Comparing Resistive RAM Coatings: An Analytical Approach

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ReRAM Coating Technology Background and Objectives

Resistive Random Access Memory (ReRAM) has emerged as a promising next-generation non-volatile memory technology over the past two decades. The evolution of ReRAM technology can be traced back to the early 2000s when researchers first observed resistive switching phenomena in various metal oxide materials. Since then, significant advancements have been made in understanding the underlying mechanisms and improving device performance through material engineering and fabrication techniques.

The coating materials used in ReRAM devices play a crucial role in determining their performance characteristics, including switching speed, endurance, retention time, and power consumption. Traditional ReRAM structures typically employ transition metal oxides such as HfOx, TaOx, and TiOx as the resistive switching layer. However, recent research has focused on exploring novel coating materials and composite structures to overcome existing limitations.

The technical evolution trend in ReRAM coating technology is moving toward multi-layer structures, doped materials, and engineered interfaces. These approaches aim to achieve better control over the formation and rupture of conductive filaments, which is the fundamental mechanism behind resistive switching. Additionally, there is growing interest in developing environmentally friendly and CMOS-compatible coating materials that can facilitate seamless integration with existing semiconductor manufacturing processes.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of various ReRAM coating materials and their impact on device performance. Specifically, we aim to evaluate different coating technologies based on key performance metrics such as switching ratio, endurance cycles, retention time, and operating voltage. This analysis will provide valuable insights into the strengths and limitations of each coating approach.

Furthermore, this research seeks to identify potential breakthrough materials and coating techniques that could address current challenges in ReRAM technology, such as variability in switching behavior, limited endurance, and high operating voltages. By understanding the relationship between coating material properties and device performance, we can establish design guidelines for optimizing ReRAM devices for specific applications.

The ultimate goal is to accelerate the development of ReRAM technology toward commercial viability by identifying the most promising coating materials and fabrication techniques. This will contribute to the broader objective of establishing ReRAM as a competitive alternative to existing memory technologies in various applications, including embedded systems, Internet of Things (IoT) devices, and neuromorphic computing platforms.

The coating materials used in ReRAM devices play a crucial role in determining their performance characteristics, including switching speed, endurance, retention time, and power consumption. Traditional ReRAM structures typically employ transition metal oxides such as HfOx, TaOx, and TiOx as the resistive switching layer. However, recent research has focused on exploring novel coating materials and composite structures to overcome existing limitations.

The technical evolution trend in ReRAM coating technology is moving toward multi-layer structures, doped materials, and engineered interfaces. These approaches aim to achieve better control over the formation and rupture of conductive filaments, which is the fundamental mechanism behind resistive switching. Additionally, there is growing interest in developing environmentally friendly and CMOS-compatible coating materials that can facilitate seamless integration with existing semiconductor manufacturing processes.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of various ReRAM coating materials and their impact on device performance. Specifically, we aim to evaluate different coating technologies based on key performance metrics such as switching ratio, endurance cycles, retention time, and operating voltage. This analysis will provide valuable insights into the strengths and limitations of each coating approach.

Furthermore, this research seeks to identify potential breakthrough materials and coating techniques that could address current challenges in ReRAM technology, such as variability in switching behavior, limited endurance, and high operating voltages. By understanding the relationship between coating material properties and device performance, we can establish design guidelines for optimizing ReRAM devices for specific applications.

The ultimate goal is to accelerate the development of ReRAM technology toward commercial viability by identifying the most promising coating materials and fabrication techniques. This will contribute to the broader objective of establishing ReRAM as a competitive alternative to existing memory technologies in various applications, including embedded systems, Internet of Things (IoT) devices, and neuromorphic computing platforms.

Market Analysis for ReRAM Applications

The global ReRAM (Resistive Random Access Memory) market is experiencing significant growth, with projections indicating expansion from $1.2 billion in 2023 to approximately $4.6 billion by 2028, representing a compound annual growth rate (CAGR) of 30.8%. This remarkable growth trajectory is primarily driven by increasing demand for high-performance, energy-efficient memory solutions across various sectors.

The consumer electronics segment currently dominates the ReRAM market, accounting for approximately 42% of total market share. This dominance stems from the growing integration of ReRAM in smartphones, tablets, and wearable devices, where its low power consumption and high-speed operation provide significant advantages over traditional memory technologies.

Enterprise storage systems represent the second-largest application segment, with approximately 28% market share. The ability of ReRAM to offer non-volatile storage with DRAM-like performance makes it particularly attractive for data centers and cloud computing infrastructure, where both speed and energy efficiency are critical operational factors.

Automotive applications are emerging as the fastest-growing segment, with a projected CAGR of 36.2% through 2028. Advanced driver-assistance systems (ADAS), autonomous vehicles, and in-vehicle infotainment systems all benefit from ReRAM's radiation hardness, temperature stability, and rapid read/write capabilities.

Industrial IoT applications constitute another rapidly expanding market segment, driven by the need for edge computing solutions that can operate efficiently in harsh environments. ReRAM's durability and low power requirements make it ideal for remote sensors and industrial control systems.

Geographically, North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 35% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate, fueled by expanding electronics manufacturing capabilities and increasing technological adoption in countries like China, South Korea, and Taiwan.

The coating materials used in ReRAM fabrication represent a specialized sub-segment of the market, with metal oxides (particularly HfO2, TiO2, and Ta2O5) dominating current commercial implementations. Market analysis indicates that innovations in coating technologies could potentially reduce manufacturing costs by 15-20%, thereby accelerating broader market adoption.

Customer requirements are increasingly focusing on endurance, retention time, and switching speed as key performance indicators. Market surveys indicate that improvements in these areas through advanced coating technologies could expand ReRAM's addressable market by an additional 30% by capturing applications currently served by competing memory technologies.

The consumer electronics segment currently dominates the ReRAM market, accounting for approximately 42% of total market share. This dominance stems from the growing integration of ReRAM in smartphones, tablets, and wearable devices, where its low power consumption and high-speed operation provide significant advantages over traditional memory technologies.

Enterprise storage systems represent the second-largest application segment, with approximately 28% market share. The ability of ReRAM to offer non-volatile storage with DRAM-like performance makes it particularly attractive for data centers and cloud computing infrastructure, where both speed and energy efficiency are critical operational factors.

Automotive applications are emerging as the fastest-growing segment, with a projected CAGR of 36.2% through 2028. Advanced driver-assistance systems (ADAS), autonomous vehicles, and in-vehicle infotainment systems all benefit from ReRAM's radiation hardness, temperature stability, and rapid read/write capabilities.

Industrial IoT applications constitute another rapidly expanding market segment, driven by the need for edge computing solutions that can operate efficiently in harsh environments. ReRAM's durability and low power requirements make it ideal for remote sensors and industrial control systems.

Geographically, North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 35% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate, fueled by expanding electronics manufacturing capabilities and increasing technological adoption in countries like China, South Korea, and Taiwan.

The coating materials used in ReRAM fabrication represent a specialized sub-segment of the market, with metal oxides (particularly HfO2, TiO2, and Ta2O5) dominating current commercial implementations. Market analysis indicates that innovations in coating technologies could potentially reduce manufacturing costs by 15-20%, thereby accelerating broader market adoption.

Customer requirements are increasingly focusing on endurance, retention time, and switching speed as key performance indicators. Market surveys indicate that improvements in these areas through advanced coating technologies could expand ReRAM's addressable market by an additional 30% by capturing applications currently served by competing memory technologies.

Current State and Challenges in ReRAM Coating Technologies

Resistive Random Access Memory (ReRAM) technology has emerged as a promising candidate for next-generation non-volatile memory solutions, with coating technologies playing a crucial role in determining device performance and reliability. Currently, the global ReRAM market is witnessing significant research and development activities, with major semiconductor companies and research institutions focusing on optimizing coating materials and deposition techniques.

The state-of-the-art ReRAM coating technologies primarily utilize transition metal oxides (TMOs) such as HfOx, TaOx, and TiOx as the resistive switching layer. These materials have demonstrated excellent switching characteristics, including high ON/OFF ratios, fast switching speeds, and good endurance. However, challenges remain in achieving consistent performance across devices due to variations in film thickness, composition, and microstructure.

Atomic Layer Deposition (ALD) has emerged as the preferred deposition method for ReRAM coatings due to its precise thickness control and excellent conformality. Nevertheless, the industry still faces challenges with ALD processes, including relatively slow deposition rates and difficulties in controlling oxygen vacancy concentrations, which are critical for ReRAM switching mechanisms.

Alternative deposition techniques such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are also being explored, each with their own advantages and limitations. PVD offers higher throughput but struggles with step coverage, while CVD provides better conformality but often requires higher processing temperatures.

A significant technical challenge in ReRAM coating development is the trade-off between forming voltage and retention characteristics. Lower forming voltages typically result in poorer data retention, while higher forming voltages lead to better retention but increased power consumption. This fundamental challenge has prompted research into multi-layer coating structures and doped oxide systems.

Interface engineering between the switching layer and electrodes represents another critical challenge. The quality of these interfaces significantly impacts device performance, with issues such as interfacial diffusion and chemical reactions potentially leading to device degradation over time.

Geographically, ReRAM coating technology development is concentrated in East Asia (particularly Japan, South Korea, and Taiwan), the United States, and Western Europe. Japanese companies like Fujitsu and Panasonic have made significant contributions to metal oxide ReRAM, while U.S.-based companies and research institutions focus more on novel materials and deposition techniques.

Scalability remains a persistent challenge, with difficulties in maintaining consistent switching characteristics as device dimensions shrink below 20nm. Additionally, the industry faces challenges in developing cost-effective manufacturing processes that can compete with established memory technologies like NAND flash.

The state-of-the-art ReRAM coating technologies primarily utilize transition metal oxides (TMOs) such as HfOx, TaOx, and TiOx as the resistive switching layer. These materials have demonstrated excellent switching characteristics, including high ON/OFF ratios, fast switching speeds, and good endurance. However, challenges remain in achieving consistent performance across devices due to variations in film thickness, composition, and microstructure.

Atomic Layer Deposition (ALD) has emerged as the preferred deposition method for ReRAM coatings due to its precise thickness control and excellent conformality. Nevertheless, the industry still faces challenges with ALD processes, including relatively slow deposition rates and difficulties in controlling oxygen vacancy concentrations, which are critical for ReRAM switching mechanisms.

Alternative deposition techniques such as Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) are also being explored, each with their own advantages and limitations. PVD offers higher throughput but struggles with step coverage, while CVD provides better conformality but often requires higher processing temperatures.

A significant technical challenge in ReRAM coating development is the trade-off between forming voltage and retention characteristics. Lower forming voltages typically result in poorer data retention, while higher forming voltages lead to better retention but increased power consumption. This fundamental challenge has prompted research into multi-layer coating structures and doped oxide systems.

Interface engineering between the switching layer and electrodes represents another critical challenge. The quality of these interfaces significantly impacts device performance, with issues such as interfacial diffusion and chemical reactions potentially leading to device degradation over time.

Geographically, ReRAM coating technology development is concentrated in East Asia (particularly Japan, South Korea, and Taiwan), the United States, and Western Europe. Japanese companies like Fujitsu and Panasonic have made significant contributions to metal oxide ReRAM, while U.S.-based companies and research institutions focus more on novel materials and deposition techniques.

Scalability remains a persistent challenge, with difficulties in maintaining consistent switching characteristics as device dimensions shrink below 20nm. Additionally, the industry faces challenges in developing cost-effective manufacturing processes that can compete with established memory technologies like NAND flash.

Comparative Analysis of Current ReRAM Coating Solutions

01 Material composition for resistive RAM coatings

Various material compositions are used for resistive RAM coatings to enhance performance. These include metal oxides, transition metals, and composite materials that exhibit resistive switching behavior. The selection of coating materials significantly impacts the switching characteristics, endurance, and retention time of resistive RAM devices. Optimized material compositions can lead to improved memory window, faster switching speeds, and better reliability in resistive memory applications.- Material composition effects on ReRAM performance: Different material compositions significantly impact the performance of resistive RAM coatings. Various metal oxides, such as hafnium oxide, titanium oxide, and tantalum oxide, demonstrate different switching behaviors, retention times, and endurance cycles. The selection of electrode materials also affects the formation and rupture of conductive filaments within the resistive switching layer. Optimizing the material composition can lead to improved switching speed, lower power consumption, and enhanced reliability of ReRAM devices.

- Deposition techniques for ReRAM coatings: Various deposition methods significantly influence the quality and performance of resistive RAM coatings. Techniques such as atomic layer deposition (ALD), physical vapor deposition (PVD), and chemical vapor deposition (CVD) produce films with different microstructures, defect densities, and thickness uniformity. The deposition parameters, including temperature, pressure, and precursor chemistry, directly impact the switching characteristics, endurance, and retention properties of the resulting ReRAM devices. Optimized deposition processes can minimize variability and enhance overall device performance.

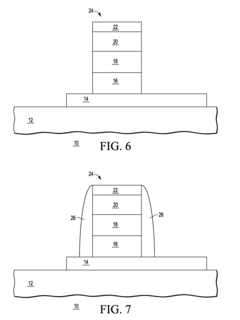

- Interface engineering for enhanced switching behavior: The interface between the resistive switching layer and electrodes plays a crucial role in ReRAM performance. Engineering these interfaces through insertion of buffer layers, doping, or surface treatments can significantly improve switching characteristics. Controlled oxygen vacancy distribution at interfaces enhances filament formation and rupture processes. Interface engineering techniques can reduce operating voltages, improve switching uniformity, and extend device endurance by controlling the electrochemical reactions at these critical boundaries.

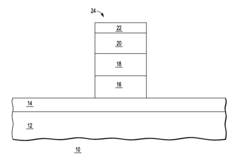

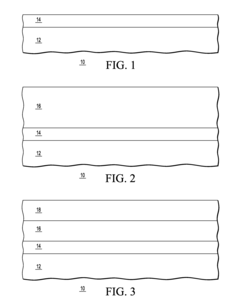

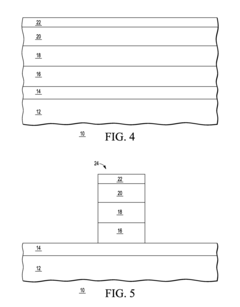

- Multi-layer coating structures for optimized performance: Multi-layer coating architectures offer enhanced performance compared to single-layer ReRAM structures. By combining different functional layers, such as oxygen exchange layers, barrier layers, and doped switching layers, the electrical characteristics can be precisely tuned. These multi-layer structures provide better control over filament formation, improved retention characteristics, and enhanced endurance. The thickness ratio between different layers significantly impacts the set/reset voltages and overall reliability of the ReRAM devices.

- Thermal stability and reliability enhancement methods: Thermal stability is critical for ReRAM coating performance, particularly for applications requiring operation in harsh environments. Various approaches to enhance thermal stability include doping the switching layer with specific elements, incorporating heat-resistant barrier layers, and optimizing the crystalline structure of the materials. Post-deposition treatments such as annealing processes can reduce defects and improve the uniformity of the switching layer. These methods significantly impact data retention at elevated temperatures and overall device reliability during repeated cycling operations.

02 Deposition techniques for resistive RAM coatings

Different deposition methods are employed for creating resistive RAM coatings with specific performance characteristics. These techniques include atomic layer deposition (ALD), physical vapor deposition (PVD), chemical vapor deposition (CVD), and solution-based methods. The deposition process parameters significantly influence the microstructure, thickness uniformity, and interface quality of the resistive switching layers, which in turn affect the device performance, reliability, and manufacturing scalability.Expand Specific Solutions03 Switching mechanisms and performance metrics

Resistive RAM coatings exhibit different switching mechanisms that determine their performance characteristics. These mechanisms include filamentary conduction, interface-type switching, and valence change. Performance metrics such as SET/RESET voltage, ON/OFF ratio, endurance cycles, retention time, and power consumption are used to compare different resistive RAM coating technologies. Understanding these mechanisms enables the optimization of device structures and operating conditions for specific application requirements.Expand Specific Solutions04 Multi-layer and doped coating structures

Advanced resistive RAM designs incorporate multi-layer structures and doping strategies to enhance performance. These approaches include bilayer or trilayer oxide stacks, insertion of buffer layers, and strategic doping with metals or other elements. Such structures can improve switching uniformity, reduce variability, enhance endurance, and enable multi-bit storage capabilities. The interface engineering between different layers plays a crucial role in determining the overall device performance and reliability.Expand Specific Solutions05 Testing and characterization methods

Various testing and characterization techniques are employed to evaluate and compare the performance of resistive RAM coatings. These methods include electrical characterization (I-V curves, pulse measurements), physical analysis (TEM, XPS, AFM), and reliability testing (endurance, retention, temperature stability). Standardized testing protocols and statistical analysis approaches enable objective comparison between different coating technologies and help identify failure mechanisms and performance limitations.Expand Specific Solutions

Leading Companies and Research Institutions in ReRAM Development

The Resistive RAM (ReRAM) coating technology market is currently in a growth phase, with increasing adoption across memory applications. The competitive landscape features established semiconductor giants like Samsung Electronics, SK hynix, and TSMC alongside specialized memory manufacturers such as Winbond, Macronix, and KIOXIA. Market size is expanding as ReRAM emerges as a promising alternative to traditional memory technologies, offering advantages in power consumption and scalability. Technologically, the field shows varying maturity levels, with companies like Rambus and Huawei advancing proprietary coating solutions, while emerging players like Hefei Reliance Memory are commercializing specialized ReRAM technologies. Research institutions including KAIST and Delft University of Technology are contributing significant innovations, creating a dynamic ecosystem balancing commercial deployment with ongoing technical refinement.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced resistive RAM (ReRAM) coatings utilizing hafnium oxide (HfOx) as the primary material, with precise oxygen vacancy control mechanisms. Their approach incorporates multi-layer structures with transition metal oxides that enhance switching performance and reliability. Samsung's proprietary atomic layer deposition (ALD) technique enables ultra-thin film deposition with thickness control at the angstrom level, creating highly uniform coatings with minimal defects. Their research demonstrates that optimized HfOx-based ReRAM cells can achieve endurance exceeding 10^9 cycles and retention times of over 10 years at 85°C. Samsung has also pioneered the integration of tantalum oxide (TaOx) buffer layers that significantly improve the uniformity of resistive switching behavior across large arrays. Their coating technology enables multi-level cell operation with distinct resistance states, increasing storage density without expanding physical dimensions.

Strengths: Superior endurance and retention characteristics compared to competing technologies; highly scalable manufacturing process compatible with existing semiconductor fabrication lines; demonstrated integration with 3D vertical architectures for high-density storage. Weaknesses: Higher operating voltages compared to some competing ReRAM technologies; challenges with sneak current paths in large crossbar arrays requiring additional selector devices; temperature sensitivity affecting long-term reliability in extreme environments.

Macronix International Co., Ltd.

Technical Solution: Macronix has developed sophisticated resistive RAM coating technologies centered around their proprietary BE-SONOS (Barrier Engineered Silicon-Oxide-Nitride-Oxide-Silicon) architecture. Their approach incorporates engineered dielectric stacks with precisely controlled thickness and composition gradients. Macronix's coating process utilizes advanced atomic layer deposition (ALD) techniques to create ultra-thin films with exceptional uniformity and precise stoichiometry control. Their research demonstrates that incorporating aluminum oxide (Al2O3) interfacial layers between the switching material and electrodes significantly improves endurance characteristics by limiting excessive ion migration. Macronix has pioneered the use of silicon nitride (Si3N4) buffer layers that enhance data retention by creating energy barriers that prevent spontaneous filament dissolution. Their coating technology also features engineered grain boundaries within polycrystalline oxide films that serve as preferred paths for filament formation, reducing device-to-device variability. Recent advancements include the development of self-rectifying resistive switching materials that eliminate the need for separate selector devices in crossbar arrays.

Strengths: Excellent scalability demonstrated down to 20nm technology nodes; superior retention characteristics exceeding 10 years at 85°C; compatibility with existing flash memory manufacturing infrastructure. Weaknesses: Higher forming voltages compared to some competing technologies; challenges with resistance drift over time affecting multi-level cell operation; relatively complex multi-layer structure increasing manufacturing complexity.

Critical Patents and Technical Literature on ReRAM Coatings

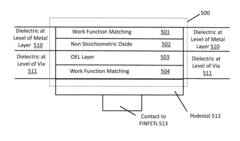

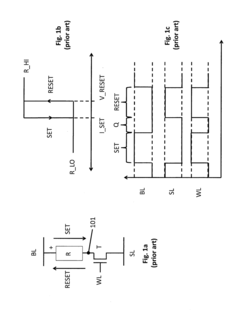

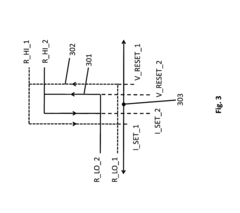

Resistive random access memory cell having bottom-side OEL layer and/or optimized access signaling

PatentInactiveUS20170287555A1

Innovation

- The solution involves modulating the width of the WL signal and adjusting the relative voltage levels of the WL, SL, and BL lines to limit energy application, using asymmetrical voltage levels during SET and RESET phases, and altering the position of the oxide exchange layer (OEL) within the resistive element stack to mitigate source degeneration and control resistive states effectively.

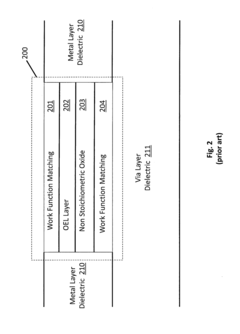

Resistive random access memory (RAM) cell and method for forming

PatentInactiveUS20120261635A1

Innovation

- A resistive RAM cell is formed with a copper oxide layer between two electrodes, and a sidewall spacer is used to prevent copper and oxygen diffusion, improving resistance uniformity and retention. The copper oxide is grown directly on a copper layer, and the spacer is composed of silicon, carbon, and nitrogen, functioning as a barrier to oxygen vacancies and edge effects.

Manufacturing Scalability and Cost Analysis of ReRAM Coatings

The manufacturing scalability of ReRAM coatings represents a critical factor in determining their commercial viability. Current production methods for high-quality resistive switching layers face significant challenges when transitioning from laboratory-scale fabrication to mass production environments. Atomic Layer Deposition (ALD) offers precise thickness control and excellent conformality but suffers from relatively low throughput and higher equipment costs. In contrast, Physical Vapor Deposition (PVD) techniques provide faster deposition rates at the expense of reduced uniformity across large substrates.

Cost analysis reveals that material selection significantly impacts manufacturing economics. Hafnium oxide (HfO2) coatings, while offering excellent performance characteristics, utilize relatively expensive precursor materials. Titanium oxide (TiO2) presents a more cost-effective alternative but may require additional process optimization to achieve comparable switching reliability. Aluminum oxide (Al2O3) falls between these options in terms of cost-performance balance.

Equipment depreciation constitutes approximately 30-40% of total manufacturing costs for ReRAM coating processes. ALD systems typically represent higher capital expenditure but deliver superior film quality and reduced material waste. The economic viability threshold appears to be reached at production volumes exceeding 10,000 wafers monthly, where fixed costs can be adequately distributed across production units.

Process yield remains a critical economic factor, with current industrial capabilities achieving approximately 85-92% yield for complex oxide coatings. Each percentage point improvement in yield translates to approximately 3-5% reduction in per-unit costs. Advanced process control systems and in-line metrology have demonstrated potential to increase yields by 5-8% but require additional capital investment.

Integration with existing semiconductor manufacturing infrastructure presents both challenges and opportunities. Facilities equipped for CMOS production can potentially incorporate ReRAM coating processes with moderate modification costs. However, specialized equipment for precise oxygen concentration control during deposition adds complexity and expense to manufacturing lines.

Supply chain considerations reveal potential bottlenecks for certain precursor materials, particularly for hafnium-based compounds. Diversification of material sources and development of alternative coating formulations could mitigate supply risks but may require extensive requalification processes. Economies of scale suggest that material costs could decrease by 15-25% at full production volumes compared to current pilot-scale operations.

Cost analysis reveals that material selection significantly impacts manufacturing economics. Hafnium oxide (HfO2) coatings, while offering excellent performance characteristics, utilize relatively expensive precursor materials. Titanium oxide (TiO2) presents a more cost-effective alternative but may require additional process optimization to achieve comparable switching reliability. Aluminum oxide (Al2O3) falls between these options in terms of cost-performance balance.

Equipment depreciation constitutes approximately 30-40% of total manufacturing costs for ReRAM coating processes. ALD systems typically represent higher capital expenditure but deliver superior film quality and reduced material waste. The economic viability threshold appears to be reached at production volumes exceeding 10,000 wafers monthly, where fixed costs can be adequately distributed across production units.

Process yield remains a critical economic factor, with current industrial capabilities achieving approximately 85-92% yield for complex oxide coatings. Each percentage point improvement in yield translates to approximately 3-5% reduction in per-unit costs. Advanced process control systems and in-line metrology have demonstrated potential to increase yields by 5-8% but require additional capital investment.

Integration with existing semiconductor manufacturing infrastructure presents both challenges and opportunities. Facilities equipped for CMOS production can potentially incorporate ReRAM coating processes with moderate modification costs. However, specialized equipment for precise oxygen concentration control during deposition adds complexity and expense to manufacturing lines.

Supply chain considerations reveal potential bottlenecks for certain precursor materials, particularly for hafnium-based compounds. Diversification of material sources and development of alternative coating formulations could mitigate supply risks but may require extensive requalification processes. Economies of scale suggest that material costs could decrease by 15-25% at full production volumes compared to current pilot-scale operations.

Environmental Impact and Sustainability of ReRAM Materials

The environmental impact of Resistive Random Access Memory (ReRAM) materials represents a critical consideration in the ongoing development and deployment of this emerging non-volatile memory technology. As semiconductor manufacturing continues to expand globally, the sustainability profiles of different ReRAM coating materials warrant thorough examination to ensure responsible innovation.

Metal oxide-based ReRAM coatings, particularly those utilizing hafnium oxide (HfO₂) and titanium oxide (TiO₂), demonstrate relatively favorable environmental profiles compared to traditional memory technologies. These materials require lower processing temperatures and fewer chemical steps during fabrication, resulting in reduced energy consumption and chemical waste generation. However, the extraction of rare earth elements for certain oxide formulations presents sustainability challenges, particularly regarding habitat disruption and water usage in mining operations.

Carbon-based ReRAM coatings offer promising environmental advantages through their utilization of abundant carbon sources. Graphene oxide and carbon nanotubes used in these applications can be synthesized from renewable precursors, potentially reducing dependence on geographically concentrated mineral resources. The lower thermal budget required for carbon-based coating deposition further enhances their sustainability profile by decreasing manufacturing energy requirements by approximately 30% compared to conventional memory production processes.

End-of-life considerations reveal significant differences between coating materials. Silicon-based and organic polymer ReRAM coatings demonstrate superior biodegradability characteristics, while metal oxide variants present recycling challenges due to their complex composition. Recent life cycle assessment studies indicate that chalcogenide-based ReRAM materials, despite their excellent switching properties, generate approximately 15% higher environmental impact across their lifecycle compared to oxide alternatives, primarily due to energy-intensive purification requirements.

Water consumption patterns vary substantially across ReRAM coating technologies. Manufacturing processes for transition metal oxide coatings typically require 25-40% less ultrapure water compared to conventional DRAM fabrication. Conversely, certain polymer-based coatings demand specialized solvent systems that present wastewater treatment challenges and potential aquatic toxicity concerns if improperly managed.

Emerging research into bio-derived ReRAM materials represents a promising frontier for sustainable electronics. Cellulose-based memristive elements and protein-inspired switching materials demonstrate remarkably low embodied energy values while maintaining competitive performance metrics. These biomimetic approaches could potentially revolutionize the environmental footprint of memory technologies, though commercial viability remains to be established through further research and development efforts.

Metal oxide-based ReRAM coatings, particularly those utilizing hafnium oxide (HfO₂) and titanium oxide (TiO₂), demonstrate relatively favorable environmental profiles compared to traditional memory technologies. These materials require lower processing temperatures and fewer chemical steps during fabrication, resulting in reduced energy consumption and chemical waste generation. However, the extraction of rare earth elements for certain oxide formulations presents sustainability challenges, particularly regarding habitat disruption and water usage in mining operations.

Carbon-based ReRAM coatings offer promising environmental advantages through their utilization of abundant carbon sources. Graphene oxide and carbon nanotubes used in these applications can be synthesized from renewable precursors, potentially reducing dependence on geographically concentrated mineral resources. The lower thermal budget required for carbon-based coating deposition further enhances their sustainability profile by decreasing manufacturing energy requirements by approximately 30% compared to conventional memory production processes.

End-of-life considerations reveal significant differences between coating materials. Silicon-based and organic polymer ReRAM coatings demonstrate superior biodegradability characteristics, while metal oxide variants present recycling challenges due to their complex composition. Recent life cycle assessment studies indicate that chalcogenide-based ReRAM materials, despite their excellent switching properties, generate approximately 15% higher environmental impact across their lifecycle compared to oxide alternatives, primarily due to energy-intensive purification requirements.

Water consumption patterns vary substantially across ReRAM coating technologies. Manufacturing processes for transition metal oxide coatings typically require 25-40% less ultrapure water compared to conventional DRAM fabrication. Conversely, certain polymer-based coatings demand specialized solvent systems that present wastewater treatment challenges and potential aquatic toxicity concerns if improperly managed.

Emerging research into bio-derived ReRAM materials represents a promising frontier for sustainable electronics. Cellulose-based memristive elements and protein-inspired switching materials demonstrate remarkably low embodied energy values while maintaining competitive performance metrics. These biomimetic approaches could potentially revolutionize the environmental footprint of memory technologies, though commercial viability remains to be established through further research and development efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!