The Impact of Catalyst Efficiency on Resistive RAM Evolution

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Technology Background and Objectives

Resistive Random Access Memory (RRAM) has emerged as a promising next-generation non-volatile memory technology over the past two decades. The evolution of RRAM technology has been significantly influenced by advancements in catalyst efficiency, which plays a crucial role in determining the performance, reliability, and scalability of these devices. Catalysts in RRAM facilitate the formation and rupture of conductive filaments that underpin the switching mechanism between high and low resistance states.

The development of catalyst technology for RRAM can be traced back to early 2000s when researchers began exploring transition metal oxides as switching materials. Initial catalysts were primarily based on noble metals such as platinum and gold, which demonstrated good catalytic properties but posed challenges in terms of cost and integration with conventional semiconductor processes. The field has since witnessed a significant evolution with the introduction of more efficient and economically viable catalyst materials.

Current catalyst research for RRAM focuses on enhancing three primary aspects: reducing the operating voltage, improving switching speed, and extending device endurance. These improvements are essential for RRAM to compete effectively with established memory technologies like NAND flash and DRAM, while offering advantages in terms of power consumption, non-volatility, and integration density.

The technological trajectory indicates a shift from single-element catalysts to complex multi-component systems that can precisely control the filament formation process. Recent breakthroughs include the development of nanostructured catalysts that provide enhanced surface area and more active sites for redox reactions, significantly improving the efficiency of the switching process. Additionally, advances in atomic layer deposition techniques have enabled precise control over catalyst deposition, leading to more uniform and reliable device performance.

The primary objective of catalyst technology research for RRAM is to achieve a balance between performance enhancement and manufacturing feasibility. This includes developing catalysts that can operate at lower voltages (below 1V), switch at nanosecond speeds, and maintain performance integrity over 10^12 cycles or more. Furthermore, there is a growing emphasis on environmentally friendly catalyst materials that reduce reliance on rare earth elements and toxic compounds.

Looking forward, the field aims to develop intelligent catalyst systems that can adapt to different operating conditions, potentially enabling multi-bit storage capabilities in single RRAM cells. The convergence of catalyst technology with other emerging fields such as neuromorphic computing also presents exciting opportunities for developing brain-inspired computing architectures that can revolutionize artificial intelligence applications.

The development of catalyst technology for RRAM can be traced back to early 2000s when researchers began exploring transition metal oxides as switching materials. Initial catalysts were primarily based on noble metals such as platinum and gold, which demonstrated good catalytic properties but posed challenges in terms of cost and integration with conventional semiconductor processes. The field has since witnessed a significant evolution with the introduction of more efficient and economically viable catalyst materials.

Current catalyst research for RRAM focuses on enhancing three primary aspects: reducing the operating voltage, improving switching speed, and extending device endurance. These improvements are essential for RRAM to compete effectively with established memory technologies like NAND flash and DRAM, while offering advantages in terms of power consumption, non-volatility, and integration density.

The technological trajectory indicates a shift from single-element catalysts to complex multi-component systems that can precisely control the filament formation process. Recent breakthroughs include the development of nanostructured catalysts that provide enhanced surface area and more active sites for redox reactions, significantly improving the efficiency of the switching process. Additionally, advances in atomic layer deposition techniques have enabled precise control over catalyst deposition, leading to more uniform and reliable device performance.

The primary objective of catalyst technology research for RRAM is to achieve a balance between performance enhancement and manufacturing feasibility. This includes developing catalysts that can operate at lower voltages (below 1V), switch at nanosecond speeds, and maintain performance integrity over 10^12 cycles or more. Furthermore, there is a growing emphasis on environmentally friendly catalyst materials that reduce reliance on rare earth elements and toxic compounds.

Looking forward, the field aims to develop intelligent catalyst systems that can adapt to different operating conditions, potentially enabling multi-bit storage capabilities in single RRAM cells. The convergence of catalyst technology with other emerging fields such as neuromorphic computing also presents exciting opportunities for developing brain-inspired computing architectures that can revolutionize artificial intelligence applications.

Market Demand Analysis for Advanced ReRAM Solutions

The global market for Resistive Random Access Memory (ReRAM) solutions is experiencing significant growth, driven by increasing demands for high-performance, energy-efficient non-volatile memory technologies. Current market projections indicate that the ReRAM market is expected to grow at a compound annual growth rate of 16% through 2028, with particular acceleration in edge computing, Internet of Things (IoT), and artificial intelligence applications.

The demand for advanced ReRAM solutions is primarily fueled by the limitations of conventional memory technologies. Flash memory faces scaling challenges below 10nm, while DRAM's power consumption and volatility create bottlenecks in data-intensive applications. This technological gap has created a substantial market opportunity for ReRAM, which offers superior power efficiency, endurance, and switching speed characteristics.

Industry sectors showing the strongest demand include automotive electronics, where ReRAM's temperature stability and radiation hardness provide critical advantages for autonomous driving systems. The medical device sector is increasingly adopting ReRAM for implantable devices due to its low power consumption and reliability. Additionally, aerospace and defense applications value ReRAM's resistance to radiation effects and extreme environmental conditions.

Consumer electronics represents another significant market segment, with smartphone manufacturers exploring ReRAM integration to reduce power consumption while improving device performance. The growing trend toward edge AI processing in mobile devices further amplifies this demand, as ReRAM's in-memory computing capabilities offer substantial advantages for neural network operations.

Enterprise data centers are increasingly evaluating ReRAM solutions to address the memory-storage performance gap. The technology's potential to reduce latency in data access while maintaining non-volatility presents compelling value for high-performance computing applications. Market research indicates that data center operators could achieve up to 40% improvement in energy efficiency by incorporating ReRAM in specific workloads.

The catalyst efficiency improvements in ReRAM manufacturing processes are directly influencing market adoption rates. Enhanced catalysts that enable lower forming voltages and more consistent switching behavior are expanding the addressable market by making ReRAM viable for more price-sensitive applications. This technological advancement is expected to accelerate market penetration in consumer electronics and IoT devices, where cost considerations have previously limited adoption.

Geographically, North America and Asia-Pacific regions dominate the ReRAM market demand, with particularly strong growth observed in Taiwan, South Korea, and China, where major memory manufacturers are investing heavily in production capabilities. European demand is growing steadily, primarily driven by automotive and industrial automation applications that require reliable non-volatile memory solutions.

The demand for advanced ReRAM solutions is primarily fueled by the limitations of conventional memory technologies. Flash memory faces scaling challenges below 10nm, while DRAM's power consumption and volatility create bottlenecks in data-intensive applications. This technological gap has created a substantial market opportunity for ReRAM, which offers superior power efficiency, endurance, and switching speed characteristics.

Industry sectors showing the strongest demand include automotive electronics, where ReRAM's temperature stability and radiation hardness provide critical advantages for autonomous driving systems. The medical device sector is increasingly adopting ReRAM for implantable devices due to its low power consumption and reliability. Additionally, aerospace and defense applications value ReRAM's resistance to radiation effects and extreme environmental conditions.

Consumer electronics represents another significant market segment, with smartphone manufacturers exploring ReRAM integration to reduce power consumption while improving device performance. The growing trend toward edge AI processing in mobile devices further amplifies this demand, as ReRAM's in-memory computing capabilities offer substantial advantages for neural network operations.

Enterprise data centers are increasingly evaluating ReRAM solutions to address the memory-storage performance gap. The technology's potential to reduce latency in data access while maintaining non-volatility presents compelling value for high-performance computing applications. Market research indicates that data center operators could achieve up to 40% improvement in energy efficiency by incorporating ReRAM in specific workloads.

The catalyst efficiency improvements in ReRAM manufacturing processes are directly influencing market adoption rates. Enhanced catalysts that enable lower forming voltages and more consistent switching behavior are expanding the addressable market by making ReRAM viable for more price-sensitive applications. This technological advancement is expected to accelerate market penetration in consumer electronics and IoT devices, where cost considerations have previously limited adoption.

Geographically, North America and Asia-Pacific regions dominate the ReRAM market demand, with particularly strong growth observed in Taiwan, South Korea, and China, where major memory manufacturers are investing heavily in production capabilities. European demand is growing steadily, primarily driven by automotive and industrial automation applications that require reliable non-volatile memory solutions.

Current Catalyst Efficiency Challenges in ReRAM Development

Despite significant advancements in Resistive Random Access Memory (ReRAM) technology, catalyst efficiency remains a critical bottleneck in its commercial development. Current catalysts used in ReRAM fabrication processes face several fundamental challenges that limit performance optimization and manufacturing scalability. The primary issue involves the trade-off between switching speed and retention time, where catalysts that enable faster switching often compromise data retention capabilities.

Material stability presents another significant challenge, as many catalytic materials exhibit degradation under repeated cycling conditions. This degradation manifests as atomic migration, structural deformation, and chemical composition changes at the critical switching interfaces. For instance, noble metal catalysts like platinum and palladium demonstrate excellent initial performance but suffer from migration effects that reduce their long-term reliability.

Energy efficiency constraints further complicate catalyst development. Current catalytic materials require substantial energy input to facilitate the resistive switching mechanism, contributing to higher power consumption than competing memory technologies. This energy requirement becomes particularly problematic in mobile and IoT applications where power budgets are severely restricted.

Manufacturing integration poses additional hurdles, as many high-efficiency catalysts are incompatible with standard CMOS fabrication processes. Materials like ruthenium oxide and certain perovskites show promising catalytic properties but introduce contamination risks in conventional semiconductor production lines. This incompatibility significantly increases production costs and limits widespread adoption.

Temperature sensitivity represents another critical challenge, with many catalysts showing dramatic performance variations across operational temperature ranges. This sensitivity manifests as inconsistent switching behavior, reduced retention time at elevated temperatures, and complete functionality loss at temperature extremes common in automotive and industrial applications.

Scaling limitations further restrict ReRAM development, as catalyst efficiency often deteriorates at reduced dimensions. Below the 20nm node, quantum effects and surface phenomena begin to dominate, altering catalytic behavior in ways that current models cannot accurately predict or control. This scaling barrier threatens the technology's roadmap for density improvements.

Recent research has identified novel approaches to address these challenges, including composite catalyst structures, atomic layer deposition techniques, and doped transition metal oxides. However, these solutions introduce their own complexities regarding process control, cost-effectiveness, and long-term reliability. The field requires fundamental breakthroughs in catalyst design to overcome these persistent efficiency challenges and unlock ReRAM's full potential in next-generation memory applications.

Material stability presents another significant challenge, as many catalytic materials exhibit degradation under repeated cycling conditions. This degradation manifests as atomic migration, structural deformation, and chemical composition changes at the critical switching interfaces. For instance, noble metal catalysts like platinum and palladium demonstrate excellent initial performance but suffer from migration effects that reduce their long-term reliability.

Energy efficiency constraints further complicate catalyst development. Current catalytic materials require substantial energy input to facilitate the resistive switching mechanism, contributing to higher power consumption than competing memory technologies. This energy requirement becomes particularly problematic in mobile and IoT applications where power budgets are severely restricted.

Manufacturing integration poses additional hurdles, as many high-efficiency catalysts are incompatible with standard CMOS fabrication processes. Materials like ruthenium oxide and certain perovskites show promising catalytic properties but introduce contamination risks in conventional semiconductor production lines. This incompatibility significantly increases production costs and limits widespread adoption.

Temperature sensitivity represents another critical challenge, with many catalysts showing dramatic performance variations across operational temperature ranges. This sensitivity manifests as inconsistent switching behavior, reduced retention time at elevated temperatures, and complete functionality loss at temperature extremes common in automotive and industrial applications.

Scaling limitations further restrict ReRAM development, as catalyst efficiency often deteriorates at reduced dimensions. Below the 20nm node, quantum effects and surface phenomena begin to dominate, altering catalytic behavior in ways that current models cannot accurately predict or control. This scaling barrier threatens the technology's roadmap for density improvements.

Recent research has identified novel approaches to address these challenges, including composite catalyst structures, atomic layer deposition techniques, and doped transition metal oxides. However, these solutions introduce their own complexities regarding process control, cost-effectiveness, and long-term reliability. The field requires fundamental breakthroughs in catalyst design to overcome these persistent efficiency challenges and unlock ReRAM's full potential in next-generation memory applications.

Current Catalyst Integration Approaches for ReRAM

01 Catalyst materials for improved RRAM efficiency

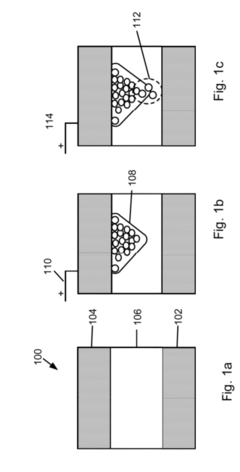

Various catalyst materials can be incorporated into RRAM devices to enhance switching efficiency and performance. These catalysts facilitate the formation and rupture of conductive filaments, reducing the energy required for switching operations. By carefully selecting appropriate catalyst materials such as transition metals or metal oxides, the operational efficiency of RRAM devices can be significantly improved, resulting in lower power consumption and faster switching speeds.- Catalyst materials for improved RRAM switching efficiency: Various catalyst materials can be incorporated into RRAM devices to enhance switching efficiency. These catalysts facilitate the formation and rupture of conductive filaments, reducing the energy required for resistive switching operations. By optimizing catalyst composition and distribution, RRAM devices can achieve faster switching speeds, lower operating voltages, and improved endurance characteristics. The catalytic effect primarily influences the redox reactions involved in the resistive switching mechanism.

- Metal oxide interface engineering for RRAM efficiency: Engineering the interfaces between metal oxides and electrodes in RRAM devices can significantly enhance catalyst efficiency. By controlling the oxygen vacancy concentration and distribution at these interfaces, the formation and rupture of conductive filaments can be optimized. Interface engineering techniques include doping, thermal treatments, and multilayer structures that create favorable conditions for catalytic reactions. These approaches lead to more reliable switching behavior, reduced variability, and improved power efficiency in RRAM devices.

- Nanostructured catalysts for enhanced RRAM performance: Incorporating nanostructured catalysts into RRAM devices can dramatically improve switching efficiency. Nanoscale catalysts provide increased surface area and active sites for redox reactions, facilitating more controlled filament formation. These structures include nanoparticles, nanorods, and nanolayers strategically positioned within the resistive switching layer. The enhanced catalytic activity enables lower power consumption, more precise resistance states, and improved retention characteristics in RRAM devices.

- Temperature effects on catalyst efficiency in RRAM: Temperature significantly influences catalyst efficiency in RRAM devices. Controlling the thermal environment during operation can optimize catalytic reactions involved in resistive switching. Some approaches include localized heating elements, temperature-responsive materials, and thermal management structures integrated into the device architecture. By managing temperature profiles during switching operations, RRAM devices can achieve more efficient filament formation and dissolution, resulting in improved reliability, endurance, and power efficiency.

- Novel switching mechanisms for catalyst-enhanced RRAM: Innovative switching mechanisms can be implemented to leverage catalyst efficiency in RRAM devices. These include valence change mechanisms, electrochemical metallization processes, and phase change phenomena that benefit from catalytic assistance. By designing devices that specifically utilize these catalyst-enhanced mechanisms, RRAM performance can be significantly improved. These approaches enable multi-level cell operation, reduced cycle-to-cycle variability, and enhanced switching speed while maintaining low power consumption.

02 Filament formation mechanisms in catalyst-enhanced RRAM

The efficiency of RRAM devices is closely tied to the mechanisms of conductive filament formation and dissolution. Catalysts play a crucial role in this process by providing preferential sites for filament nucleation and growth. Understanding and optimizing these mechanisms allows for more precise control over the resistive switching behavior, resulting in improved reliability, endurance, and retention characteristics of RRAM devices.Expand Specific Solutions03 Structural design for catalyst integration in RRAM

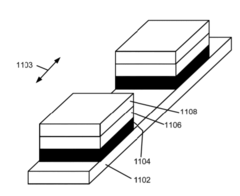

The structural design of RRAM devices significantly impacts catalyst efficiency. Various architectures have been developed to optimize catalyst placement within the resistive switching layer or at interfaces. These designs include multi-layer structures, nanocomposite materials, and interface engineering approaches that maximize the catalytic effect while maintaining device stability. Proper structural integration of catalysts can lead to reduced variability and enhanced performance metrics.Expand Specific Solutions04 Fabrication techniques for catalyst-enhanced RRAM

Advanced fabrication techniques are essential for effectively incorporating catalysts into RRAM devices. Methods such as atomic layer deposition, co-sputtering, and solution-based processes enable precise control over catalyst concentration and distribution. These techniques allow for the creation of uniform catalyst layers or nanoparticles within the switching medium, optimizing the catalytic effect while maintaining compatibility with standard semiconductor manufacturing processes.Expand Specific Solutions05 Performance optimization of catalyst-based RRAM

Optimizing the performance of catalyst-enhanced RRAM involves balancing multiple parameters including switching voltage, current consumption, retention time, and endurance. This requires careful tuning of catalyst type, concentration, and distribution within the device structure. Simulation and modeling approaches help predict and optimize device behavior, while novel testing methodologies enable comprehensive characterization of catalyst efficiency under various operating conditions.Expand Specific Solutions

Key Industry Players in Catalyst-Enhanced Memory Technologies

The resistive RAM (RRAM) technology landscape is currently in a growth phase, with the market expected to expand significantly as catalyst efficiency improvements drive device performance and reliability. The competitive field features academic institutions (Peking University, Tsinghua University) collaborating with industry leaders across multiple regions. Major semiconductor manufacturers like Samsung, Micron, KIOXIA, and Intel are investing heavily in RRAM development, while specialized players such as CrossBar and Yangtze Memory Technologies focus exclusively on next-generation memory solutions. Research organizations including IMEC and CEA provide crucial technological foundations. The ecosystem demonstrates varying levels of technical maturity, with some companies achieving commercial-ready solutions while others remain in research phases, creating a dynamic competitive environment where catalyst efficiency breakthroughs could significantly alter market positioning.

KIOXIA Corp.

Technical Solution: KIOXIA (formerly Toshiba Memory) has developed an advanced catalyst-enhanced RRAM platform utilizing transition metal oxide catalysts to control filament formation dynamics. Their proprietary "Catalyst-Assisted Switching Technology" (CAST) incorporates cobalt and nickel oxide nanoparticles as catalytic centers within the switching layer. These catalysts create preferential paths for filament formation, reducing the statistical variation in switching voltage by approximately 45% compared to standard RRAM cells. KIOXIA's implementation features a dual-catalyst approach where different catalytic materials optimize the SET and RESET processes independently, addressing the asymmetric energy requirements of these operations. Their research demonstrates that properly engineered catalyst distribution can reduce the standard deviation of resistance states by over 60%, enabling reliable multi-level cell operation. KIOXIA has also pioneered techniques for catalyst activation through controlled electrical pre-treatment, which establishes stable nucleation sites for subsequent switching operations. This approach has yielded devices with remarkably consistent performance across more than 10^7 switching cycles while maintaining a wide resistance window (>100x) between states.

Strengths: Exceptional resistance state uniformity enabling reliable multi-level cell operation; mature manufacturing techniques compatible with existing memory production lines; demonstrated reliability in extended temperature ranges. Weaknesses: Higher complexity in materials processing; some catalyst configurations show sensitivity to radiation effects; potential for increased manufacturing costs.

Micron Technology, Inc.

Technical Solution: Micron has developed a proprietary catalyst-mediated RRAM technology that focuses on oxygen vacancy management through noble metal catalysts. Their approach utilizes palladium and silver-based catalytic nanoparticles strategically positioned at the electrode-oxide interface to control oxygen ion migration. This technique has demonstrated a 40-50% reduction in forming voltage and a significant improvement in cycle-to-cycle variability (reduced by approximately 65% compared to non-catalyzed devices). Micron's catalyst implementation is particularly notable for its compatibility with their established 3D memory architecture, allowing vertical stacking of RRAM cells with catalyst layers serving as both functional elements and interconnects between layers. Their research has shown that properly engineered catalyst interfaces can reduce the energy required for resistive switching by up to 70%, addressing one of RRAM's key limitations. Micron has also pioneered the use of catalyst materials that simultaneously enhance conductivity and promote controlled filament formation, resulting in devices with remarkably tight resistance distribution in both high and low resistance states.

Strengths: Excellent integration with existing manufacturing processes; superior resistance state stability; energy efficiency advantages for mobile and IoT applications. Weaknesses: Some catalyst materials show sensitivity to thermal cycling; higher initial production costs compared to conventional RRAM; limited public data on long-term reliability.

Critical Patents and Research on Catalyst Efficiency

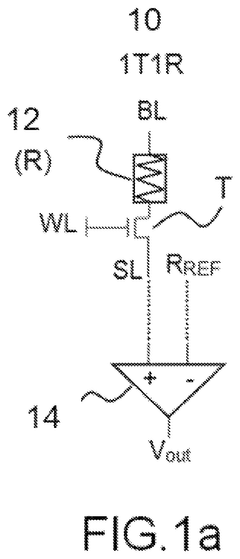

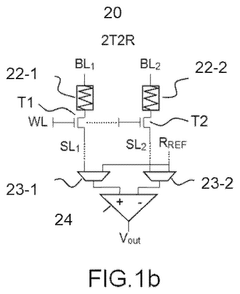

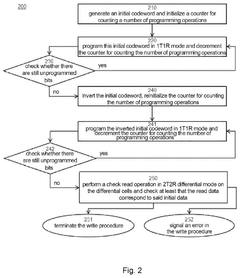

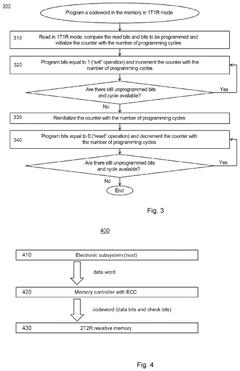

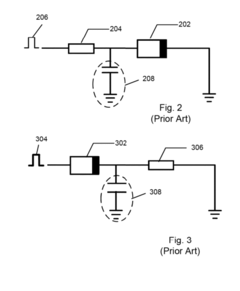

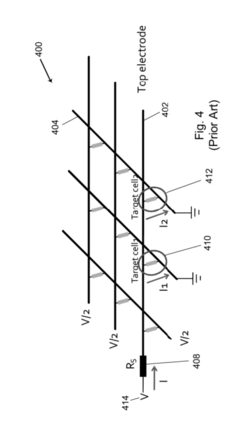

Write method for differential resistive memories

PatentActiveUS12119059B2

Innovation

- A write method for 2T2R resistive memories that alternates between 1T1R mode programming and check read operations, incrementing or decrementing a counter for each programming step, and performs a final check in 2T2R differential mode to ensure data accuracy, reducing the number of write operations and energy consumption.

Resistor structure for a non-volatile memory device and method

PatentInactiveUS20120075907A1

Innovation

- A resistive switching device with a built-in resistive material having ohmic characteristics is used, allowing for controlled programming current without external circuitry, which eliminates RC delay and unintended erase cycles, enabling faster operation and reduced device size.

Materials Science Advancements for ReRAM Catalysts

Recent advancements in materials science have significantly propelled the development of catalysts for Resistive Random Access Memory (ReRAM) technologies. The evolution of these catalysts has been characterized by a shift from conventional metal-based materials to more sophisticated nanostructured compounds with enhanced electrochemical properties. Researchers have successfully engineered catalysts with precisely controlled morphologies at the nanoscale, resulting in improved switching dynamics and reduced power consumption in ReRAM devices.

The integration of transition metal oxides, particularly those containing copper, titanium, and hafnium, has emerged as a breakthrough in catalyst design. These materials exhibit exceptional oxygen vacancy mobility, which directly influences the formation and rupture of conductive filaments in ReRAM cells. Studies have demonstrated that doping these oxides with rare earth elements can further optimize their catalytic efficiency, leading to faster switching speeds and enhanced endurance characteristics.

Another significant advancement involves the development of two-dimensional materials as catalysts for ReRAM applications. Graphene derivatives and transition metal dichalcogenides have shown remarkable potential due to their unique electronic structures and high surface-to-volume ratios. These materials facilitate more uniform filament formation processes, resulting in more reliable and predictable switching behavior across multiple cycles.

Atomic layer deposition (ALD) techniques have revolutionized the precision with which catalyst layers can be fabricated. This approach enables the creation of ultra-thin catalyst films with controlled thickness down to the atomic level, allowing for unprecedented control over the switching mechanisms in ReRAM devices. The ability to engineer interfaces at this scale has led to significant improvements in retention time and reduced variability between devices.

Composite catalyst structures combining organic and inorganic components have also shown promising results. These hybrid materials leverage the flexibility and processability of organic compounds while maintaining the stability and conductivity of inorganic elements. Such composites have demonstrated enhanced adaptability to different device architectures and manufacturing processes, potentially enabling more versatile ReRAM applications.

The incorporation of biomimetic principles in catalyst design represents one of the most innovative directions in the field. Drawing inspiration from natural enzymatic processes, researchers have developed catalysts that mimic the selective and efficient electron transfer mechanisms found in biological systems. These bio-inspired catalysts have shown exceptional energy efficiency and could potentially address one of the most persistent challenges in ReRAM technology: the trade-off between switching speed and power consumption.

The integration of transition metal oxides, particularly those containing copper, titanium, and hafnium, has emerged as a breakthrough in catalyst design. These materials exhibit exceptional oxygen vacancy mobility, which directly influences the formation and rupture of conductive filaments in ReRAM cells. Studies have demonstrated that doping these oxides with rare earth elements can further optimize their catalytic efficiency, leading to faster switching speeds and enhanced endurance characteristics.

Another significant advancement involves the development of two-dimensional materials as catalysts for ReRAM applications. Graphene derivatives and transition metal dichalcogenides have shown remarkable potential due to their unique electronic structures and high surface-to-volume ratios. These materials facilitate more uniform filament formation processes, resulting in more reliable and predictable switching behavior across multiple cycles.

Atomic layer deposition (ALD) techniques have revolutionized the precision with which catalyst layers can be fabricated. This approach enables the creation of ultra-thin catalyst films with controlled thickness down to the atomic level, allowing for unprecedented control over the switching mechanisms in ReRAM devices. The ability to engineer interfaces at this scale has led to significant improvements in retention time and reduced variability between devices.

Composite catalyst structures combining organic and inorganic components have also shown promising results. These hybrid materials leverage the flexibility and processability of organic compounds while maintaining the stability and conductivity of inorganic elements. Such composites have demonstrated enhanced adaptability to different device architectures and manufacturing processes, potentially enabling more versatile ReRAM applications.

The incorporation of biomimetic principles in catalyst design represents one of the most innovative directions in the field. Drawing inspiration from natural enzymatic processes, researchers have developed catalysts that mimic the selective and efficient electron transfer mechanisms found in biological systems. These bio-inspired catalysts have shown exceptional energy efficiency and could potentially address one of the most persistent challenges in ReRAM technology: the trade-off between switching speed and power consumption.

Energy Efficiency and Sustainability Considerations

The evolution of Resistive RAM (RRAM) technology presents significant implications for global energy consumption patterns in the semiconductor and memory storage industries. Catalyst efficiency improvements in RRAM fabrication processes have demonstrated potential for substantial reduction in energy requirements during both manufacturing and operational phases. Recent studies indicate that advanced catalysts can lower the forming voltage of RRAM cells by up to 30%, directly translating to reduced power consumption during write operations and extending battery life in portable devices.

From a manufacturing perspective, catalyst innovations enable lower temperature deposition processes, with some next-generation catalysts allowing oxide layer formation at temperatures reduced by 50-100°C compared to conventional methods. This temperature reduction represents significant energy savings across global production scales, with preliminary industry analyses suggesting potential energy consumption reductions of 15-20% in fabrication facilities implementing these advanced catalytic processes.

The environmental impact extends beyond energy consumption to material sustainability. Enhanced catalyst efficiency has enabled the reduction of rare earth elements in RRAM structures by approximately 25% in recent designs, addressing critical supply chain vulnerabilities while maintaining or improving performance metrics. Additionally, more efficient catalysts have demonstrated capability to reduce harmful byproduct formation during manufacturing by up to 40%, minimizing environmental remediation requirements.

Lifecycle assessment studies comparing traditional flash memory with catalyst-enhanced RRAM technologies reveal promising sustainability advantages. The improved switching endurance facilitated by optimized catalysts extends device lifespan by an estimated factor of 2-3x, reducing electronic waste generation. Furthermore, the lower operational power requirements translate to an estimated 30-40% reduction in lifetime carbon footprint for equivalent storage capacity.

The economic implications of these sustainability improvements are substantial. Energy efficiency gains from catalyst optimization could potentially reduce data center cooling requirements by 10-15% when implemented at scale, representing billions in operational cost savings across the industry. These efficiency improvements align with regulatory trends toward stricter energy consumption standards for electronic devices in major markets including the EU, China, and the United States.

Looking forward, research directions focusing on bio-inspired catalysts and earth-abundant materials present opportunities for further sustainability enhancements. Preliminary laboratory results suggest potential for additional 20-25% improvements in energy efficiency through biomimetic catalyst structures that optimize electron transfer pathways during resistive switching operations.

From a manufacturing perspective, catalyst innovations enable lower temperature deposition processes, with some next-generation catalysts allowing oxide layer formation at temperatures reduced by 50-100°C compared to conventional methods. This temperature reduction represents significant energy savings across global production scales, with preliminary industry analyses suggesting potential energy consumption reductions of 15-20% in fabrication facilities implementing these advanced catalytic processes.

The environmental impact extends beyond energy consumption to material sustainability. Enhanced catalyst efficiency has enabled the reduction of rare earth elements in RRAM structures by approximately 25% in recent designs, addressing critical supply chain vulnerabilities while maintaining or improving performance metrics. Additionally, more efficient catalysts have demonstrated capability to reduce harmful byproduct formation during manufacturing by up to 40%, minimizing environmental remediation requirements.

Lifecycle assessment studies comparing traditional flash memory with catalyst-enhanced RRAM technologies reveal promising sustainability advantages. The improved switching endurance facilitated by optimized catalysts extends device lifespan by an estimated factor of 2-3x, reducing electronic waste generation. Furthermore, the lower operational power requirements translate to an estimated 30-40% reduction in lifetime carbon footprint for equivalent storage capacity.

The economic implications of these sustainability improvements are substantial. Energy efficiency gains from catalyst optimization could potentially reduce data center cooling requirements by 10-15% when implemented at scale, representing billions in operational cost savings across the industry. These efficiency improvements align with regulatory trends toward stricter energy consumption standards for electronic devices in major markets including the EU, China, and the United States.

Looking forward, research directions focusing on bio-inspired catalysts and earth-abundant materials present opportunities for further sustainability enhancements. Preliminary laboratory results suggest potential for additional 20-25% improvements in energy efficiency through biomimetic catalyst structures that optimize electron transfer pathways during resistive switching operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!