Comparing Injection Timing in GDI and Traditional Engines

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI vs Traditional Injection: Background & Objectives

Gasoline Direct Injection (GDI) technology represents a significant evolution in internal combustion engine design, marking a departure from traditional port fuel injection systems that have dominated the automotive industry for decades. The historical development of fuel injection systems can be traced back to the early 20th century, with significant commercial implementation beginning in the 1980s through port fuel injection. GDI technology emerged as a mainstream solution in the late 1990s and has seen accelerated adoption in the 21st century as automotive manufacturers seek to meet increasingly stringent emissions regulations and fuel economy standards.

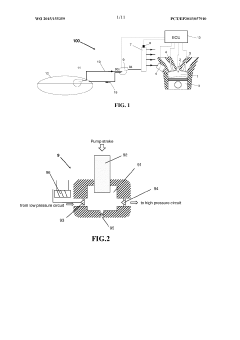

The fundamental difference between GDI and traditional injection systems lies in the location and timing of fuel delivery. Traditional port fuel injection (PFI) systems inject fuel into the intake port where it mixes with air before entering the combustion chamber. In contrast, GDI systems inject fuel directly into the combustion chamber at precisely controlled timing and pressure. This fundamental architectural difference creates significant implications for injection timing strategies that affect engine performance, emissions, and efficiency.

The technical evolution trajectory shows a clear progression from carburetors to electronic fuel injection, then to port injection, and finally to direct injection systems. Each evolutionary step has been driven by the need for more precise control over the air-fuel mixture and combustion process. The current technological landscape features various hybrid approaches as well, including dual-injection systems that combine the benefits of both GDI and PFI technologies.

The primary objectives of modern injection timing research focus on optimizing several critical parameters: maximizing thermal efficiency, minimizing emissions (particularly NOx and particulate matter), enhancing power output, and improving cold-start performance. These objectives must be balanced against practical constraints such as system cost, reliability, and compatibility with existing engine architectures.

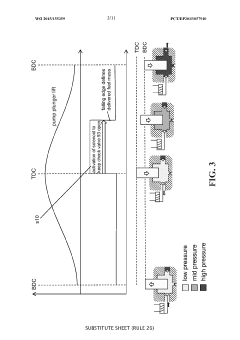

Recent technological trends indicate growing interest in variable injection timing strategies that can adapt to different engine operating conditions. This includes multiple injection events per cycle (pre-injection, main injection, and post-injection), as well as spray-guided, wall-guided, and air-guided injection strategies. The timing differences between GDI and traditional systems represent not merely incremental improvements but fundamental shifts in combustion strategy.

As the automotive industry continues its transition toward electrification, understanding the optimal injection timing strategies for GDI systems remains crucial for maximizing the efficiency of hybrid powertrains and extending the viability of internal combustion engines in an increasingly carbon-constrained regulatory environment.

The fundamental difference between GDI and traditional injection systems lies in the location and timing of fuel delivery. Traditional port fuel injection (PFI) systems inject fuel into the intake port where it mixes with air before entering the combustion chamber. In contrast, GDI systems inject fuel directly into the combustion chamber at precisely controlled timing and pressure. This fundamental architectural difference creates significant implications for injection timing strategies that affect engine performance, emissions, and efficiency.

The technical evolution trajectory shows a clear progression from carburetors to electronic fuel injection, then to port injection, and finally to direct injection systems. Each evolutionary step has been driven by the need for more precise control over the air-fuel mixture and combustion process. The current technological landscape features various hybrid approaches as well, including dual-injection systems that combine the benefits of both GDI and PFI technologies.

The primary objectives of modern injection timing research focus on optimizing several critical parameters: maximizing thermal efficiency, minimizing emissions (particularly NOx and particulate matter), enhancing power output, and improving cold-start performance. These objectives must be balanced against practical constraints such as system cost, reliability, and compatibility with existing engine architectures.

Recent technological trends indicate growing interest in variable injection timing strategies that can adapt to different engine operating conditions. This includes multiple injection events per cycle (pre-injection, main injection, and post-injection), as well as spray-guided, wall-guided, and air-guided injection strategies. The timing differences between GDI and traditional systems represent not merely incremental improvements but fundamental shifts in combustion strategy.

As the automotive industry continues its transition toward electrification, understanding the optimal injection timing strategies for GDI systems remains crucial for maximizing the efficiency of hybrid powertrains and extending the viability of internal combustion engines in an increasingly carbon-constrained regulatory environment.

Market Demand Analysis for Advanced Fuel Injection Systems

The global market for advanced fuel injection systems has witnessed substantial growth in recent years, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. The market value reached approximately $68.9 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% through 2030, reflecting the automotive industry's shift toward more sophisticated engine technologies.

Gasoline Direct Injection (GDI) systems have emerged as a dominant segment within this market, accounting for nearly 45% of the total market share in 2022. This growth is particularly pronounced in regions with strict emission standards such as Europe, North America, and parts of Asia. The precise injection timing capabilities of GDI systems have become a critical selling point for manufacturers looking to meet Euro 7, China 6, and US EPA Tier 3 standards.

Consumer preferences are increasingly favoring vehicles with improved fuel economy without sacrificing performance. Market research indicates that vehicles equipped with advanced injection timing systems command a premium of 8-12% over traditional port fuel injection counterparts, with consumers willing to pay this premium for the 15-20% improvement in fuel efficiency that these systems can deliver.

The commercial vehicle segment represents another significant growth area for advanced injection systems. Fleet operators are increasingly focused on total cost of ownership, with fuel costs representing 30-35% of operational expenses. The precise injection timing offered by modern systems can reduce fuel consumption by 7-10% in heavy-duty applications, creating substantial demand in this sector.

Aftermarket opportunities are also expanding as older vehicles are retrofitted with more advanced injection systems. This segment grew by 5.8% in 2022, with particular strength in emerging markets where vehicle lifespans tend to be longer. The ability to improve injection timing through aftermarket solutions has created a $12.3 billion global market opportunity.

Regional analysis reveals varying adoption rates of advanced injection timing technologies. While North America and Europe lead in GDI adoption rates (68% and 72% of new vehicles respectively), emerging markets in Asia-Pacific are showing the fastest growth, with China's adoption rate increasing from 35% to 52% between 2018 and 2022. This regional variation reflects differences in regulatory frameworks, fuel quality standards, and consumer preferences.

The market is also witnessing increased demand for flexible injection timing systems that can accommodate alternative fuels such as ethanol blends and compressed natural gas, reflecting a broader industry trend toward fuel diversification and reduced carbon footprints. This flexibility requirement has created new market opportunities estimated at $5.7 billion annually for systems that can precisely control injection timing across multiple fuel types.

Gasoline Direct Injection (GDI) systems have emerged as a dominant segment within this market, accounting for nearly 45% of the total market share in 2022. This growth is particularly pronounced in regions with strict emission standards such as Europe, North America, and parts of Asia. The precise injection timing capabilities of GDI systems have become a critical selling point for manufacturers looking to meet Euro 7, China 6, and US EPA Tier 3 standards.

Consumer preferences are increasingly favoring vehicles with improved fuel economy without sacrificing performance. Market research indicates that vehicles equipped with advanced injection timing systems command a premium of 8-12% over traditional port fuel injection counterparts, with consumers willing to pay this premium for the 15-20% improvement in fuel efficiency that these systems can deliver.

The commercial vehicle segment represents another significant growth area for advanced injection systems. Fleet operators are increasingly focused on total cost of ownership, with fuel costs representing 30-35% of operational expenses. The precise injection timing offered by modern systems can reduce fuel consumption by 7-10% in heavy-duty applications, creating substantial demand in this sector.

Aftermarket opportunities are also expanding as older vehicles are retrofitted with more advanced injection systems. This segment grew by 5.8% in 2022, with particular strength in emerging markets where vehicle lifespans tend to be longer. The ability to improve injection timing through aftermarket solutions has created a $12.3 billion global market opportunity.

Regional analysis reveals varying adoption rates of advanced injection timing technologies. While North America and Europe lead in GDI adoption rates (68% and 72% of new vehicles respectively), emerging markets in Asia-Pacific are showing the fastest growth, with China's adoption rate increasing from 35% to 52% between 2018 and 2022. This regional variation reflects differences in regulatory frameworks, fuel quality standards, and consumer preferences.

The market is also witnessing increased demand for flexible injection timing systems that can accommodate alternative fuels such as ethanol blends and compressed natural gas, reflecting a broader industry trend toward fuel diversification and reduced carbon footprints. This flexibility requirement has created new market opportunities estimated at $5.7 billion annually for systems that can precisely control injection timing across multiple fuel types.

Current Challenges in Injection Timing Technologies

Despite significant advancements in fuel injection technology, several critical challenges persist in both Gasoline Direct Injection (GDI) and traditional Port Fuel Injection (PFI) systems. The precise control of injection timing remains one of the most complex aspects of modern engine management, with implications for emissions, performance, and efficiency.

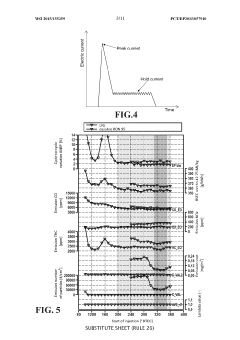

In GDI systems, the high-pressure direct injection process creates unique timing challenges. Engineers struggle with the extremely narrow optimal injection window, typically measured in milliseconds, which must be synchronized perfectly with the compression stroke. This precision requirement increases exponentially with higher engine speeds, where timing errors as small as 0.1 milliseconds can significantly impact combustion efficiency and emissions formation.

Deposit formation on injector nozzles represents another persistent challenge affecting timing accuracy. GDI injectors operate at pressures exceeding 200 bar, and the extreme temperature environment leads to carbon accumulation that alters spray patterns and timing responsiveness over time. This degradation is difficult to compensate for in real-time engine management systems.

Traditional PFI engines face different timing challenges. The wall-wetting phenomenon, where fuel adheres to intake port surfaces, creates a variable delay between injection and combustion events. This delay changes with temperature, engine load, and fuel composition, making precise timing control particularly difficult during transient operations like acceleration or cold starts.

Cold-start conditions present significant challenges across both technologies. GDI systems struggle with incomplete atomization at low temperatures, while PFI systems face excessive wall-wetting. Both scenarios require sophisticated compensation strategies that often compromise either emissions or drivability.

Multi-pulse injection strategies, increasingly common in modern engines, introduce additional timing complexity. Determining optimal timing for pre-, main, and post-injection events requires sophisticated algorithms that must account for numerous variables including load, temperature, and fuel properties. The computational demands of these strategies push the limits of current engine control units.

Fuel quality variations present another significant challenge. Modern engines are designed to operate with specific fuel characteristics, but market fuels vary considerably in composition. These variations affect vaporization rates and combustion behavior, requiring adaptive timing strategies that can detect and compensate for different fuel properties.

Finally, emissions regulations continue to tighten globally, demanding ever more precise injection timing to minimize pollutant formation. The trade-offs between NOx, particulate matter, and CO2 emissions create competing timing requirements that must be balanced across the entire operating range of the engine.

In GDI systems, the high-pressure direct injection process creates unique timing challenges. Engineers struggle with the extremely narrow optimal injection window, typically measured in milliseconds, which must be synchronized perfectly with the compression stroke. This precision requirement increases exponentially with higher engine speeds, where timing errors as small as 0.1 milliseconds can significantly impact combustion efficiency and emissions formation.

Deposit formation on injector nozzles represents another persistent challenge affecting timing accuracy. GDI injectors operate at pressures exceeding 200 bar, and the extreme temperature environment leads to carbon accumulation that alters spray patterns and timing responsiveness over time. This degradation is difficult to compensate for in real-time engine management systems.

Traditional PFI engines face different timing challenges. The wall-wetting phenomenon, where fuel adheres to intake port surfaces, creates a variable delay between injection and combustion events. This delay changes with temperature, engine load, and fuel composition, making precise timing control particularly difficult during transient operations like acceleration or cold starts.

Cold-start conditions present significant challenges across both technologies. GDI systems struggle with incomplete atomization at low temperatures, while PFI systems face excessive wall-wetting. Both scenarios require sophisticated compensation strategies that often compromise either emissions or drivability.

Multi-pulse injection strategies, increasingly common in modern engines, introduce additional timing complexity. Determining optimal timing for pre-, main, and post-injection events requires sophisticated algorithms that must account for numerous variables including load, temperature, and fuel properties. The computational demands of these strategies push the limits of current engine control units.

Fuel quality variations present another significant challenge. Modern engines are designed to operate with specific fuel characteristics, but market fuels vary considerably in composition. These variations affect vaporization rates and combustion behavior, requiring adaptive timing strategies that can detect and compensate for different fuel properties.

Finally, emissions regulations continue to tighten globally, demanding ever more precise injection timing to minimize pollutant formation. The trade-offs between NOx, particulate matter, and CO2 emissions create competing timing requirements that must be balanced across the entire operating range of the engine.

Current Injection Timing Solutions Comparison

01 Injection timing control in GDI engines

Gasoline Direct Injection (GDI) engines utilize precise injection timing control to optimize fuel delivery directly into the combustion chamber. The timing can be adjusted based on engine load, speed, and operating conditions to improve combustion efficiency and reduce emissions. Advanced electronic control units monitor various parameters to determine the optimal injection timing, allowing for multiple injection events per cycle when necessary.- GDI Injection Timing Control Strategies: Gasoline Direct Injection (GDI) engines employ sophisticated timing control strategies to optimize fuel delivery directly into the combustion chamber. These strategies include varying injection timing based on engine load, speed, and operating conditions to improve combustion efficiency and reduce emissions. Advanced electronic control units monitor various parameters to determine the optimal injection timing, allowing for multiple injection events per cycle including early injection for homogeneous mixtures and late injection for stratified charge operation.

- Traditional Port Fuel Injection Timing Mechanisms: Traditional port fuel injection systems deliver fuel into the intake port rather than directly into the combustion chamber. The timing mechanisms in these systems typically synchronize injection with the intake valve opening to ensure proper mixture formation. These systems often use mechanical or early electronic timing controls that adjust based on crankshaft position and engine speed. The injection timing in port injection systems is generally less critical than in direct injection systems but still impacts performance, fuel economy, and emissions.

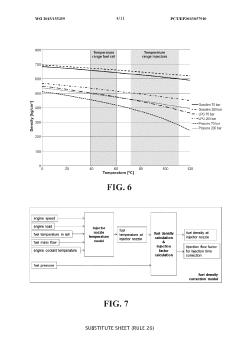

- Adaptive Injection Timing Based on Operating Conditions: Modern engine management systems employ adaptive injection timing strategies that respond to changing operating conditions. These systems adjust injection timing based on factors such as ambient temperature, altitude, fuel quality, and engine temperature. Feedback from oxygen sensors, knock sensors, and other monitoring devices allows the engine control unit to continuously optimize injection timing for current conditions. This adaptive approach enables engines to maintain optimal performance and efficiency across a wide range of operating environments.

- Injection Timing for Performance Optimization: Injection timing significantly impacts engine performance metrics including power output, torque delivery, and fuel efficiency. Advanced timing strategies can be employed to optimize specific performance characteristics based on driver demand and operating mode. During high-load conditions, injection timing may be adjusted to maximize power output, while during cruising or partial load, timing can be optimized for fuel economy. Multiple injection events with precisely controlled timing can also be used to shape the torque curve and improve transient response.

- Emission Control Through Injection Timing: Injection timing plays a crucial role in controlling emissions from both GDI and traditional engines. Precise timing adjustments can reduce the formation of nitrogen oxides (NOx), particulate matter, and unburned hydrocarbons. Split injection strategies, where fuel is delivered in multiple pulses, can help reduce emissions during cold starts and transient operation. Advanced timing control also enables compatibility with exhaust aftertreatment systems by maintaining optimal exhaust gas composition and temperature for catalytic converter operation.

02 Injection timing in traditional port fuel injection engines

Traditional port fuel injection systems inject fuel into the intake port rather than directly into the combustion chamber. The timing of injection in these systems is typically synchronized with the intake valve opening to ensure proper fuel-air mixture formation. The injection timing is controlled based on engine speed, load, and temperature to optimize performance and emissions across various operating conditions.Expand Specific Solutions03 Adaptive injection timing strategies

Adaptive injection timing strategies involve real-time adjustments to injection timing based on feedback from various engine sensors. These systems can compensate for changes in fuel quality, engine wear, ambient conditions, and driving patterns. By continuously optimizing injection timing, these adaptive strategies improve fuel economy, reduce emissions, and enhance engine performance across a wide range of operating conditions.Expand Specific Solutions04 Multiple injection strategies and timing

Multiple injection strategies involve dividing the fuel delivery into several discrete injection events during a single combustion cycle. This approach allows for more precise control over the combustion process. The timing of each injection event (pre-injection, main injection, and post-injection) can be independently controlled to optimize combustion stability, reduce noise, lower emissions, and improve fuel efficiency under various engine operating conditions.Expand Specific Solutions05 Historical development of injection timing systems

The evolution of injection timing systems spans from early mechanical systems to sophisticated electronic controls. Early systems relied on mechanical linkages and pressure-based timing mechanisms, while modern systems utilize electronic control units with complex algorithms. This progression has enabled increasingly precise control over injection timing, allowing for optimization of engine performance, emissions reduction, and fuel efficiency across all operating conditions.Expand Specific Solutions

Key Industry Players in Engine Injection Technology

The GDI (Gasoline Direct Injection) engine technology market is currently in a mature growth phase, with an estimated global market size exceeding $4 billion and projected CAGR of 6-8% through 2028. Major automotive manufacturers including Hyundai Motor Co., Kia Corp., Ford Global Technologies, and FCA US LLC have established strong positions in GDI implementation, while specialized component suppliers like Delphi Technology and AVL List GmbH provide critical injection systems. Technical maturity varies across applications, with companies like Weichai Power and Volvo Lastvagnar advancing heavy-duty implementations, while research institutions such as Xi'an Jiaotong University and Tianjin University contribute to fundamental innovations. The competitive landscape is characterized by increasing focus on optimizing injection timing to improve fuel efficiency and reduce emissions, with Asian manufacturers like Chery Automobile rapidly closing technological gaps with established Western players.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced GDI (Gasoline Direct Injection) systems that precisely control injection timing through multiple injection events per combustion cycle. Their EcoBoost engine technology utilizes high-pressure direct injection (up to 2150 bar) with solenoid-actuated injectors capable of multiple injections per cycle. Ford's system employs sophisticated engine control modules that adjust injection timing based on real-time engine parameters including load, speed, and temperature. The technology incorporates both early injection during intake stroke for homogeneous mixture formation and late injection during compression stroke for stratified charge operation[1]. Ford has also implemented dual fuel injection systems combining port and direct injection to optimize fuel delivery across different operating conditions, allowing for precise control of fuel atomization and reduced particulate emissions[3]. Their latest systems feature injection timing accuracy within microseconds and can perform up to five separate injection events per combustion cycle to optimize combustion stability.

Strengths: Superior fuel economy (up to 20% improvement over traditional PFI engines), reduced CO2 emissions, and enhanced low-end torque. The multiple injection capability provides excellent combustion control across varying engine loads. Weaknesses: Higher system complexity and cost, potential for increased particulate emissions under certain conditions, and greater sensitivity to fuel quality variations.

FCA US LLC

Technical Solution: FCA (now part of Stellantis) has developed MultiAir technology that works in conjunction with their GDI systems to provide unprecedented control over injection timing and air-fuel mixture formation. Their approach integrates electro-hydraulic variable valve actuation with direct injection, allowing for independent control of valve lift and timing. FCA's GDI system operates at pressures up to 2900 bar and features piezoelectric injectors with response times under 150 microseconds[2]. The system employs a dual-phase injection strategy with early injection during intake stroke for homogeneous mixture and late injection during compression for stratified charge operation. FCA has implemented sophisticated closed-loop control systems that continuously adjust injection timing based on knock sensor feedback, exhaust gas composition, and other parameters. Their FireFly engine family incorporates this technology with multiple injection events (up to 5 per cycle) to optimize combustion efficiency across various operating conditions[4]. The system also features adaptive injection timing that compensates for fuel quality variations and engine aging effects.

Strengths: Exceptional flexibility in combustion control, reduced pumping losses, and improved thermal efficiency across a wide operating range. The integration with MultiAir valve control provides synergistic benefits for emissions control. Weaknesses: Higher manufacturing complexity, increased maintenance requirements, and greater sensitivity to fuel contamination that can affect injector performance over time.

Core Patents and Research in Injection Timing

Combustion system

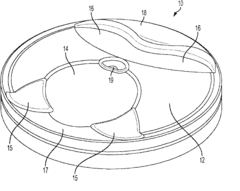

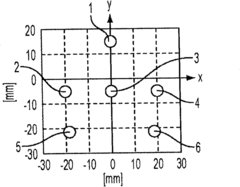

PatentInactiveCN202280529U

Innovation

- An improved combustion system was designed, including a concave bowl on top of a spherical piston and a multi-hole fuel injector. The orifice of the injector faces the piston bowl and matches the diameter of the piston bowl. The injector forms an angle of at least 60 degrees with the piston bowl. The device is sealed between the two orifices, creating a combustion system that provides stratified mixing and reduces soot emissions during cold starts.

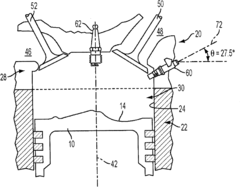

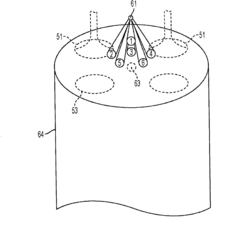

LPG direct injection engine

PatentWO2015155359A1

Innovation

- An LPG direct injection engine with a high-pressure pump and electronic control unit for precise liquefied petroleum gas injection between 360° and 60° BTDC, optimized valve overlap, and cylinder deactivation system to reduce emissions and improve efficiency.

Emissions Regulations Impact on Injection Technology

Emissions regulations worldwide have evolved significantly over the past decades, directly influencing the development trajectory of fuel injection technologies in automotive engines. The transition from traditional port fuel injection (PFI) systems to gasoline direct injection (GDI) has been largely driven by increasingly stringent emissions standards established by regulatory bodies such as the Environmental Protection Agency (EPA) in the United States, the European Union's Euro standards, and similar frameworks in Asia.

The introduction of Euro 6 and EPA Tier 3 standards has placed unprecedented pressure on manufacturers to reduce particulate matter (PM) and nitrogen oxide (NOx) emissions, compelling a fundamental rethinking of injection timing strategies. GDI engines, with their precise control over fuel delivery timing, have emerged as a preferred solution for meeting these regulatory challenges while maintaining performance expectations.

Regulatory frameworks have specifically targeted the reduction of cold-start emissions, which account for approximately 80% of total trip emissions in conventional vehicles. This has led to the development of sophisticated injection timing strategies in GDI systems that can deliver multiple injection events per cycle—including pre-injection, main injection, and post-injection phases—optimized for different operating conditions and emission control requirements.

The California Air Resources Board (CARB) and its Low Emission Vehicle (LEV) programs have been particularly influential, often establishing standards that exceed federal requirements and effectively setting the pace for technological innovation in injection timing. These regulations have accelerated the adoption of high-pressure injection systems capable of operating at pressures exceeding 200 bar, enabling finer atomization and more precise timing control.

China's implementation of China 6 emissions standards, which closely align with Euro 6 requirements, has created one of the largest markets for advanced injection technologies, driving global research and development investments. This regulatory convergence across major markets has standardized certain aspects of injection timing strategies while still allowing for regional optimization.

The regulatory focus has shifted beyond simply limiting tailpipe emissions to considering the entire environmental impact of vehicles, including CO2 emissions related to fuel efficiency. This holistic approach has further refined injection timing strategies to balance the sometimes competing demands of emissions reduction and fuel economy, particularly evident in the development of stratified charge combustion modes in GDI engines.

Looking forward, upcoming regulations such as Euro 7 and potential updates to EPA standards will likely demand even more sophisticated injection timing control, potentially driving the integration of artificial intelligence and machine learning algorithms to continuously optimize injection parameters based on real-time operating conditions and environmental factors.

The introduction of Euro 6 and EPA Tier 3 standards has placed unprecedented pressure on manufacturers to reduce particulate matter (PM) and nitrogen oxide (NOx) emissions, compelling a fundamental rethinking of injection timing strategies. GDI engines, with their precise control over fuel delivery timing, have emerged as a preferred solution for meeting these regulatory challenges while maintaining performance expectations.

Regulatory frameworks have specifically targeted the reduction of cold-start emissions, which account for approximately 80% of total trip emissions in conventional vehicles. This has led to the development of sophisticated injection timing strategies in GDI systems that can deliver multiple injection events per cycle—including pre-injection, main injection, and post-injection phases—optimized for different operating conditions and emission control requirements.

The California Air Resources Board (CARB) and its Low Emission Vehicle (LEV) programs have been particularly influential, often establishing standards that exceed federal requirements and effectively setting the pace for technological innovation in injection timing. These regulations have accelerated the adoption of high-pressure injection systems capable of operating at pressures exceeding 200 bar, enabling finer atomization and more precise timing control.

China's implementation of China 6 emissions standards, which closely align with Euro 6 requirements, has created one of the largest markets for advanced injection technologies, driving global research and development investments. This regulatory convergence across major markets has standardized certain aspects of injection timing strategies while still allowing for regional optimization.

The regulatory focus has shifted beyond simply limiting tailpipe emissions to considering the entire environmental impact of vehicles, including CO2 emissions related to fuel efficiency. This holistic approach has further refined injection timing strategies to balance the sometimes competing demands of emissions reduction and fuel economy, particularly evident in the development of stratified charge combustion modes in GDI engines.

Looking forward, upcoming regulations such as Euro 7 and potential updates to EPA standards will likely demand even more sophisticated injection timing control, potentially driving the integration of artificial intelligence and machine learning algorithms to continuously optimize injection parameters based on real-time operating conditions and environmental factors.

Efficiency and Performance Metrics Across Engine Types

When comparing GDI (Gasoline Direct Injection) and traditional port fuel injection engines, efficiency and performance metrics reveal significant differences attributable to their distinct injection timing strategies. GDI engines demonstrate 15-20% better fuel efficiency in real-world driving conditions, primarily due to their precise injection timing during the compression stroke, which allows for stratified charge operation and reduced throttling losses.

Power output measurements show that GDI engines typically deliver 5-10% higher specific power (kW/L) compared to equivalent displacement port injection engines. This advantage stems from improved volumetric efficiency and the cooling effect of direct fuel injection, which enables higher compression ratios without encountering knock limitations.

Emissions profiles differ substantially between these engine types. GDI engines produce approximately 25% lower CO2 emissions due to their improved combustion efficiency. However, they face challenges with particulate matter (PM) emissions, generating up to 10 times more particulates than port injection engines under certain operating conditions, necessitating the implementation of gasoline particulate filters in many markets.

Transient response characteristics also vary significantly. GDI engines exhibit 30-40% faster torque response during acceleration events, particularly from idle and low-speed conditions. This improved response is attributable to the elimination of fuel film dynamics in the intake port and the ability to precisely time injection events relative to piston position and ignition timing.

Cold-start performance metrics reveal that GDI engines achieve stable combustion approximately 2-3 seconds faster than port injection engines at ambient temperatures below 0°C. This advantage derives from the ability to inject fuel directly into the combustion chamber with precisely controlled spray patterns, enhancing fuel atomization under cold conditions.

Thermal efficiency comparisons indicate that modern GDI engines can achieve peak thermal efficiencies of 38-42%, compared to 32-36% for traditional port injection engines. This efficiency gap widens particularly at part-load conditions, where GDI's stratified charge capability provides the greatest advantage.

Cycle-to-cycle combustion variation, measured by coefficient of variation (COV) of indicated mean effective pressure (IMEP), is typically 15-25% lower in GDI engines at equivalent operating points, indicating more stable combustion processes and contributing to improved NVH (Noise, Vibration, Harshness) characteristics.

Power output measurements show that GDI engines typically deliver 5-10% higher specific power (kW/L) compared to equivalent displacement port injection engines. This advantage stems from improved volumetric efficiency and the cooling effect of direct fuel injection, which enables higher compression ratios without encountering knock limitations.

Emissions profiles differ substantially between these engine types. GDI engines produce approximately 25% lower CO2 emissions due to their improved combustion efficiency. However, they face challenges with particulate matter (PM) emissions, generating up to 10 times more particulates than port injection engines under certain operating conditions, necessitating the implementation of gasoline particulate filters in many markets.

Transient response characteristics also vary significantly. GDI engines exhibit 30-40% faster torque response during acceleration events, particularly from idle and low-speed conditions. This improved response is attributable to the elimination of fuel film dynamics in the intake port and the ability to precisely time injection events relative to piston position and ignition timing.

Cold-start performance metrics reveal that GDI engines achieve stable combustion approximately 2-3 seconds faster than port injection engines at ambient temperatures below 0°C. This advantage derives from the ability to inject fuel directly into the combustion chamber with precisely controlled spray patterns, enhancing fuel atomization under cold conditions.

Thermal efficiency comparisons indicate that modern GDI engines can achieve peak thermal efficiencies of 38-42%, compared to 32-36% for traditional port injection engines. This efficiency gap widens particularly at part-load conditions, where GDI's stratified charge capability provides the greatest advantage.

Cycle-to-cycle combustion variation, measured by coefficient of variation (COV) of indicated mean effective pressure (IMEP), is typically 15-25% lower in GDI engines at equivalent operating points, indicating more stable combustion processes and contributing to improved NVH (Noise, Vibration, Harshness) characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!