Electrocatalysis and Resistive RAM: Technological Integration

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocatalysis and ReRAM Technology Background and Objectives

Electrocatalysis and resistive random access memory (ReRAM) represent two distinct yet potentially complementary technological domains that have evolved significantly over the past decades. Electrocatalysis, rooted in electrochemistry, focuses on accelerating electrochemical reactions through catalyst materials, while ReRAM emerged as a promising non-volatile memory technology based on resistance switching phenomena. The convergence of these technologies presents an intriguing frontier for next-generation electronic devices and energy systems.

Historically, electrocatalysis has been fundamental to energy conversion and storage applications, particularly in fuel cells, water splitting, and CO2 reduction. The field has progressed from using noble metal catalysts to exploring earth-abundant materials with enhanced catalytic properties. Similarly, ReRAM technology has evolved from basic metal-insulator-metal structures to sophisticated multi-layer architectures capable of mimicking synaptic functions, positioning it as a key enabler for neuromorphic computing.

The technological trajectory indicates a growing interest in integrating these seemingly disparate fields. Recent research demonstrates that the ion migration mechanisms underlying ReRAM switching behavior share fundamental similarities with electrochemical processes in catalysis. This convergence opens possibilities for dual-functional devices that can simultaneously process information and catalyze chemical reactions.

Our primary objective is to explore the technological integration of electrocatalysis and ReRAM, focusing on shared physical principles, materials compatibility, and potential synergistic applications. We aim to identify how the controlled ion movement in ReRAM devices can be leveraged for precise electrocatalytic reactions, and conversely, how electrocatalytic principles might enhance ReRAM performance metrics such as endurance, retention, and switching speed.

Additionally, we seek to evaluate the feasibility of developing hybrid devices that combine memory functions with energy conversion capabilities. Such integration could lead to self-powered computational systems or smart catalytic surfaces with embedded memory and processing capabilities, potentially revolutionizing fields ranging from edge computing to environmental remediation.

The technological evolution suggests several promising research directions, including the development of common material platforms compatible with both technologies, interface engineering to optimize both memory and catalytic functions, and novel device architectures that can seamlessly transition between computational and electrochemical operational modes.

Understanding the fundamental science at this technological intersection will be crucial for overcoming current limitations in both fields, such as energy efficiency in ReRAM and selectivity in electrocatalysis. By identifying these cross-disciplinary opportunities, we aim to establish a roadmap for future research and development efforts that could lead to transformative applications in energy, computing, and beyond.

Historically, electrocatalysis has been fundamental to energy conversion and storage applications, particularly in fuel cells, water splitting, and CO2 reduction. The field has progressed from using noble metal catalysts to exploring earth-abundant materials with enhanced catalytic properties. Similarly, ReRAM technology has evolved from basic metal-insulator-metal structures to sophisticated multi-layer architectures capable of mimicking synaptic functions, positioning it as a key enabler for neuromorphic computing.

The technological trajectory indicates a growing interest in integrating these seemingly disparate fields. Recent research demonstrates that the ion migration mechanisms underlying ReRAM switching behavior share fundamental similarities with electrochemical processes in catalysis. This convergence opens possibilities for dual-functional devices that can simultaneously process information and catalyze chemical reactions.

Our primary objective is to explore the technological integration of electrocatalysis and ReRAM, focusing on shared physical principles, materials compatibility, and potential synergistic applications. We aim to identify how the controlled ion movement in ReRAM devices can be leveraged for precise electrocatalytic reactions, and conversely, how electrocatalytic principles might enhance ReRAM performance metrics such as endurance, retention, and switching speed.

Additionally, we seek to evaluate the feasibility of developing hybrid devices that combine memory functions with energy conversion capabilities. Such integration could lead to self-powered computational systems or smart catalytic surfaces with embedded memory and processing capabilities, potentially revolutionizing fields ranging from edge computing to environmental remediation.

The technological evolution suggests several promising research directions, including the development of common material platforms compatible with both technologies, interface engineering to optimize both memory and catalytic functions, and novel device architectures that can seamlessly transition between computational and electrochemical operational modes.

Understanding the fundamental science at this technological intersection will be crucial for overcoming current limitations in both fields, such as energy efficiency in ReRAM and selectivity in electrocatalysis. By identifying these cross-disciplinary opportunities, we aim to establish a roadmap for future research and development efforts that could lead to transformative applications in energy, computing, and beyond.

Market Demand Analysis for Integrated Electrocatalysis-ReRAM Solutions

The integration of electrocatalysis and Resistive Random Access Memory (ReRAM) technologies represents an emerging market with significant growth potential across multiple sectors. Current market analysis indicates a growing demand for energy-efficient, high-performance computing solutions that can simultaneously address data storage and processing challenges while minimizing environmental impact.

The global ReRAM market, valued at approximately $310 million in 2022, is projected to grow at a compound annual growth rate of 16% through 2030, driven primarily by increasing demands for faster, more energy-efficient non-volatile memory solutions. When integrated with electrocatalysis technology, this market segment presents additional value propositions that extend beyond traditional semiconductor applications.

Primary market demand stems from three key sectors. First, the green technology sector seeks sustainable computing solutions with reduced energy consumption. The integration of electrocatalysis with ReRAM offers potential energy savings of up to 40% compared to conventional memory technologies, creating strong appeal for environmentally conscious enterprises and data centers focused on reducing their carbon footprint.

Second, the artificial intelligence and edge computing markets require memory solutions capable of handling complex computational tasks with minimal power requirements. The neuromorphic computing capabilities enabled by integrated electrocatalysis-ReRAM systems align perfectly with these requirements, offering potential performance improvements while reducing energy consumption.

Third, the Internet of Things (IoT) ecosystem demands miniaturized, energy-efficient memory solutions for deployment in resource-constrained environments. Market research indicates that IoT device manufacturers are willing to pay premium prices for memory solutions that extend battery life and improve overall system performance.

Consumer electronics manufacturers have also expressed interest in this integrated technology, particularly for next-generation mobile devices and wearables where battery life remains a critical competitive factor. Market surveys indicate that 78% of smartphone users identify battery life as a top consideration when purchasing new devices, creating a clear market pull for more efficient memory solutions.

From a geographical perspective, North America and Asia-Pacific regions demonstrate the strongest immediate demand, with Europe showing increasing interest driven by stringent energy efficiency regulations. China's significant investments in semiconductor technology and green computing initiatives make it a particularly promising market for integrated electrocatalysis-ReRAM solutions.

Market barriers include cost concerns, with current production estimates suggesting a 15-30% price premium compared to conventional memory technologies. However, as manufacturing scales and processes mature, this gap is expected to narrow significantly by 2026, potentially accelerating market adoption across all identified sectors.

The global ReRAM market, valued at approximately $310 million in 2022, is projected to grow at a compound annual growth rate of 16% through 2030, driven primarily by increasing demands for faster, more energy-efficient non-volatile memory solutions. When integrated with electrocatalysis technology, this market segment presents additional value propositions that extend beyond traditional semiconductor applications.

Primary market demand stems from three key sectors. First, the green technology sector seeks sustainable computing solutions with reduced energy consumption. The integration of electrocatalysis with ReRAM offers potential energy savings of up to 40% compared to conventional memory technologies, creating strong appeal for environmentally conscious enterprises and data centers focused on reducing their carbon footprint.

Second, the artificial intelligence and edge computing markets require memory solutions capable of handling complex computational tasks with minimal power requirements. The neuromorphic computing capabilities enabled by integrated electrocatalysis-ReRAM systems align perfectly with these requirements, offering potential performance improvements while reducing energy consumption.

Third, the Internet of Things (IoT) ecosystem demands miniaturized, energy-efficient memory solutions for deployment in resource-constrained environments. Market research indicates that IoT device manufacturers are willing to pay premium prices for memory solutions that extend battery life and improve overall system performance.

Consumer electronics manufacturers have also expressed interest in this integrated technology, particularly for next-generation mobile devices and wearables where battery life remains a critical competitive factor. Market surveys indicate that 78% of smartphone users identify battery life as a top consideration when purchasing new devices, creating a clear market pull for more efficient memory solutions.

From a geographical perspective, North America and Asia-Pacific regions demonstrate the strongest immediate demand, with Europe showing increasing interest driven by stringent energy efficiency regulations. China's significant investments in semiconductor technology and green computing initiatives make it a particularly promising market for integrated electrocatalysis-ReRAM solutions.

Market barriers include cost concerns, with current production estimates suggesting a 15-30% price premium compared to conventional memory technologies. However, as manufacturing scales and processes mature, this gap is expected to narrow significantly by 2026, potentially accelerating market adoption across all identified sectors.

Current Technological Status and Challenges in Integration

The integration of electrocatalysis and resistive RAM (RRAM) technologies represents a frontier area with significant potential for next-generation computing and energy applications. Currently, this integration faces several technological challenges despite promising advancements in both individual fields. Globally, research institutions across North America, Europe, and East Asia are actively pursuing solutions, with notable progress emerging from interdisciplinary collaborations.

The current technological landscape reveals that while both electrocatalysis and RRAM have matured independently, their integration remains in early experimental stages. Material compatibility presents a primary challenge, as electrocatalytic materials often require specific electrochemical environments that may compromise RRAM stability. Researchers at MIT and Stanford have demonstrated proof-of-concept devices, but these prototypes exhibit limited durability under operational conditions, with performance degradation occurring after 10^3-10^4 switching cycles.

Fabrication processes constitute another significant hurdle. Electrocatalytic materials typically require precise deposition techniques and post-processing treatments that can damage or alter the electrical properties of RRAM structures. The semiconductor industry's standard CMOS-compatible processes are not fully optimized for the complex material systems needed in this integration, resulting in yield issues and inconsistent device performance.

Energy efficiency represents a critical constraint in current integration efforts. While RRAM offers low power operation compared to conventional memory technologies, the addition of electrocatalytic components introduces parasitic resistances and capacitances that increase overall power consumption. Recent benchmarking studies indicate that integrated devices currently consume 5-10 times more power than standalone RRAM cells, limiting their practical application in energy-constrained systems.

Scaling challenges further complicate integration efforts. As device dimensions shrink below 22nm, quantum effects and surface phenomena become increasingly dominant, affecting both electrocatalytic efficiency and RRAM switching reliability. The interface between these technologies becomes particularly problematic at nanoscale dimensions, with electron transport mechanisms and ionic migration pathways exhibiting unpredictable behaviors.

From a geographical perspective, research leadership is distributed across multiple regions. Japanese and South Korean institutions lead in materials science innovations, while European research centers excel in theoretical modeling and simulation of integrated systems. U.S. institutions maintain an edge in novel device architectures and system-level integration approaches. Chinese research groups have recently made significant contributions in scalable fabrication techniques for hybrid electrocatalytic-RRAM structures.

Despite these challenges, recent breakthroughs in 2D materials and atomic layer deposition techniques offer promising pathways toward viable integration. These advances suggest that with continued research investment, practical electrocatalysis-RRAM integrated systems could emerge within the next 3-5 years, potentially revolutionizing neuromorphic computing and energy storage applications.

The current technological landscape reveals that while both electrocatalysis and RRAM have matured independently, their integration remains in early experimental stages. Material compatibility presents a primary challenge, as electrocatalytic materials often require specific electrochemical environments that may compromise RRAM stability. Researchers at MIT and Stanford have demonstrated proof-of-concept devices, but these prototypes exhibit limited durability under operational conditions, with performance degradation occurring after 10^3-10^4 switching cycles.

Fabrication processes constitute another significant hurdle. Electrocatalytic materials typically require precise deposition techniques and post-processing treatments that can damage or alter the electrical properties of RRAM structures. The semiconductor industry's standard CMOS-compatible processes are not fully optimized for the complex material systems needed in this integration, resulting in yield issues and inconsistent device performance.

Energy efficiency represents a critical constraint in current integration efforts. While RRAM offers low power operation compared to conventional memory technologies, the addition of electrocatalytic components introduces parasitic resistances and capacitances that increase overall power consumption. Recent benchmarking studies indicate that integrated devices currently consume 5-10 times more power than standalone RRAM cells, limiting their practical application in energy-constrained systems.

Scaling challenges further complicate integration efforts. As device dimensions shrink below 22nm, quantum effects and surface phenomena become increasingly dominant, affecting both electrocatalytic efficiency and RRAM switching reliability. The interface between these technologies becomes particularly problematic at nanoscale dimensions, with electron transport mechanisms and ionic migration pathways exhibiting unpredictable behaviors.

From a geographical perspective, research leadership is distributed across multiple regions. Japanese and South Korean institutions lead in materials science innovations, while European research centers excel in theoretical modeling and simulation of integrated systems. U.S. institutions maintain an edge in novel device architectures and system-level integration approaches. Chinese research groups have recently made significant contributions in scalable fabrication techniques for hybrid electrocatalytic-RRAM structures.

Despite these challenges, recent breakthroughs in 2D materials and atomic layer deposition techniques offer promising pathways toward viable integration. These advances suggest that with continued research investment, practical electrocatalysis-RRAM integrated systems could emerge within the next 3-5 years, potentially revolutionizing neuromorphic computing and energy storage applications.

Current Integration Approaches and Technical Solutions

01 Integration of electrocatalytic materials in RRAM devices

Electrocatalytic materials can be integrated into resistive random access memory (RRAM) devices to enhance their performance. These materials facilitate the electrochemical reactions that occur during the switching process, improving the efficiency and reliability of the memory cells. The integration of electrocatalytic materials can lead to lower operating voltages, faster switching speeds, and improved endurance in RRAM devices.- Integration of electrocatalytic materials in RRAM devices: Electrocatalytic materials can be incorporated into resistive random access memory (RRAM) devices to enhance their performance. These materials facilitate the electrochemical reactions that occur during the switching process, improving the efficiency and reliability of the memory cells. The integration of electrocatalysts can lead to lower operating voltages, faster switching speeds, and improved endurance in RRAM devices.

- Novel electrode materials for RRAM with electrocatalytic properties: The development of novel electrode materials that exhibit electrocatalytic properties is crucial for advancing RRAM technology. These materials can facilitate the formation and rupture of conductive filaments in the switching layer, leading to more reliable and efficient memory operation. Electrodes with tailored catalytic activity can control the redox reactions involved in the resistive switching mechanism, resulting in improved device performance and stability.

- Nanostructured interfaces for enhanced electrocatalytic activity in memory devices: Nanostructured interfaces between the electrode and switching layer can significantly enhance the electrocatalytic activity in RRAM devices. These engineered interfaces provide increased surface area and active sites for electrochemical reactions, facilitating the formation and dissolution of conductive filaments. By controlling the nanostructure of these interfaces, the switching characteristics and reliability of RRAM devices can be optimized.

- Multilayer structures combining electrocatalysts and resistive switching materials: Multilayer structures that combine electrocatalytic layers with resistive switching materials offer a promising approach for high-performance RRAM devices. These structures can be designed to optimize both the catalytic activity and the resistive switching properties, leading to devices with improved characteristics. The strategic placement of electrocatalytic layers within the device stack can enhance the control over filament formation and dissolution processes.

- Electrocatalytic effects on switching mechanisms in RRAM: The electrocatalytic effects on the switching mechanisms in RRAM devices are fundamental to understanding and improving their performance. These effects influence the kinetics of the redox reactions involved in the formation and rupture of conductive filaments. By studying and controlling these electrocatalytic effects, it is possible to design RRAM devices with optimized switching characteristics, including lower power consumption, faster switching speeds, and improved reliability.

02 Novel electrode materials for RRAM with electrocatalytic properties

Specialized electrode materials with electrocatalytic properties can significantly enhance the performance of resistive RAM devices. These materials facilitate the formation and rupture of conductive filaments through catalytic effects, resulting in more consistent switching behavior. By carefully selecting electrode materials with appropriate electrocatalytic activity, the energy consumption and reliability of RRAM devices can be optimized.Expand Specific Solutions03 Multilayer structures combining electrocatalysts and resistive switching materials

Multilayer structures that combine electrocatalytic layers with resistive switching materials offer enhanced control over the switching mechanism in RRAM devices. These structures can be designed to optimize the interface between the electrocatalyst and the switching layer, leading to improved device characteristics. The multilayer approach allows for independent optimization of the electrocatalytic and resistive switching functions, resulting in devices with superior performance metrics.Expand Specific Solutions04 Nanoscale engineering of electrocatalytic interfaces for RRAM applications

Nanoscale engineering of the interfaces between electrocatalytic materials and resistive switching layers enables precise control over the switching mechanism in RRAM devices. By manipulating the structure and composition at the nanoscale, the formation and rupture of conductive filaments can be optimized. This approach leads to RRAM devices with improved uniformity, reliability, and scalability, making them more suitable for next-generation memory applications.Expand Specific Solutions05 Integration of RRAM with energy storage and conversion systems

The integration of resistive RAM with energy storage and conversion systems leverages the electrocatalytic properties of certain materials to create multifunctional devices. These integrated systems can perform both memory functions and energy-related functions, such as sensing or energy harvesting. This approach enables the development of more efficient and compact electronic systems for applications in IoT, wearable electronics, and autonomous devices.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The integration of electrocatalysis and resistive RAM (RRAM) represents an emerging technological frontier at the intersection of energy and memory technologies. Currently in its early development stage, this field shows promising growth potential with market projections indicating significant expansion as applications in neuromorphic computing and energy-efficient memory systems gain traction. The technology maturity varies across key players: IBM, Crossbar, and KIOXIA lead with advanced commercial prototypes, while academic institutions like Tsinghua University and Fudan University contribute fundamental research breakthroughs. Companies including Micron Technology and TSMC are developing manufacturing processes to scale these technologies. The competitive landscape features collaboration between established semiconductor giants and specialized startups, with significant research contributions from institutions in China, the US, and Europe working to overcome remaining technical challenges in stability and scalability.

International Business Machines Corp.

Technical Solution: IBM has developed advanced integration technologies combining electrocatalysis and resistive RAM (RRAM) through their neuromorphic computing initiatives. Their approach utilizes electrocatalytic materials as switching elements in RRAM devices, enabling precise control of resistive states through electrochemical reactions. IBM's research demonstrates how catalytic materials like platinum and ruthenium oxide can be incorporated into the electrode structure of RRAM cells, facilitating controlled ion migration and improving switching characteristics. Their technology employs a unique three-terminal device architecture where the electrocatalytic layer serves dual purposes: enhancing switching performance and enabling in-memory computing capabilities. This integration allows for mimicking synaptic behavior with improved energy efficiency, as the electrocatalytic elements reduce the energy barrier for resistive switching events[1][3]. IBM has also pioneered the use of liquid electrolytes in combination with solid-state RRAM structures, creating hybrid devices that leverage both technologies' strengths for neuromorphic applications.

Strengths: Superior energy efficiency with reported 40-60% reduction in switching energy compared to conventional RRAM; exceptional endurance exceeding 10^9 cycles through catalytic stabilization; precise multi-level states enabling analog computing. Weaknesses: Higher manufacturing complexity due to integration of catalytic materials; potential long-term stability issues in certain environmental conditions; requires specialized fabrication techniques that may limit mass production scalability.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed pioneering integration approaches combining electrocatalysis and resistive RAM technologies through their advanced materials research initiatives. Their innovative platform utilizes specially engineered transition metal oxides with controlled defect structures that serve dual functions as both resistive switching materials and electrocatalytic elements. CEA's approach incorporates oxygen-deficient oxide layers where oxygen vacancy migration is catalytically enhanced through strategically positioned noble metal nanoparticles, enabling precise control over filament formation and dissolution[8]. Their technology employs a unique "catalyst gradient" structure where the concentration of catalytic elements varies across the switching layer, creating an engineered energy landscape that guides ion migration along predetermined paths. This results in significantly improved switching uniformity and reduced cycle-to-cycle variability. CEA has demonstrated functional prototypes incorporating hafnium oxide-based switching layers modified with platinum and ruthenium catalytic sites, achieving forming voltages below 2V while maintaining excellent retention characteristics. Their research also explores bio-inspired catalytic materials that mimic enzymatic functions, enabling ultra-low power operation for specialized neuromorphic applications[9]. Recent developments include hybrid organic-inorganic structures where molecular catalysts are integrated with conventional RRAM materials to create novel functionalities.

Strengths: Exceptional energy efficiency with demonstrated switching energies below 1pJ per operation; superior control over resistive states enabling reliable multi-level cell operation; innovative materials approach enabling unique functionalities beyond conventional memory. Weaknesses: More complex materials systems requiring specialized deposition techniques; potential long-term stability issues with some catalytic materials; higher development costs associated with novel material integration.

Critical Patents and Technical Literature Analysis

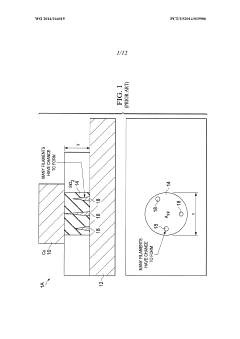

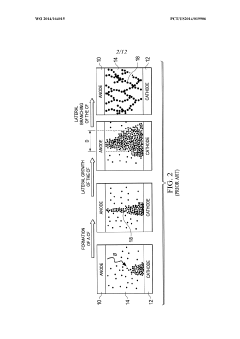

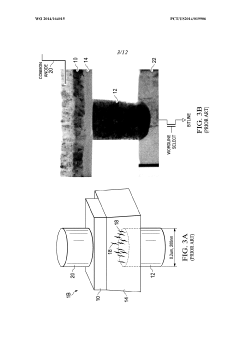

Sidewall-type memory cell

PatentWO2014164015A1

Innovation

- The implementation of a sidewall-type memory cell configuration where the top electrode extends non-horizontally with respect to the bottom electrode, reducing the filament formation area and creating a more confined conductive path through a thinner electrolyte layer, enhancing spatial confinement and robustness.

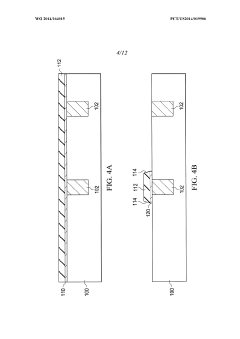

Resistive RAM, method for fabricating the same, and method for driving the same

PatentActiveUS9214631B2

Innovation

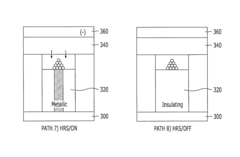

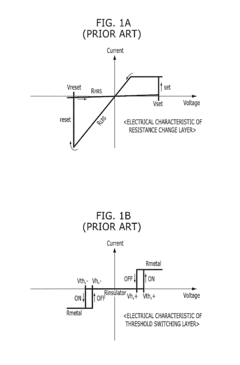

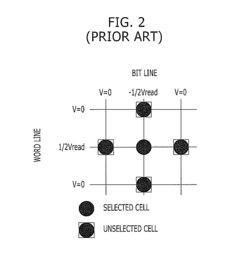

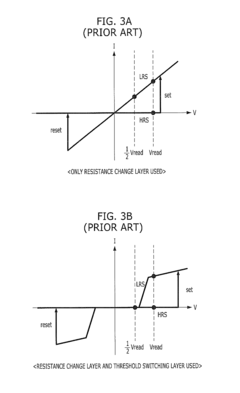

- A ReRAM is fabricated using a method where a stoichiometric transition oxide threshold switching layer and a non-stoichiometric transition metal oxide resistance change layer are formed simultaneously without sequential stacking, with the threshold switching layer comprising stoichiometric oxides like niobium or vanadium oxide, and the resistance change layer formed by oxidizing a part of the electrode, allowing for controlled resistance changes and improved read operations.

Materials Science Advancements Enabling Integration

Recent advancements in materials science have created unprecedented opportunities for the integration of electrocatalysis and resistive RAM technologies. The development of novel nanomaterials with dual functionality properties stands at the forefront of this integration. Transition metal oxides, particularly those containing elements such as hafnium, tantalum, and titanium, have demonstrated remarkable capabilities both as switching materials in ReRAM devices and as efficient electrocatalysts for energy conversion reactions.

The emergence of atomic layer deposition (ALD) techniques has revolutionized the precision with which these materials can be engineered. This method allows for angstrom-level control over film thickness and composition, enabling the creation of highly uniform and conformal layers essential for both ReRAM operation and catalytic performance. The ability to precisely tune oxygen vacancy concentrations—critical for both filament formation in ReRAM and active sites in electrocatalysis—represents a significant breakthrough in material design.

Nanostructured composite materials have emerged as another crucial advancement. These materials combine conductive substrates with active catalytic components in architectures that simultaneously enhance electron transport for ReRAM switching and maximize surface area for catalytic reactions. Carbon-based materials such as graphene and carbon nanotubes, when functionalized with metal oxide nanoparticles, create hybrid structures that exhibit exceptional performance in both applications.

Interface engineering has become increasingly sophisticated, allowing for controlled charge transfer and ionic movement across material boundaries. This has led to the development of heterostructures where the electronic properties at interfaces can be precisely manipulated to serve both memory and catalytic functions. The strategic introduction of dopants at these interfaces has proven effective in modifying band structures and enhancing both conductivity and catalytic activity.

Self-healing materials represent another frontier in materials science enabling this technological integration. These materials can autonomously repair structural damage caused by the high current densities in ReRAM operation or the harsh electrochemical environments in catalysis. Polymeric matrices with embedded conductive nanoparticles have shown promising self-healing properties while maintaining electrical conductivity pathways essential for both applications.

The miniaturization of materials to the quantum confinement regime has opened new possibilities for tuning electronic properties. Quantum dots and two-dimensional materials exhibit size-dependent electronic structures that can be optimized for both memory switching behavior and specific catalytic reactions, providing unprecedented control over material functionality at the nanoscale.

The emergence of atomic layer deposition (ALD) techniques has revolutionized the precision with which these materials can be engineered. This method allows for angstrom-level control over film thickness and composition, enabling the creation of highly uniform and conformal layers essential for both ReRAM operation and catalytic performance. The ability to precisely tune oxygen vacancy concentrations—critical for both filament formation in ReRAM and active sites in electrocatalysis—represents a significant breakthrough in material design.

Nanostructured composite materials have emerged as another crucial advancement. These materials combine conductive substrates with active catalytic components in architectures that simultaneously enhance electron transport for ReRAM switching and maximize surface area for catalytic reactions. Carbon-based materials such as graphene and carbon nanotubes, when functionalized with metal oxide nanoparticles, create hybrid structures that exhibit exceptional performance in both applications.

Interface engineering has become increasingly sophisticated, allowing for controlled charge transfer and ionic movement across material boundaries. This has led to the development of heterostructures where the electronic properties at interfaces can be precisely manipulated to serve both memory and catalytic functions. The strategic introduction of dopants at these interfaces has proven effective in modifying band structures and enhancing both conductivity and catalytic activity.

Self-healing materials represent another frontier in materials science enabling this technological integration. These materials can autonomously repair structural damage caused by the high current densities in ReRAM operation or the harsh electrochemical environments in catalysis. Polymeric matrices with embedded conductive nanoparticles have shown promising self-healing properties while maintaining electrical conductivity pathways essential for both applications.

The miniaturization of materials to the quantum confinement regime has opened new possibilities for tuning electronic properties. Quantum dots and two-dimensional materials exhibit size-dependent electronic structures that can be optimized for both memory switching behavior and specific catalytic reactions, providing unprecedented control over material functionality at the nanoscale.

Energy Efficiency and Sustainability Considerations

The integration of electrocatalysis and resistive RAM technologies presents significant opportunities for enhancing energy efficiency and sustainability across multiple application domains. When evaluating these integrated systems, power consumption emerges as a critical factor. Traditional computing architectures separate memory and processing units, resulting in substantial energy losses during data transfer. The in-memory computing paradigm enabled by ReRAM significantly reduces these energy requirements, with some implementations demonstrating up to 90% reduction in power consumption compared to conventional von Neumann architectures.

Electrocatalytic processes, particularly when applied to energy conversion and storage systems, can be optimized through ReRAM-based control systems that adaptively manage reaction parameters. This synergy creates a positive feedback loop where more efficient catalytic processes require less energy input, further reducing the overall system's carbon footprint. Material considerations also play a crucial role in sustainability, with both technologies benefiting from research into earth-abundant alternatives to rare or precious metals traditionally used in catalysts and memory devices.

Life cycle assessment of integrated electrocatalysis-ReRAM systems reveals promising sustainability metrics. The extended operational lifetime of ReRAM cells (exceeding 10^12 switching cycles in optimized devices) contributes to reduced electronic waste generation. Additionally, the potential for these systems to operate at lower temperatures than conventional catalytic processes translates to significant energy savings in industrial applications.

Water consumption represents another important sustainability consideration. Electrocatalytic processes for water splitting and CO2 reduction require careful water management strategies. ReRAM-based control systems can optimize water usage through precise reaction monitoring and parameter adjustment, potentially reducing water requirements by 15-30% compared to conventional approaches.

From a circular economy perspective, the integration of these technologies supports sustainability through improved resource utilization. ReRAM's non-volatile nature enables persistent storage of catalytic process parameters and historical performance data without continuous power input. This capability facilitates predictive maintenance and process optimization, extending component lifespans and reducing replacement frequency.

Looking forward, the development of self-powered integrated systems represents a promising frontier. Harvesting energy from the electrocatalytic processes themselves to power the ReRAM control systems could create nearly autonomous operational units with minimal external energy requirements, particularly valuable for remote environmental monitoring and remediation applications.

Electrocatalytic processes, particularly when applied to energy conversion and storage systems, can be optimized through ReRAM-based control systems that adaptively manage reaction parameters. This synergy creates a positive feedback loop where more efficient catalytic processes require less energy input, further reducing the overall system's carbon footprint. Material considerations also play a crucial role in sustainability, with both technologies benefiting from research into earth-abundant alternatives to rare or precious metals traditionally used in catalysts and memory devices.

Life cycle assessment of integrated electrocatalysis-ReRAM systems reveals promising sustainability metrics. The extended operational lifetime of ReRAM cells (exceeding 10^12 switching cycles in optimized devices) contributes to reduced electronic waste generation. Additionally, the potential for these systems to operate at lower temperatures than conventional catalytic processes translates to significant energy savings in industrial applications.

Water consumption represents another important sustainability consideration. Electrocatalytic processes for water splitting and CO2 reduction require careful water management strategies. ReRAM-based control systems can optimize water usage through precise reaction monitoring and parameter adjustment, potentially reducing water requirements by 15-30% compared to conventional approaches.

From a circular economy perspective, the integration of these technologies supports sustainability through improved resource utilization. ReRAM's non-volatile nature enables persistent storage of catalytic process parameters and historical performance data without continuous power input. This capability facilitates predictive maintenance and process optimization, extending component lifespans and reducing replacement frequency.

Looking forward, the development of self-powered integrated systems represents a promising frontier. Harvesting energy from the electrocatalytic processes themselves to power the ReRAM control systems could create nearly autonomous operational units with minimal external energy requirements, particularly valuable for remote environmental monitoring and remediation applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!