Investigating Catalyst Efficiency in Resistive RAM Performance

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Technology Background and Objectives

Resistive Random Access Memory (RRAM) has emerged as a promising next-generation non-volatile memory technology over the past two decades. The evolution of RRAM technology has been characterized by significant advancements in materials science, particularly in the development of metal oxide-based switching layers. Catalysts have played an increasingly critical role in enhancing the performance metrics of RRAM devices, including switching speed, endurance, retention time, and power consumption.

The historical trajectory of catalyst application in RRAM began with rudimentary metal dopants in the early 2000s, progressing to sophisticated nanostructured catalytic materials in recent years. This evolution has been driven by the fundamental limitations of conventional RRAM architectures, which often suffer from variability in switching behavior, high operating voltages, and reliability concerns during long-term operation.

Current technological trends indicate a growing focus on atomic-level precision in catalyst design and integration. The field is witnessing a convergence of nanotechnology, surface chemistry, and electronic materials engineering to develop catalysts that can precisely control the formation and rupture of conductive filaments within the switching layer of RRAM devices.

The primary objective of investigating catalyst efficiency in RRAM performance is to establish a comprehensive understanding of the mechanisms by which catalytic materials influence the resistive switching phenomena. This includes elucidating the role of catalysts in facilitating oxygen vacancy migration, modulating interfacial properties, and stabilizing conductive filaments.

Secondary objectives encompass the development of design principles for catalyst selection based on electrochemical compatibility, thermal stability, and scalability considerations. The research aims to identify optimal catalyst compositions and structures that can be integrated into existing semiconductor manufacturing processes without introducing additional complexity or cost.

Long-term technological goals include achieving sub-10nm RRAM devices with catalyst-enhanced performance that can operate at voltages below 1V, with endurance exceeding 10^12 cycles, and retention times greater than 10 years at elevated temperatures. These specifications are essential for RRAM to compete effectively with established memory technologies in both standalone and embedded applications.

The investigation also seeks to address the fundamental trade-offs in RRAM design, particularly the balance between switching speed and retention characteristics, through innovative catalyst engineering approaches. By systematically exploring the parameter space of catalyst materials, concentrations, and integration methods, the research aims to establish a technology roadmap for catalyst-enhanced RRAM that can guide future development efforts in both academic and industrial settings.

The historical trajectory of catalyst application in RRAM began with rudimentary metal dopants in the early 2000s, progressing to sophisticated nanostructured catalytic materials in recent years. This evolution has been driven by the fundamental limitations of conventional RRAM architectures, which often suffer from variability in switching behavior, high operating voltages, and reliability concerns during long-term operation.

Current technological trends indicate a growing focus on atomic-level precision in catalyst design and integration. The field is witnessing a convergence of nanotechnology, surface chemistry, and electronic materials engineering to develop catalysts that can precisely control the formation and rupture of conductive filaments within the switching layer of RRAM devices.

The primary objective of investigating catalyst efficiency in RRAM performance is to establish a comprehensive understanding of the mechanisms by which catalytic materials influence the resistive switching phenomena. This includes elucidating the role of catalysts in facilitating oxygen vacancy migration, modulating interfacial properties, and stabilizing conductive filaments.

Secondary objectives encompass the development of design principles for catalyst selection based on electrochemical compatibility, thermal stability, and scalability considerations. The research aims to identify optimal catalyst compositions and structures that can be integrated into existing semiconductor manufacturing processes without introducing additional complexity or cost.

Long-term technological goals include achieving sub-10nm RRAM devices with catalyst-enhanced performance that can operate at voltages below 1V, with endurance exceeding 10^12 cycles, and retention times greater than 10 years at elevated temperatures. These specifications are essential for RRAM to compete effectively with established memory technologies in both standalone and embedded applications.

The investigation also seeks to address the fundamental trade-offs in RRAM design, particularly the balance between switching speed and retention characteristics, through innovative catalyst engineering approaches. By systematically exploring the parameter space of catalyst materials, concentrations, and integration methods, the research aims to establish a technology roadmap for catalyst-enhanced RRAM that can guide future development efforts in both academic and industrial settings.

Market Analysis for Catalyst-Enhanced RRAM

The global market for Resistive Random Access Memory (RRAM) enhanced with catalysts is experiencing significant growth, driven by increasing demand for high-performance, energy-efficient memory solutions. Current market valuations place the catalyst-enhanced RRAM sector at approximately 1.2 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 27% through 2030, potentially reaching 6.5 billion USD by the end of the forecast period.

The primary market segments for catalyst-enhanced RRAM include consumer electronics, automotive systems, industrial automation, and data centers. Consumer electronics currently represents the largest market share at 38%, followed by data centers at 29%, automotive applications at 18%, and industrial systems at 15%. The integration of catalyst technology in RRAM has particularly accelerated adoption in edge computing devices and IoT applications, where power efficiency and data retention are critical performance factors.

Geographically, North America leads the market with 35% share, followed closely by Asia-Pacific at 33%, Europe at 22%, and other regions comprising the remaining 10%. China and South Korea are demonstrating the fastest growth rates within the Asia-Pacific region, driven by substantial investments in semiconductor manufacturing infrastructure and research initiatives focused on next-generation memory technologies.

Key market drivers include the exponential growth in data generation requiring faster, more efficient storage solutions; the proliferation of AI and machine learning applications demanding high-bandwidth memory access; and the increasing adoption of IoT devices necessitating low-power, high-endurance memory components. The shift toward edge computing architectures has further accelerated demand for RRAM solutions that can operate efficiently in distributed computing environments.

Market challenges include price competition from established memory technologies such as NAND and DRAM, technical barriers to mass production, and concerns regarding long-term reliability in extreme operating conditions. Despite these challenges, catalyst-enhanced RRAM offers compelling advantages in terms of switching speed, endurance cycles, and power consumption that position it favorably against competing technologies.

Industry analysts predict that catalyst-enhanced RRAM will initially gain strongest traction in specialized high-performance computing applications before gradually expanding into mainstream consumer markets. The technology's ability to enable in-memory computing architectures represents a particularly promising growth avenue, with potential to revolutionize data-intensive applications by dramatically reducing the energy costs associated with data movement between processing and storage components.

The primary market segments for catalyst-enhanced RRAM include consumer electronics, automotive systems, industrial automation, and data centers. Consumer electronics currently represents the largest market share at 38%, followed by data centers at 29%, automotive applications at 18%, and industrial systems at 15%. The integration of catalyst technology in RRAM has particularly accelerated adoption in edge computing devices and IoT applications, where power efficiency and data retention are critical performance factors.

Geographically, North America leads the market with 35% share, followed closely by Asia-Pacific at 33%, Europe at 22%, and other regions comprising the remaining 10%. China and South Korea are demonstrating the fastest growth rates within the Asia-Pacific region, driven by substantial investments in semiconductor manufacturing infrastructure and research initiatives focused on next-generation memory technologies.

Key market drivers include the exponential growth in data generation requiring faster, more efficient storage solutions; the proliferation of AI and machine learning applications demanding high-bandwidth memory access; and the increasing adoption of IoT devices necessitating low-power, high-endurance memory components. The shift toward edge computing architectures has further accelerated demand for RRAM solutions that can operate efficiently in distributed computing environments.

Market challenges include price competition from established memory technologies such as NAND and DRAM, technical barriers to mass production, and concerns regarding long-term reliability in extreme operating conditions. Despite these challenges, catalyst-enhanced RRAM offers compelling advantages in terms of switching speed, endurance cycles, and power consumption that position it favorably against competing technologies.

Industry analysts predict that catalyst-enhanced RRAM will initially gain strongest traction in specialized high-performance computing applications before gradually expanding into mainstream consumer markets. The technology's ability to enable in-memory computing architectures represents a particularly promising growth avenue, with potential to revolutionize data-intensive applications by dramatically reducing the energy costs associated with data movement between processing and storage components.

Current Challenges in Catalyst Integration for RRAM

Despite significant advancements in Resistive Random Access Memory (RRAM) technology, the integration of catalysts remains a critical challenge that impedes widespread commercial adoption. The primary obstacle lies in achieving consistent catalyst distribution throughout the switching layer, as non-uniform distribution leads to unpredictable switching behavior and reliability issues. Current deposition techniques, including atomic layer deposition and physical vapor deposition, struggle to deliver precise control over catalyst concentration gradients, particularly at nanoscale dimensions.

Material compatibility presents another significant hurdle, as many effective catalysts exhibit poor thermal stability during standard semiconductor processing steps. Noble metal catalysts such as platinum and palladium demonstrate excellent catalytic properties but suffer from diffusion into adjacent layers at elevated temperatures, compromising device performance and longevity. Additionally, these materials often create undesirable interfacial reactions with common electrode materials, generating resistive barriers that counteract the intended catalytic effects.

Scalability concerns further complicate catalyst integration, as techniques that work effectively in laboratory settings frequently fail to translate to high-volume manufacturing environments. The industry faces substantial challenges in maintaining catalyst efficiency while scaling down device dimensions below 20nm, where quantum effects and surface phenomena begin to dominate device physics. This dimensional scaling introduces variability in switching characteristics that current catalyst integration methods cannot adequately address.

The economic viability of catalyst materials represents another significant barrier. Many high-performance catalysts incorporate rare earth elements or precious metals, driving up production costs substantially. The semiconductor industry requires cost-effective alternatives that maintain performance metrics while utilizing more abundant materials. Current research into transition metal oxides shows promise but has yet to match the performance of more expensive catalyst systems.

Long-term reliability issues persist even when initial catalyst integration appears successful. Catalyst degradation mechanisms, including oxidation, electromigration, and phase separation, emerge during extended cycling, leading to progressive performance deterioration. The industry lacks comprehensive understanding of these degradation pathways, particularly under varied operating conditions and environmental stresses typical in commercial applications.

Process integration complexity further compounds these challenges, as catalyst incorporation must be compatible with existing semiconductor fabrication flows. Many promising catalyst materials require specialized handling or processing conditions that disrupt established manufacturing sequences. The development of integration schemes that preserve catalyst efficacy while maintaining compatibility with standard CMOS processes remains an unresolved technical challenge that significantly impacts commercialization timelines.

Material compatibility presents another significant hurdle, as many effective catalysts exhibit poor thermal stability during standard semiconductor processing steps. Noble metal catalysts such as platinum and palladium demonstrate excellent catalytic properties but suffer from diffusion into adjacent layers at elevated temperatures, compromising device performance and longevity. Additionally, these materials often create undesirable interfacial reactions with common electrode materials, generating resistive barriers that counteract the intended catalytic effects.

Scalability concerns further complicate catalyst integration, as techniques that work effectively in laboratory settings frequently fail to translate to high-volume manufacturing environments. The industry faces substantial challenges in maintaining catalyst efficiency while scaling down device dimensions below 20nm, where quantum effects and surface phenomena begin to dominate device physics. This dimensional scaling introduces variability in switching characteristics that current catalyst integration methods cannot adequately address.

The economic viability of catalyst materials represents another significant barrier. Many high-performance catalysts incorporate rare earth elements or precious metals, driving up production costs substantially. The semiconductor industry requires cost-effective alternatives that maintain performance metrics while utilizing more abundant materials. Current research into transition metal oxides shows promise but has yet to match the performance of more expensive catalyst systems.

Long-term reliability issues persist even when initial catalyst integration appears successful. Catalyst degradation mechanisms, including oxidation, electromigration, and phase separation, emerge during extended cycling, leading to progressive performance deterioration. The industry lacks comprehensive understanding of these degradation pathways, particularly under varied operating conditions and environmental stresses typical in commercial applications.

Process integration complexity further compounds these challenges, as catalyst incorporation must be compatible with existing semiconductor fabrication flows. Many promising catalyst materials require specialized handling or processing conditions that disrupt established manufacturing sequences. The development of integration schemes that preserve catalyst efficacy while maintaining compatibility with standard CMOS processes remains an unresolved technical challenge that significantly impacts commercialization timelines.

Current Catalyst Solutions for RRAM Performance Enhancement

01 Metal oxide catalysts for RRAM efficiency

Metal oxide materials serve as effective catalysts in RRAM devices, enhancing switching efficiency and performance. These catalysts facilitate the formation and rupture of conductive filaments through redox reactions. By optimizing the metal oxide composition and structure, the energy required for resistive switching can be reduced while improving retention and endurance characteristics. Common metal oxides used include titanium oxide, hafnium oxide, and tantalum oxide, which demonstrate superior catalytic properties for oxygen vacancy migration.- Catalyst materials for improved RRAM efficiency: Various catalyst materials can be incorporated into RRAM devices to enhance switching efficiency and performance. These catalysts facilitate the formation and rupture of conductive filaments, reducing the energy required for resistive switching operations. Metal catalysts such as platinum, palladium, and ruthenium have shown significant improvements in switching speed and power consumption. The strategic placement of these catalysts within the resistive switching layer optimizes the electrochemical reactions that govern RRAM operation.

- Oxygen vacancy management techniques: Controlling oxygen vacancy concentration and distribution is crucial for RRAM catalyst efficiency. Various techniques have been developed to manage oxygen vacancies, including doping the switching layer with specific elements, applying forming gas treatments, and engineering interfaces between layers. These approaches enable precise control over the formation and migration of oxygen vacancies, which act as charge carriers in the resistive switching process. Optimized oxygen vacancy management leads to improved switching reliability, reduced variability, and enhanced endurance in RRAM devices.

- Nanostructured catalytic interfaces: Incorporating nanostructured interfaces in RRAM devices significantly enhances catalytic efficiency. These interfaces include nanodots, nanolayers, and three-dimensional nanostructures that increase the effective surface area for catalytic reactions. The engineered interfaces facilitate controlled ion migration and filament formation at lower energy thresholds. Nanostructured catalytic interfaces also improve the uniformity of switching behavior across the device, leading to more consistent performance and extended device lifetime.

- Multi-layer catalyst architectures: Multi-layer catalyst architectures have been developed to optimize RRAM efficiency through synergistic effects between different materials. These architectures typically consist of strategically stacked layers with complementary catalytic properties. The combination of different catalytic materials creates energy band alignments that facilitate electron transfer and ion migration. Multi-layer approaches also enable separate optimization of SET and RESET operations, resulting in improved switching symmetry, reduced operating voltages, and enhanced cycling endurance.

- Temperature and environmental control for catalyst optimization: The efficiency of catalysts in RRAM devices is significantly influenced by temperature and environmental conditions during both fabrication and operation. Precise control of annealing temperatures, ambient gas composition, and pressure during manufacturing processes can optimize catalyst activity. During device operation, localized temperature management through pulse engineering and thermal design enhances catalytic reactions while preventing thermal degradation. Environmental factors such as humidity and oxygen partial pressure also affect catalyst performance and must be controlled to maintain consistent RRAM operation.

02 Doped switching layers for enhanced catalytic activity

Introducing dopants into the switching layer of RRAM devices significantly enhances catalytic efficiency. Dopants such as nitrogen, aluminum, or rare earth elements modify the electronic structure of the switching material, creating additional defect sites that serve as catalytic centers. These doped structures facilitate faster ion migration and more efficient filament formation at lower operating voltages. The strategic selection and concentration of dopants can be tailored to optimize specific performance parameters such as switching speed, power consumption, and reliability.Expand Specific Solutions03 Interface engineering for improved catalytic efficiency

The interface between electrodes and the switching layer plays a crucial role in RRAM catalyst efficiency. By engineering these interfaces through insertion of buffer layers, creation of oxygen reservoirs, or introduction of specific defect structures, the catalytic activity at the interface can be significantly enhanced. These engineered interfaces provide preferential sites for redox reactions and filament formation, reducing the energy barrier for resistive switching. Techniques such as atomic layer deposition and interface functionalization enable precise control over the interface properties to optimize catalytic performance.Expand Specific Solutions04 Nanostructured materials as catalytic elements

Incorporating nanostructured materials such as nanoparticles, nanowires, or nanolayers significantly enhances the catalytic efficiency of RRAM devices. These nanostructures provide high surface-to-volume ratios and unique electronic properties that facilitate ion migration and filament formation. The size, shape, and distribution of these nanostructures can be engineered to create preferential paths for conductive filament growth, resulting in more consistent switching behavior and lower operating voltages. Additionally, nanostructured catalysts can improve the spatial confinement of filaments, leading to better device reliability and endurance.Expand Specific Solutions05 Multi-layer catalyst systems for optimized RRAM performance

Multi-layer catalyst systems incorporate strategically designed layers with complementary catalytic functions to optimize RRAM performance. These systems typically include oxygen exchange layers, ion storage layers, and reaction promotion layers working in concert to enhance switching efficiency. By separating and optimizing specific catalytic functions across different layers, these systems can simultaneously improve multiple performance parameters such as switching speed, energy consumption, retention, and endurance. The thickness and composition of each layer can be precisely controlled to achieve the desired balance of performance characteristics for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions in RRAM Catalysis

The Resistive RAM (RRAM) technology market is currently in a growth phase, transitioning from research to commercialization with an estimated market size of $1-2 billion, projected to reach $4-5 billion by 2026. Major semiconductor manufacturers including Samsung, Micron, TSMC, and Intel are actively developing RRAM solutions, while research institutions like IMEC, Tsinghua University, and Fudan University are advancing fundamental catalyst efficiency innovations. The competitive landscape features established players (Hitachi, SMIC, GlobalFoundries) alongside specialized startups like CrossBar. Technical maturity varies significantly across implementations, with catalyst efficiency improvements representing a critical focus area as companies strive to overcome reliability, endurance, and power consumption challenges before widespread commercial adoption.

Samsung Electronics Co., Ltd.

Technical Solution: 三星电子在ReRAM催化剂效率研究领域采用了双金属氧化物结构(DMO)技术方案,通过在传统金属氧化物层中引入过渡金属催化剂纳米颗粒,显著提高了氧空位迁移效率。该技术利用精确控制的原子层沉积(ALD)工艺,在HfOx或TaOx基础材料中嵌入Pt、Ru等贵金属催化剂,形成高度均匀的纳米催化网络。三星的研究表明,这种结构可将形成电压降低约30%,同时提高电阻比达4倍。其专利的"催化增强型自限制电流"(CE-SLC)技术通过催化剂辅助的局部热效应控制导电丝形成过程,解决了传统ReRAM的变异性和可靠性问题。三星已成功演示了基于该技术的28nm工艺节点的4Gb ReRAM原型,展示了亚10ns的切换速度和超过10^6次的耐久性,同时功耗比传统DRAM降低70%。该技术已整合到三星的嵌入式存储解决方案中,特别针对低功耗物联网和可穿戴设备应用场景。

优势:强大的半导体制造能力和规模化生产优势;专利的催化增强型自限制电流技术有效解决了ReRAM的变异性问题;完整的从材料研发到产品集成的垂直整合能力;已有成熟的原型产品验证。劣势:贵金属催化剂的使用增加了生产成本;技术复杂度高,对制造工艺要求严格;在某些应用场景下,其ReRAM解决方案与自家NAND闪存产品线存在潜在的内部竞争。

Micron Technology, Inc.

Technical Solution: 美光科技在ReRAM催化剂效率研究领域开发了"氧工程催化层"(OECL)技术方案,通过在传统金属氧化物ReRAM结构中引入专门设计的氧亲和性催化层,精确调控氧空位的形成和迁移。该技术使用了创新的Cu-Te合金作为催化剂材料,在HfO2或Ta2O5基础介电层的界面处形成纳米级厚度的催化区域。美光的研究表明,这种结构可以将操作电流降低65%,同时提高电阻窗口比达5倍。其专利的"梯度催化界面"(GCI)技术通过在垂直方向上创建催化剂浓度梯度,实现了导电丝形成路径的精确控制,大幅提高了器件的均匀性和可靠性。美光已在其300mm晶圆厂成功验证了基于该技术的20nm工艺节点的ReRAM阵列,展示了超过10^7次的耐久性和85°C下10年的数据保留能力。该技术特别适用于存储级内存(SCM)应用,填补DRAM和NAND闪存之间的性能差距,已被整合到美光的3D XPoint™技术路线图中。

优势:专利的氧工程催化层技术显著提高了ReRAM的能效比和可靠性;作为存储行业领导者,具备成熟的大规模生产能力;已有商业化产品验证;在存储级内存市场具有战略布局。劣势:技术实现复杂,需要精确的材料控制和界面工程;在某些应用场景下,其ReRAM解决方案与现有NAND和3D XPoint产品存在市场定位重叠;技术转化为大规模商业产品的周期较长。

Key Patents and Research on Catalyst Efficiency Mechanisms

Resistive random-access memory

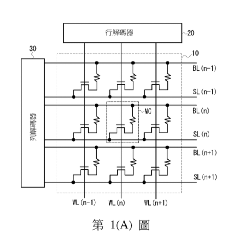

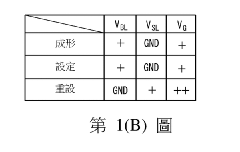

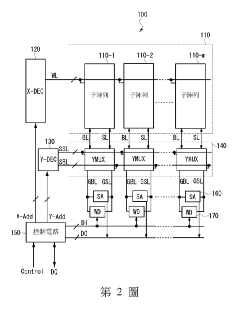

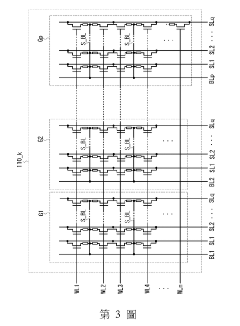

PatentActiveTW202034327A

Innovation

- The memory array is configured with shared bit lines and source lines, precharging selected lines to a first voltage, and applying a write pulse by discharging the selected source lines, thereby reducing line widths and minimizing power consumption and voltage drop.

Environmental Impact of Catalyst Materials in RRAM

The environmental impact of catalyst materials used in Resistive Random Access Memory (RRAM) technology represents a critical consideration as this emerging memory solution gains traction in the electronics industry. Catalysts play a fundamental role in enhancing RRAM performance by facilitating redox reactions and filament formation, yet their environmental footprint remains inadequately addressed in current research paradigms.

Traditional catalyst materials employed in RRAM devices often include precious metals such as platinum, palladium, and gold, as well as transition metals like copper, nickel, and ruthenium. The extraction processes for these materials involve energy-intensive mining operations that contribute significantly to carbon emissions. For instance, platinum mining generates approximately 40 tons of CO2 emissions per kilogram of refined metal, representing one of the highest carbon footprints among materials used in electronic components.

Water consumption and contamination present another environmental challenge. The purification processes required to achieve semiconductor-grade catalyst materials typically consume between 7,000-10,000 liters of water per square meter of processed material. Additionally, acid leaching techniques commonly employed in metal catalyst preparation introduce toxic compounds including sulfuric acid and cyanide into water systems, potentially causing long-term ecological damage in mining regions.

Rare earth elements frequently utilized as dopants or catalytic enhancers in advanced RRAM structures pose particular sustainability concerns. Their extraction is concentrated in regions with limited environmental regulations, resulting in substantial habitat destruction and toxic waste generation. The refining process for these elements produces radioactive thorium and uranium byproducts that require specialized containment and disposal protocols rarely implemented in developing nations where processing occurs.

End-of-life considerations for RRAM devices containing catalytic materials present recycling challenges due to the complex integration of these materials within nanoscale structures. Current electronic waste processing techniques recover less than 15% of precious metal catalysts from discarded memory devices, resulting in significant material loss and continued demand for virgin resource extraction.

Emerging research into bio-derived and sustainable catalyst alternatives shows promise for reducing environmental impact. Carbon-based catalysts derived from agricultural waste, nitrogen-doped graphene, and metal-organic frameworks offer potentially lower environmental footprints while maintaining performance parameters. These alternatives could reduce dependence on geopolitically concentrated supply chains while minimizing ecological damage associated with conventional catalyst materials.

Traditional catalyst materials employed in RRAM devices often include precious metals such as platinum, palladium, and gold, as well as transition metals like copper, nickel, and ruthenium. The extraction processes for these materials involve energy-intensive mining operations that contribute significantly to carbon emissions. For instance, platinum mining generates approximately 40 tons of CO2 emissions per kilogram of refined metal, representing one of the highest carbon footprints among materials used in electronic components.

Water consumption and contamination present another environmental challenge. The purification processes required to achieve semiconductor-grade catalyst materials typically consume between 7,000-10,000 liters of water per square meter of processed material. Additionally, acid leaching techniques commonly employed in metal catalyst preparation introduce toxic compounds including sulfuric acid and cyanide into water systems, potentially causing long-term ecological damage in mining regions.

Rare earth elements frequently utilized as dopants or catalytic enhancers in advanced RRAM structures pose particular sustainability concerns. Their extraction is concentrated in regions with limited environmental regulations, resulting in substantial habitat destruction and toxic waste generation. The refining process for these elements produces radioactive thorium and uranium byproducts that require specialized containment and disposal protocols rarely implemented in developing nations where processing occurs.

End-of-life considerations for RRAM devices containing catalytic materials present recycling challenges due to the complex integration of these materials within nanoscale structures. Current electronic waste processing techniques recover less than 15% of precious metal catalysts from discarded memory devices, resulting in significant material loss and continued demand for virgin resource extraction.

Emerging research into bio-derived and sustainable catalyst alternatives shows promise for reducing environmental impact. Carbon-based catalysts derived from agricultural waste, nitrogen-doped graphene, and metal-organic frameworks offer potentially lower environmental footprints while maintaining performance parameters. These alternatives could reduce dependence on geopolitically concentrated supply chains while minimizing ecological damage associated with conventional catalyst materials.

Manufacturing Scalability of Catalyst-Enhanced RRAM

The scalability of catalyst-enhanced RRAM manufacturing processes represents a critical factor in determining the commercial viability of this emerging memory technology. Current fabrication methods for catalyst-enhanced RRAM face several significant challenges when transitioning from laboratory-scale production to high-volume manufacturing environments. The integration of catalytic materials into existing semiconductor fabrication lines requires careful consideration of process compatibility, yield management, and cost-effectiveness.

Material deposition techniques for catalysts in RRAM structures must be optimized for uniformity across large wafer sizes. Physical vapor deposition (PVD) and atomic layer deposition (ALD) have shown promising results for catalyst integration, with ALD demonstrating superior thickness control and conformality at the nanoscale. However, the throughput limitations of ALD processes remain a concern for high-volume manufacturing scenarios, potentially impacting production economics.

Temperature sensitivity during catalyst integration presents another manufacturing challenge. Many catalytic materials require specific thermal processing windows that must be carefully aligned with the thermal budget constraints of CMOS back-end-of-line (BEOL) processes. This alignment becomes increasingly difficult as device dimensions shrink, necessitating the development of low-temperature catalyst activation methods compatible with advanced node requirements.

The reproducibility of switching characteristics across wafers represents a significant hurdle for mass production. Statistical variations in catalyst distribution and activity can lead to device-to-device variability, affecting yield rates and reliability metrics. Advanced process control systems incorporating in-line metrology and feedback mechanisms are being developed to address these variations, though their implementation adds complexity to the manufacturing flow.

Equipment compatibility presents another dimension of the scalability challenge. Existing semiconductor manufacturing equipment must be adapted or supplemented to accommodate the unique requirements of catalyst deposition and activation. This adaptation often requires substantial capital investment and process engineering efforts, potentially slowing technology adoption in production environments.

Cost considerations ultimately drive manufacturing decisions. While catalyst materials can enhance RRAM performance, their integration must not significantly increase the overall device cost structure. Economic analyses suggest that catalyst-enhanced RRAM becomes commercially viable when the performance benefits outweigh the incremental manufacturing costs, a balance that depends heavily on production volume and yield optimization.

Material deposition techniques for catalysts in RRAM structures must be optimized for uniformity across large wafer sizes. Physical vapor deposition (PVD) and atomic layer deposition (ALD) have shown promising results for catalyst integration, with ALD demonstrating superior thickness control and conformality at the nanoscale. However, the throughput limitations of ALD processes remain a concern for high-volume manufacturing scenarios, potentially impacting production economics.

Temperature sensitivity during catalyst integration presents another manufacturing challenge. Many catalytic materials require specific thermal processing windows that must be carefully aligned with the thermal budget constraints of CMOS back-end-of-line (BEOL) processes. This alignment becomes increasingly difficult as device dimensions shrink, necessitating the development of low-temperature catalyst activation methods compatible with advanced node requirements.

The reproducibility of switching characteristics across wafers represents a significant hurdle for mass production. Statistical variations in catalyst distribution and activity can lead to device-to-device variability, affecting yield rates and reliability metrics. Advanced process control systems incorporating in-line metrology and feedback mechanisms are being developed to address these variations, though their implementation adds complexity to the manufacturing flow.

Equipment compatibility presents another dimension of the scalability challenge. Existing semiconductor manufacturing equipment must be adapted or supplemented to accommodate the unique requirements of catalyst deposition and activation. This adaptation often requires substantial capital investment and process engineering efforts, potentially slowing technology adoption in production environments.

Cost considerations ultimately drive manufacturing decisions. While catalyst materials can enhance RRAM performance, their integration must not significantly increase the overall device cost structure. Economic analyses suggest that catalyst-enhanced RRAM becomes commercially viable when the performance benefits outweigh the incremental manufacturing costs, a balance that depends heavily on production volume and yield optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!