Corrosion Monitoring in Plate Heat Exchanger Operations

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Corrosion Challenges in PHE

Corrosion in plate heat exchangers (PHEs) presents significant challenges for industrial operations, particularly in sectors such as chemical processing, food and beverage production, and power generation. The intricate design of PHEs, while efficient for heat transfer, creates an environment conducive to various forms of corrosion. These corrosion processes can lead to reduced heat transfer efficiency, increased maintenance costs, and potential safety hazards.

One of the primary corrosion challenges in PHEs is the occurrence of crevice corrosion. The narrow gaps between plates provide ideal conditions for this type of localized attack. In these crevices, stagnant fluid can become oxygen-depleted, leading to the formation of differential aeration cells. This phenomenon accelerates the corrosion process in these confined spaces, potentially causing rapid deterioration of the plate material.

Pitting corrosion is another significant concern in PHE operations. This form of localized corrosion can initiate at weak points in the passive film of stainless steel plates, often due to the presence of chlorides or other aggressive ions in the process fluids. Pitting can progress rapidly, leading to through-wall penetration and leaks, which can compromise the integrity of the entire heat exchanger system.

Galvanic corrosion poses a challenge when different metallic materials are used within the PHE or in connected piping systems. The electrical potential difference between dissimilar metals in the presence of an electrolyte can accelerate corrosion of the less noble metal. This is particularly problematic in PHEs with mixed-metal construction or in systems where the PHE interfaces with other equipment made of different alloys.

Erosion-corrosion is a combined degradation mechanism that affects PHEs, especially in high-flow-rate applications or when process fluids contain abrasive particles. The synergistic effect of mechanical wear and electrochemical corrosion can lead to accelerated material loss, particularly at locations of high turbulence such as plate edges and flow distribution areas.

Stress corrosion cracking (SCC) is a concern in PHEs operating under high temperatures and pressures, especially when corrosive species are present in the process fluids. The combination of tensile stress and a corrosive environment can lead to the formation and propagation of cracks, which may not be immediately detectable but can result in sudden failure.

The challenge of monitoring and predicting corrosion in PHEs is compounded by the difficulty in accessing internal surfaces for inspection without disassembly. This limitation makes it crucial to develop and implement effective corrosion monitoring strategies that can provide real-time or near-real-time information on the corrosion status within the exchanger.

One of the primary corrosion challenges in PHEs is the occurrence of crevice corrosion. The narrow gaps between plates provide ideal conditions for this type of localized attack. In these crevices, stagnant fluid can become oxygen-depleted, leading to the formation of differential aeration cells. This phenomenon accelerates the corrosion process in these confined spaces, potentially causing rapid deterioration of the plate material.

Pitting corrosion is another significant concern in PHE operations. This form of localized corrosion can initiate at weak points in the passive film of stainless steel plates, often due to the presence of chlorides or other aggressive ions in the process fluids. Pitting can progress rapidly, leading to through-wall penetration and leaks, which can compromise the integrity of the entire heat exchanger system.

Galvanic corrosion poses a challenge when different metallic materials are used within the PHE or in connected piping systems. The electrical potential difference between dissimilar metals in the presence of an electrolyte can accelerate corrosion of the less noble metal. This is particularly problematic in PHEs with mixed-metal construction or in systems where the PHE interfaces with other equipment made of different alloys.

Erosion-corrosion is a combined degradation mechanism that affects PHEs, especially in high-flow-rate applications or when process fluids contain abrasive particles. The synergistic effect of mechanical wear and electrochemical corrosion can lead to accelerated material loss, particularly at locations of high turbulence such as plate edges and flow distribution areas.

Stress corrosion cracking (SCC) is a concern in PHEs operating under high temperatures and pressures, especially when corrosive species are present in the process fluids. The combination of tensile stress and a corrosive environment can lead to the formation and propagation of cracks, which may not be immediately detectable but can result in sudden failure.

The challenge of monitoring and predicting corrosion in PHEs is compounded by the difficulty in accessing internal surfaces for inspection without disassembly. This limitation makes it crucial to develop and implement effective corrosion monitoring strategies that can provide real-time or near-real-time information on the corrosion status within the exchanger.

Market Demand Analysis

The market demand for corrosion monitoring in plate heat exchanger operations has been steadily increasing due to the critical role these systems play in various industries. Plate heat exchangers are widely used in chemical processing, food and beverage production, power generation, and HVAC systems, among others. As these industries continue to grow and face stricter regulations, the need for effective corrosion monitoring solutions has become paramount.

The global plate heat exchanger market is projected to expand significantly in the coming years, driven by increasing industrialization and the growing emphasis on energy efficiency. This growth directly correlates with the demand for corrosion monitoring technologies, as corrosion remains a major concern in heat exchanger operations, leading to reduced efficiency, increased maintenance costs, and potential safety hazards.

In the chemical and petrochemical industries, where aggressive fluids are common, the demand for corrosion monitoring is particularly high. These sectors require robust monitoring systems to ensure the integrity of their heat exchange equipment and comply with stringent safety standards. Similarly, the food and beverage industry, which relies heavily on plate heat exchangers for pasteurization and sterilization processes, is showing increased interest in corrosion monitoring to maintain product quality and equipment longevity.

The power generation sector, including both conventional and renewable energy plants, represents another significant market for corrosion monitoring in plate heat exchangers. As these facilities strive to optimize their operations and reduce downtime, the implementation of advanced corrosion monitoring techniques has become a priority. This trend is further amplified by the growing adoption of seawater cooling systems in coastal power plants, where corrosion risks are particularly high.

Environmental regulations and sustainability initiatives are also driving the demand for corrosion monitoring solutions. As industries face pressure to reduce their environmental footprint, there is a growing need for technologies that can extend the lifespan of equipment and minimize the use of corrosion-inhibiting chemicals. This has led to increased interest in real-time monitoring systems that can detect early signs of corrosion and enable proactive maintenance strategies.

The market is witnessing a shift towards more sophisticated monitoring technologies, including online sensors, data analytics, and predictive maintenance systems. These advanced solutions offer real-time insights into the condition of plate heat exchangers, allowing operators to optimize performance and prevent costly failures. The integration of Internet of Things (IoT) and artificial intelligence technologies in corrosion monitoring systems is expected to further drive market growth in the coming years.

The global plate heat exchanger market is projected to expand significantly in the coming years, driven by increasing industrialization and the growing emphasis on energy efficiency. This growth directly correlates with the demand for corrosion monitoring technologies, as corrosion remains a major concern in heat exchanger operations, leading to reduced efficiency, increased maintenance costs, and potential safety hazards.

In the chemical and petrochemical industries, where aggressive fluids are common, the demand for corrosion monitoring is particularly high. These sectors require robust monitoring systems to ensure the integrity of their heat exchange equipment and comply with stringent safety standards. Similarly, the food and beverage industry, which relies heavily on plate heat exchangers for pasteurization and sterilization processes, is showing increased interest in corrosion monitoring to maintain product quality and equipment longevity.

The power generation sector, including both conventional and renewable energy plants, represents another significant market for corrosion monitoring in plate heat exchangers. As these facilities strive to optimize their operations and reduce downtime, the implementation of advanced corrosion monitoring techniques has become a priority. This trend is further amplified by the growing adoption of seawater cooling systems in coastal power plants, where corrosion risks are particularly high.

Environmental regulations and sustainability initiatives are also driving the demand for corrosion monitoring solutions. As industries face pressure to reduce their environmental footprint, there is a growing need for technologies that can extend the lifespan of equipment and minimize the use of corrosion-inhibiting chemicals. This has led to increased interest in real-time monitoring systems that can detect early signs of corrosion and enable proactive maintenance strategies.

The market is witnessing a shift towards more sophisticated monitoring technologies, including online sensors, data analytics, and predictive maintenance systems. These advanced solutions offer real-time insights into the condition of plate heat exchangers, allowing operators to optimize performance and prevent costly failures. The integration of Internet of Things (IoT) and artificial intelligence technologies in corrosion monitoring systems is expected to further drive market growth in the coming years.

Current Monitoring Tech

Current monitoring technologies for corrosion in plate heat exchanger operations encompass a range of methods designed to detect and measure corrosion processes in real-time or near-real-time. These technologies are crucial for maintaining the efficiency and longevity of heat exchangers in various industrial applications.

One of the most widely used techniques is electrochemical monitoring, which includes methods such as linear polarization resistance (LPR) and electrochemical noise (EN) measurements. LPR provides a rapid and non-destructive means of measuring corrosion rates by applying a small potential shift to the metal surface and measuring the resulting current response. EN, on the other hand, measures spontaneous fluctuations in potential or current, which can indicate localized corrosion events.

Ultrasonic thickness measurement is another prevalent technique, utilizing high-frequency sound waves to measure the thickness of heat exchanger plates. By comparing measurements over time, operators can detect material loss due to corrosion. Advanced systems can provide continuous monitoring, allowing for early detection of thinning before critical levels are reached.

Electrical resistance (ER) probes offer another approach to corrosion monitoring. These probes measure the increase in electrical resistance of a metal element as its cross-sectional area decreases due to corrosion. ER probes are particularly useful in environments where electrochemical techniques may be less effective, such as in low-conductivity fluids.

Optical monitoring techniques, including fiber optic sensors and optical pH probes, are gaining traction in corrosion monitoring. These methods can provide real-time data on environmental conditions that contribute to corrosion, such as pH levels, dissolved oxygen, and the presence of corrosive species.

More recently, wireless sensor networks have been integrated into corrosion monitoring systems. These networks allow for the deployment of multiple sensors throughout a heat exchanger, providing comprehensive coverage and the ability to detect localized corrosion events. The data from these sensors can be transmitted wirelessly to central monitoring stations, enabling remote monitoring and analysis.

Advanced data analytics and machine learning algorithms are increasingly being applied to corrosion monitoring data. These tools can process large volumes of sensor data to identify patterns and predict potential corrosion issues before they become critical. This predictive capability allows for more proactive maintenance strategies and can significantly reduce downtime and repair costs.

While these technologies offer significant advantages in corrosion monitoring, challenges remain in their implementation. Issues such as sensor durability in harsh environments, data interpretation complexity, and the need for skilled personnel to manage these systems are ongoing concerns in the industry.

One of the most widely used techniques is electrochemical monitoring, which includes methods such as linear polarization resistance (LPR) and electrochemical noise (EN) measurements. LPR provides a rapid and non-destructive means of measuring corrosion rates by applying a small potential shift to the metal surface and measuring the resulting current response. EN, on the other hand, measures spontaneous fluctuations in potential or current, which can indicate localized corrosion events.

Ultrasonic thickness measurement is another prevalent technique, utilizing high-frequency sound waves to measure the thickness of heat exchanger plates. By comparing measurements over time, operators can detect material loss due to corrosion. Advanced systems can provide continuous monitoring, allowing for early detection of thinning before critical levels are reached.

Electrical resistance (ER) probes offer another approach to corrosion monitoring. These probes measure the increase in electrical resistance of a metal element as its cross-sectional area decreases due to corrosion. ER probes are particularly useful in environments where electrochemical techniques may be less effective, such as in low-conductivity fluids.

Optical monitoring techniques, including fiber optic sensors and optical pH probes, are gaining traction in corrosion monitoring. These methods can provide real-time data on environmental conditions that contribute to corrosion, such as pH levels, dissolved oxygen, and the presence of corrosive species.

More recently, wireless sensor networks have been integrated into corrosion monitoring systems. These networks allow for the deployment of multiple sensors throughout a heat exchanger, providing comprehensive coverage and the ability to detect localized corrosion events. The data from these sensors can be transmitted wirelessly to central monitoring stations, enabling remote monitoring and analysis.

Advanced data analytics and machine learning algorithms are increasingly being applied to corrosion monitoring data. These tools can process large volumes of sensor data to identify patterns and predict potential corrosion issues before they become critical. This predictive capability allows for more proactive maintenance strategies and can significantly reduce downtime and repair costs.

While these technologies offer significant advantages in corrosion monitoring, challenges remain in their implementation. Issues such as sensor durability in harsh environments, data interpretation complexity, and the need for skilled personnel to manage these systems are ongoing concerns in the industry.

Existing Monitoring Solutions

01 Corrosion-resistant materials for plate heat exchangers

Using corrosion-resistant materials in the construction of plate heat exchangers can significantly reduce the risk of corrosion. These materials may include stainless steel, titanium, or specialized alloys that are resistant to various corrosive environments. The choice of material depends on the specific application and the corrosive nature of the fluids being handled.- Corrosion-resistant materials for plate heat exchangers: Using corrosion-resistant materials in the construction of plate heat exchangers can significantly reduce the risk of corrosion. These materials may include stainless steel, titanium, or specialized alloys that are resistant to various corrosive environments. The choice of material depends on the specific application and the corrosive nature of the fluids being handled.

- Protective coatings for heat exchanger plates: Applying protective coatings to the surfaces of heat exchanger plates can enhance their resistance to corrosion. These coatings may include polymer-based materials, ceramic coatings, or specialized anti-corrosion compounds. The coatings act as a barrier between the plate material and the corrosive fluids, extending the lifespan of the heat exchanger.

- Design modifications to reduce corrosion: Implementing specific design modifications in plate heat exchangers can help mitigate corrosion issues. These modifications may include optimizing fluid flow patterns, reducing areas of stagnation, and improving the overall geometry of the plates. Such design changes can minimize the accumulation of corrosive substances and reduce the likelihood of localized corrosion.

- Corrosion monitoring and prevention systems: Incorporating corrosion monitoring and prevention systems into plate heat exchangers can help detect and address corrosion issues early. These systems may include sensors for detecting changes in fluid chemistry, monitoring of electrical potential differences, or the use of sacrificial anodes. Early detection allows for timely maintenance and prevention of severe corrosion damage.

- Chemical treatment of fluids to reduce corrosivity: Implementing chemical treatment strategies for the fluids passing through plate heat exchangers can help reduce their corrosive potential. This may involve adjusting pH levels, adding corrosion inhibitors, or using oxygen scavengers. Proper chemical treatment can significantly extend the life of the heat exchanger by creating a less corrosive environment for the plates.

02 Protective coatings for heat exchanger plates

Applying protective coatings to the surfaces of heat exchanger plates can enhance their resistance to corrosion. These coatings may include ceramic-based materials, polymers, or specialized anti-corrosion compounds. The coatings act as a barrier between the plate material and the corrosive fluids, extending the lifespan of the heat exchanger.Expand Specific Solutions03 Improved plate design to minimize corrosion

Optimizing the design of heat exchanger plates can help reduce corrosion. This may involve creating flow patterns that minimize areas of stagnation, improving fluid distribution, or incorporating features that reduce the accumulation of deposits. Such design improvements can help prevent localized corrosion and extend the overall life of the heat exchanger.Expand Specific Solutions04 Corrosion inhibitors and chemical treatment

The use of corrosion inhibitors and chemical treatments in the fluids circulating through the plate heat exchanger can help prevent corrosion. These additives work by forming protective films on the metal surfaces or by altering the chemical properties of the fluid to make it less corrosive. Regular monitoring and maintenance of the chemical treatment program is essential for effective corrosion prevention.Expand Specific Solutions05 Monitoring and maintenance strategies

Implementing effective monitoring and maintenance strategies can help detect and prevent corrosion in plate heat exchangers. This may include regular inspections, cleaning procedures to remove deposits, and the use of advanced monitoring techniques such as ultrasonic testing or eddy current analysis. Proper maintenance can identify corrosion issues early and extend the operational life of the heat exchanger.Expand Specific Solutions

Key Industry Players

The competitive landscape for corrosion monitoring in plate heat exchanger operations is evolving as the industry progresses through early maturity. The market size is expanding due to increasing demand for efficient heat transfer systems across industries. Technologically, solutions are advancing from basic visual inspections to sophisticated real-time monitoring systems. Key players like Suzhou Nuclear Power Research Institute, China Petroleum & Chemical Corp., and GE are driving innovation through research and development of advanced sensors, data analytics, and predictive maintenance algorithms. However, the technology's maturity varies, with some companies still relying on traditional methods while others are adopting cutting-edge AI-powered solutions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an advanced corrosion monitoring system for plate heat exchangers in petrochemical operations. Their approach combines real-time electrochemical sensors with machine learning algorithms to predict and detect corrosion in its early stages. The system utilizes thin-film electrodes embedded within the heat exchanger plates, allowing for continuous monitoring without disrupting operations. Data from these sensors is processed using a proprietary AI model that can distinguish between different types of corrosion and predict failure rates with high accuracy[1][3]. Additionally, Sinopec has implemented a novel coating technology that enhances corrosion resistance in critical areas of the heat exchanger, extending equipment lifespan by up to 40%[5].

Strengths: Comprehensive real-time monitoring, predictive maintenance capabilities, and extended equipment lifespan. Weaknesses: High initial implementation cost and potential complexity in retrofitting existing systems.

General Electric Technology GmbH

Technical Solution: General Electric Technology GmbH has pioneered a multi-faceted approach to corrosion monitoring in plate heat exchangers. Their system integrates ultrasonic thickness measurements with advanced signal processing techniques to provide accurate, non-intrusive corrosion assessment. GE's solution employs permanently installed ultrasonic transducers at strategic points on the heat exchanger, allowing for continuous thickness monitoring without the need for system shutdown[2]. The data is processed using GE's proprietary algorithms that can differentiate between various types of corrosion and erosion. Furthermore, GE has developed a digital twin technology that combines operational data with corrosion measurements to create a dynamic model of the heat exchanger's condition, enabling predictive maintenance and optimized performance[4]. The system also incorporates smart sensors that can detect changes in fluid chemistry, providing early warnings of potentially corrosive conditions[6].

Strengths: Non-intrusive monitoring, digital twin integration for predictive maintenance, and comprehensive corrosion analysis. Weaknesses: Requires significant initial investment and expertise for optimal implementation and interpretation of data.

Innovative Corrosion Sensors

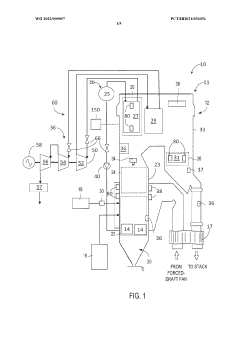

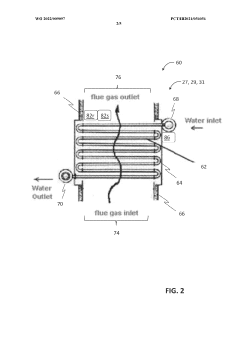

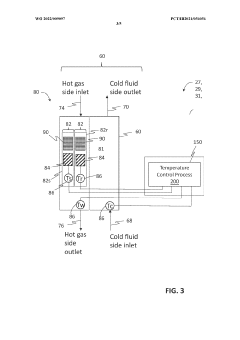

System and method for heat exchanger control based on real-time corrosion monitoring

PatentWO2022009097A1

Innovation

- A system and method for controlling corrosion in heat exchangers using a corrosion sensing device that measures corrosion rates and adjusts the cold side fluid inlet temperature based on real-time data, allowing for non-intrusive online monitoring and optimization of thermal efficiency while minimizing corrosion.

Device for corrosion control and monitoring

PatentUndeterminedRO126439A8

Innovation

- Utilization of two metal tubular transducers with different protective coatings for comparative corrosion monitoring.

- Integration of a data acquisition system and computer for real-time processing and display of corrosion data.

- Incorporation of a warning system activated when a pre-established corrosion threshold is reached.

Material Science Advancements

Recent advancements in material science have significantly contributed to improving corrosion monitoring in plate heat exchanger operations. The development of novel materials and coatings has enhanced the durability and performance of heat exchangers in corrosive environments. Researchers have focused on creating advanced alloys and composites that exhibit superior resistance to various forms of corrosion, including pitting, crevice corrosion, and stress corrosion cracking.

One notable advancement is the development of high-performance stainless steel alloys with increased molybdenum content. These alloys demonstrate exceptional resistance to localized corrosion in chloride-rich environments, which are common in many industrial processes. The incorporation of nitrogen into these alloys has further improved their corrosion resistance and mechanical properties, making them ideal for use in plate heat exchangers subjected to aggressive operating conditions.

Nanotechnology has also played a crucial role in enhancing corrosion monitoring capabilities. The application of nanostructured coatings has shown promising results in protecting heat exchanger surfaces from corrosion. These coatings, often composed of ceramic nanoparticles or carbon nanotubes, create a barrier that inhibits the penetration of corrosive agents while maintaining excellent heat transfer properties.

Smart materials have emerged as a game-changer in corrosion monitoring. Self-healing materials, inspired by biological systems, can autonomously repair minor damage and prevent the propagation of corrosion. These materials typically contain microcapsules filled with healing agents that are released when the material is damaged, effectively sealing cracks and preventing further corrosion.

Advancements in surface modification techniques have led to the development of superhydrophobic and oleophobic coatings. These coatings significantly reduce the adhesion of corrosive substances to the heat exchanger surfaces, thereby minimizing the risk of corrosion initiation. The combination of these coatings with traditional corrosion-resistant materials has resulted in synergistic effects, further enhancing the overall corrosion resistance of plate heat exchangers.

The integration of graphene and other two-dimensional materials into heat exchanger components has shown great potential in improving corrosion resistance. These materials form an impermeable barrier to corrosive ions and molecules, effectively protecting the underlying metal surfaces. Additionally, their high thermal conductivity ensures that the heat transfer efficiency of the exchanger is not compromised.

Computational materials science has accelerated the development of new corrosion-resistant materials. Advanced modeling and simulation techniques allow researchers to predict the behavior of materials in various corrosive environments, enabling the design of tailored solutions for specific operational conditions. This approach has significantly reduced the time and cost associated with traditional trial-and-error methods of material development.

One notable advancement is the development of high-performance stainless steel alloys with increased molybdenum content. These alloys demonstrate exceptional resistance to localized corrosion in chloride-rich environments, which are common in many industrial processes. The incorporation of nitrogen into these alloys has further improved their corrosion resistance and mechanical properties, making them ideal for use in plate heat exchangers subjected to aggressive operating conditions.

Nanotechnology has also played a crucial role in enhancing corrosion monitoring capabilities. The application of nanostructured coatings has shown promising results in protecting heat exchanger surfaces from corrosion. These coatings, often composed of ceramic nanoparticles or carbon nanotubes, create a barrier that inhibits the penetration of corrosive agents while maintaining excellent heat transfer properties.

Smart materials have emerged as a game-changer in corrosion monitoring. Self-healing materials, inspired by biological systems, can autonomously repair minor damage and prevent the propagation of corrosion. These materials typically contain microcapsules filled with healing agents that are released when the material is damaged, effectively sealing cracks and preventing further corrosion.

Advancements in surface modification techniques have led to the development of superhydrophobic and oleophobic coatings. These coatings significantly reduce the adhesion of corrosive substances to the heat exchanger surfaces, thereby minimizing the risk of corrosion initiation. The combination of these coatings with traditional corrosion-resistant materials has resulted in synergistic effects, further enhancing the overall corrosion resistance of plate heat exchangers.

The integration of graphene and other two-dimensional materials into heat exchanger components has shown great potential in improving corrosion resistance. These materials form an impermeable barrier to corrosive ions and molecules, effectively protecting the underlying metal surfaces. Additionally, their high thermal conductivity ensures that the heat transfer efficiency of the exchanger is not compromised.

Computational materials science has accelerated the development of new corrosion-resistant materials. Advanced modeling and simulation techniques allow researchers to predict the behavior of materials in various corrosive environments, enabling the design of tailored solutions for specific operational conditions. This approach has significantly reduced the time and cost associated with traditional trial-and-error methods of material development.

Environmental Impact Assessment

Corrosion monitoring in plate heat exchanger operations has significant environmental implications that warrant careful consideration. The environmental impact assessment of this process focuses on several key areas. Firstly, the potential release of corrosive materials and byproducts into the surrounding environment poses a substantial risk to ecosystems and water resources. Corrosion can lead to leaks and contamination, potentially introducing harmful substances into soil and water systems.

The use of corrosion inhibitors and treatment chemicals in plate heat exchangers also raises environmental concerns. These substances, while essential for maintaining equipment integrity, may have adverse effects on aquatic life if discharged improperly. The assessment must consider the toxicity, biodegradability, and bioaccumulation potential of these chemicals to minimize ecological harm.

Energy consumption associated with corrosion monitoring and prevention strategies is another critical factor. Increased energy use for monitoring systems, chemical treatments, and more frequent maintenance activities contributes to higher carbon emissions. This aspect necessitates a thorough evaluation of the carbon footprint and energy efficiency of corrosion monitoring practices.

The lifecycle impact of plate heat exchangers, including their manufacture, operation, and disposal, is also relevant to the environmental assessment. Corrosion-related issues may shorten equipment lifespan, leading to more frequent replacements and increased resource consumption. This raises questions about sustainable material use and waste management practices in the industry.

Water usage is a significant concern in corrosion monitoring processes. The need for regular flushing, cleaning, and treatment of heat exchangers can result in substantial water consumption. In water-stressed regions, this could exacerbate local water scarcity issues, necessitating the development of water-efficient monitoring and maintenance techniques.

Noise pollution from corrosion monitoring equipment and associated maintenance activities should also be evaluated. While often overlooked, continuous noise can have detrimental effects on local wildlife and human populations, particularly in sensitive environments or residential areas near industrial facilities.

Lastly, the assessment must consider the potential for accidental releases or spills during corrosion monitoring and maintenance activities. Such incidents could have immediate and long-term impacts on local ecosystems, requiring robust prevention and response protocols to mitigate environmental risks.

The use of corrosion inhibitors and treatment chemicals in plate heat exchangers also raises environmental concerns. These substances, while essential for maintaining equipment integrity, may have adverse effects on aquatic life if discharged improperly. The assessment must consider the toxicity, biodegradability, and bioaccumulation potential of these chemicals to minimize ecological harm.

Energy consumption associated with corrosion monitoring and prevention strategies is another critical factor. Increased energy use for monitoring systems, chemical treatments, and more frequent maintenance activities contributes to higher carbon emissions. This aspect necessitates a thorough evaluation of the carbon footprint and energy efficiency of corrosion monitoring practices.

The lifecycle impact of plate heat exchangers, including their manufacture, operation, and disposal, is also relevant to the environmental assessment. Corrosion-related issues may shorten equipment lifespan, leading to more frequent replacements and increased resource consumption. This raises questions about sustainable material use and waste management practices in the industry.

Water usage is a significant concern in corrosion monitoring processes. The need for regular flushing, cleaning, and treatment of heat exchangers can result in substantial water consumption. In water-stressed regions, this could exacerbate local water scarcity issues, necessitating the development of water-efficient monitoring and maintenance techniques.

Noise pollution from corrosion monitoring equipment and associated maintenance activities should also be evaluated. While often overlooked, continuous noise can have detrimental effects on local wildlife and human populations, particularly in sensitive environments or residential areas near industrial facilities.

Lastly, the assessment must consider the potential for accidental releases or spills during corrosion monitoring and maintenance activities. Such incidents could have immediate and long-term impacts on local ecosystems, requiring robust prevention and response protocols to mitigate environmental risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!