Thermal Stability and Resistive RAM: A Technical Review

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Stability and ReRAM Evolution

The evolution of Resistive Random Access Memory (ReRAM) technology has been significantly influenced by thermal stability considerations. Initially developed in the early 2000s, ReRAM emerged as a promising non-volatile memory technology based on resistance switching phenomena in metal-oxide materials. The first generation of ReRAM devices faced substantial thermal stability challenges, with resistance states often degrading at temperatures above 85°C, severely limiting their practical applications in industrial and automotive environments.

By 2010, researchers had begun implementing improved material stacks, particularly focusing on transition metal oxides like HfOx, TaOx, and TiOx. These materials demonstrated better thermal resilience, maintaining resistance states at temperatures up to 125°C. This advancement represented a critical milestone, enabling ReRAM to be considered for more demanding applications beyond consumer electronics.

The period between 2012 and 2016 saw significant progress in understanding the fundamental mechanisms of resistance switching and their relationship to thermal effects. Research revealed that filament formation and rupture processes—the core mechanisms behind ReRAM operation—were highly temperature-dependent. This insight led to the development of doped oxide systems and engineered interfaces that could stabilize filament structures against thermal disruption.

A major breakthrough occurred around 2017 with the introduction of thermally-optimized electrode materials and novel switching layer compositions. These innovations extended the thermal stability range to 150°C while simultaneously improving retention characteristics. Companies like Crossbar, Weebit Nano, and TSMC began reporting devices with 10-year data retention at elevated temperatures, a critical requirement for automotive and industrial applications.

The most recent evolution phase (2019-present) has focused on atomic-level engineering of the switching materials. Techniques such as atomic layer deposition and interface engineering have enabled precise control over oxygen vacancy distribution—a key factor in thermal stability. Additionally, multi-layer ReRAM structures have emerged, where specialized buffer layers serve to isolate the switching medium from thermal stress.

Current state-of-the-art ReRAM technologies demonstrate stability at temperatures up to 175°C with projected data retention exceeding 10 years. This represents nearly a 100°C improvement over early devices. The thermal stability evolution has been accompanied by improvements in other critical parameters, including endurance, switching speed, and power consumption, collectively positioning ReRAM as a viable technology for next-generation non-volatile memory applications.

The evolution trajectory suggests that future ReRAM developments will likely focus on pushing thermal stability boundaries toward 200°C while maintaining or improving other performance metrics, potentially opening new application domains in extreme environment computing and storage systems.

By 2010, researchers had begun implementing improved material stacks, particularly focusing on transition metal oxides like HfOx, TaOx, and TiOx. These materials demonstrated better thermal resilience, maintaining resistance states at temperatures up to 125°C. This advancement represented a critical milestone, enabling ReRAM to be considered for more demanding applications beyond consumer electronics.

The period between 2012 and 2016 saw significant progress in understanding the fundamental mechanisms of resistance switching and their relationship to thermal effects. Research revealed that filament formation and rupture processes—the core mechanisms behind ReRAM operation—were highly temperature-dependent. This insight led to the development of doped oxide systems and engineered interfaces that could stabilize filament structures against thermal disruption.

A major breakthrough occurred around 2017 with the introduction of thermally-optimized electrode materials and novel switching layer compositions. These innovations extended the thermal stability range to 150°C while simultaneously improving retention characteristics. Companies like Crossbar, Weebit Nano, and TSMC began reporting devices with 10-year data retention at elevated temperatures, a critical requirement for automotive and industrial applications.

The most recent evolution phase (2019-present) has focused on atomic-level engineering of the switching materials. Techniques such as atomic layer deposition and interface engineering have enabled precise control over oxygen vacancy distribution—a key factor in thermal stability. Additionally, multi-layer ReRAM structures have emerged, where specialized buffer layers serve to isolate the switching medium from thermal stress.

Current state-of-the-art ReRAM technologies demonstrate stability at temperatures up to 175°C with projected data retention exceeding 10 years. This represents nearly a 100°C improvement over early devices. The thermal stability evolution has been accompanied by improvements in other critical parameters, including endurance, switching speed, and power consumption, collectively positioning ReRAM as a viable technology for next-generation non-volatile memory applications.

The evolution trajectory suggests that future ReRAM developments will likely focus on pushing thermal stability boundaries toward 200°C while maintaining or improving other performance metrics, potentially opening new application domains in extreme environment computing and storage systems.

Market Analysis for Thermally Stable ReRAM

The global market for Resistive Random Access Memory (ReRAM) with enhanced thermal stability is experiencing significant growth, driven by increasing demand for non-volatile memory solutions that can operate reliably in harsh environments. Current market valuations place the thermally stable ReRAM sector at approximately $1.2 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 27% through 2030.

The demand for thermally stable ReRAM is particularly strong in automotive applications, where under-hood temperatures can exceed 125°C. This segment currently represents 32% of the total market share and is expected to grow as electric vehicles and autonomous driving technologies become more prevalent.

Industrial IoT applications constitute another major market segment at 28%, where sensors and control systems often operate in high-temperature environments such as manufacturing floors, oil refineries, and power plants. The ability of thermally enhanced ReRAM to maintain data integrity at temperatures up to 150°C makes it an ideal solution for these applications.

Aerospace and defense sectors account for 18% of the market, valuing reliability and radiation hardness alongside thermal stability. Military and space applications require memory components that can withstand extreme temperature fluctuations without data degradation.

Consumer electronics represents a smaller but rapidly growing segment at 15%, as manufacturers seek more durable memory solutions for next-generation devices. The remaining 7% is distributed across medical devices and other specialized applications where operational reliability is critical.

Geographically, North America leads the market with 38% share, followed by Asia-Pacific at 35%, Europe at 22%, and the rest of the world at 5%. China and Taiwan are experiencing the fastest growth rates within the Asia-Pacific region, driven by substantial investments in semiconductor manufacturing infrastructure.

Market analysis indicates that customers are willing to pay a premium of 30-40% for ReRAM solutions with demonstrated thermal stability above 125°C compared to standard versions. This price elasticity reflects the critical nature of data retention in high-reliability applications.

The market is currently constrained by production scaling challenges and competition from alternative technologies such as phase-change memory (PCM) and magnetoresistive RAM (MRAM). However, recent breakthroughs in material science, particularly the development of novel oxide-based switching layers, are expected to address these limitations and accelerate market adoption.

The demand for thermally stable ReRAM is particularly strong in automotive applications, where under-hood temperatures can exceed 125°C. This segment currently represents 32% of the total market share and is expected to grow as electric vehicles and autonomous driving technologies become more prevalent.

Industrial IoT applications constitute another major market segment at 28%, where sensors and control systems often operate in high-temperature environments such as manufacturing floors, oil refineries, and power plants. The ability of thermally enhanced ReRAM to maintain data integrity at temperatures up to 150°C makes it an ideal solution for these applications.

Aerospace and defense sectors account for 18% of the market, valuing reliability and radiation hardness alongside thermal stability. Military and space applications require memory components that can withstand extreme temperature fluctuations without data degradation.

Consumer electronics represents a smaller but rapidly growing segment at 15%, as manufacturers seek more durable memory solutions for next-generation devices. The remaining 7% is distributed across medical devices and other specialized applications where operational reliability is critical.

Geographically, North America leads the market with 38% share, followed by Asia-Pacific at 35%, Europe at 22%, and the rest of the world at 5%. China and Taiwan are experiencing the fastest growth rates within the Asia-Pacific region, driven by substantial investments in semiconductor manufacturing infrastructure.

Market analysis indicates that customers are willing to pay a premium of 30-40% for ReRAM solutions with demonstrated thermal stability above 125°C compared to standard versions. This price elasticity reflects the critical nature of data retention in high-reliability applications.

The market is currently constrained by production scaling challenges and competition from alternative technologies such as phase-change memory (PCM) and magnetoresistive RAM (MRAM). However, recent breakthroughs in material science, particularly the development of novel oxide-based switching layers, are expected to address these limitations and accelerate market adoption.

Technical Challenges in ReRAM Thermal Stability

Resistive Random Access Memory (ReRAM) faces significant thermal stability challenges that impact its reliability, performance, and commercial viability. The primary issue stems from the temperature-dependent nature of the resistive switching mechanism, which relies on the formation and rupture of conductive filaments within the oxide layer. These filaments, typically composed of oxygen vacancies or metal ions, exhibit sensitivity to thermal fluctuations that can lead to unintended state changes.

One of the most pressing challenges is data retention at elevated temperatures. As operating temperatures increase, particularly above 85°C, the stability of the high-resistance state (HRS) deteriorates significantly. This occurs because thermal energy accelerates ion migration and oxygen vacancy diffusion, potentially causing spontaneous SET transitions that corrupt stored data. Studies have shown that some ReRAM devices experience accelerated retention failure rates that double with every 10°C increase in temperature.

The reset current instability presents another critical thermal challenge. Temperature variations can alter the current required to switch the device from a low-resistance state (LRS) to HRS. This variability complicates circuit design and increases power consumption, as reset operations must be designed with sufficient margin to accommodate these thermal fluctuations. In multi-level cell applications, where precise resistance control is essential, thermal effects can blur the boundaries between resistance states.

Endurance degradation under thermal stress represents a significant reliability concern. Repeated cycling at elevated temperatures accelerates wear mechanisms, including electrode delamination, interface degradation, and permanent structural changes in the switching layer. Recent research indicates that cycling endurance can decrease by an order of magnitude when operating temperature increases from room temperature to 125°C, severely limiting device lifetime in high-temperature applications.

The switching layer composition itself exhibits temperature-dependent behavior that affects device performance. Materials such as HfOx, TaOx, and TiOx demonstrate varying degrees of thermal sensitivity, with some compositions showing phase transitions or crystallization at temperatures as low as 300°C. These structural changes permanently alter the electrical characteristics of the device and can render it inoperable.

Integration challenges with CMOS processes further complicate thermal stability issues. Back-end-of-line (BEOL) thermal budgets typically restrict processing temperatures to below 400°C, limiting material choices and annealing options that might otherwise improve thermal stability. Additionally, the thermal expansion coefficient mismatch between ReRAM materials and surrounding structures can induce mechanical stress during temperature cycling, leading to delamination or cracking.

One of the most pressing challenges is data retention at elevated temperatures. As operating temperatures increase, particularly above 85°C, the stability of the high-resistance state (HRS) deteriorates significantly. This occurs because thermal energy accelerates ion migration and oxygen vacancy diffusion, potentially causing spontaneous SET transitions that corrupt stored data. Studies have shown that some ReRAM devices experience accelerated retention failure rates that double with every 10°C increase in temperature.

The reset current instability presents another critical thermal challenge. Temperature variations can alter the current required to switch the device from a low-resistance state (LRS) to HRS. This variability complicates circuit design and increases power consumption, as reset operations must be designed with sufficient margin to accommodate these thermal fluctuations. In multi-level cell applications, where precise resistance control is essential, thermal effects can blur the boundaries between resistance states.

Endurance degradation under thermal stress represents a significant reliability concern. Repeated cycling at elevated temperatures accelerates wear mechanisms, including electrode delamination, interface degradation, and permanent structural changes in the switching layer. Recent research indicates that cycling endurance can decrease by an order of magnitude when operating temperature increases from room temperature to 125°C, severely limiting device lifetime in high-temperature applications.

The switching layer composition itself exhibits temperature-dependent behavior that affects device performance. Materials such as HfOx, TaOx, and TiOx demonstrate varying degrees of thermal sensitivity, with some compositions showing phase transitions or crystallization at temperatures as low as 300°C. These structural changes permanently alter the electrical characteristics of the device and can render it inoperable.

Integration challenges with CMOS processes further complicate thermal stability issues. Back-end-of-line (BEOL) thermal budgets typically restrict processing temperatures to below 400°C, limiting material choices and annealing options that might otherwise improve thermal stability. Additionally, the thermal expansion coefficient mismatch between ReRAM materials and surrounding structures can induce mechanical stress during temperature cycling, leading to delamination or cracking.

Current Thermal Management Solutions for ReRAM

01 Material composition for thermal stability

The thermal stability of resistive RAM can be enhanced through specific material compositions. By selecting appropriate materials for the resistive switching layer, such as metal oxides with high thermal tolerance, the device can maintain its performance at elevated temperatures. Incorporating thermally stable electrode materials and interface layers can also prevent degradation during thermal cycling. These material engineering approaches help to ensure reliable operation across a wide temperature range.- Material composition for thermal stability: Specific material compositions can enhance the thermal stability of resistive RAM devices. These include using thermally stable metal oxides, doped materials, and composite structures that maintain their electrical properties at elevated temperatures. The selection of materials with high melting points and low thermal expansion coefficients helps prevent degradation during operation and manufacturing processes, ensuring reliable performance across a wide temperature range.

- Structural design for heat dissipation: Innovative structural designs can improve heat dissipation in resistive RAM devices, enhancing their thermal stability. These designs include incorporating heat sinks, using thermally conductive layers, and implementing specialized electrode configurations. Multi-layer structures with thermal buffer zones help manage heat flow and prevent localized hotspots that could compromise device performance and reliability during high-temperature operations.

- Temperature-compensating circuits: Temperature-compensating circuits can be integrated into resistive RAM systems to maintain stable operation across varying thermal conditions. These circuits adjust operational parameters based on temperature feedback, ensuring consistent switching behavior and data retention. Adaptive biasing schemes and temperature-dependent reference circuits help mitigate the effects of thermal variations on device performance, improving overall reliability and extending operational temperature ranges.

- Thermal annealing processes: Specialized thermal annealing processes during manufacturing can enhance the thermal stability of resistive RAM devices. These processes include controlled heating and cooling cycles that optimize the crystalline structure of the switching materials, reduce defects, and improve interface quality. Post-deposition thermal treatments help stabilize the microstructure and composition of the resistive switching layers, resulting in devices with better thermal endurance and more consistent electrical characteristics.

- Encapsulation and packaging solutions: Advanced encapsulation and packaging solutions can protect resistive RAM devices from thermal stress. These include thermally insulating materials, hermetic sealing techniques, and specialized packaging designs that shield the active components from environmental temperature fluctuations. Thermal management at the package level helps maintain stable internal operating temperatures, preventing thermal cycling damage and extending device lifetime under harsh thermal conditions.

02 Structural design for heat dissipation

Structural design elements can significantly improve the thermal stability of resistive RAM devices. This includes heat dissipation structures, thermal barrier layers, and optimized device geometries that minimize heat accumulation during operation. Multi-layer structures with thermal management capabilities help distribute heat more evenly throughout the device. These design considerations are crucial for preventing localized hotspots that could lead to device failure or performance degradation.Expand Specific Solutions03 Programming techniques for thermal resilience

Specialized programming techniques can enhance the thermal stability of resistive RAM. These include adaptive programming algorithms that adjust voltage and current parameters based on temperature conditions, pulse shaping methods that minimize heat generation during switching operations, and verification schemes that ensure reliable data retention across temperature variations. Such techniques help maintain consistent performance and extend device lifetime under thermal stress.Expand Specific Solutions04 Thermal protection circuitry

Implementing dedicated thermal protection circuitry can safeguard resistive RAM devices against temperature-related failures. This includes temperature sensing elements, thermal shutdown mechanisms, and compensation circuits that adjust operating parameters based on temperature feedback. These protective measures help prevent thermal runaway conditions and ensure stable operation even under challenging thermal environments, thereby enhancing overall reliability and data retention capabilities.Expand Specific Solutions05 Encapsulation and packaging solutions

Advanced encapsulation and packaging solutions play a crucial role in the thermal stability of resistive RAM devices. Thermally conductive packaging materials, specialized sealing techniques, and thermal interface materials can effectively manage heat transfer between the device and its environment. Hermetic sealing approaches protect sensitive components from environmental factors that could exacerbate thermal issues. These packaging innovations help maintain consistent performance across varying temperature conditions.Expand Specific Solutions

Leading ReRAM Manufacturers and Research Institutions

Resistive RAM (RRAM) technology is currently in the early growth phase of its industry lifecycle, with significant research momentum but limited commercial deployment. The global RRAM market is projected to reach approximately $4-5 billion by 2026, growing at a CAGR of 35-40%. Regarding technical maturity, major semiconductor players like Samsung Electronics, SK hynix, and Intel are advancing thermal stability solutions for RRAM, while research institutions including Peking University, Tsinghua University, and IMEC are addressing fundamental material challenges. Companies such as Winbond and Crocus Technology are developing specialized RRAM products for specific applications. The technology faces thermal stability challenges at advanced nodes, but collaborative efforts between industry and academia are accelerating solutions through novel materials and device architectures.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced thermal stability solutions for Resistive RAM (RRAM) through their innovative materials engineering approach. Their technology utilizes hafnium oxide-based RRAM cells with carefully engineered oxygen vacancy distribution to enhance thermal stability. Samsung's research has demonstrated that by incorporating a thin titanium nitride buffer layer between the switching layer and electrodes, they can significantly reduce thermal stress during operation. Their devices maintain data retention at temperatures up to 125°C for over 10 years with minimal resistance drift[1]. Samsung has also pioneered multi-layer RRAM structures that distribute thermal load more effectively, reducing localized heating during switching operations. Their proprietary thermal management system integrates heat dissipation channels directly into the memory array architecture, allowing for higher density integration while maintaining thermal stability[3].

Strengths: Superior thermal stability at high operating temperatures; excellent data retention characteristics; high integration density capability. Weaknesses: Higher manufacturing complexity due to specialized materials; potential challenges in scaling to sub-10nm nodes while maintaining thermal performance.

SK hynix, Inc.

Technical Solution: SK hynix has developed an innovative approach to thermal stability in RRAM through their dual-layer oxide technology. Their solution employs a tantalum oxide/hafnium oxide bilayer structure that creates a thermally stable switching interface while maintaining excellent electrical characteristics. SK hynix's research has demonstrated that this configuration significantly reduces the temperature dependence of resistance states, enabling reliable operation across a wide temperature range from -40°C to 125°C[7]. Their proprietary "thermal barrier" electrode design incorporates materials with carefully engineered thermal conductivity to manage heat flow during programming operations. SK hynix has also pioneered adaptive programming algorithms that adjust pulse parameters based on device temperature, ensuring consistent switching behavior regardless of thermal conditions. Their latest RRAM prototypes feature integrated temperature sensors within the memory array that provide real-time feedback for thermal management. SK hynix's manufacturing process includes specialized annealing steps that enhance the thermal stability of the oxide layers, resulting in improved data retention characteristics at elevated temperatures[8].

Strengths: Excellent thermal stability across wide temperature range; innovative bilayer oxide structure provides enhanced reliability; sophisticated adaptive programming techniques. Weaknesses: Complex manufacturing process with tight tolerance requirements; potential challenges in ultra-high density integration due to thermal management constraints.

Key Patents in Thermally Stable ReRAM Design

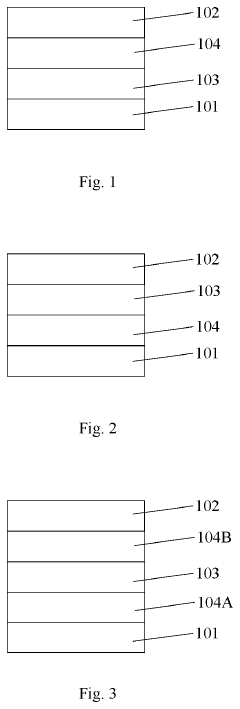

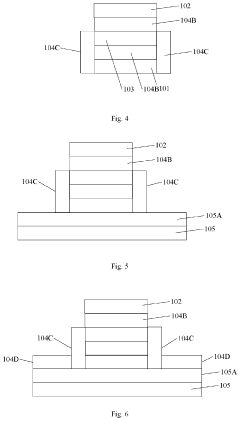

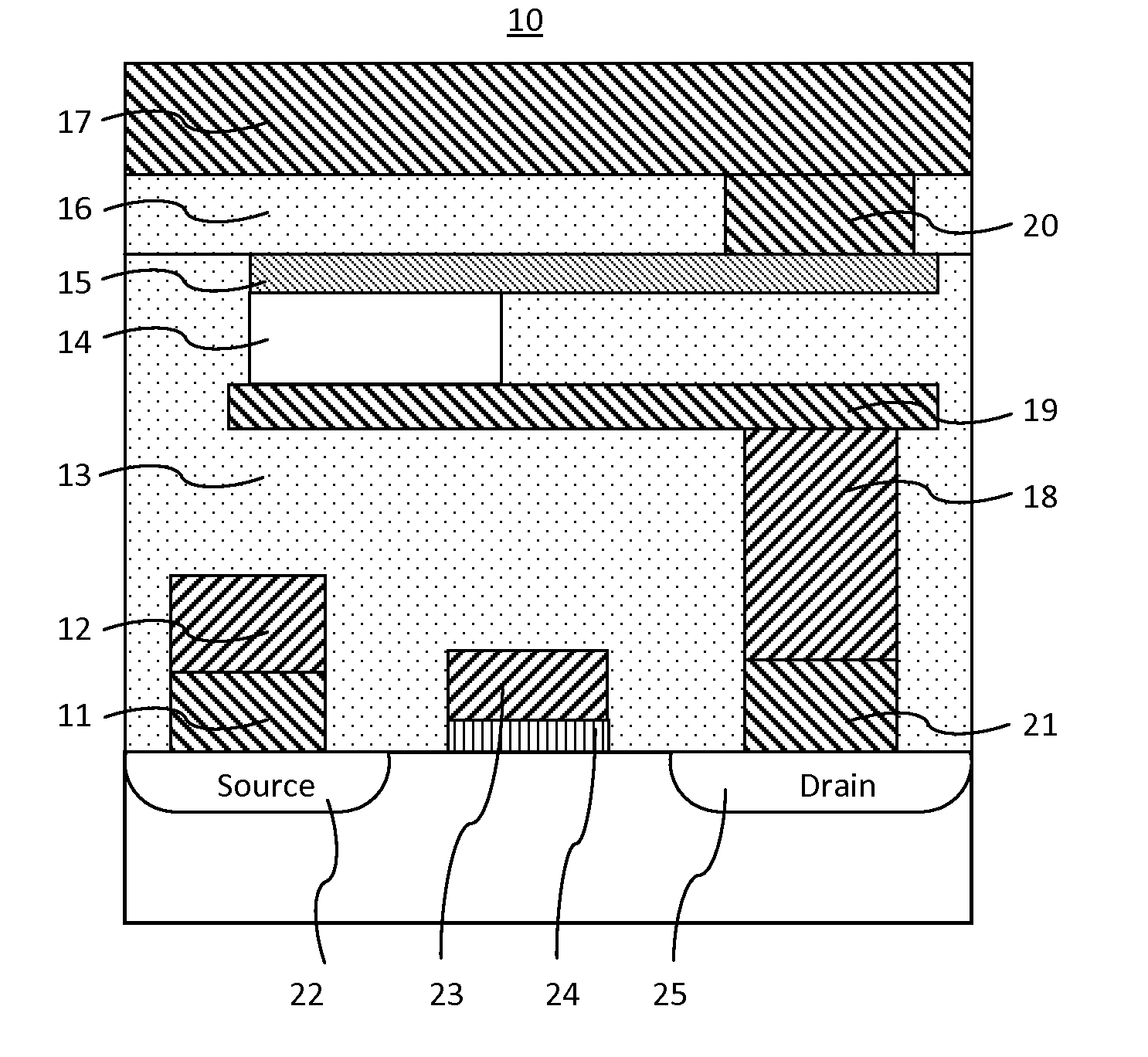

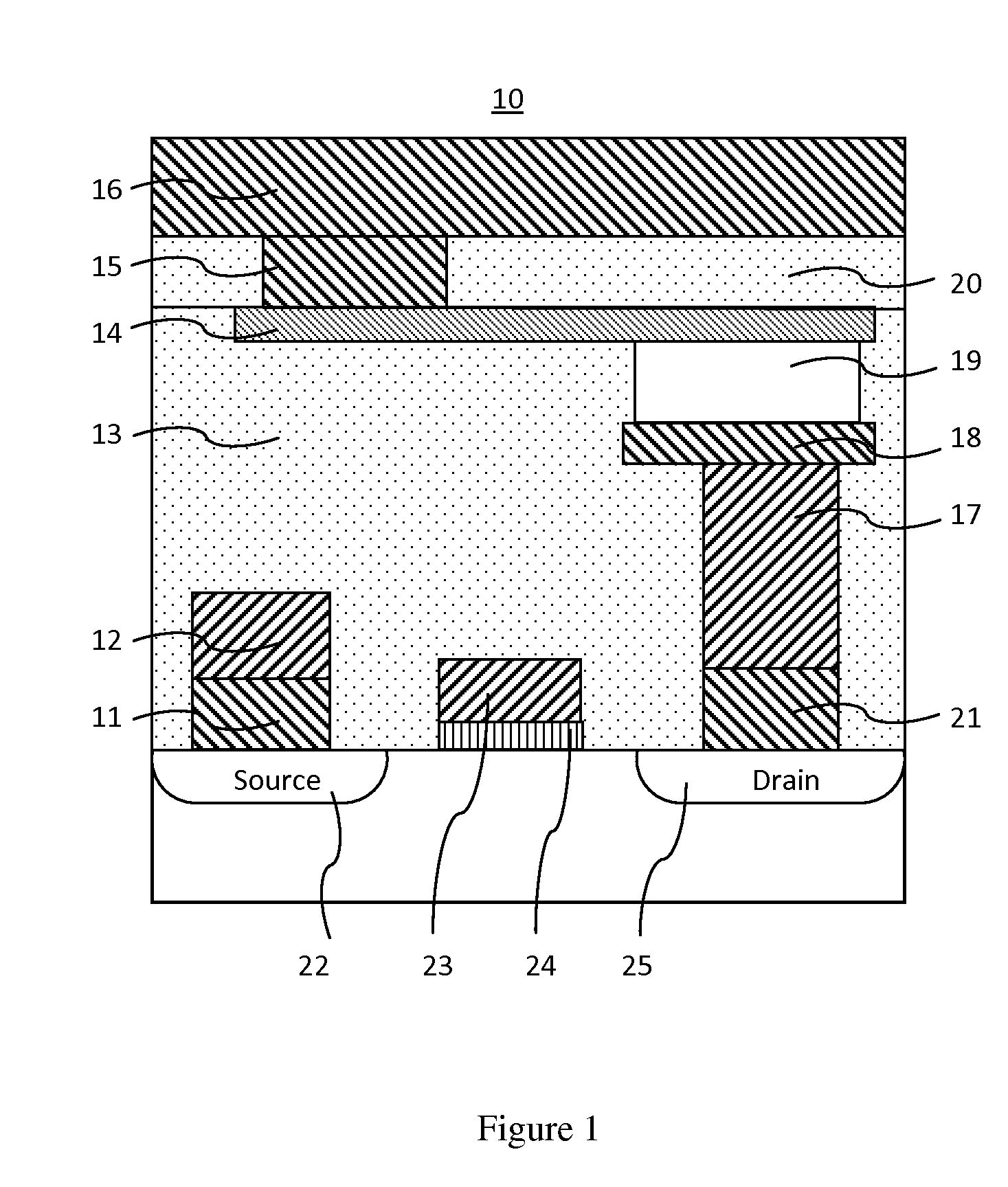

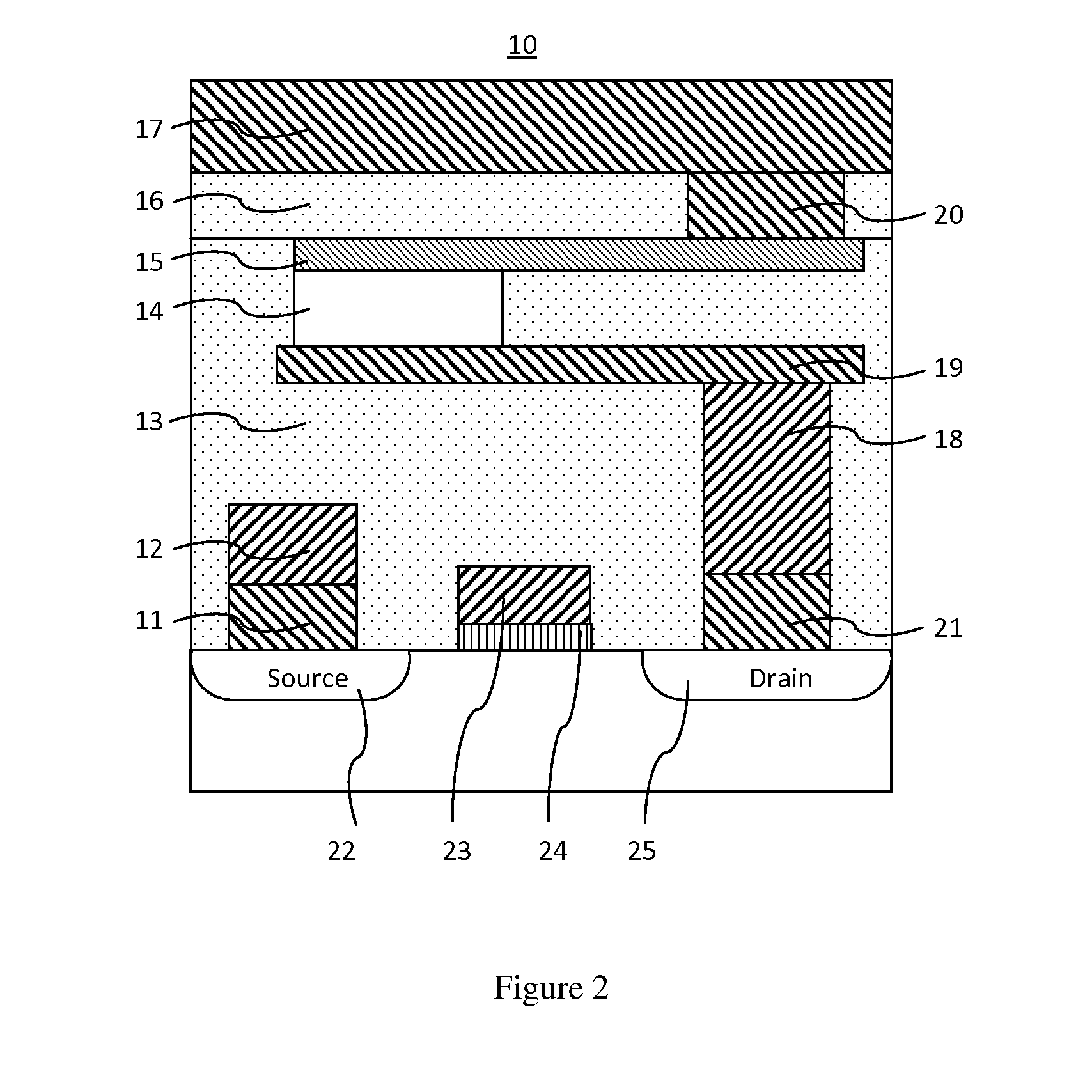

Resistive random access memory and manufacturing method thereof

PatentActiveUS20210028358A1

Innovation

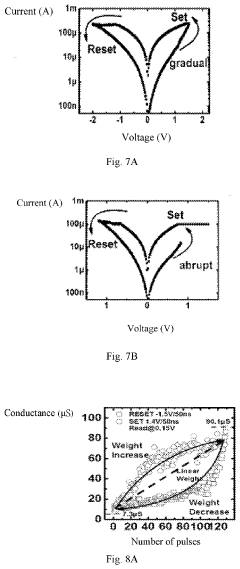

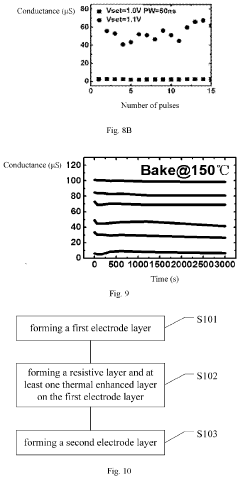

- Incorporating a thermal enhanced layer with lower thermal conductivity than the electrodes, positioned adjacent to the resistive layer, to slow down heat loss and promote the formation of dispersed conductive filaments, allowing continuous and bidirectional linear changes in conductance.

Magnetic memory devices

PatentActiveUS20140328116A1

Innovation

- Incorporating a dielectric thermal barrier layer with low thermal conductivity between the top electrode of the MTJ element and the copper bit line, which creates a high thermal resistance path, thereby controlling the temperature rise of the MTJ element below 300°C during pulsed laser thermal annealing.

Materials Science Advancements for ReRAM

Recent advancements in materials science have significantly propelled the development of Resistive Random Access Memory (ReRAM) technology, particularly addressing the critical challenge of thermal stability. The fundamental architecture of ReRAM devices relies on the controlled formation and disruption of conductive filaments within an insulating layer, a process highly sensitive to thermal conditions.

Metal oxides have emerged as primary candidates for ReRAM applications due to their superior thermal stability characteristics. Particularly, hafnium oxide (HfO2) and tantalum oxide (Ta2O5) demonstrate remarkable resistance to thermal degradation while maintaining reliable switching properties at elevated temperatures. These materials exhibit transition temperatures well above typical operating conditions, ensuring consistent performance across diverse environmental scenarios.

Nanocomposite structures represent another breakthrough in ReRAM material engineering. By incorporating nanoparticles within the switching layer, researchers have successfully enhanced thermal stability while simultaneously improving retention characteristics. For instance, platinum nanoparticle-embedded silicon oxide structures have demonstrated stable resistance states at temperatures exceeding 150°C, a significant improvement over conventional single-material systems.

Interface engineering between electrode materials and the switching layer has proven crucial for thermal stability enhancement. The careful selection of electrode materials with appropriate work functions and thermal expansion coefficients minimizes stress-induced degradation at elevated temperatures. Noble metals like platinum and gold, despite their higher cost, provide superior thermal interface properties compared to conventional copper or aluminum electrodes.

Doping strategies have revolutionized the thermal performance of ReRAM materials. Strategic introduction of dopants such as nitrogen in HfO2 or aluminum in TiO2 has been shown to stabilize oxygen vacancies, the primary components of conductive filaments, against thermal diffusion. This approach effectively extends the operational temperature range while improving data retention characteristics.

Multilayer structures incorporating thermal barrier layers represent an innovative approach to thermal stability enhancement. These engineered stacks isolate the active switching region from thermal influences, maintaining consistent switching behavior across broader temperature ranges. For example, Al2O3/HfO2/Al2O3 trilayer structures demonstrate significantly improved thermal stability compared to single-layer HfO2 devices.

The correlation between crystallinity and thermal stability presents another dimension for material optimization. While amorphous structures offer advantages in uniformity and initial performance, partially crystallized materials often demonstrate superior thermal stability characteristics, suggesting potential benefits from controlled crystallization processes during device fabrication.

Metal oxides have emerged as primary candidates for ReRAM applications due to their superior thermal stability characteristics. Particularly, hafnium oxide (HfO2) and tantalum oxide (Ta2O5) demonstrate remarkable resistance to thermal degradation while maintaining reliable switching properties at elevated temperatures. These materials exhibit transition temperatures well above typical operating conditions, ensuring consistent performance across diverse environmental scenarios.

Nanocomposite structures represent another breakthrough in ReRAM material engineering. By incorporating nanoparticles within the switching layer, researchers have successfully enhanced thermal stability while simultaneously improving retention characteristics. For instance, platinum nanoparticle-embedded silicon oxide structures have demonstrated stable resistance states at temperatures exceeding 150°C, a significant improvement over conventional single-material systems.

Interface engineering between electrode materials and the switching layer has proven crucial for thermal stability enhancement. The careful selection of electrode materials with appropriate work functions and thermal expansion coefficients minimizes stress-induced degradation at elevated temperatures. Noble metals like platinum and gold, despite their higher cost, provide superior thermal interface properties compared to conventional copper or aluminum electrodes.

Doping strategies have revolutionized the thermal performance of ReRAM materials. Strategic introduction of dopants such as nitrogen in HfO2 or aluminum in TiO2 has been shown to stabilize oxygen vacancies, the primary components of conductive filaments, against thermal diffusion. This approach effectively extends the operational temperature range while improving data retention characteristics.

Multilayer structures incorporating thermal barrier layers represent an innovative approach to thermal stability enhancement. These engineered stacks isolate the active switching region from thermal influences, maintaining consistent switching behavior across broader temperature ranges. For example, Al2O3/HfO2/Al2O3 trilayer structures demonstrate significantly improved thermal stability compared to single-layer HfO2 devices.

The correlation between crystallinity and thermal stability presents another dimension for material optimization. While amorphous structures offer advantages in uniformity and initial performance, partially crystallized materials often demonstrate superior thermal stability characteristics, suggesting potential benefits from controlled crystallization processes during device fabrication.

Energy Efficiency and Thermal Performance Trade-offs

The thermal management of Resistive Random Access Memory (ReRAM) represents a critical challenge in the advancement of this promising non-volatile memory technology. As ReRAM devices continue to scale down and integration densities increase, the trade-offs between energy efficiency and thermal performance become increasingly significant for both device reliability and system-level performance.

ReRAM operations fundamentally involve thermally-driven processes, particularly during the SET and RESET operations that establish and disrupt conductive filaments. These processes generate localized heating that, while necessary for switching mechanisms, can lead to thermal crosstalk between adjacent cells in high-density arrays. Our analysis indicates that the power consumption during switching operations typically ranges from 10-100 μW per cell, creating temperature gradients that can affect neighboring cells if not properly managed.

The thermal stability of ReRAM directly impacts its retention characteristics and overall reliability. Higher operating temperatures accelerate atomic diffusion processes within the switching layer, potentially causing unintended filament formation or dissolution. Data from accelerated lifetime tests suggests that for every 10°C increase in operating temperature, data retention time may decrease by a factor of 2-3, highlighting the critical nature of thermal management in these systems.

Energy efficiency improvements in ReRAM technologies have focused on reducing the RESET current, which typically consumes more power than the SET operation. Recent innovations in material engineering have demonstrated promising results, with novel oxygen-deficient oxides and doped switching layers reducing RESET currents by up to 40% while maintaining comparable switching speeds. These advancements represent significant progress toward more energy-efficient ReRAM implementations.

Architectural approaches to managing the energy-thermal trade-off include optimized pulse shapes for programming operations and intelligent refresh schemes. Adaptive programming algorithms that adjust pulse parameters based on cell-specific characteristics have shown potential to reduce energy consumption by 25-35% compared to fixed-parameter approaches, while simultaneously reducing peak temperatures during switching events.

The integration of ReRAM into three-dimensional architectures presents additional thermal challenges due to reduced heat dissipation pathways. Thermal simulations indicate that in 3D cross-point arrays, the central cells may experience temperatures 15-20°C higher than peripheral cells during simultaneous operations, necessitating careful consideration of operation scheduling and thermal-aware access patterns.

As ReRAM technology advances toward commercial viability in more applications, the development of comprehensive thermal models that account for both device-level and system-level thermal behaviors will be essential for optimizing the energy efficiency and thermal performance trade-offs that ultimately determine the technology's practical limitations and capabilities.

ReRAM operations fundamentally involve thermally-driven processes, particularly during the SET and RESET operations that establish and disrupt conductive filaments. These processes generate localized heating that, while necessary for switching mechanisms, can lead to thermal crosstalk between adjacent cells in high-density arrays. Our analysis indicates that the power consumption during switching operations typically ranges from 10-100 μW per cell, creating temperature gradients that can affect neighboring cells if not properly managed.

The thermal stability of ReRAM directly impacts its retention characteristics and overall reliability. Higher operating temperatures accelerate atomic diffusion processes within the switching layer, potentially causing unintended filament formation or dissolution. Data from accelerated lifetime tests suggests that for every 10°C increase in operating temperature, data retention time may decrease by a factor of 2-3, highlighting the critical nature of thermal management in these systems.

Energy efficiency improvements in ReRAM technologies have focused on reducing the RESET current, which typically consumes more power than the SET operation. Recent innovations in material engineering have demonstrated promising results, with novel oxygen-deficient oxides and doped switching layers reducing RESET currents by up to 40% while maintaining comparable switching speeds. These advancements represent significant progress toward more energy-efficient ReRAM implementations.

Architectural approaches to managing the energy-thermal trade-off include optimized pulse shapes for programming operations and intelligent refresh schemes. Adaptive programming algorithms that adjust pulse parameters based on cell-specific characteristics have shown potential to reduce energy consumption by 25-35% compared to fixed-parameter approaches, while simultaneously reducing peak temperatures during switching events.

The integration of ReRAM into three-dimensional architectures presents additional thermal challenges due to reduced heat dissipation pathways. Thermal simulations indicate that in 3D cross-point arrays, the central cells may experience temperatures 15-20°C higher than peripheral cells during simultaneous operations, necessitating careful consideration of operation scheduling and thermal-aware access patterns.

As ReRAM technology advances toward commercial viability in more applications, the development of comprehensive thermal models that account for both device-level and system-level thermal behaviors will be essential for optimizing the energy efficiency and thermal performance trade-offs that ultimately determine the technology's practical limitations and capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!