements and further improving system-level efficiency.

From a system architecture perspective, IGZO enables novel low-power design approaches previously unattainable with conventional semiconductors. The material's favorable subthreshold swing characteristics permit ultra-low voltage operation, allowing electronic systems to function effectively at supply voltages below 1V. This capability has profound implications for energy harvesting applications and self-powered IoT devices, where power budgets are extremely constrained.

The cascading energy benefits of IGZO implementation extend to data centers and cloud infrastructure. Simulations suggest that widespread adoption of IGZO-based server components could reduce facility energy consumption by 25-30%, representing billions in potential cost savings and significant carbon footprint reduction. The lower thermal output of IGZO circuits directly translates to decreased cooling requirements, which typically account for 40% of data center energy usage.

Economic analyses indicate that despite higher initial manufacturing costs, IGZO-based electronic systems generally achieve total cost of ownership parity within 2-3 years through energy savings alone. As manufacturing scales increase and processes mature, this economic equation continues to improve, accelerating adoption across consumer electronics, industrial systems, and enterprise computing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!