Comparative Study of Power Steering Fluids in Cold Weather Conditions

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Power Steering Fluid Evolution and Objectives

Power steering fluid has undergone significant evolution since its introduction in the 1950s. Initially, automotive manufacturers used automatic transmission fluid (ATF) for power steering systems due to its availability and similar properties. However, as vehicle technologies advanced, the need for specialized power steering fluids became apparent, especially in cold weather conditions.

The development of power steering fluids has been driven by the increasing demands of modern vehicles, including improved fuel efficiency, reduced emissions, and enhanced performance in extreme temperatures. Early power steering fluids were primarily mineral oil-based, which provided adequate lubrication but had limitations in terms of thermal stability and low-temperature performance.

In the 1970s and 1980s, synthetic-based power steering fluids emerged, offering improved thermal stability and better low-temperature flow characteristics. These synthetic fluids, often based on polyalphaolefins (PAOs) or synthetic esters, demonstrated superior performance in cold weather conditions compared to their mineral oil counterparts.

The 1990s saw the introduction of hybrid fluids, combining mineral oils with synthetic components to balance performance and cost. These hybrid fluids aimed to provide improved cold-weather performance while maintaining compatibility with existing power steering system components.

Recent advancements in power steering fluid technology have focused on enhancing low-temperature performance, reducing pump wear, and improving overall system efficiency. Modern power steering fluids are formulated with advanced additive packages that provide anti-wear protection, oxidation stability, and seal compatibility across a wide temperature range.

The primary objectives of power steering fluid evolution in cold weather conditions include:

1. Improving low-temperature fluidity to ensure smooth operation during cold starts and prevent pump cavitation.

2. Enhancing thermal stability to maintain fluid properties under extreme temperature fluctuations.

3. Reducing power steering system wear, particularly in cold weather when metal-to-metal contact is more likely.

4. Optimizing viscosity characteristics to provide consistent steering feel across a wide temperature range.

5. Ensuring compatibility with modern power steering system materials, including seals and hoses.

As environmental concerns grow, there is an increasing focus on developing eco-friendly power steering fluids that maintain excellent cold weather performance while reducing environmental impact. This includes the use of biodegradable base oils and additives that meet stringent environmental regulations.

The ongoing evolution of power steering fluids aims to address the challenges posed by cold weather conditions while meeting the demands of modern vehicle technologies, such as electric power steering systems and hybrid vehicles. Future developments are likely to focus on further improving low-temperature performance, extending fluid life, and enhancing overall system efficiency in cold climates.

The development of power steering fluids has been driven by the increasing demands of modern vehicles, including improved fuel efficiency, reduced emissions, and enhanced performance in extreme temperatures. Early power steering fluids were primarily mineral oil-based, which provided adequate lubrication but had limitations in terms of thermal stability and low-temperature performance.

In the 1970s and 1980s, synthetic-based power steering fluids emerged, offering improved thermal stability and better low-temperature flow characteristics. These synthetic fluids, often based on polyalphaolefins (PAOs) or synthetic esters, demonstrated superior performance in cold weather conditions compared to their mineral oil counterparts.

The 1990s saw the introduction of hybrid fluids, combining mineral oils with synthetic components to balance performance and cost. These hybrid fluids aimed to provide improved cold-weather performance while maintaining compatibility with existing power steering system components.

Recent advancements in power steering fluid technology have focused on enhancing low-temperature performance, reducing pump wear, and improving overall system efficiency. Modern power steering fluids are formulated with advanced additive packages that provide anti-wear protection, oxidation stability, and seal compatibility across a wide temperature range.

The primary objectives of power steering fluid evolution in cold weather conditions include:

1. Improving low-temperature fluidity to ensure smooth operation during cold starts and prevent pump cavitation.

2. Enhancing thermal stability to maintain fluid properties under extreme temperature fluctuations.

3. Reducing power steering system wear, particularly in cold weather when metal-to-metal contact is more likely.

4. Optimizing viscosity characteristics to provide consistent steering feel across a wide temperature range.

5. Ensuring compatibility with modern power steering system materials, including seals and hoses.

As environmental concerns grow, there is an increasing focus on developing eco-friendly power steering fluids that maintain excellent cold weather performance while reducing environmental impact. This includes the use of biodegradable base oils and additives that meet stringent environmental regulations.

The ongoing evolution of power steering fluids aims to address the challenges posed by cold weather conditions while meeting the demands of modern vehicle technologies, such as electric power steering systems and hybrid vehicles. Future developments are likely to focus on further improving low-temperature performance, extending fluid life, and enhancing overall system efficiency in cold climates.

Cold Weather Market Analysis for Power Steering Fluids

The power steering fluid market in cold weather conditions presents a significant opportunity for manufacturers and suppliers. As temperatures drop, the demand for specialized fluids that can maintain optimal performance in harsh winter environments increases. This market segment is particularly crucial in regions with long, severe winters, such as Northern Europe, Canada, and parts of the United States.

The cold weather power steering fluid market is driven by several factors. Firstly, there is a growing awareness among vehicle owners about the importance of using appropriate fluids for different climatic conditions. This awareness is fueled by automotive manufacturers' recommendations and the increasing availability of information through digital channels. Secondly, the expansion of the automotive industry in cold climate regions has led to a higher demand for cold-weather-specific automotive fluids.

Market research indicates that the global power steering fluid market is expected to grow steadily over the next few years, with cold weather formulations playing a significant role in this growth. The increasing number of vehicles on the road, coupled with the trend towards longer vehicle lifespans, contributes to the sustained demand for power steering fluids, including those designed for cold weather use.

In terms of market segmentation, cold weather power steering fluids cater to both the OEM (Original Equipment Manufacturer) and aftermarket sectors. The OEM segment is particularly important, as automotive manufacturers are increasingly focusing on providing vehicles that can perform optimally in diverse weather conditions. The aftermarket segment, on the other hand, offers opportunities for fluid manufacturers to directly target consumers and automotive service centers.

Consumer behavior in this market is influenced by factors such as brand reputation, product performance, and price. There is a growing trend towards premium, high-performance fluids that offer enhanced protection in extreme cold conditions. This trend is particularly evident in regions where severe winter weather is common, as consumers are willing to invest in products that ensure the longevity and reliability of their vehicles.

The competitive landscape of the cold weather power steering fluid market is characterized by the presence of both large multinational corporations and smaller, specialized manufacturers. Key players in this market are investing in research and development to create innovative formulations that can withstand extremely low temperatures while maintaining optimal viscosity and performance characteristics.

Looking ahead, the market for cold weather power steering fluids is expected to evolve with technological advancements in automotive engineering. The shift towards electric power steering systems may impact the traditional hydraulic fluid market, but it also opens up opportunities for new types of specialized fluids designed for these systems in cold weather conditions.

The cold weather power steering fluid market is driven by several factors. Firstly, there is a growing awareness among vehicle owners about the importance of using appropriate fluids for different climatic conditions. This awareness is fueled by automotive manufacturers' recommendations and the increasing availability of information through digital channels. Secondly, the expansion of the automotive industry in cold climate regions has led to a higher demand for cold-weather-specific automotive fluids.

Market research indicates that the global power steering fluid market is expected to grow steadily over the next few years, with cold weather formulations playing a significant role in this growth. The increasing number of vehicles on the road, coupled with the trend towards longer vehicle lifespans, contributes to the sustained demand for power steering fluids, including those designed for cold weather use.

In terms of market segmentation, cold weather power steering fluids cater to both the OEM (Original Equipment Manufacturer) and aftermarket sectors. The OEM segment is particularly important, as automotive manufacturers are increasingly focusing on providing vehicles that can perform optimally in diverse weather conditions. The aftermarket segment, on the other hand, offers opportunities for fluid manufacturers to directly target consumers and automotive service centers.

Consumer behavior in this market is influenced by factors such as brand reputation, product performance, and price. There is a growing trend towards premium, high-performance fluids that offer enhanced protection in extreme cold conditions. This trend is particularly evident in regions where severe winter weather is common, as consumers are willing to invest in products that ensure the longevity and reliability of their vehicles.

The competitive landscape of the cold weather power steering fluid market is characterized by the presence of both large multinational corporations and smaller, specialized manufacturers. Key players in this market are investing in research and development to create innovative formulations that can withstand extremely low temperatures while maintaining optimal viscosity and performance characteristics.

Looking ahead, the market for cold weather power steering fluids is expected to evolve with technological advancements in automotive engineering. The shift towards electric power steering systems may impact the traditional hydraulic fluid market, but it also opens up opportunities for new types of specialized fluids designed for these systems in cold weather conditions.

Current Challenges in Cold Weather Power Steering Performance

Power steering systems face significant challenges in cold weather conditions, primarily due to the increased viscosity of power steering fluids at low temperatures. This heightened viscosity can lead to reduced system efficiency, increased wear on components, and potential system failures. One of the main issues is the difficulty in pumping thicker fluid through the system, which can cause sluggish steering response and increased power consumption.

Cold temperatures also affect the seals and hoses within the power steering system. These components may become brittle and prone to cracking or leaking, leading to fluid loss and potential system failure. Additionally, the extreme temperature changes between cold starts and normal operating conditions can cause thermal expansion and contraction, further stressing system components.

Another challenge is the potential for moisture accumulation within the power steering fluid. In cold weather, condensation can form inside the system, leading to water contamination. This can cause corrosion of metal components and degradation of the fluid's lubricating properties, ultimately reducing the system's lifespan and performance.

The formation of ice crystals within the power steering fluid is a critical concern in extremely cold conditions. These crystals can cause abrasion and damage to pump components, valves, and seals. They may also lead to blockages in narrow passages within the system, further impeding fluid flow and reducing steering assistance.

Cold weather also impacts the performance of power steering pumps. The increased fluid viscosity places additional strain on the pump, potentially leading to premature wear or failure. This can result in reduced pump efficiency, increased fuel consumption, and a higher likelihood of system breakdowns.

Furthermore, the cold start-up process poses unique challenges for power steering systems. The initial surge of cold, viscous fluid through the system can cause momentary spikes in pressure, potentially damaging sensitive components. This issue is particularly pronounced in vehicles that are left outdoors in freezing temperatures for extended periods.

Addressing these challenges requires a multifaceted approach, including the development of advanced power steering fluids specifically formulated for cold weather performance, improved system designs that account for extreme temperature variations, and enhanced maintenance practices to mitigate the effects of cold weather on power steering systems.

Cold temperatures also affect the seals and hoses within the power steering system. These components may become brittle and prone to cracking or leaking, leading to fluid loss and potential system failure. Additionally, the extreme temperature changes between cold starts and normal operating conditions can cause thermal expansion and contraction, further stressing system components.

Another challenge is the potential for moisture accumulation within the power steering fluid. In cold weather, condensation can form inside the system, leading to water contamination. This can cause corrosion of metal components and degradation of the fluid's lubricating properties, ultimately reducing the system's lifespan and performance.

The formation of ice crystals within the power steering fluid is a critical concern in extremely cold conditions. These crystals can cause abrasion and damage to pump components, valves, and seals. They may also lead to blockages in narrow passages within the system, further impeding fluid flow and reducing steering assistance.

Cold weather also impacts the performance of power steering pumps. The increased fluid viscosity places additional strain on the pump, potentially leading to premature wear or failure. This can result in reduced pump efficiency, increased fuel consumption, and a higher likelihood of system breakdowns.

Furthermore, the cold start-up process poses unique challenges for power steering systems. The initial surge of cold, viscous fluid through the system can cause momentary spikes in pressure, potentially damaging sensitive components. This issue is particularly pronounced in vehicles that are left outdoors in freezing temperatures for extended periods.

Addressing these challenges requires a multifaceted approach, including the development of advanced power steering fluids specifically formulated for cold weather performance, improved system designs that account for extreme temperature variations, and enhanced maintenance practices to mitigate the effects of cold weather on power steering systems.

Existing Cold Weather Power Steering Fluid Solutions

01 Fluid composition for improved performance

Power steering fluid compositions are designed to enhance overall system performance. These formulations may include specific additives to improve lubrication, reduce wear, and maintain viscosity under various operating conditions. The carefully balanced composition ensures optimal hydraulic performance and protection of power steering components.- Composition of power steering fluids: Power steering fluids are formulated with specific additives to enhance performance. These may include viscosity modifiers, anti-wear agents, and corrosion inhibitors. The composition is designed to maintain optimal viscosity across a range of temperatures and operating conditions, ensuring smooth and efficient power steering operation.

- Hydraulic systems for power steering: Hydraulic systems play a crucial role in power steering performance. These systems typically include pumps, valves, and cylinders that work together to assist in steering. The design and efficiency of these components significantly impact the overall performance of the power steering system, including responsiveness and energy consumption.

- Temperature management in power steering systems: Effective temperature management is essential for maintaining power steering fluid performance. This involves the use of cooling systems, heat exchangers, or specially designed fluid reservoirs. Proper temperature control helps prevent fluid degradation, maintains optimal viscosity, and ensures consistent steering performance across various operating conditions.

- Filtration and contamination control: Filtration systems are crucial for maintaining power steering fluid performance. These systems remove contaminants and particles that can degrade fluid quality and damage steering components. Advanced filtration techniques and materials are employed to ensure the longevity and efficiency of power steering systems.

- Electric and hybrid power steering systems: Electric and hybrid power steering systems are emerging technologies that aim to improve performance and efficiency. These systems may reduce or eliminate the need for traditional hydraulic fluids, instead relying on electric motors and sensors. They offer potential benefits in terms of energy efficiency, responsiveness, and adaptability to different driving conditions.

02 Pump design for efficient fluid circulation

Innovative pump designs are crucial for efficient power steering fluid circulation. These designs focus on improving flow rates, reducing energy consumption, and minimizing noise. Advanced pump configurations may incorporate features such as variable displacement or electric-driven systems to optimize fluid delivery based on steering demands.Expand Specific Solutions03 Fluid reservoir and circulation system improvements

Enhancements in fluid reservoir design and circulation systems contribute to better power steering performance. These improvements may include features like integrated filtration systems, temperature regulation mechanisms, or air removal devices. Such advancements help maintain fluid quality, prevent contamination, and ensure consistent steering assistance.Expand Specific Solutions04 Adaptive power steering systems

Adaptive power steering systems adjust fluid pressure and flow based on various factors such as vehicle speed, steering angle, and driver input. These systems may incorporate electronic controls, sensors, and variable-assist mechanisms to optimize steering feel and performance across different driving conditions.Expand Specific Solutions05 Fluid maintenance and monitoring technologies

Advanced technologies for monitoring and maintaining power steering fluid quality are essential for long-term performance. These may include real-time fluid condition sensors, automatic fluid level adjustment systems, or integrated fluid cooling mechanisms. Such technologies help prevent fluid degradation, ensure proper viscosity, and extend the lifespan of power steering components.Expand Specific Solutions

Major Power Steering Fluid Manufacturers and Suppliers

The comparative study of power steering fluids in cold weather conditions reflects a mature market with established players and ongoing innovation. The automotive industry's focus on improving vehicle performance in extreme conditions drives this research. Key players like Volvo Lastvagnar AB, ZF Friedrichshafen AG, and JTEKT Corp. are likely leading the charge, leveraging their extensive experience in automotive systems. The market size is substantial, given the global demand for vehicles equipped with power steering systems. Technological advancements from companies such as Siemens AG and Ford Global Technologies LLC are pushing the boundaries of fluid performance in low temperatures, enhancing overall vehicle reliability and safety in cold climates.

Ford Global Technologies LLC

Technical Solution: Ford has developed a proprietary power steering fluid formulation optimized for cold weather performance. Their fluid utilizes a blend of synthetic base oils and advanced polymer technology to maintain consistent viscosity across a wide temperature range. Ford's research indicates that their fluid can provide smooth steering response at temperatures as low as -30°C[2]. Additionally, Ford has implemented a thermal management system in their power steering units that works in conjunction with the specialized fluid to rapidly warm the system to optimal operating temperature, reducing the impact of cold starts on steering performance[4].

Strengths: Rapid warm-up capabilities, wide temperature range effectiveness. Weakness: May require more frequent fluid changes in extreme cold conditions.

ZF Friedrichshafen AG

Technical Solution: ZF Friedrichshafen AG has developed advanced power steering fluids specifically designed for cold weather conditions. Their innovative fluid formulation incorporates low-temperature viscosity modifiers and anti-wear additives to maintain optimal performance in extreme cold. The company's research has shown that their fluid can maintain proper viscosity down to -40°C, ensuring smooth steering operation even in arctic conditions[1]. ZF's fluid also includes corrosion inhibitors to protect steering system components from moisture-related damage, which is particularly crucial in cold environments where condensation can be a significant issue[3].

Strengths: Excellent low-temperature performance, enhanced component protection. Weakness: Potentially higher cost due to specialized additives.

Key Innovations in Cold-Resistant Power Steering Fluids

Hydraulic composition for extreme cold

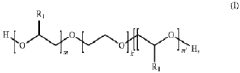

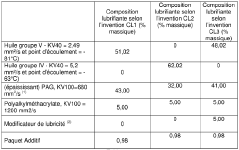

PatentWO2019086423A1

Innovation

- A hydraulic composition combining a base oil with a very low pour point and low kinematic viscosity at 40°C, paired with a thickener such as polyalkylene glycol (PAG) or alkoxylated polyethylene glycols, which provides improved shear stability, storage stability, and compatibility with seals.

Power steering pump flow control

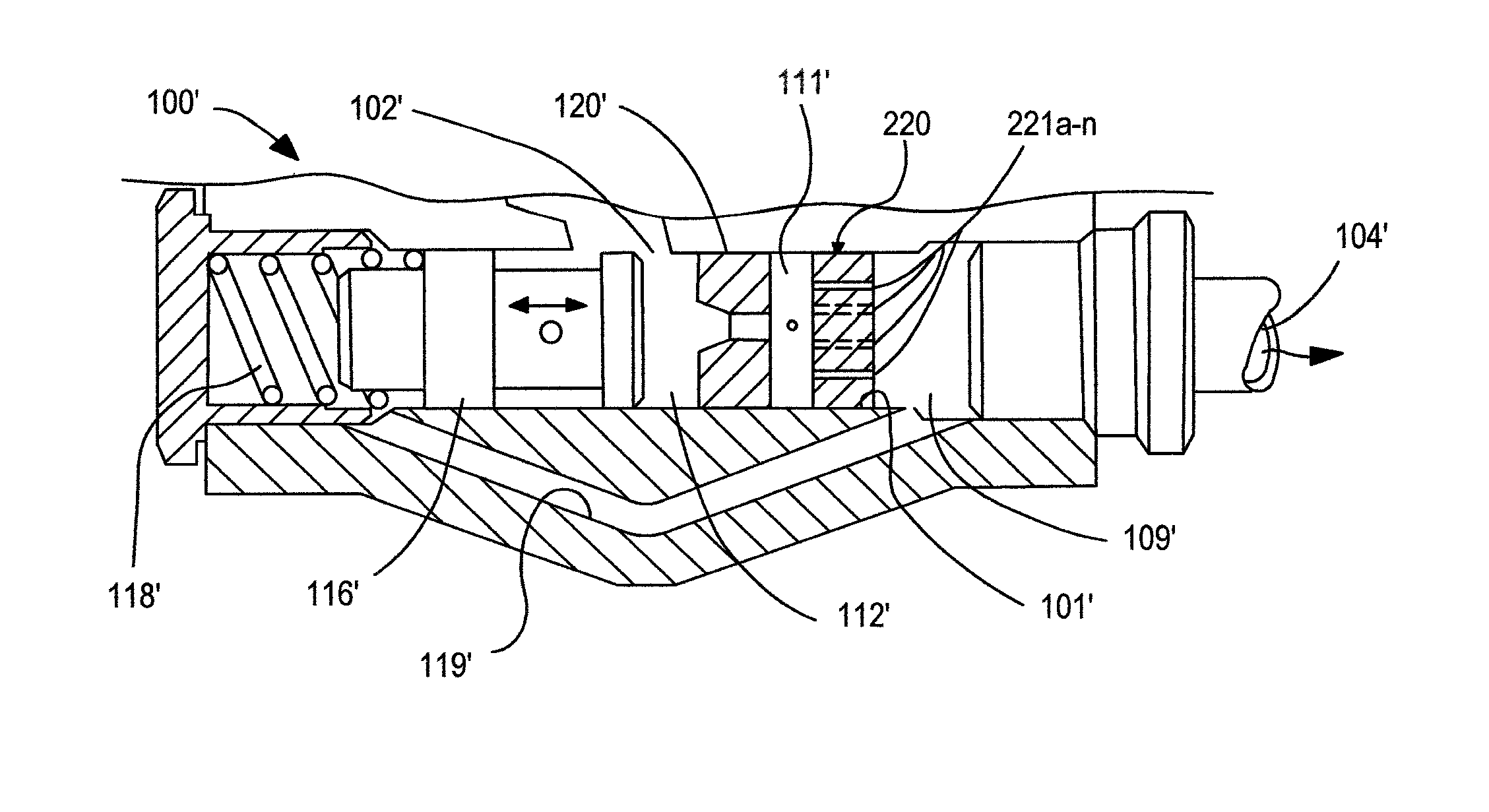

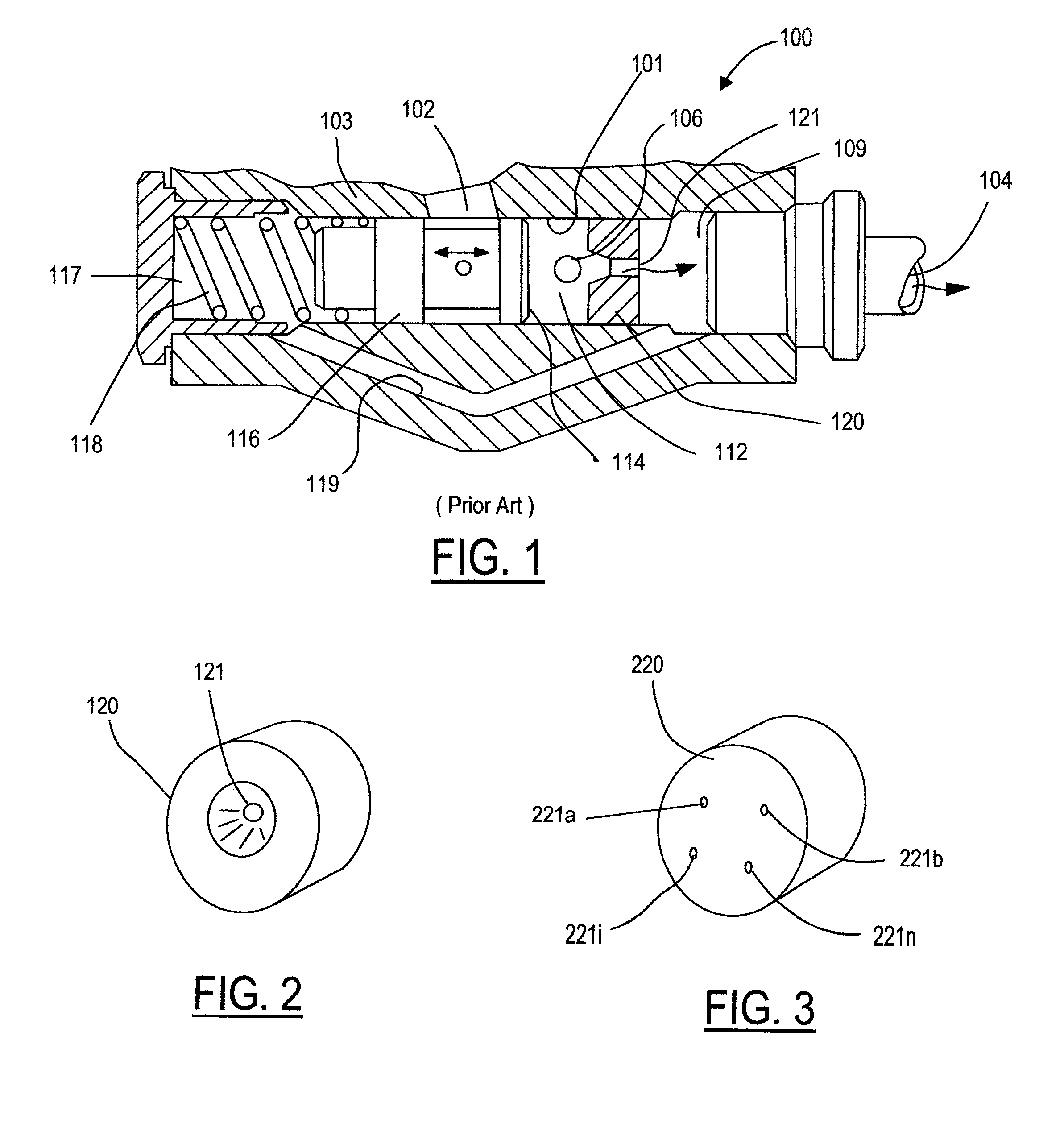

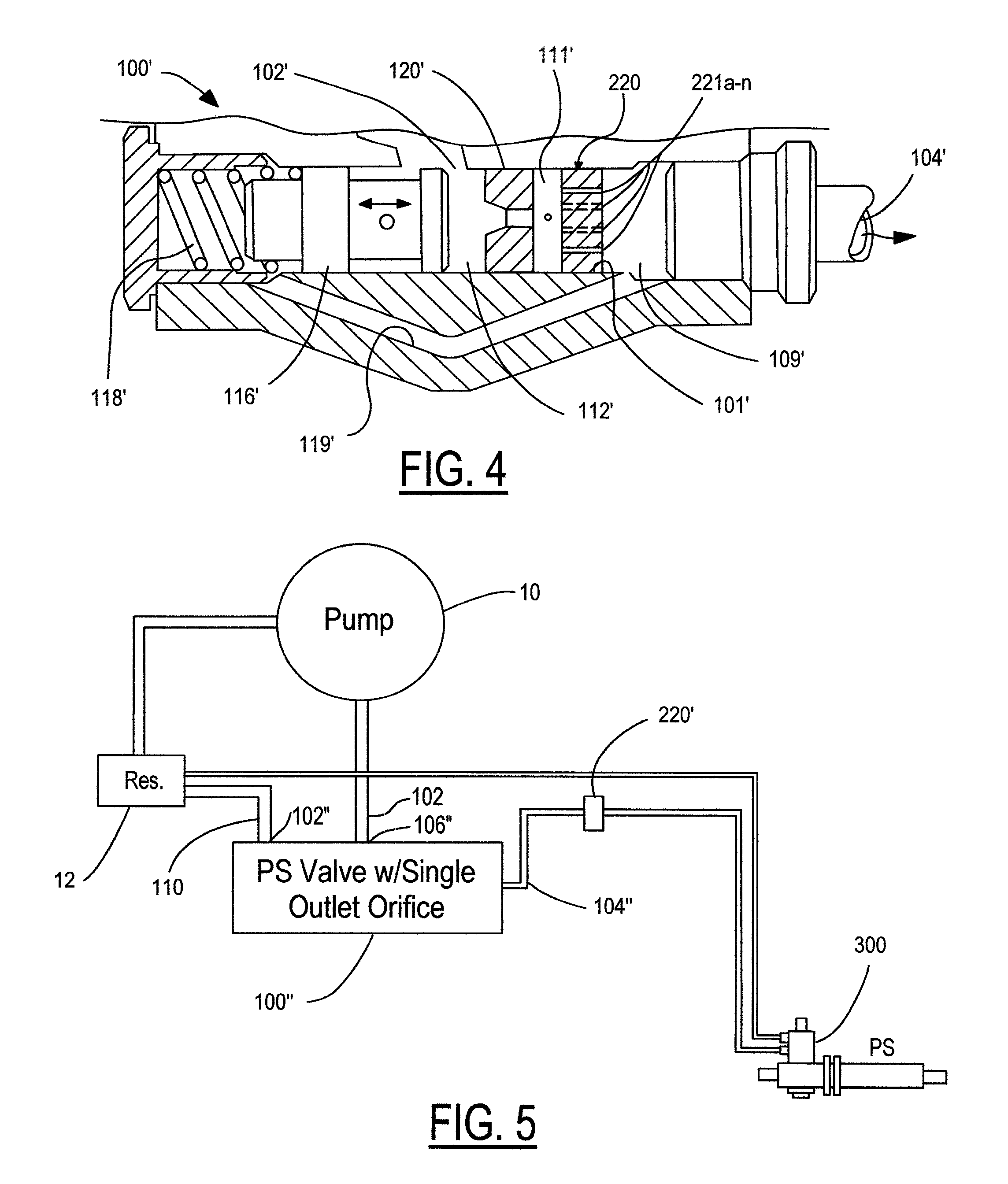

PatentInactiveUS7993111B2

Innovation

- A multiple passage orifice element is added downstream of a single passage outlet orifice element in a hydraulic flow control valve, providing increased resistance to high viscosity fluid flow through a greater wetted surface area, which prevents pulsation and noise by increasing shear forces and backpressure during cold starts, while maintaining normal operation at higher temperatures.

Environmental Impact of Power Steering Fluids

The environmental impact of power steering fluids is a critical consideration in the comparative study of these fluids under cold weather conditions. Power steering fluids, while essential for vehicle operation, can pose significant environmental risks if not properly managed or disposed of. These fluids typically contain a mixture of synthetic or mineral oils, additives, and other chemicals that can be harmful to ecosystems if released into the environment.

In cold weather conditions, the environmental concerns associated with power steering fluids become more pronounced. Low temperatures can affect the viscosity and performance of these fluids, potentially leading to increased leakage or system failures. This heightened risk of fluid release amplifies the potential for environmental contamination, particularly in sensitive ecosystems such as water bodies or soil systems.

One of the primary environmental concerns is the potential for soil contamination. When power steering fluids leak or are improperly disposed of, they can seep into the ground, affecting soil quality and potentially harming plant life. In cold weather, frozen ground can impede the natural filtration process, allowing contaminants to spread more easily once thawing occurs.

Water pollution is another significant risk associated with power steering fluids. In cold climates, snow and ice melt can carry leaked fluids into water systems, potentially impacting aquatic ecosystems. The chemicals present in these fluids can be toxic to fish, plants, and other aquatic organisms, disrupting the delicate balance of freshwater environments.

The production and disposal of power steering fluids also contribute to their environmental footprint. Manufacturing processes often involve energy-intensive operations and the use of non-renewable resources. End-of-life disposal, if not managed properly, can lead to the release of harmful substances into the environment. In cold weather regions, proper disposal becomes more challenging due to limited access to recycling facilities or appropriate waste management systems during harsh winter conditions.

To mitigate these environmental impacts, particularly in cold weather scenarios, several approaches are being explored. These include the development of more environmentally friendly power steering fluid formulations, improved sealing technologies to prevent leaks in extreme temperatures, and enhanced recycling and disposal methods tailored for cold climate regions. Additionally, there is a growing focus on educating vehicle owners and maintenance professionals about the importance of proper fluid handling and disposal practices, especially in areas prone to severe winter conditions.

As the automotive industry continues to evolve, there is an increasing emphasis on developing alternative power steering systems that reduce or eliminate the need for traditional hydraulic fluids. Electric power steering systems, for instance, offer a more environmentally friendly alternative, particularly in cold weather conditions where traditional fluids may face performance challenges.

In cold weather conditions, the environmental concerns associated with power steering fluids become more pronounced. Low temperatures can affect the viscosity and performance of these fluids, potentially leading to increased leakage or system failures. This heightened risk of fluid release amplifies the potential for environmental contamination, particularly in sensitive ecosystems such as water bodies or soil systems.

One of the primary environmental concerns is the potential for soil contamination. When power steering fluids leak or are improperly disposed of, they can seep into the ground, affecting soil quality and potentially harming plant life. In cold weather, frozen ground can impede the natural filtration process, allowing contaminants to spread more easily once thawing occurs.

Water pollution is another significant risk associated with power steering fluids. In cold climates, snow and ice melt can carry leaked fluids into water systems, potentially impacting aquatic ecosystems. The chemicals present in these fluids can be toxic to fish, plants, and other aquatic organisms, disrupting the delicate balance of freshwater environments.

The production and disposal of power steering fluids also contribute to their environmental footprint. Manufacturing processes often involve energy-intensive operations and the use of non-renewable resources. End-of-life disposal, if not managed properly, can lead to the release of harmful substances into the environment. In cold weather regions, proper disposal becomes more challenging due to limited access to recycling facilities or appropriate waste management systems during harsh winter conditions.

To mitigate these environmental impacts, particularly in cold weather scenarios, several approaches are being explored. These include the development of more environmentally friendly power steering fluid formulations, improved sealing technologies to prevent leaks in extreme temperatures, and enhanced recycling and disposal methods tailored for cold climate regions. Additionally, there is a growing focus on educating vehicle owners and maintenance professionals about the importance of proper fluid handling and disposal practices, especially in areas prone to severe winter conditions.

As the automotive industry continues to evolve, there is an increasing emphasis on developing alternative power steering systems that reduce or eliminate the need for traditional hydraulic fluids. Electric power steering systems, for instance, offer a more environmentally friendly alternative, particularly in cold weather conditions where traditional fluids may face performance challenges.

Safety Standards for Automotive Fluids in Extreme Conditions

Safety standards for automotive fluids in extreme conditions are crucial for ensuring the reliability and performance of vehicles in challenging environments. These standards are designed to address the unique challenges posed by extreme temperatures, particularly in cold weather conditions where power steering fluids play a critical role in vehicle operation.

The primary focus of these safety standards is to ensure that automotive fluids, including power steering fluids, maintain their essential properties and functionality across a wide range of temperatures. This is particularly important in cold weather, where fluids can thicken or even freeze, potentially leading to system failures and compromised vehicle safety.

One key aspect of these standards is the requirement for low-temperature fluidity. Power steering fluids must maintain adequate flow characteristics at extremely low temperatures to ensure smooth and responsive steering operation. This is typically measured through viscosity testing at various temperature points, with specific thresholds established for different climate zones.

Thermal stability is another critical factor addressed by these safety standards. Fluids must demonstrate the ability to withstand repeated temperature cycles without degrading or losing their protective properties. This is essential for maintaining long-term performance and preventing premature wear of steering system components.

The standards also emphasize the importance of corrosion protection. In cold weather conditions, moisture can accumulate in the steering system, potentially leading to corrosion of metal components. Power steering fluids must therefore incorporate effective corrosion inhibitors that remain active across the entire temperature range.

Compatibility with system materials is a crucial consideration in these safety standards. Fluids must be formulated to prevent degradation of seals, hoses, and other components, even when subjected to extreme temperature fluctuations. This ensures the integrity of the entire steering system over time.

Environmental considerations are increasingly being incorporated into these standards. This includes requirements for biodegradability and reduced toxicity, ensuring that any leaks or disposal of these fluids have minimal environmental impact, regardless of the temperature conditions.

Testing protocols form a significant part of these safety standards. They typically include accelerated aging tests, extreme temperature cycling, and simulated real-world conditions to verify the long-term performance and safety of the fluids. These tests are designed to replicate the most challenging scenarios that vehicles might encounter in cold weather operations.

The primary focus of these safety standards is to ensure that automotive fluids, including power steering fluids, maintain their essential properties and functionality across a wide range of temperatures. This is particularly important in cold weather, where fluids can thicken or even freeze, potentially leading to system failures and compromised vehicle safety.

One key aspect of these standards is the requirement for low-temperature fluidity. Power steering fluids must maintain adequate flow characteristics at extremely low temperatures to ensure smooth and responsive steering operation. This is typically measured through viscosity testing at various temperature points, with specific thresholds established for different climate zones.

Thermal stability is another critical factor addressed by these safety standards. Fluids must demonstrate the ability to withstand repeated temperature cycles without degrading or losing their protective properties. This is essential for maintaining long-term performance and preventing premature wear of steering system components.

The standards also emphasize the importance of corrosion protection. In cold weather conditions, moisture can accumulate in the steering system, potentially leading to corrosion of metal components. Power steering fluids must therefore incorporate effective corrosion inhibitors that remain active across the entire temperature range.

Compatibility with system materials is a crucial consideration in these safety standards. Fluids must be formulated to prevent degradation of seals, hoses, and other components, even when subjected to extreme temperature fluctuations. This ensures the integrity of the entire steering system over time.

Environmental considerations are increasingly being incorporated into these standards. This includes requirements for biodegradability and reduced toxicity, ensuring that any leaks or disposal of these fluids have minimal environmental impact, regardless of the temperature conditions.

Testing protocols form a significant part of these safety standards. They typically include accelerated aging tests, extreme temperature cycling, and simulated real-world conditions to verify the long-term performance and safety of the fluids. These tests are designed to replicate the most challenging scenarios that vehicles might encounter in cold weather operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!