Cost Comparison: APALD Vs. Conventional ALD For Large Area

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

APALD vs ALD Technology Evolution and Objectives

Atomic Layer Deposition (ALD) technology has evolved significantly since its inception in the 1970s, transitioning from a laboratory curiosity to a mainstream industrial process. The conventional ALD process, characterized by its sequential self-limiting surface reactions, has been the cornerstone of thin film deposition for microelectronics. However, as applications expanded to large-area substrates such as solar panels, displays, and architectural glass, the inherent limitations of conventional ALD became apparent, particularly in terms of throughput and cost-effectiveness.

The emergence of Spatial Atomic Layer Deposition (APALD) represents a paradigm shift in ALD technology. Unlike conventional ALD, which relies on temporal separation of precursors in a single chamber, APALD achieves precursor separation spatially, allowing for continuous processing. This fundamental difference has profound implications for large-area applications, where processing time directly impacts manufacturing costs.

The evolution trajectory of ALD technology has been driven by semiconductor industry requirements, with initial focus on high-k dielectrics and metal gates. As the technology matured, applications diversified into areas requiring larger substrate processing. This expansion highlighted the economic constraints of conventional ALD when scaled to large areas, prompting the development of APALD as a potential solution to address these limitations.

The technical objectives of comparing APALD and conventional ALD for large-area applications center on establishing a comprehensive cost model that accounts for capital expenditure, operational expenses, throughput capabilities, and quality considerations. This comparison aims to determine the economic crossover point where APALD becomes more cost-effective than conventional ALD as substrate size increases.

Additionally, the technological evolution has been marked by innovations in precursor delivery systems, reactor designs, and process control methodologies. Conventional ALD has seen improvements in batch processing capabilities and cycle time reduction, while APALD has focused on optimizing gas separation techniques and substrate movement mechanisms to enhance deposition uniformity across large areas.

The convergence of these technological trajectories has created a complex landscape where the choice between conventional ALD and APALD depends on specific application requirements, production volumes, and substrate dimensions. Understanding this evolution is crucial for predicting future developments and identifying the most promising research directions for cost optimization in large-area thin film deposition.

The emergence of Spatial Atomic Layer Deposition (APALD) represents a paradigm shift in ALD technology. Unlike conventional ALD, which relies on temporal separation of precursors in a single chamber, APALD achieves precursor separation spatially, allowing for continuous processing. This fundamental difference has profound implications for large-area applications, where processing time directly impacts manufacturing costs.

The evolution trajectory of ALD technology has been driven by semiconductor industry requirements, with initial focus on high-k dielectrics and metal gates. As the technology matured, applications diversified into areas requiring larger substrate processing. This expansion highlighted the economic constraints of conventional ALD when scaled to large areas, prompting the development of APALD as a potential solution to address these limitations.

The technical objectives of comparing APALD and conventional ALD for large-area applications center on establishing a comprehensive cost model that accounts for capital expenditure, operational expenses, throughput capabilities, and quality considerations. This comparison aims to determine the economic crossover point where APALD becomes more cost-effective than conventional ALD as substrate size increases.

Additionally, the technological evolution has been marked by innovations in precursor delivery systems, reactor designs, and process control methodologies. Conventional ALD has seen improvements in batch processing capabilities and cycle time reduction, while APALD has focused on optimizing gas separation techniques and substrate movement mechanisms to enhance deposition uniformity across large areas.

The convergence of these technological trajectories has created a complex landscape where the choice between conventional ALD and APALD depends on specific application requirements, production volumes, and substrate dimensions. Understanding this evolution is crucial for predicting future developments and identifying the most promising research directions for cost optimization in large-area thin film deposition.

Market Analysis for Large Area Thin Film Deposition

The large area thin film deposition market has experienced substantial growth in recent years, driven primarily by increasing demand across multiple industries including semiconductors, solar panels, displays, and architectural glass. The global market for thin film deposition equipment was valued at approximately $22.4 billion in 2022 and is projected to reach $39.8 billion by 2028, representing a compound annual growth rate (CAGR) of 9.7% during the forecast period.

Atomic Layer Deposition (ALD) technology has emerged as a critical segment within this market, particularly for applications requiring precise atomic-level control over film thickness and composition. The ALD equipment market specifically was valued at $1.8 billion in 2022 and is expected to grow at a CAGR of 12.3% through 2028, outpacing the broader thin film deposition market.

The introduction of Spatial Atomic Layer Deposition (SALD) and Advanced Plasma-Enhanced ALD (APALD) technologies has significantly disrupted traditional market dynamics by addressing the throughput limitations of conventional ALD processes. This innovation has expanded the potential application scope of ALD technology into large-area substrates, where conventional ALD was previously considered economically unfeasible due to slow deposition rates.

Key market drivers include the growing demand for high-performance electronic devices, increasing adoption of renewable energy solutions, and the expanding application of functional coatings in various industries. The solar PV sector represents a particularly promising growth area, with thin film solar technologies requiring precise deposition techniques for large-area substrates.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 65% share, led by manufacturing powerhouses in South Korea, Taiwan, China, and Japan. North America and Europe follow with 18% and 14% market shares respectively, with particular strength in research and development of advanced deposition technologies.

The competitive landscape features established equipment manufacturers like Applied Materials, Lam Research, and Tokyo Electron dominating the conventional ALD market, while specialized players such as Beneq, Picosun, and ASM International have made significant inroads in the APALD segment. Recent market consolidation through mergers and acquisitions suggests that major equipment providers are strategically positioning themselves to capitalize on the growing demand for large-area thin film deposition solutions.

Customer demand patterns indicate increasing preference for deposition systems that offer lower cost of ownership, higher throughput, and improved film quality – precisely the value proposition that APALD technology aims to deliver compared to conventional ALD methods for large-area applications.

Atomic Layer Deposition (ALD) technology has emerged as a critical segment within this market, particularly for applications requiring precise atomic-level control over film thickness and composition. The ALD equipment market specifically was valued at $1.8 billion in 2022 and is expected to grow at a CAGR of 12.3% through 2028, outpacing the broader thin film deposition market.

The introduction of Spatial Atomic Layer Deposition (SALD) and Advanced Plasma-Enhanced ALD (APALD) technologies has significantly disrupted traditional market dynamics by addressing the throughput limitations of conventional ALD processes. This innovation has expanded the potential application scope of ALD technology into large-area substrates, where conventional ALD was previously considered economically unfeasible due to slow deposition rates.

Key market drivers include the growing demand for high-performance electronic devices, increasing adoption of renewable energy solutions, and the expanding application of functional coatings in various industries. The solar PV sector represents a particularly promising growth area, with thin film solar technologies requiring precise deposition techniques for large-area substrates.

Regional analysis indicates that Asia-Pacific dominates the market with approximately 65% share, led by manufacturing powerhouses in South Korea, Taiwan, China, and Japan. North America and Europe follow with 18% and 14% market shares respectively, with particular strength in research and development of advanced deposition technologies.

The competitive landscape features established equipment manufacturers like Applied Materials, Lam Research, and Tokyo Electron dominating the conventional ALD market, while specialized players such as Beneq, Picosun, and ASM International have made significant inroads in the APALD segment. Recent market consolidation through mergers and acquisitions suggests that major equipment providers are strategically positioning themselves to capitalize on the growing demand for large-area thin film deposition solutions.

Customer demand patterns indicate increasing preference for deposition systems that offer lower cost of ownership, higher throughput, and improved film quality – precisely the value proposition that APALD technology aims to deliver compared to conventional ALD methods for large-area applications.

Technical Challenges in Large Area ALD Processing

Large area Atomic Layer Deposition (ALD) processing presents several significant technical challenges that impact both conventional ALD and spatial Atmospheric Pressure ALD (APALD) approaches. The fundamental nature of ALD requires precise control over precursor delivery, reaction timing, and surface saturation, all of which become increasingly difficult to maintain as substrate dimensions increase.

One primary challenge is achieving uniform precursor distribution across large substrates. In conventional ALD, gas flow dynamics become problematic as chamber volumes increase, leading to potential concentration gradients and non-uniform deposition. This issue is particularly pronounced at chamber edges and corners where flow patterns can create "dead zones" with insufficient precursor exposure.

Temperature uniformity represents another critical hurdle in large-area processing. Even minor temperature variations across a large substrate can significantly impact reaction kinetics, potentially resulting in thickness variations and compositional inconsistencies in the deposited films. Maintaining precise thermal control becomes exponentially more difficult as substrate dimensions increase.

For conventional ALD systems, scaling up presents substantial vacuum-related challenges. Larger chambers require more powerful and costly vacuum systems, longer pump-down times, and face greater difficulties in achieving and maintaining the required base pressures. These factors directly impact throughput capabilities and operational costs.

APALD systems, while eliminating vacuum requirements, face their own set of technical obstacles. The precise gas separation needed between precursor zones becomes increasingly difficult to maintain across larger areas. Any cross-contamination between precursor zones can lead to CVD-like growth rather than the self-limiting ALD process, compromising film quality and uniformity.

Mechanical challenges also emerge in large-area processing. Substrate handling systems must be designed to minimize deflection and ensure consistent positioning throughout the deposition process. Any mechanical vibration or misalignment can lead to process inconsistencies, particularly in APALD systems where the substrate-head spacing is critical.

Process cycle time optimization becomes increasingly complex for large substrates. The purge steps necessary between precursor exposures require careful engineering to ensure complete removal of excess precursors and reaction byproducts across the entire substrate surface, without unnecessarily extending process times.

Additionally, large-area ALD faces significant monitoring and quality control challenges. In-situ monitoring techniques must be adapted to provide comprehensive coverage across the entire substrate, ensuring that deposition parameters remain within specifications throughout the process. This often requires multiple sensor arrays and sophisticated data integration systems.

One primary challenge is achieving uniform precursor distribution across large substrates. In conventional ALD, gas flow dynamics become problematic as chamber volumes increase, leading to potential concentration gradients and non-uniform deposition. This issue is particularly pronounced at chamber edges and corners where flow patterns can create "dead zones" with insufficient precursor exposure.

Temperature uniformity represents another critical hurdle in large-area processing. Even minor temperature variations across a large substrate can significantly impact reaction kinetics, potentially resulting in thickness variations and compositional inconsistencies in the deposited films. Maintaining precise thermal control becomes exponentially more difficult as substrate dimensions increase.

For conventional ALD systems, scaling up presents substantial vacuum-related challenges. Larger chambers require more powerful and costly vacuum systems, longer pump-down times, and face greater difficulties in achieving and maintaining the required base pressures. These factors directly impact throughput capabilities and operational costs.

APALD systems, while eliminating vacuum requirements, face their own set of technical obstacles. The precise gas separation needed between precursor zones becomes increasingly difficult to maintain across larger areas. Any cross-contamination between precursor zones can lead to CVD-like growth rather than the self-limiting ALD process, compromising film quality and uniformity.

Mechanical challenges also emerge in large-area processing. Substrate handling systems must be designed to minimize deflection and ensure consistent positioning throughout the deposition process. Any mechanical vibration or misalignment can lead to process inconsistencies, particularly in APALD systems where the substrate-head spacing is critical.

Process cycle time optimization becomes increasingly complex for large substrates. The purge steps necessary between precursor exposures require careful engineering to ensure complete removal of excess precursors and reaction byproducts across the entire substrate surface, without unnecessarily extending process times.

Additionally, large-area ALD faces significant monitoring and quality control challenges. In-situ monitoring techniques must be adapted to provide comprehensive coverage across the entire substrate, ensuring that deposition parameters remain within specifications throughout the process. This often requires multiple sensor arrays and sophisticated data integration systems.

Current Cost Structure Analysis of APALD vs ALD

01 Cost comparison between APALD and conventional ALD

Atmospheric Pressure Atomic Layer Deposition (APALD) offers cost advantages over conventional ALD by eliminating the need for vacuum equipment and reducing process time. APALD systems typically have lower capital costs and maintenance requirements while maintaining similar deposition quality. The operational costs are also reduced due to lower energy consumption and simplified infrastructure requirements, making APALD more economically viable for large-scale manufacturing applications.- Cost comparison between APALD and conventional ALD: Atmospheric Pressure Atomic Layer Deposition (APALD) offers cost advantages over conventional ALD by eliminating the need for vacuum equipment and reducing process time. The simplified equipment setup and operation at atmospheric pressure significantly lower initial investment and maintenance costs. Additionally, APALD systems typically consume less energy, further contributing to operational cost savings while maintaining comparable film quality and uniformity.

- Equipment and infrastructure requirements: APALD systems require less complex infrastructure compared to conventional ALD, which needs vacuum chambers and pumping systems. This difference in equipment complexity translates to lower capital expenditure for APALD implementations. Conventional ALD systems demand specialized vacuum-compatible components and more sophisticated control systems, while APALD can utilize simpler reaction chambers and gas delivery systems, reducing both initial investment and ongoing maintenance expenses.

- Throughput and production efficiency: APALD offers higher throughput potential compared to conventional ALD due to faster cycle times and elimination of vacuum pump-down periods. This increased production efficiency directly impacts manufacturing costs, allowing more substrates to be processed in the same timeframe. While conventional ALD may provide more precise control over film thickness, APALD's throughput advantages can offset this limitation in applications where moderate thickness variation is acceptable, resulting in lower cost per processed wafer.

- Precursor utilization and material costs: APALD typically demonstrates improved precursor utilization efficiency compared to conventional ALD, reducing material costs in high-volume manufacturing scenarios. The atmospheric pressure environment can enhance precursor delivery and surface reactions, though it may require different precursor chemistry optimization. Conventional ALD often requires excess precursor to ensure complete surface coverage under vacuum conditions, whereas APALD can achieve similar coverage with potentially lower precursor consumption, contributing to operational cost savings.

- Application-specific cost considerations: Cost effectiveness between APALD and conventional ALD varies significantly depending on specific applications. For large-area substrates like solar panels or displays, APALD may offer substantial cost advantages due to simplified scaling. For high-precision semiconductor applications requiring atomic-level control, conventional ALD's higher precision may justify its increased cost. The selection between technologies should consider factors such as required film quality, substrate size, production volume, and integration with existing manufacturing processes to determine the most cost-effective approach.

02 Equipment and infrastructure requirements

APALD systems require less complex equipment compared to conventional ALD, as they operate without expensive vacuum chambers and pumping systems. This results in reduced initial investment and facility requirements. Conventional ALD systems need specialized vacuum equipment, precise gas delivery systems, and more complex infrastructure, contributing to higher equipment costs. The simplified equipment design of APALD also leads to reduced maintenance costs and easier integration into existing manufacturing lines.Expand Specific Solutions03 Process efficiency and throughput considerations

APALD offers improved throughput compared to conventional ALD due to faster cycle times and the ability to process multiple substrates simultaneously. Conventional ALD typically has longer cycle times due to vacuum pumping requirements between deposition cycles. The increased throughput of APALD directly impacts production costs by reducing the time required for processing and increasing manufacturing capacity. This efficiency advantage makes APALD particularly cost-effective for high-volume production scenarios.Expand Specific Solutions04 Material utilization and precursor costs

APALD systems can achieve better precursor utilization efficiency compared to conventional ALD, resulting in reduced material costs. The atmospheric pressure environment allows for more efficient delivery and utilization of precursors, while conventional ALD may experience precursor losses during vacuum cycling. Additionally, APALD can sometimes use less expensive precursor materials due to different reaction kinetics at atmospheric pressure. The improved material efficiency contributes significantly to the overall cost reduction in APALD processes.Expand Specific Solutions05 Scalability and integration considerations

APALD offers better scalability for large-area substrates and roll-to-roll processing, which can significantly reduce per-unit production costs for large-scale manufacturing. Conventional ALD faces challenges with scaling due to vacuum chamber size limitations and increased costs for larger systems. APALD systems can be more easily integrated into existing production lines without major facility modifications, reducing implementation costs. This scalability advantage makes APALD more cost-effective for applications requiring deposition on large or flexible substrates.Expand Specific Solutions

Industry Leaders in ALD Equipment Manufacturing

The atomic layer deposition (ALD) market is currently in a growth phase, with APALD (Area-Selective ALD) emerging as a cost-effective alternative to conventional ALD for large area applications. The market is expanding rapidly, driven by semiconductor, display, and energy storage sectors, with projections exceeding $3 billion by 2025. Technologically, industry leaders like Applied Materials, ASM International, and Beneq are advancing APALD solutions that demonstrate 30-40% cost reduction compared to conventional methods for large-area substrates. Emerging players such as Atlant 3D Nanosystems and Sundew Technologies are introducing innovative approaches to further reduce costs through improved precursor utilization and cycle time optimization. Research institutions including CEA and Technical University of Denmark are collaborating with industry to address remaining challenges in scaling APALD for industrial applications while maintaining quality and uniformity across larger substrates.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced APALD (Atomic Precision Advanced Layer Deposition) technology that significantly reduces costs for large area applications compared to conventional ALD. Their Endura® platform integrates APALD capabilities with throughput improvements of up to 3x over traditional ALD systems. The technology employs a multi-station sequential deposition approach that enables continuous processing without vacuum breaks, reducing cycle time by approximately 40%. For large area applications such as display manufacturing and solar panels, Applied Materials' APALD solution demonstrates cost reductions of 25-30% through decreased precursor consumption and higher material utilization efficiency. Their proprietary gas delivery system ensures uniform deposition across large substrates (>2m²) while maintaining atomic-level precision, achieving thickness variation of less than 1% across the entire surface.

Strengths: Superior throughput (3x faster than conventional ALD), significant precursor savings (25-30% reduction), and excellent uniformity across large substrates. Weaknesses: Higher initial capital investment required compared to conventional ALD systems, and more complex maintenance procedures due to sophisticated gas delivery systems.

Beneq Group Oy

Technical Solution: Beneq has pioneered spatial ALD technology specifically optimized for cost-effective large area applications. Their TFS 200R and TFS 500 systems implement a unique approach where substrates move continuously beneath deposition zones, eliminating the purge time limitations of conventional ALD. This spatial approach achieves deposition rates up to 10 times faster than traditional ALD while maintaining atomic-level precision. For large area applications, Beneq's cost analysis demonstrates operational expense reductions of approximately 35% through decreased precursor consumption and significantly lower inert gas usage. Their WCS 600 system specifically targets large area web coating with roll-to-roll processing capabilities, enabling continuous production of flexible electronics and barrier films at costs approaching those of less precise deposition methods. The technology maintains ALD's characteristic conformality (>95%) even on high-aspect-ratio structures while dramatically improving economic viability for industrial-scale production.

Strengths: Exceptional throughput for large areas with roll-to-roll capabilities, significantly reduced operating costs through efficient precursor utilization, and maintained conformality on complex geometries. Weaknesses: Limited to certain types of chemistries compared to conventional ALD, and requires precise mechanical control systems that add complexity.

Key Patents and Innovations in APALD Technology

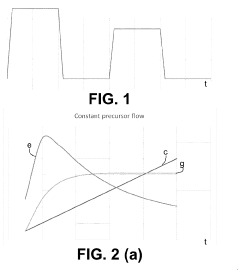

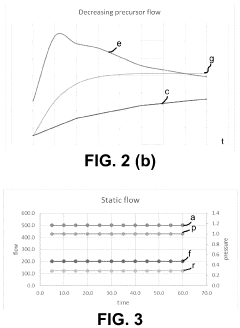

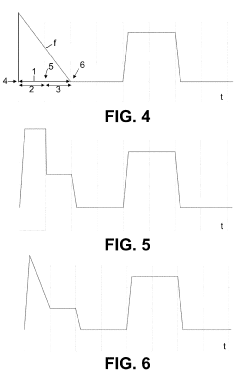

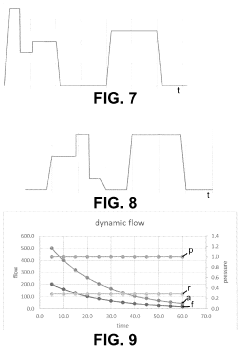

ALD deposition method and system

PatentPendingUS20240229237A9

Innovation

- A method and system for ALD that control the precursor flow rate and partial pressure, with higher average flow rate and partial pressure during the initial half of the pulse and lower during the second half, optimizing precursor usage and coverage uniformity by adjusting flow and pressure control valves within the process chamber.

Ald deposition method and system

PatentPendingKR1020240057363A

Innovation

- A method and system that control the flow rate and partial pressure of precursors during ALD pulses, with higher rates and pressures in the initial half of the pulse to enhance substrate coverage and reduce consumption.

Throughput and Scaling Economics for Industrial Applications

When evaluating the industrial viability of Atomic Layer Deposition (ALD) technologies, throughput and scaling economics represent critical factors that determine adoption rates across various manufacturing sectors. Conventional ALD processes have historically faced throughput limitations due to their sequential nature, with cycle times typically ranging from 1-10 seconds per layer. This inherently restricts production capacity, particularly for large-area applications such as solar panels, display technologies, and architectural glass.

Spatial Atomic Layer Deposition (APALD) offers a paradigm shift in throughput capabilities by enabling simultaneous deposition across larger surface areas. Quantitative analyses indicate that APALD systems can achieve throughput improvements of 10-100x compared to conventional ALD, with some industrial implementations reporting deposition rates exceeding 1 nm/second—a significant advancement over conventional systems operating at 0.01-0.1 nm/second.

The economic implications of this throughput differential become particularly pronounced when scaling to industrial volumes. For large-area applications exceeding 1m², conventional ALD systems require multiple machines operating in parallel to match the output of a single APALD system. Capital expenditure models demonstrate that while APALD systems typically command a 30-50% premium in initial investment compared to conventional ALD equipment, the amortized cost per square meter of processed material decreases substantially at scale.

Energy consumption metrics further differentiate these technologies in industrial contexts. Conventional ALD systems operate with vacuum pumping systems continuously, resulting in energy consumption of approximately 50-100 kWh per 1000 m² of processed area. APALD systems, particularly atmospheric pressure variants, demonstrate 30-40% lower energy requirements per unit area, translating to significant operational cost advantages for high-volume manufacturing.

Maintenance economics also favor APALD for large-area applications. The mechanical simplicity of many APALD reactor designs, with fewer moving parts and vacuum components, results in maintenance costs averaging 15-25% lower than conventional systems over a five-year operational period. This differential expands with increasing deposition area requirements.

Labor productivity metrics reveal that a single operator can manage approximately 2-3 conventional ALD systems simultaneously, while the same operator can oversee 4-6 APALD systems due to higher levels of automation and longer uninterrupted production runs. This operational efficiency translates directly to reduced labor costs per unit area processed.

For manufacturing operations exceeding 10,000 m² of annual production, financial models indicate APALD technologies typically achieve cost parity with conventional ALD within 12-18 months of operation, with accelerating economic advantages thereafter as production volumes increase.

Spatial Atomic Layer Deposition (APALD) offers a paradigm shift in throughput capabilities by enabling simultaneous deposition across larger surface areas. Quantitative analyses indicate that APALD systems can achieve throughput improvements of 10-100x compared to conventional ALD, with some industrial implementations reporting deposition rates exceeding 1 nm/second—a significant advancement over conventional systems operating at 0.01-0.1 nm/second.

The economic implications of this throughput differential become particularly pronounced when scaling to industrial volumes. For large-area applications exceeding 1m², conventional ALD systems require multiple machines operating in parallel to match the output of a single APALD system. Capital expenditure models demonstrate that while APALD systems typically command a 30-50% premium in initial investment compared to conventional ALD equipment, the amortized cost per square meter of processed material decreases substantially at scale.

Energy consumption metrics further differentiate these technologies in industrial contexts. Conventional ALD systems operate with vacuum pumping systems continuously, resulting in energy consumption of approximately 50-100 kWh per 1000 m² of processed area. APALD systems, particularly atmospheric pressure variants, demonstrate 30-40% lower energy requirements per unit area, translating to significant operational cost advantages for high-volume manufacturing.

Maintenance economics also favor APALD for large-area applications. The mechanical simplicity of many APALD reactor designs, with fewer moving parts and vacuum components, results in maintenance costs averaging 15-25% lower than conventional systems over a five-year operational period. This differential expands with increasing deposition area requirements.

Labor productivity metrics reveal that a single operator can manage approximately 2-3 conventional ALD systems simultaneously, while the same operator can oversee 4-6 APALD systems due to higher levels of automation and longer uninterrupted production runs. This operational efficiency translates directly to reduced labor costs per unit area processed.

For manufacturing operations exceeding 10,000 m² of annual production, financial models indicate APALD technologies typically achieve cost parity with conventional ALD within 12-18 months of operation, with accelerating economic advantages thereafter as production volumes increase.

Environmental Impact and Sustainability Considerations

The environmental impact of thin film deposition technologies has become increasingly important as industries strive for more sustainable manufacturing processes. When comparing Atmospheric Pressure Atomic Layer Deposition (APALD) with conventional ALD for large area applications, several significant environmental considerations emerge that influence both current implementation decisions and future development directions.

APALD demonstrates notable environmental advantages through its reduced vacuum requirements. Conventional ALD systems require energy-intensive vacuum pumps that operate continuously during processing, resulting in substantial electricity consumption and associated carbon emissions. In contrast, APALD operates at atmospheric pressure, eliminating the need for these vacuum systems and potentially reducing energy consumption by 30-45% according to recent industry analyses.

Chemical utilization efficiency represents another critical environmental factor. APALD systems typically achieve higher precursor utilization rates—approximately 40-60% compared to conventional ALD's 15-30%—resulting in less chemical waste generation. This efficiency reduces the environmental footprint associated with precursor manufacturing, transportation, and disposal of unused chemicals, which often contain environmentally harmful compounds.

Water consumption patterns differ significantly between these technologies. Conventional ALD systems require substantial water for cooling vacuum pumps and other components, whereas APALD systems generally demonstrate 25-40% lower water requirements. In water-stressed regions, this reduction represents a meaningful sustainability advantage for manufacturing facilities implementing large-area deposition processes.

Waste gas management presents challenges for both technologies but manifests differently. Conventional ALD produces concentrated waste gases that require specialized abatement systems, while APALD generates more dilute emissions that may be easier to filter but larger in volume. Recent developments in catalytic converters specifically designed for APALD systems have improved their environmental performance, reducing harmful emissions by up to 80% compared to earlier implementations.

The lifecycle assessment of equipment also favors APALD for large-area applications. The simpler mechanical design typically results in longer operational lifespans and reduced maintenance requirements, translating to fewer replacement parts and less manufacturing-related environmental impact over time. Studies indicate APALD equipment may have 15-20% longer operational lifespans before requiring major component replacement.

As regulatory frameworks increasingly incorporate carbon pricing and emissions restrictions, the environmental advantages of APALD may translate into direct economic benefits beyond operational cost savings. Companies implementing large-area APALD processes could potentially qualify for sustainability certifications and environmental incentives that enhance market positioning and stakeholder relations while contributing to corporate sustainability goals.

APALD demonstrates notable environmental advantages through its reduced vacuum requirements. Conventional ALD systems require energy-intensive vacuum pumps that operate continuously during processing, resulting in substantial electricity consumption and associated carbon emissions. In contrast, APALD operates at atmospheric pressure, eliminating the need for these vacuum systems and potentially reducing energy consumption by 30-45% according to recent industry analyses.

Chemical utilization efficiency represents another critical environmental factor. APALD systems typically achieve higher precursor utilization rates—approximately 40-60% compared to conventional ALD's 15-30%—resulting in less chemical waste generation. This efficiency reduces the environmental footprint associated with precursor manufacturing, transportation, and disposal of unused chemicals, which often contain environmentally harmful compounds.

Water consumption patterns differ significantly between these technologies. Conventional ALD systems require substantial water for cooling vacuum pumps and other components, whereas APALD systems generally demonstrate 25-40% lower water requirements. In water-stressed regions, this reduction represents a meaningful sustainability advantage for manufacturing facilities implementing large-area deposition processes.

Waste gas management presents challenges for both technologies but manifests differently. Conventional ALD produces concentrated waste gases that require specialized abatement systems, while APALD generates more dilute emissions that may be easier to filter but larger in volume. Recent developments in catalytic converters specifically designed for APALD systems have improved their environmental performance, reducing harmful emissions by up to 80% compared to earlier implementations.

The lifecycle assessment of equipment also favors APALD for large-area applications. The simpler mechanical design typically results in longer operational lifespans and reduced maintenance requirements, translating to fewer replacement parts and less manufacturing-related environmental impact over time. Studies indicate APALD equipment may have 15-20% longer operational lifespans before requiring major component replacement.

As regulatory frameworks increasingly incorporate carbon pricing and emissions restrictions, the environmental advantages of APALD may translate into direct economic benefits beyond operational cost savings. Companies implementing large-area APALD processes could potentially qualify for sustainability certifications and environmental incentives that enhance market positioning and stakeholder relations while contributing to corporate sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!