Design Considerations for Quantum Dot Stability in Cold Forming

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Stability Background and Objectives

Quantum dots (QDs) have emerged as a revolutionary class of semiconductor nanocrystals with unique optical and electronic properties that vary based on their size, shape, and composition. Since their discovery in the 1980s, quantum dots have evolved from laboratory curiosities to critical components in various high-tech applications, including display technologies, photovoltaics, biomedical imaging, and quantum computing. The evolution of quantum dot technology has been marked by significant improvements in synthesis methods, stability enhancement, and integration techniques.

The fundamental challenge in quantum dot applications lies in maintaining their stability during manufacturing processes, particularly in cold forming environments. Cold forming introduces mechanical stresses, temperature fluctuations, and potential chemical interactions that can significantly alter quantum dot properties or lead to their degradation. The stability of quantum dots is primarily governed by their surface chemistry, core-shell structure, and the surrounding matrix material, all of which can be compromised during industrial processing.

Recent technological trends indicate a growing focus on developing quantum dots with enhanced environmental stability, reduced toxicity, and improved quantum yield retention under mechanical stress. The shift from cadmium-based to cadmium-free quantum dots represents a significant trend driven by environmental regulations and safety concerns. Additionally, there is increasing interest in developing quantum dots that maintain their optical properties even after integration into solid-state devices through cold forming processes.

The primary objective of this technical research is to comprehensively evaluate the factors affecting quantum dot stability during cold forming processes and to identify design considerations that can enhance their resilience. Specifically, we aim to investigate the impact of different ligand chemistries, core-shell architectures, and matrix materials on quantum dot stability under mechanical stress and temperature variations typical in cold forming environments.

Furthermore, this research seeks to establish quantitative metrics for assessing quantum dot stability, including photoluminescence quantum yield retention, emission peak shift, and full width at half maximum (FWHM) changes after cold forming. By developing these metrics, we intend to provide a standardized framework for evaluating and comparing different quantum dot formulations for industrial applications requiring cold forming integration.

The ultimate goal is to develop design guidelines that enable the creation of quantum dots with superior stability characteristics specifically tailored for cold forming manufacturing processes, thereby expanding their potential applications in flexible electronics, conformable displays, and other emerging technologies that rely on mechanical forming processes during production.

The fundamental challenge in quantum dot applications lies in maintaining their stability during manufacturing processes, particularly in cold forming environments. Cold forming introduces mechanical stresses, temperature fluctuations, and potential chemical interactions that can significantly alter quantum dot properties or lead to their degradation. The stability of quantum dots is primarily governed by their surface chemistry, core-shell structure, and the surrounding matrix material, all of which can be compromised during industrial processing.

Recent technological trends indicate a growing focus on developing quantum dots with enhanced environmental stability, reduced toxicity, and improved quantum yield retention under mechanical stress. The shift from cadmium-based to cadmium-free quantum dots represents a significant trend driven by environmental regulations and safety concerns. Additionally, there is increasing interest in developing quantum dots that maintain their optical properties even after integration into solid-state devices through cold forming processes.

The primary objective of this technical research is to comprehensively evaluate the factors affecting quantum dot stability during cold forming processes and to identify design considerations that can enhance their resilience. Specifically, we aim to investigate the impact of different ligand chemistries, core-shell architectures, and matrix materials on quantum dot stability under mechanical stress and temperature variations typical in cold forming environments.

Furthermore, this research seeks to establish quantitative metrics for assessing quantum dot stability, including photoluminescence quantum yield retention, emission peak shift, and full width at half maximum (FWHM) changes after cold forming. By developing these metrics, we intend to provide a standardized framework for evaluating and comparing different quantum dot formulations for industrial applications requiring cold forming integration.

The ultimate goal is to develop design guidelines that enable the creation of quantum dots with superior stability characteristics specifically tailored for cold forming manufacturing processes, thereby expanding their potential applications in flexible electronics, conformable displays, and other emerging technologies that rely on mechanical forming processes during production.

Market Analysis for Cold-Formed Quantum Dot Applications

The quantum dot market for cold-forming applications is experiencing significant growth, driven by advancements in display technologies, photovoltaics, and biomedical applications. Current market valuations place the global quantum dot industry at approximately 4.5 billion USD in 2023, with projections indicating a compound annual growth rate of 23.6% through 2030. Cold-formed quantum dot applications represent an emerging segment within this broader market, with particular strength in flexible display technologies and next-generation lighting solutions.

Consumer electronics remains the dominant application sector, accounting for nearly 65% of quantum dot market demand. The display segment specifically has seen rapid adoption of quantum dot technology, with major manufacturers incorporating quantum dot enhancement films (QDEF) into their premium television and monitor lines. Market penetration in this sector continues to accelerate as manufacturing costs decrease and stability issues in cold-forming processes are addressed.

Lighting applications represent the fastest-growing segment for cold-formed quantum dots, with an estimated growth rate of 29% annually. This is primarily driven by the superior color rendering capabilities and energy efficiency of quantum dot-enhanced LED lighting. Commercial adoption has begun in high-end retail, museum, and hospitality settings where precise color reproduction is valued.

The photovoltaic sector presents substantial long-term market potential for cold-formed quantum dots, though current market share remains below 8%. Research indicates that quantum dot solar cells could potentially achieve theoretical efficiency limits approaching 66%, significantly outperforming conventional silicon technologies. However, stability challenges in cold-forming processes have limited commercial deployment to date.

Regional analysis reveals Asia-Pacific as the dominant market for cold-formed quantum dot applications, accounting for approximately 58% of global demand. This concentration is primarily due to the region's robust display manufacturing infrastructure. North America follows at 22%, with particularly strong research activity in biomedical applications of cold-formed quantum dots.

Market barriers include persistent concerns regarding the environmental impact of cadmium-based quantum dots, though cadmium-free alternatives are gaining traction. Price sensitivity remains a significant factor, with quantum dot materials commanding premium pricing compared to conventional alternatives. Manufacturing scalability for cold-forming processes represents another key challenge, with current production volumes insufficient to meet projected demand growth.

Customer adoption patterns indicate a willingness to pay premium prices for quantum dot-enhanced products when tangible benefits in color reproduction, energy efficiency, or form factor are demonstrated. This suggests that addressing stability issues in cold-forming processes could unlock significant market value by enabling new product categories and applications previously constrained by manufacturing limitations.

Consumer electronics remains the dominant application sector, accounting for nearly 65% of quantum dot market demand. The display segment specifically has seen rapid adoption of quantum dot technology, with major manufacturers incorporating quantum dot enhancement films (QDEF) into their premium television and monitor lines. Market penetration in this sector continues to accelerate as manufacturing costs decrease and stability issues in cold-forming processes are addressed.

Lighting applications represent the fastest-growing segment for cold-formed quantum dots, with an estimated growth rate of 29% annually. This is primarily driven by the superior color rendering capabilities and energy efficiency of quantum dot-enhanced LED lighting. Commercial adoption has begun in high-end retail, museum, and hospitality settings where precise color reproduction is valued.

The photovoltaic sector presents substantial long-term market potential for cold-formed quantum dots, though current market share remains below 8%. Research indicates that quantum dot solar cells could potentially achieve theoretical efficiency limits approaching 66%, significantly outperforming conventional silicon technologies. However, stability challenges in cold-forming processes have limited commercial deployment to date.

Regional analysis reveals Asia-Pacific as the dominant market for cold-formed quantum dot applications, accounting for approximately 58% of global demand. This concentration is primarily due to the region's robust display manufacturing infrastructure. North America follows at 22%, with particularly strong research activity in biomedical applications of cold-formed quantum dots.

Market barriers include persistent concerns regarding the environmental impact of cadmium-based quantum dots, though cadmium-free alternatives are gaining traction. Price sensitivity remains a significant factor, with quantum dot materials commanding premium pricing compared to conventional alternatives. Manufacturing scalability for cold-forming processes represents another key challenge, with current production volumes insufficient to meet projected demand growth.

Customer adoption patterns indicate a willingness to pay premium prices for quantum dot-enhanced products when tangible benefits in color reproduction, energy efficiency, or form factor are demonstrated. This suggests that addressing stability issues in cold-forming processes could unlock significant market value by enabling new product categories and applications previously constrained by manufacturing limitations.

Current Challenges in Quantum Dot Stability During Cold Forming

Quantum dot stability during cold forming processes presents significant technical challenges that must be addressed to enable widespread industrial adoption. The inherent sensitivity of quantum dots to mechanical stress, temperature fluctuations, and chemical environments creates a complex matrix of stability issues during manufacturing operations.

The primary challenge lies in maintaining the structural integrity of quantum dots when subjected to the high pressures characteristic of cold forming processes. Research indicates that pressures exceeding 200 MPa can induce lattice deformations in conventional CdSe/ZnS quantum dots, resulting in altered bandgap properties and diminished quantum yield. These structural changes directly impact the optical and electronic properties that make quantum dots valuable in applications ranging from displays to photovoltaics.

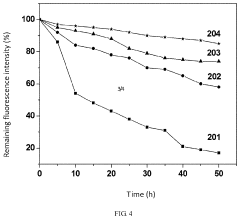

Surface ligand displacement represents another critical challenge. During cold forming, the shear forces can strip or rearrange the organic ligands that passivate quantum dot surfaces. This ligand disruption exposes core materials to oxidation and creates surface trap states that significantly reduce photoluminescence efficiency. Studies have documented quantum yield reductions of up to 60% following cold forming processes without appropriate stabilization strategies.

Matrix compatibility issues further complicate quantum dot integration. The polymer or resin matrices commonly used in cold forming applications often exhibit poor compatibility with quantum dot surface chemistry, leading to aggregation and phase separation. This non-uniform distribution creates "hot spots" of quantum dot concentration that exhibit inconsistent optical properties and accelerated degradation pathways.

Temperature management during cold forming presents a paradoxical challenge. While "cold" forming operates below recrystallization temperatures, local temperature increases from deformation energy can still reach levels that compromise quantum dot stability. For InP-based quantum dots, temperature spikes above 120°C during forming can trigger irreversible core/shell interdiffusion, permanently altering emission characteristics.

Chemical stability concerns also emerge during processing. Exposure to oxygen, moisture, and reactive species in processing environments can catalyze oxidation of quantum dot surfaces. This is particularly problematic for materials like PbS and PbSe quantum dots, where surface oxidation can progress rapidly under mechanical stress, creating deep trap states that quench luminescence.

Scale-up challenges compound these technical issues. Laboratory-scale stabilization techniques often prove impractical or prohibitively expensive at industrial production volumes. The development of cost-effective stabilization approaches that can be implemented in high-throughput manufacturing environments remains an active research frontier with significant economic implications.

The primary challenge lies in maintaining the structural integrity of quantum dots when subjected to the high pressures characteristic of cold forming processes. Research indicates that pressures exceeding 200 MPa can induce lattice deformations in conventional CdSe/ZnS quantum dots, resulting in altered bandgap properties and diminished quantum yield. These structural changes directly impact the optical and electronic properties that make quantum dots valuable in applications ranging from displays to photovoltaics.

Surface ligand displacement represents another critical challenge. During cold forming, the shear forces can strip or rearrange the organic ligands that passivate quantum dot surfaces. This ligand disruption exposes core materials to oxidation and creates surface trap states that significantly reduce photoluminescence efficiency. Studies have documented quantum yield reductions of up to 60% following cold forming processes without appropriate stabilization strategies.

Matrix compatibility issues further complicate quantum dot integration. The polymer or resin matrices commonly used in cold forming applications often exhibit poor compatibility with quantum dot surface chemistry, leading to aggregation and phase separation. This non-uniform distribution creates "hot spots" of quantum dot concentration that exhibit inconsistent optical properties and accelerated degradation pathways.

Temperature management during cold forming presents a paradoxical challenge. While "cold" forming operates below recrystallization temperatures, local temperature increases from deformation energy can still reach levels that compromise quantum dot stability. For InP-based quantum dots, temperature spikes above 120°C during forming can trigger irreversible core/shell interdiffusion, permanently altering emission characteristics.

Chemical stability concerns also emerge during processing. Exposure to oxygen, moisture, and reactive species in processing environments can catalyze oxidation of quantum dot surfaces. This is particularly problematic for materials like PbS and PbSe quantum dots, where surface oxidation can progress rapidly under mechanical stress, creating deep trap states that quench luminescence.

Scale-up challenges compound these technical issues. Laboratory-scale stabilization techniques often prove impractical or prohibitively expensive at industrial production volumes. The development of cost-effective stabilization approaches that can be implemented in high-throughput manufacturing environments remains an active research frontier with significant economic implications.

Current Technical Solutions for Quantum Dot Stability Enhancement

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help to prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

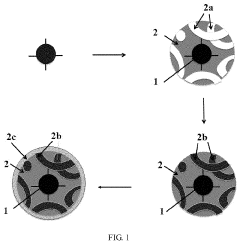

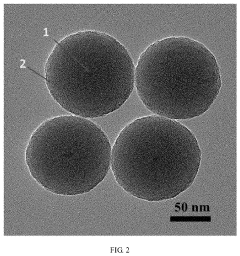

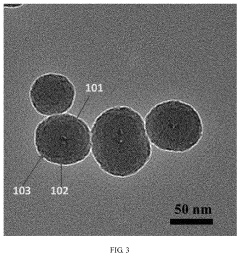

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. This architecture also improves quantum yield and reduces surface defects, resulting in quantum dots with superior optical properties and enhanced resistance to photo-oxidation and thermal degradation.

- Polymer encapsulation for quantum dot stabilization: Polymer encapsulation provides an effective method for stabilizing quantum dots in various environments. By embedding quantum dots within polymer matrices or coating them with polymer layers, their susceptibility to degradation from oxygen, moisture, and light exposure is significantly reduced. This approach also enables better dispersion in different media and prevents aggregation, making the quantum dots more suitable for applications in displays, biomedical imaging, and sensing technologies.

- Ligand chemistry for quantum dot stability enhancement: The choice and design of surface ligands play a crucial role in quantum dot stability. Ligands with strong binding affinity to the quantum dot surface can prevent detachment and subsequent degradation. Multidentate ligands, polymeric ligands, and specially designed organic molecules can provide superior surface passivation, reducing surface defects and enhancing resistance to environmental factors. Proper ligand engineering also improves colloidal stability in various solvents and prevents aggregation.

- Environmental factors affecting quantum dot stability: Various environmental factors significantly impact quantum dot stability, including exposure to oxygen, moisture, heat, and light. Understanding these factors is essential for developing effective stabilization strategies. Research has shown that controlling storage conditions, using oxygen scavengers, and incorporating UV absorbers can extend quantum dot lifetime. Additionally, pH control and ionic strength management in solution-based applications are critical for maintaining long-term stability and preventing degradation of optical properties.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing a protective layer around the core material. The shell material, often composed of wider bandgap semiconductors, shields the core from environmental factors while maintaining the desired optical and electronic properties. This architecture reduces surface defects and prevents degradation, resulting in quantum dots with superior stability under various operating conditions.Expand Specific Solutions03 Encapsulation methods for quantum dot protection

Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials provides enhanced environmental stability. These encapsulation methods create physical barriers that protect quantum dots from oxygen, moisture, and other degrading factors. The encapsulating materials can be tailored to specific applications while maintaining the optical properties of the quantum dots and extending their operational lifetime.Expand Specific Solutions04 Synthesis parameters affecting quantum dot stability

The stability of quantum dots is significantly influenced by synthesis parameters including temperature, reaction time, precursor ratios, and solvent choice. Optimizing these parameters can lead to quantum dots with fewer defects, more uniform size distribution, and better crystallinity. Controlled synthesis conditions result in quantum dots with enhanced thermal, chemical, and photostability, making them more reliable for various applications.Expand Specific Solutions05 Stabilization additives and ligand engineering

Specific additives and carefully engineered ligands can dramatically improve quantum dot stability. These include antioxidants, free radical scavengers, and specially designed coordinating ligands that bind strongly to the quantum dot surface. Such additives prevent degradation mechanisms like photooxidation and ligand detachment, while maintaining colloidal stability and preventing aggregation in various media, thereby extending the functional lifetime of quantum dot-based devices.Expand Specific Solutions

Leading Companies and Research Institutions in Quantum Dot Technology

The quantum dot stability in cold forming technology landscape is currently in an early growth phase, characterized by significant R&D investments but limited commercial applications. The market is projected to expand rapidly as quantum dot technology matures, with applications spanning displays, lighting, and photovoltaics. Leading players demonstrate varying levels of technical maturity: Mojo Vision has pioneered micro-LED display integration with proprietary quantum-dot technology; Najing Technology focuses on advanced semiconductor nanocrystal platforms; Samsung and TCL are leveraging quantum dots for next-generation displays; while academic institutions like Xiamen University and Shanghai Jiao Tong University contribute fundamental research. Specialized firms like Qustomdot and Wuxi UtmoLight are developing application-specific solutions, indicating a diversifying competitive landscape with both established electronics giants and emerging materials specialists.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered a comprehensive approach to quantum dot stability in cold forming processes, particularly for their QLED display technology. Their design considerations focus on a multi-layered protection strategy that begins with core-shell quantum dot structures where the emissive core is surrounded by a wider-bandgap semiconductor shell that provides electronic and chemical isolation. For cold forming applications, Samsung has developed temperature-adaptive ligand systems that maintain QD dispersion and prevent aggregation at low temperatures. Their process incorporates specialized siloxane-based encapsulation materials that form strong covalent bonds with the QD surface ligands while remaining flexible at reduced temperatures. Samsung's cold-forming protocol utilizes controlled atmosphere processing with precise oxygen and moisture levels below 1ppm to prevent oxidative degradation. Additionally, they've implemented gradient temperature transitions during manufacturing to minimize thermal shock to the quantum dot structures, with cooling rates carefully optimized at 1-2°C per minute to prevent stress-induced defects.

Strengths: Extensive manufacturing infrastructure allows for precise control of processing parameters, resulting in highly consistent QD performance. Their approach enables large-scale production with high yield rates for commercial display applications. Weaknesses: The complex multi-step protection system increases production complexity and potentially raises manufacturing costs. Their approach may be optimized specifically for display applications and might require significant modification for other quantum dot applications like sensing or photovoltaics.

FUJIFILM Corp.

Technical Solution: FUJIFILM has developed an innovative approach to quantum dot stability during cold forming processes, leveraging their extensive expertise in film technology and nanomaterials. Their technique centers on a proprietary polymer-QD composite system specifically engineered for low-temperature processing. FUJIFILM's method employs amphiphilic block copolymers that form micelle-like structures around individual quantum dots, creating nanoscale protective environments that shield QDs from environmental stressors. These polymer shells are designed with functional groups that interact favorably with the QD surface ligands while presenting compatible interfaces to the host matrix material. For cold forming applications, FUJIFILM utilizes a gradual solvent exchange process that slowly transitions the QDs from solution to solid state without thermal stress. Their research has demonstrated that controlling the rate of solvent removal is critical, with optimal processing occurring over 12-24 hours to allow polymer chains to achieve equilibrium configurations around the QDs. Additionally, FUJIFILM incorporates UV-curable components that can be solidified through photopolymerization rather than thermal curing, eliminating thermal degradation pathways entirely.

Strengths: The polymer-based approach provides excellent compatibility with flexible substrates and roll-to-roll manufacturing processes, enabling large-area applications. Their photopolymerization technique eliminates thermal stress entirely, preserving QD optical properties. Weaknesses: The extended processing time for optimal solvent exchange may limit production throughput compared to faster thermal methods. The complex polymer chemistry may introduce additional variables that affect batch-to-batch consistency.

Key Patents and Research on Cold-Resistant Quantum Dot Formulations

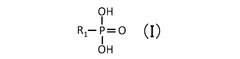

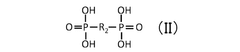

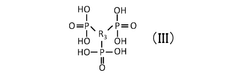

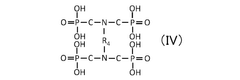

Quantum dot body, quantum dot composition, and wavelength conversion material and production method thereof

PatentWO2025088985A1

Innovation

- A quantum dot body is developed with a core-shell structure of semiconductor nanoparticles, coated with a metal oxide and modified with a phosphonic acid derivative, and further encapsulated in a polymer coating layer. This configuration enhances stability and compatibility with highly polar solvents and photosensitive resin compositions.

Core-shell type quantum dot, preparation method and use thereof

PatentActiveUS20220025253A9

Innovation

- A core-shell type quantum dot is developed with a light-transmitting inorganic mesoporous material layer and a filler in its mesopores, which provides improved optical and chemical stability by isolating the quantum dot core from external moisture and oxygen, and optionally includes a metal oxide passivation layer for further protection.

Material Science Considerations for Quantum Dot-Matrix Interactions

The interaction between quantum dots and their host matrix materials represents a critical factor in determining the overall stability and performance of quantum dot systems during cold forming processes. The matrix material serves as both a protective environment and a functional component that directly influences the electronic, optical, and mechanical properties of the embedded quantum dots.

Matrix materials must possess specific physical and chemical characteristics to maintain quantum dot integrity during cold forming. Polymeric matrices such as polyethylene, polystyrene, and poly(methyl methacrylate) offer flexibility and processability advantages but may permit oxygen diffusion that leads to oxidative degradation of quantum dots. Conversely, inorganic matrices like silica and alumina provide superior barrier properties against environmental contaminants but introduce challenges related to brittleness and processing limitations.

The interface between quantum dots and the matrix material constitutes a crucial region where surface chemistry plays a determinant role. Surface ligands on quantum dots not only passivate dangling bonds but also mediate compatibility with the surrounding matrix. Long-chain organic ligands typically enhance dispersibility in polymeric matrices, while shorter ligands or inorganic shells may improve integration with ceramic or glass-based matrices.

Mechanical stress transfer during cold forming processes must be carefully managed through matrix selection. Viscoelastic properties of the matrix determine how external forces propagate to the quantum dots. Matrices with appropriate modulus values can absorb and redistribute stress, preventing localized pressure points that might compromise quantum dot structural integrity or alter their optoelectronic properties through strain-induced band gap modifications.

Thermal expansion coefficient matching between quantum dots and matrix materials represents another critical consideration. Even in cold forming processes, localized temperature variations can occur, and mismatched thermal expansion coefficients generate internal stresses that may lead to delamination, cracking, or quantum dot displacement within the matrix.

Recent advances in nanocomposite science have introduced gradient interface designs where the mechanical and chemical properties transition gradually between the quantum dot surface and bulk matrix material. This approach minimizes abrupt property changes that typically concentrate stress and serve as failure initiation points. Additionally, self-healing matrix materials incorporating dynamic covalent bonds or supramolecular interactions show promise for applications where quantum dots must withstand repeated mechanical deformation cycles.

Matrix materials must possess specific physical and chemical characteristics to maintain quantum dot integrity during cold forming. Polymeric matrices such as polyethylene, polystyrene, and poly(methyl methacrylate) offer flexibility and processability advantages but may permit oxygen diffusion that leads to oxidative degradation of quantum dots. Conversely, inorganic matrices like silica and alumina provide superior barrier properties against environmental contaminants but introduce challenges related to brittleness and processing limitations.

The interface between quantum dots and the matrix material constitutes a crucial region where surface chemistry plays a determinant role. Surface ligands on quantum dots not only passivate dangling bonds but also mediate compatibility with the surrounding matrix. Long-chain organic ligands typically enhance dispersibility in polymeric matrices, while shorter ligands or inorganic shells may improve integration with ceramic or glass-based matrices.

Mechanical stress transfer during cold forming processes must be carefully managed through matrix selection. Viscoelastic properties of the matrix determine how external forces propagate to the quantum dots. Matrices with appropriate modulus values can absorb and redistribute stress, preventing localized pressure points that might compromise quantum dot structural integrity or alter their optoelectronic properties through strain-induced band gap modifications.

Thermal expansion coefficient matching between quantum dots and matrix materials represents another critical consideration. Even in cold forming processes, localized temperature variations can occur, and mismatched thermal expansion coefficients generate internal stresses that may lead to delamination, cracking, or quantum dot displacement within the matrix.

Recent advances in nanocomposite science have introduced gradient interface designs where the mechanical and chemical properties transition gradually between the quantum dot surface and bulk matrix material. This approach minimizes abrupt property changes that typically concentrate stress and serve as failure initiation points. Additionally, self-healing matrix materials incorporating dynamic covalent bonds or supramolecular interactions show promise for applications where quantum dots must withstand repeated mechanical deformation cycles.

Environmental and Safety Implications of Quantum Dot Manufacturing

The manufacturing processes for quantum dots involve various chemicals and materials that pose significant environmental and safety concerns. Heavy metals such as cadmium, lead, selenium, and indium are commonly used in quantum dot synthesis, presenting substantial toxicity risks. These materials can bioaccumulate in living organisms and persist in the environment for extended periods, potentially causing long-term ecological damage if improperly managed.

Production facilities must implement comprehensive waste management protocols to prevent the release of these hazardous substances into water systems and soil. Advanced filtration systems, chemical precipitation methods, and specialized containment procedures are essential for preventing environmental contamination. The semiconductor industry's established protocols for handling toxic materials provide valuable frameworks that quantum dot manufacturers can adapt and enhance.

Worker safety represents another critical dimension of quantum dot manufacturing. Exposure to nanoparticles through inhalation, dermal contact, or accidental ingestion presents unique occupational hazards. The small size of quantum dots allows them to penetrate biological barriers more easily than larger particles, potentially causing cellular damage and inflammatory responses. Manufacturing facilities must therefore implement rigorous engineering controls including specialized ventilation systems, enclosed production environments, and automated handling processes to minimize human exposure.

Regulatory frameworks governing quantum dot production vary significantly across regions, creating compliance challenges for global manufacturers. The European Union's REACH regulations and RoHS directive impose strict limitations on heavy metal content in electronic products, directly impacting quantum dot applications. In the United States, the EPA and OSHA provide oversight through various regulations addressing nanomaterials and hazardous substances, though specific quantum dot regulations remain under development.

Sustainable manufacturing approaches are emerging as industry priorities, with green chemistry principles increasingly applied to quantum dot synthesis. Alternative synthesis routes using less toxic precursors, aqueous-based processes, and lower energy requirements are being developed. Some researchers have successfully created cadmium-free quantum dots using indium phosphide, zinc selenide, or carbon-based materials, though these alternatives often face challenges in matching the optical performance of traditional formulations.

Life cycle assessment studies indicate that the environmental footprint of quantum dot manufacturing extends beyond production to include raw material extraction, energy consumption, and end-of-life disposal considerations. As quantum dot applications expand into consumer electronics, medical devices, and energy systems, developing comprehensive recycling and recovery methods becomes increasingly important to mitigate environmental impacts and recover valuable materials from discarded products.

Production facilities must implement comprehensive waste management protocols to prevent the release of these hazardous substances into water systems and soil. Advanced filtration systems, chemical precipitation methods, and specialized containment procedures are essential for preventing environmental contamination. The semiconductor industry's established protocols for handling toxic materials provide valuable frameworks that quantum dot manufacturers can adapt and enhance.

Worker safety represents another critical dimension of quantum dot manufacturing. Exposure to nanoparticles through inhalation, dermal contact, or accidental ingestion presents unique occupational hazards. The small size of quantum dots allows them to penetrate biological barriers more easily than larger particles, potentially causing cellular damage and inflammatory responses. Manufacturing facilities must therefore implement rigorous engineering controls including specialized ventilation systems, enclosed production environments, and automated handling processes to minimize human exposure.

Regulatory frameworks governing quantum dot production vary significantly across regions, creating compliance challenges for global manufacturers. The European Union's REACH regulations and RoHS directive impose strict limitations on heavy metal content in electronic products, directly impacting quantum dot applications. In the United States, the EPA and OSHA provide oversight through various regulations addressing nanomaterials and hazardous substances, though specific quantum dot regulations remain under development.

Sustainable manufacturing approaches are emerging as industry priorities, with green chemistry principles increasingly applied to quantum dot synthesis. Alternative synthesis routes using less toxic precursors, aqueous-based processes, and lower energy requirements are being developed. Some researchers have successfully created cadmium-free quantum dots using indium phosphide, zinc selenide, or carbon-based materials, though these alternatives often face challenges in matching the optical performance of traditional formulations.

Life cycle assessment studies indicate that the environmental footprint of quantum dot manufacturing extends beyond production to include raw material extraction, energy consumption, and end-of-life disposal considerations. As quantum dot applications expand into consumer electronics, medical devices, and energy systems, developing comprehensive recycling and recovery methods becomes increasingly important to mitigate environmental impacts and recover valuable materials from discarded products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!