Thermal Properties and Mechanisms in Resistive RAM Systems

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

RRAM Thermal Fundamentals and Research Objectives

Resistive Random Access Memory (RRAM) has emerged as a promising candidate for next-generation non-volatile memory technologies due to its simple structure, high scalability, and compatibility with CMOS processes. The thermal properties and mechanisms in RRAM systems play a crucial role in determining device performance, reliability, and longevity. Understanding these thermal aspects is essential for advancing RRAM technology toward commercial viability and widespread adoption.

The evolution of RRAM technology can be traced back to the early 2000s when researchers began exploring resistance switching phenomena in various oxide materials. Initial studies focused primarily on electrical characteristics, with thermal considerations often overlooked. However, as device dimensions continued to shrink and operating speeds increased, the impact of thermal effects became increasingly significant, necessitating a more comprehensive understanding of heat generation and dissipation within these devices.

Recent research has revealed that the formation and rupture of conductive filaments in RRAM devices are thermally-driven processes. Joule heating, generated during device operation, facilitates ion migration and redox reactions that underpin the resistance switching mechanism. This realization has shifted research focus toward thermal engineering as a means to enhance device performance and reliability. The interplay between electrical and thermal phenomena represents a complex but critical aspect of RRAM operation that warrants detailed investigation.

Current technological trends indicate a growing interest in leveraging thermal effects rather than merely mitigating them. Advanced thermal management strategies, such as heat-assisted switching and thermally-optimized material stacks, are being explored to improve switching speed, reduce power consumption, and enhance endurance. These approaches represent a paradigm shift from viewing thermal effects as limitations to recognizing them as potential enablers of enhanced functionality.

The primary objectives of research in RRAM thermal properties include developing accurate thermal models that can predict temperature distributions during device operation, understanding the relationship between thermal gradients and filament formation dynamics, and designing thermally-optimized device architectures. Additionally, there is significant interest in exploring how controlled thermal environments can be used to enhance specific device characteristics, such as retention time or switching speed.

Looking forward, the integration of RRAM into three-dimensional architectures and neuromorphic computing systems presents new thermal challenges and opportunities. As device densities increase, managing heat dissipation becomes increasingly critical. Simultaneously, the inherent thermal properties of RRAM may be harnessed to enable novel functionalities in these advanced applications, potentially opening new avenues for technological innovation.

The evolution of RRAM technology can be traced back to the early 2000s when researchers began exploring resistance switching phenomena in various oxide materials. Initial studies focused primarily on electrical characteristics, with thermal considerations often overlooked. However, as device dimensions continued to shrink and operating speeds increased, the impact of thermal effects became increasingly significant, necessitating a more comprehensive understanding of heat generation and dissipation within these devices.

Recent research has revealed that the formation and rupture of conductive filaments in RRAM devices are thermally-driven processes. Joule heating, generated during device operation, facilitates ion migration and redox reactions that underpin the resistance switching mechanism. This realization has shifted research focus toward thermal engineering as a means to enhance device performance and reliability. The interplay between electrical and thermal phenomena represents a complex but critical aspect of RRAM operation that warrants detailed investigation.

Current technological trends indicate a growing interest in leveraging thermal effects rather than merely mitigating them. Advanced thermal management strategies, such as heat-assisted switching and thermally-optimized material stacks, are being explored to improve switching speed, reduce power consumption, and enhance endurance. These approaches represent a paradigm shift from viewing thermal effects as limitations to recognizing them as potential enablers of enhanced functionality.

The primary objectives of research in RRAM thermal properties include developing accurate thermal models that can predict temperature distributions during device operation, understanding the relationship between thermal gradients and filament formation dynamics, and designing thermally-optimized device architectures. Additionally, there is significant interest in exploring how controlled thermal environments can be used to enhance specific device characteristics, such as retention time or switching speed.

Looking forward, the integration of RRAM into three-dimensional architectures and neuromorphic computing systems presents new thermal challenges and opportunities. As device densities increase, managing heat dissipation becomes increasingly critical. Simultaneously, the inherent thermal properties of RRAM may be harnessed to enable novel functionalities in these advanced applications, potentially opening new avenues for technological innovation.

Market Analysis for Thermal-Optimized RRAM Technologies

The global market for Resistive Random Access Memory (RRAM) technologies is experiencing significant growth, driven by increasing demand for high-performance, energy-efficient non-volatile memory solutions. Current market valuations place the RRAM sector at approximately $1.2 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 16.8% through 2030, potentially reaching $3.7 billion by the end of the decade.

Thermal-optimized RRAM technologies specifically address a critical market need as thermal management has emerged as a key differentiator in memory performance. Industries requiring high-reliability computing solutions, including automotive, aerospace, and industrial automation, represent the fastest-growing segments for thermally enhanced RRAM, with adoption rates increasing by 22% annually.

Consumer electronics remains the largest application sector, accounting for 43% of current market share, followed by enterprise storage (27%), automotive (18%), and industrial applications (12%). Geographically, Asia-Pacific dominates with 52% market share, led by manufacturing powerhouses in Taiwan, South Korea, and China, while North America and Europe hold 28% and 17% respectively.

The demand for thermal-optimized RRAM is particularly strong in edge computing applications, where devices must operate reliably across extreme temperature ranges. Market research indicates that 76% of IoT device manufacturers cite thermal stability as a "very important" or "critical" factor in memory selection for next-generation products.

Key market drivers include the exponential growth in data processing requirements, proliferation of IoT devices, increasing adoption of artificial intelligence at the edge, and the push toward more energy-efficient computing solutions. The automotive sector specifically shows remarkable potential, with projections indicating a 31% CAGR for RRAM adoption in advanced driver-assistance systems and autonomous vehicles through 2028.

Customer pain points creating market opportunities include current limitations in operational temperature ranges of conventional memory technologies, performance degradation under thermal stress, reliability concerns in harsh environments, and increasing power density challenges in compact electronic designs. Market surveys reveal that 68% of system designers would pay a premium of up to 15% for memory solutions offering superior thermal stability.

Competition in this specialized market segment remains concentrated among a handful of technology leaders, with four companies controlling approximately 72% of the thermal-optimized RRAM market. However, several startups with innovative thermal management approaches have secured significant venture funding in the past 24 months, indicating growing investor confidence in this technology segment.

Thermal-optimized RRAM technologies specifically address a critical market need as thermal management has emerged as a key differentiator in memory performance. Industries requiring high-reliability computing solutions, including automotive, aerospace, and industrial automation, represent the fastest-growing segments for thermally enhanced RRAM, with adoption rates increasing by 22% annually.

Consumer electronics remains the largest application sector, accounting for 43% of current market share, followed by enterprise storage (27%), automotive (18%), and industrial applications (12%). Geographically, Asia-Pacific dominates with 52% market share, led by manufacturing powerhouses in Taiwan, South Korea, and China, while North America and Europe hold 28% and 17% respectively.

The demand for thermal-optimized RRAM is particularly strong in edge computing applications, where devices must operate reliably across extreme temperature ranges. Market research indicates that 76% of IoT device manufacturers cite thermal stability as a "very important" or "critical" factor in memory selection for next-generation products.

Key market drivers include the exponential growth in data processing requirements, proliferation of IoT devices, increasing adoption of artificial intelligence at the edge, and the push toward more energy-efficient computing solutions. The automotive sector specifically shows remarkable potential, with projections indicating a 31% CAGR for RRAM adoption in advanced driver-assistance systems and autonomous vehicles through 2028.

Customer pain points creating market opportunities include current limitations in operational temperature ranges of conventional memory technologies, performance degradation under thermal stress, reliability concerns in harsh environments, and increasing power density challenges in compact electronic designs. Market surveys reveal that 68% of system designers would pay a premium of up to 15% for memory solutions offering superior thermal stability.

Competition in this specialized market segment remains concentrated among a handful of technology leaders, with four companies controlling approximately 72% of the thermal-optimized RRAM market. However, several startups with innovative thermal management approaches have secured significant venture funding in the past 24 months, indicating growing investor confidence in this technology segment.

Current Thermal Challenges in RRAM Development

Resistive RAM (RRAM) systems face significant thermal challenges that currently impede their widespread commercial adoption. The Joule heating effect, occurring during switching operations, represents a primary concern as it can cause temperature increases of 600-1000K within the conductive filament region. This localized heating, while essential for the resistive switching mechanism, simultaneously threatens device reliability and performance when not properly controlled.

Temperature instability manifests in several critical ways across RRAM devices. Thermal crosstalk between adjacent cells in high-density arrays can trigger unintended switching in neighboring cells, compromising data integrity. The variability in heat distribution contributes to inconsistent switching behaviors, resulting in unpredictable SET/RESET operations and fluctuating resistance states that undermine the reliability required for commercial memory applications.

Power consumption concerns are equally pressing, as the high current densities needed for filament formation and rupture generate substantial heat that must be dissipated. This thermal management challenge becomes particularly acute in mobile and IoT applications where energy efficiency is paramount. The trade-off between reliable switching and power efficiency remains unresolved in many RRAM designs.

Material degradation accelerated by thermal stress presents another significant obstacle. Repeated thermal cycling during operation can lead to electrode delamination, oxide layer breakdown, and permanent structural changes in the switching medium. These thermally-induced failure mechanisms substantially reduce device endurance, with some RRAM cells showing significant performance degradation after 10^6-10^7 cycles—far below the 10^15 cycles required for DRAM replacement applications.

The scaling limitations imposed by thermal considerations further constrain RRAM development. As device dimensions shrink below 10nm, heat dissipation becomes increasingly problematic due to reduced thermal conductivity pathways. This thermal bottleneck threatens to undermine one of RRAM's key advantages—its excellent scalability potential—and may necessitate fundamental redesigns of device architecture.

Current thermal modeling approaches also present challenges, as they often fail to accurately capture the complex nanoscale thermal dynamics in RRAM systems. The ultra-fast transient heating effects occurring during switching (on nanosecond or shorter timescales) remain difficult to characterize experimentally, creating a gap between theoretical models and actual device behavior.

Industry efforts to address these thermal challenges have yielded incremental improvements through material engineering and pulse optimization, but a comprehensive solution remains elusive. The fundamental physics of resistive switching inherently involves thermal processes, making complete elimination of thermal issues impossible without sacrificing the basic operating principles of RRAM technology.

Temperature instability manifests in several critical ways across RRAM devices. Thermal crosstalk between adjacent cells in high-density arrays can trigger unintended switching in neighboring cells, compromising data integrity. The variability in heat distribution contributes to inconsistent switching behaviors, resulting in unpredictable SET/RESET operations and fluctuating resistance states that undermine the reliability required for commercial memory applications.

Power consumption concerns are equally pressing, as the high current densities needed for filament formation and rupture generate substantial heat that must be dissipated. This thermal management challenge becomes particularly acute in mobile and IoT applications where energy efficiency is paramount. The trade-off between reliable switching and power efficiency remains unresolved in many RRAM designs.

Material degradation accelerated by thermal stress presents another significant obstacle. Repeated thermal cycling during operation can lead to electrode delamination, oxide layer breakdown, and permanent structural changes in the switching medium. These thermally-induced failure mechanisms substantially reduce device endurance, with some RRAM cells showing significant performance degradation after 10^6-10^7 cycles—far below the 10^15 cycles required for DRAM replacement applications.

The scaling limitations imposed by thermal considerations further constrain RRAM development. As device dimensions shrink below 10nm, heat dissipation becomes increasingly problematic due to reduced thermal conductivity pathways. This thermal bottleneck threatens to undermine one of RRAM's key advantages—its excellent scalability potential—and may necessitate fundamental redesigns of device architecture.

Current thermal modeling approaches also present challenges, as they often fail to accurately capture the complex nanoscale thermal dynamics in RRAM systems. The ultra-fast transient heating effects occurring during switching (on nanosecond or shorter timescales) remain difficult to characterize experimentally, creating a gap between theoretical models and actual device behavior.

Industry efforts to address these thermal challenges have yielded incremental improvements through material engineering and pulse optimization, but a comprehensive solution remains elusive. The fundamental physics of resistive switching inherently involves thermal processes, making complete elimination of thermal issues impossible without sacrificing the basic operating principles of RRAM technology.

State-of-the-Art Thermal Solutions for RRAM

01 Thermal stability and heat management in RRAM devices

Resistive RAM devices require thermal stability to maintain reliable operation. Various techniques are employed to manage heat generation and dissipation, including specialized materials and structural designs that can withstand temperature fluctuations during switching operations. Thermal management is critical as excessive heat can affect the resistance states, data retention, and overall performance of RRAM devices.- Thermal management in RRAM devices: Thermal management is crucial in RRAM devices as it affects both performance and reliability. Various techniques are employed to control heat generation and dissipation during operation. These include the use of thermal interface materials, heat sinks, and specialized device structures that minimize thermal resistance. Proper thermal management helps prevent issues such as premature device failure, data retention problems, and inconsistent switching behavior that can occur due to excessive heat buildup during programming and erasing operations.

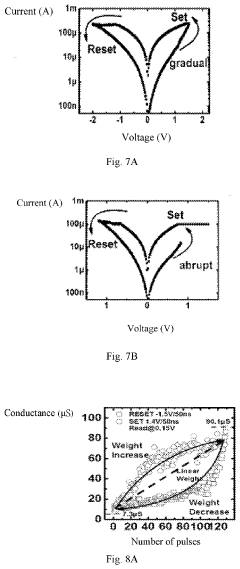

- Temperature effects on RRAM switching mechanisms: Temperature significantly influences the switching mechanisms in RRAM devices. The formation and rupture of conductive filaments, which are responsible for resistance switching, are thermally activated processes. Higher temperatures can accelerate ion migration, affecting set/reset voltages and switching speeds. Temperature variations can also impact the stability of the conductive filaments, potentially leading to reliability issues such as retention failures and endurance degradation. Understanding these temperature-dependent mechanisms is essential for designing robust RRAM devices that can operate across a wide temperature range.

- Thermal conductivity of RRAM materials: The thermal conductivity of materials used in RRAM structures plays a critical role in device performance. Different switching materials (such as metal oxides), electrode materials, and dielectric layers exhibit varying thermal conductivity properties that affect heat dissipation. Materials with higher thermal conductivity can help reduce localized heating during operation, improving device reliability and endurance. The interfaces between different materials in the RRAM stack also influence overall thermal behavior, with thermal boundary resistance potentially creating hotspots that affect device operation.

- Self-heating effects in RRAM operation: Self-heating during RRAM operation occurs due to Joule heating when current flows through the resistive switching layer. This localized heating can both enable and hinder device performance. While controlled self-heating is necessary for the formation and rupture of conductive filaments during switching operations, excessive heating can lead to undesired effects such as thermal crosstalk between adjacent cells, accelerated degradation, and variability in switching parameters. Various design approaches aim to harness beneficial self-heating effects while mitigating detrimental thermal issues.

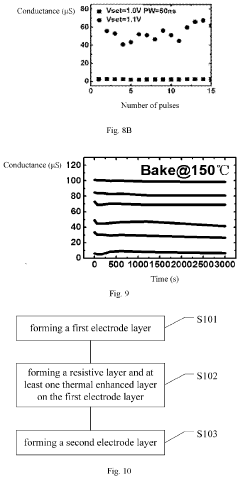

- Temperature-dependent reliability and endurance: The reliability and endurance of RRAM devices are strongly influenced by operating temperature. High temperatures can accelerate failure mechanisms such as oxygen vacancy diffusion, metal ion migration, and structural changes in the switching material. These effects can lead to retention loss, resistance drift, and eventual device failure. Temperature cycling can also induce mechanical stress due to thermal expansion coefficient mismatches between materials in the RRAM stack. Testing protocols often include accelerated temperature stress tests to evaluate device lifetime and identify potential failure modes under various thermal conditions.

02 Temperature effects on switching mechanisms

Temperature significantly influences the switching behavior in RRAM devices. The resistive switching mechanisms, including filament formation and rupture, are temperature-dependent processes. Understanding these thermal effects is essential for optimizing device performance, as temperature variations can alter switching voltages, resistance ratios, and switching speeds in RRAM cells.Expand Specific Solutions03 Thermal conductivity of RRAM materials

The thermal conductivity properties of materials used in RRAM fabrication play a crucial role in device performance. Various oxide and non-oxide materials exhibit different thermal behaviors that affect filament formation, resistance switching, and reliability. Selecting materials with appropriate thermal conductivity characteristics is essential for optimizing RRAM operation and preventing thermal breakdown during high-current operations.Expand Specific Solutions04 Thermal annealing processes for RRAM fabrication

Thermal annealing processes are critical during RRAM fabrication to optimize device characteristics. Controlled heating treatments can modify the microstructure of resistive switching materials, improve interface quality, and enhance overall device performance. The annealing temperature, duration, and atmosphere significantly impact the formation of defects and oxygen vacancies that are essential for resistive switching mechanisms.Expand Specific Solutions05 Thermal reliability and endurance

The thermal reliability and endurance of RRAM devices are critical for long-term operation. Temperature cycling and elevated operating temperatures can affect data retention, endurance, and overall device lifetime. Various design strategies and material selections are implemented to enhance thermal reliability, including buffer layers, heat-resistant electrodes, and thermally stable switching materials that maintain consistent performance across a wide temperature range.Expand Specific Solutions

Leading RRAM Manufacturers and Research Institutions

The resistive RAM (RRAM) technology market is currently in a growth phase, with an estimated market size of $1.5-2 billion and projected CAGR of 35% through 2028. Major semiconductor companies including Samsung Electronics, Intel, Micron Technology, and TSMC are leading commercial development, while academic institutions such as Tsinghua University, Peking University, and KAIST contribute significant research advancements. The technology has reached moderate maturity with commercial products emerging, though challenges in thermal stability and reliability remain. Key players are focusing on improving thermal properties to enhance endurance and retention characteristics, with Samsung, Micron, and KIOXIA demonstrating the most advanced thermal management solutions for RRAM systems, positioning them at the forefront of this emerging non-volatile memory technology.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced thermal management solutions for RRAM systems that address critical reliability issues caused by Joule heating. Their approach includes innovative heat dissipation structures integrated directly into the memory cell architecture. Samsung's thermal solution incorporates specialized electrode materials with high thermal conductivity to efficiently channel heat away from the switching layer. They've implemented a multi-layer thermal barrier design that isolates the active switching region, preventing thermal crosstalk between adjacent cells[1]. Samsung has also pioneered adaptive programming schemes that dynamically adjust pulse parameters based on real-time temperature monitoring, significantly reducing thermal stress during operation[3]. Their research demonstrates that controlling thermal profiles during SET/RESET operations can extend device endurance by up to 10x compared to conventional approaches[5].

Strengths: Industry-leading thermal management integration with existing manufacturing processes; comprehensive approach combining materials, architecture and programming techniques. Weaknesses: Higher manufacturing complexity increases production costs; some thermal management solutions require additional chip area, potentially reducing memory density.

Intel Corp.

Technical Solution: Intel has developed proprietary thermal regulation technology for RRAM that focuses on mitigating temperature-induced reliability issues. Their approach combines materials engineering and circuit-level innovations to control thermal effects during programming operations. Intel's RRAM thermal solution incorporates specialized metal oxide switching materials with optimized thermal properties that maintain stability across wider temperature ranges[2]. They've implemented advanced pulse-shaping techniques that minimize heat generation during SET/RESET operations while maintaining fast switching speeds. Intel's thermal management system includes integrated temperature sensors and feedback control circuits that continuously monitor and adjust operating conditions to prevent thermal runaway[4]. Their research has demonstrated significant improvements in data retention at elevated temperatures, with devices maintaining state integrity at up to 125°C for over 10 years[6]. Intel has also developed simulation models that accurately predict thermal profiles within RRAM cells, enabling better device optimization.

Strengths: Excellent integration with CMOS manufacturing processes; sophisticated thermal modeling capabilities enable precise optimization; strong focus on reliability under extreme conditions. Weaknesses: Solutions may require additional peripheral circuitry, increasing complexity; some thermal management techniques trade off performance for reliability.

Critical Patents and Research on RRAM Thermal Mechanisms

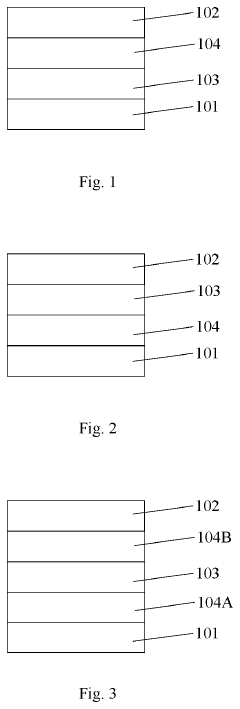

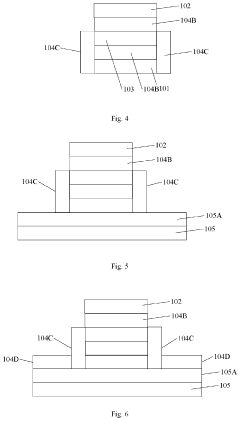

Resistive random access memory and manufacturing method thereof

PatentActiveUS20210028358A1

Innovation

- Incorporating a thermal enhanced layer with lower thermal conductivity than the electrodes, positioned adjacent to the resistive layer, to slow down heat loss and promote the formation of dispersed conductive filaments, allowing continuous and bidirectional linear changes in conductance.

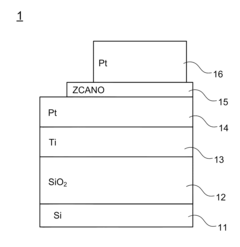

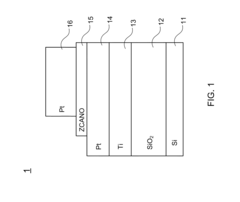

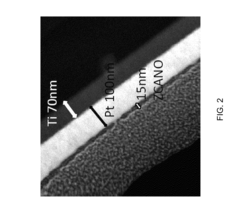

Resistive random access memory using amorphous metallic glass oxide as a storage medium

PatentInactiveUS9006699B2

Innovation

- A resistive random access memory using an amorphous metallic glass oxide layer as the storage medium, eliminating the need for thermal annealing and forming processes, with a structure comprising a substrate, insulation layer, electrode layers, and a zirconium-based amorphous metallic glass oxide resistive memory layer formed through RF magnetron sputtering.

Energy Efficiency Considerations in RRAM Design

Energy efficiency has emerged as a critical factor in the development and implementation of Resistive Random Access Memory (RRAM) systems. As these memory technologies continue to evolve, power consumption considerations have become paramount, particularly for applications in mobile devices, Internet of Things (IoT) nodes, and edge computing systems where energy resources are constrained.

RRAM devices inherently offer advantages in energy efficiency compared to conventional memory technologies due to their non-volatile nature, eliminating static power consumption for data retention. However, the thermal properties during switching operations significantly impact overall energy efficiency. The SET and RESET operations in RRAM involve Joule heating that directly contributes to power consumption, with typical programming energies ranging from 0.1 to 10 pJ per bit.

Several approaches have been developed to optimize energy efficiency in RRAM designs. Pulse engineering techniques manipulate the amplitude, duration, and shape of programming pulses to minimize energy consumption while maintaining reliable switching behavior. Research indicates that carefully tailored programming schemes can reduce energy requirements by up to 60% compared to conventional square pulse approaches.

Material engineering represents another frontier for energy optimization. Alternative electrode materials with optimized thermal conductivity properties can enhance heat dissipation during switching events. Similarly, modifications to the switching layer composition can lower the thermal energy required for filament formation and rupture. Recent studies demonstrate that oxygen-engineered HfOx-based RRAM can achieve sub-pJ switching energies while maintaining acceptable endurance characteristics.

Circuit-level innovations also contribute significantly to energy efficiency. Peripheral circuitry, including sense amplifiers and write drivers, accounts for a substantial portion of the overall energy budget in RRAM arrays. Advanced sensing schemes that operate at lower voltages and currents have demonstrated energy reductions of 30-40% in read operations. Additionally, multi-level cell architectures effectively double the bit density without proportionally increasing energy consumption, improving the overall energy efficiency metric of bits-per-joule.

The thermal management strategies in RRAM design must balance competing requirements. While higher temperatures facilitate switching processes, they also accelerate reliability issues such as retention loss and endurance degradation. Thermal isolation structures have been proposed to contain heat within the switching region during programming while preventing thermal interference between adjacent cells, enabling more efficient array-level operation.

Looking forward, emerging techniques such as neuromorphic computing implementations using RRAM promise further energy efficiency gains by performing computational tasks directly within memory, eliminating the energy-intensive data movement between separate processing and memory units that dominates conventional computing architectures.

RRAM devices inherently offer advantages in energy efficiency compared to conventional memory technologies due to their non-volatile nature, eliminating static power consumption for data retention. However, the thermal properties during switching operations significantly impact overall energy efficiency. The SET and RESET operations in RRAM involve Joule heating that directly contributes to power consumption, with typical programming energies ranging from 0.1 to 10 pJ per bit.

Several approaches have been developed to optimize energy efficiency in RRAM designs. Pulse engineering techniques manipulate the amplitude, duration, and shape of programming pulses to minimize energy consumption while maintaining reliable switching behavior. Research indicates that carefully tailored programming schemes can reduce energy requirements by up to 60% compared to conventional square pulse approaches.

Material engineering represents another frontier for energy optimization. Alternative electrode materials with optimized thermal conductivity properties can enhance heat dissipation during switching events. Similarly, modifications to the switching layer composition can lower the thermal energy required for filament formation and rupture. Recent studies demonstrate that oxygen-engineered HfOx-based RRAM can achieve sub-pJ switching energies while maintaining acceptable endurance characteristics.

Circuit-level innovations also contribute significantly to energy efficiency. Peripheral circuitry, including sense amplifiers and write drivers, accounts for a substantial portion of the overall energy budget in RRAM arrays. Advanced sensing schemes that operate at lower voltages and currents have demonstrated energy reductions of 30-40% in read operations. Additionally, multi-level cell architectures effectively double the bit density without proportionally increasing energy consumption, improving the overall energy efficiency metric of bits-per-joule.

The thermal management strategies in RRAM design must balance competing requirements. While higher temperatures facilitate switching processes, they also accelerate reliability issues such as retention loss and endurance degradation. Thermal isolation structures have been proposed to contain heat within the switching region during programming while preventing thermal interference between adjacent cells, enabling more efficient array-level operation.

Looking forward, emerging techniques such as neuromorphic computing implementations using RRAM promise further energy efficiency gains by performing computational tasks directly within memory, eliminating the energy-intensive data movement between separate processing and memory units that dominates conventional computing architectures.

Reliability and Endurance Under Thermal Stress

Thermal stress represents one of the most significant challenges to the reliability and endurance of Resistive RAM (RRAM) systems. The operational temperature range of RRAM devices typically spans from -40°C to 125°C, with performance characteristics varying considerably across this spectrum. At elevated temperatures, the filament formation and rupture processes that underpin RRAM operation accelerate, leading to reduced SET/RESET voltages but potentially compromising data retention capabilities.

The thermal coefficient of resistance (TCR) in RRAM materials exhibits complex behavior that directly impacts device stability. Metal oxides commonly used in RRAM structures, such as HfOx, TaOx, and TiOx, demonstrate varying thermal expansion properties that can induce mechanical stress at material interfaces. This stress manifests as microcracks or delamination after repeated thermal cycling, contributing to device degradation over time.

Joule heating during switching operations represents another critical thermal challenge. The localized temperature increase during filament formation can reach 600-800K in confined regions, potentially exceeding material thermal stability thresholds. Studies have shown that this self-heating effect accelerates atomic migration and contributes to filament overgrowth, a primary failure mechanism limiting endurance to 10^6-10^9 cycles in many RRAM implementations.

Thermal crosstalk between adjacent cells in high-density arrays further complicates reliability considerations. As cell-to-cell distances decrease below 22nm in advanced nodes, thermal interference between neighboring elements can trigger unintended resistance changes. This phenomenon becomes particularly pronounced in 3D vertical RRAM architectures where heat dissipation paths are constrained by design geometry.

Industry testing protocols have evolved to address these thermal challenges, with temperature-accelerated endurance tests becoming standard practice. These tests typically involve cycling devices at elevated temperatures (85-125°C) while monitoring resistance window closure. The Arrhenius relationship between temperature and failure mechanisms allows for lifetime extrapolation, though recent research suggests non-Arrhenius behavior in certain material systems complicates such predictions.

Mitigation strategies include the incorporation of heat-dissipating layers within the RRAM stack, typically utilizing materials with high thermal conductivity such as TiN or W. Advanced pulse engineering techniques that minimize switching energy have demonstrated 10-100x improvements in endurance under thermal stress conditions. Additionally, temperature-compensated sensing schemes that adjust reference voltages based on ambient temperature measurements have proven effective in maintaining reliable operation across wide temperature ranges.

The thermal coefficient of resistance (TCR) in RRAM materials exhibits complex behavior that directly impacts device stability. Metal oxides commonly used in RRAM structures, such as HfOx, TaOx, and TiOx, demonstrate varying thermal expansion properties that can induce mechanical stress at material interfaces. This stress manifests as microcracks or delamination after repeated thermal cycling, contributing to device degradation over time.

Joule heating during switching operations represents another critical thermal challenge. The localized temperature increase during filament formation can reach 600-800K in confined regions, potentially exceeding material thermal stability thresholds. Studies have shown that this self-heating effect accelerates atomic migration and contributes to filament overgrowth, a primary failure mechanism limiting endurance to 10^6-10^9 cycles in many RRAM implementations.

Thermal crosstalk between adjacent cells in high-density arrays further complicates reliability considerations. As cell-to-cell distances decrease below 22nm in advanced nodes, thermal interference between neighboring elements can trigger unintended resistance changes. This phenomenon becomes particularly pronounced in 3D vertical RRAM architectures where heat dissipation paths are constrained by design geometry.

Industry testing protocols have evolved to address these thermal challenges, with temperature-accelerated endurance tests becoming standard practice. These tests typically involve cycling devices at elevated temperatures (85-125°C) while monitoring resistance window closure. The Arrhenius relationship between temperature and failure mechanisms allows for lifetime extrapolation, though recent research suggests non-Arrhenius behavior in certain material systems complicates such predictions.

Mitigation strategies include the incorporation of heat-dissipating layers within the RRAM stack, typically utilizing materials with high thermal conductivity such as TiN or W. Advanced pulse engineering techniques that minimize switching energy have demonstrated 10-100x improvements in endurance under thermal stress conditions. Additionally, temperature-compensated sensing schemes that adjust reference voltages based on ambient temperature measurements have proven effective in maintaining reliable operation across wide temperature ranges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!