Quantum Dot Stability in Additive Manufacturing Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Background and Objectives

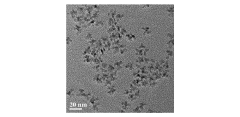

Quantum dots (QDs) represent a revolutionary class of semiconductor nanocrystals that have emerged as transformative materials in various technological applications over the past three decades. These nanoscale particles, typically ranging from 2 to 10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. Since their initial discovery in the 1980s, quantum dots have evolved from laboratory curiosities to commercially viable materials with applications spanning display technologies, biomedical imaging, solar cells, and more recently, additive manufacturing.

The integration of quantum dots into additive manufacturing processes presents both unprecedented opportunities and significant challenges. Historically, quantum dot technology has progressed through several key developmental phases: from fundamental research in the 1980s and 1990s, to early commercialization in the 2000s, to today's advanced applications across multiple industries. This technological evolution has been characterized by continuous improvements in synthesis methods, surface chemistry, and stability control.

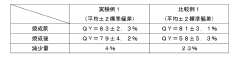

The primary objective in addressing quantum dot stability in additive manufacturing applications is to overcome the inherent vulnerability of these nanostructures to environmental factors while maintaining their exceptional optical and electronic properties. Quantum dots typically suffer from degradation when exposed to heat, oxygen, moisture, and UV radiation—all conditions commonly encountered in additive manufacturing processes. This degradation manifests as decreased quantum yield, spectral shifts, and ultimately, loss of functionality.

Current technological goals focus on developing quantum dot formulations with enhanced thermal stability to withstand the high-temperature conditions of various 3D printing techniques, including fused deposition modeling, stereolithography, and selective laser sintering. Additionally, research aims to create effective encapsulation strategies that shield quantum dots from oxidative degradation while preserving their ability to interact with light and electricity in desired ways.

The trajectory of quantum dot technology suggests a convergence toward multifunctional materials that can simultaneously provide structural, optical, and electronic functionalities in additively manufactured components. This convergence represents a paradigm shift from traditional manufacturing approaches, where functional properties are typically added post-production, to integrated processes where functionality is built directly into the structure during fabrication.

As quantum dot technology continues to mature, the focus increasingly shifts toward scalable, cost-effective production methods that can deliver consistent performance in real-world applications. This evolution necessitates interdisciplinary collaboration between materials scientists, chemical engineers, and manufacturing specialists to overcome the complex challenges of quantum dot stability in dynamic processing environments.

The integration of quantum dots into additive manufacturing processes presents both unprecedented opportunities and significant challenges. Historically, quantum dot technology has progressed through several key developmental phases: from fundamental research in the 1980s and 1990s, to early commercialization in the 2000s, to today's advanced applications across multiple industries. This technological evolution has been characterized by continuous improvements in synthesis methods, surface chemistry, and stability control.

The primary objective in addressing quantum dot stability in additive manufacturing applications is to overcome the inherent vulnerability of these nanostructures to environmental factors while maintaining their exceptional optical and electronic properties. Quantum dots typically suffer from degradation when exposed to heat, oxygen, moisture, and UV radiation—all conditions commonly encountered in additive manufacturing processes. This degradation manifests as decreased quantum yield, spectral shifts, and ultimately, loss of functionality.

Current technological goals focus on developing quantum dot formulations with enhanced thermal stability to withstand the high-temperature conditions of various 3D printing techniques, including fused deposition modeling, stereolithography, and selective laser sintering. Additionally, research aims to create effective encapsulation strategies that shield quantum dots from oxidative degradation while preserving their ability to interact with light and electricity in desired ways.

The trajectory of quantum dot technology suggests a convergence toward multifunctional materials that can simultaneously provide structural, optical, and electronic functionalities in additively manufactured components. This convergence represents a paradigm shift from traditional manufacturing approaches, where functional properties are typically added post-production, to integrated processes where functionality is built directly into the structure during fabrication.

As quantum dot technology continues to mature, the focus increasingly shifts toward scalable, cost-effective production methods that can deliver consistent performance in real-world applications. This evolution necessitates interdisciplinary collaboration between materials scientists, chemical engineers, and manufacturing specialists to overcome the complex challenges of quantum dot stability in dynamic processing environments.

Market Analysis for QD-Enhanced Additive Manufacturing

The quantum dot (QD) enhanced additive manufacturing market is experiencing significant growth, driven by the unique optical, electronic, and mechanical properties that quantum dots bring to 3D printed materials. Current market analysis indicates that the global market for QD-enhanced additive manufacturing was valued at approximately $1.2 billion in 2022 and is projected to reach $4.5 billion by 2028, representing a compound annual growth rate of 24.7%.

The primary market segments adopting this technology include electronics manufacturing, healthcare devices, automotive components, and advanced optoelectronic applications. Electronics manufacturing currently holds the largest market share at 38%, followed by healthcare at 27%, automotive at 21%, and other applications comprising the remaining 14%. This distribution reflects the versatility of QD technology across multiple industries.

Regional analysis shows North America leading the market with 42% share, followed by Asia-Pacific at 35%, Europe at 18%, and rest of the world at 5%. The Asia-Pacific region, particularly China, South Korea, and Japan, is expected to witness the fastest growth due to expanding electronics manufacturing capabilities and increasing R&D investments in quantum technologies.

Customer demand is primarily driven by the need for enhanced material properties, including improved electrical conductivity, optical performance, and mechanical strength in 3D printed components. End-users are particularly interested in QD-enhanced materials that can maintain stability under various environmental conditions, addressing a critical pain point in current applications.

Market research indicates that price sensitivity varies significantly across application segments. High-value sectors like medical devices and aerospace are willing to pay premium prices for QD-enhanced materials that offer superior performance and reliability, while consumer electronics manufacturers are more price-conscious despite requiring high volumes.

Key market restraints include concerns about long-term stability of quantum dots in polymer matrices, regulatory uncertainties regarding nanomaterials, and the relatively high cost of QD production. These factors are currently limiting broader market penetration, particularly in cost-sensitive applications.

Future market growth is expected to be driven by technological advancements in QD synthesis methods that improve stability and reduce production costs, expanding applications in emerging fields such as wearable technology and smart packaging, and increasing adoption of additive manufacturing across industries. The development of QD formulations specifically optimized for different 3D printing technologies represents a significant market opportunity with potential to unlock new application areas.

The primary market segments adopting this technology include electronics manufacturing, healthcare devices, automotive components, and advanced optoelectronic applications. Electronics manufacturing currently holds the largest market share at 38%, followed by healthcare at 27%, automotive at 21%, and other applications comprising the remaining 14%. This distribution reflects the versatility of QD technology across multiple industries.

Regional analysis shows North America leading the market with 42% share, followed by Asia-Pacific at 35%, Europe at 18%, and rest of the world at 5%. The Asia-Pacific region, particularly China, South Korea, and Japan, is expected to witness the fastest growth due to expanding electronics manufacturing capabilities and increasing R&D investments in quantum technologies.

Customer demand is primarily driven by the need for enhanced material properties, including improved electrical conductivity, optical performance, and mechanical strength in 3D printed components. End-users are particularly interested in QD-enhanced materials that can maintain stability under various environmental conditions, addressing a critical pain point in current applications.

Market research indicates that price sensitivity varies significantly across application segments. High-value sectors like medical devices and aerospace are willing to pay premium prices for QD-enhanced materials that offer superior performance and reliability, while consumer electronics manufacturers are more price-conscious despite requiring high volumes.

Key market restraints include concerns about long-term stability of quantum dots in polymer matrices, regulatory uncertainties regarding nanomaterials, and the relatively high cost of QD production. These factors are currently limiting broader market penetration, particularly in cost-sensitive applications.

Future market growth is expected to be driven by technological advancements in QD synthesis methods that improve stability and reduce production costs, expanding applications in emerging fields such as wearable technology and smart packaging, and increasing adoption of additive manufacturing across industries. The development of QD formulations specifically optimized for different 3D printing technologies represents a significant market opportunity with potential to unlock new application areas.

Current Challenges in QD Stability for 3D Printing

Despite significant advancements in quantum dot (QD) technology, their integration into additive manufacturing processes faces several critical stability challenges. The primary concern is thermal degradation during the printing process, as most 3D printing techniques involve high temperatures (ranging from 180°C to 300°C for FDM printing) that can destabilize QDs, leading to reduced quantum yield and altered optical properties. This thermal sensitivity significantly limits the types of printing technologies compatible with QD materials.

Chemical stability presents another major hurdle, particularly in polymer-based printing materials. QDs often react with functional groups in photopolymers and thermoplastics, causing surface oxidation and degradation of the nanocrystal structure. This reactivity not only diminishes the luminescent properties but also affects the long-term stability of printed objects, with degradation observable within weeks under normal environmental conditions.

Photostability issues emerge when QDs are exposed to UV light during certain printing processes, especially in SLA and DLP technologies. Continuous UV exposure can trigger photobleaching and photodegradation, resulting in diminished optical performance. Studies indicate that unprotected QDs can lose up to 60% of their initial luminescence intensity after just 24 hours of UV exposure during processing.

Aggregation tendency represents a persistent challenge in maintaining QD stability. During the printing process, QDs frequently form clusters due to van der Waals forces and surface interactions, particularly at higher concentrations necessary for effective functionality. This aggregation disrupts the quantum confinement effect, causing red-shifting of emission wavelengths and reduced quantum efficiency, ultimately compromising the precision of color reproduction in final printed products.

Environmental sensitivity further complicates QD integration, as exposure to oxygen and moisture during and after printing can accelerate degradation processes. Current encapsulation methods provide insufficient protection against these environmental factors, with humidity levels above 60% showing measurable degradation effects within days.

The challenge of uniform dispersion remains largely unsolved, as achieving homogeneous distribution of QDs throughout printing materials is technically difficult. Current mixing and dispersion techniques result in concentration gradients and "hot spots" within printed objects, leading to inconsistent optical and electronic properties across the printed structure.

These stability challenges collectively represent significant barriers to the widespread adoption of QDs in additive manufacturing applications, necessitating innovative approaches to QD surface engineering, encapsulation strategies, and printing process modifications to realize the full potential of these nanomaterials in 3D printing technologies.

Chemical stability presents another major hurdle, particularly in polymer-based printing materials. QDs often react with functional groups in photopolymers and thermoplastics, causing surface oxidation and degradation of the nanocrystal structure. This reactivity not only diminishes the luminescent properties but also affects the long-term stability of printed objects, with degradation observable within weeks under normal environmental conditions.

Photostability issues emerge when QDs are exposed to UV light during certain printing processes, especially in SLA and DLP technologies. Continuous UV exposure can trigger photobleaching and photodegradation, resulting in diminished optical performance. Studies indicate that unprotected QDs can lose up to 60% of their initial luminescence intensity after just 24 hours of UV exposure during processing.

Aggregation tendency represents a persistent challenge in maintaining QD stability. During the printing process, QDs frequently form clusters due to van der Waals forces and surface interactions, particularly at higher concentrations necessary for effective functionality. This aggregation disrupts the quantum confinement effect, causing red-shifting of emission wavelengths and reduced quantum efficiency, ultimately compromising the precision of color reproduction in final printed products.

Environmental sensitivity further complicates QD integration, as exposure to oxygen and moisture during and after printing can accelerate degradation processes. Current encapsulation methods provide insufficient protection against these environmental factors, with humidity levels above 60% showing measurable degradation effects within days.

The challenge of uniform dispersion remains largely unsolved, as achieving homogeneous distribution of QDs throughout printing materials is technically difficult. Current mixing and dispersion techniques result in concentration gradients and "hot spots" within printed objects, leading to inconsistent optical and electronic properties across the printed structure.

These stability challenges collectively represent significant barriers to the widespread adoption of QDs in additive manufacturing applications, necessitating innovative approaches to QD surface engineering, encapsulation strategies, and printing process modifications to realize the full potential of these nanomaterials in 3D printing technologies.

Current Stabilization Techniques for QDs in Printing Materials

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

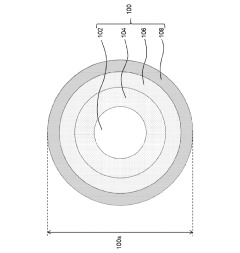

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core quantum dot to prevent degradation. Multi-shell structures can further improve stability by gradually transitioning between materials with different lattice constants, reducing strain and enhancing photoluminescence stability over time.

- Environmental stability factors for quantum dots: Quantum dots are sensitive to various environmental factors that can affect their stability. These include exposure to oxygen, moisture, heat, and light, which can lead to oxidation, degradation, and loss of optical properties. Understanding and controlling these environmental factors is crucial for maintaining the stability of quantum dots in different applications and storage conditions.

- Polymer encapsulation for quantum dot stabilization: Polymer encapsulation provides an effective method for stabilizing quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or encapsulating them with specific polymers, their resistance to oxidation, moisture, and mechanical stress can be significantly improved. This approach also enables better dispersion in various media and prevents aggregation, leading to enhanced stability and longer functional lifetimes.

- Manufacturing processes affecting quantum dot stability: The stability of quantum dots is significantly influenced by their manufacturing processes. Parameters such as synthesis temperature, reaction time, precursor ratios, and purification methods directly impact the crystallinity, defect density, and surface properties of quantum dots. Optimized manufacturing processes can yield quantum dots with fewer defects, more uniform size distribution, and better surface passivation, all contributing to enhanced stability and performance.

02 Core-shell structures for enhanced quantum dot stability

Core-shell quantum dot structures significantly improve stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core quantum dot to prevent oxidation and leaching of core materials. This architecture maintains optical properties while enhancing chemical stability, thermal resistance, and photostability under continuous illumination conditions.Expand Specific Solutions03 Polymer encapsulation methods for quantum dot stabilization

Polymer encapsulation provides an effective approach to stabilize quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, these methods create protective barriers that shield the nanoparticles from oxygen, moisture, and other reactive species. The polymer encapsulation also prevents aggregation and can be tailored to enhance compatibility with specific applications.Expand Specific Solutions04 Environmental factors affecting quantum dot stability

Multiple environmental factors significantly impact quantum dot stability, including exposure to oxygen, moisture, light, temperature fluctuations, and pH variations. These factors can trigger oxidation of surface atoms, ligand detachment, and structural degradation, leading to diminished optical properties and quantum yield. Understanding these environmental influences is crucial for developing effective stabilization strategies and appropriate storage conditions.Expand Specific Solutions05 Manufacturing processes to improve quantum dot stability

Advanced manufacturing processes can significantly enhance quantum dot stability. These include precise control of synthesis parameters, post-synthesis treatments, purification techniques, and specialized doping methods. Optimized manufacturing protocols can reduce defects, improve crystallinity, and create more uniform quantum dot populations with consistent properties, resulting in nanoparticles with superior stability characteristics for various applications.Expand Specific Solutions

Leading Companies in QD and Additive Manufacturing

Quantum Dot Stability in Additive Manufacturing is currently in an early growth phase, with the market expected to expand significantly due to increasing applications in displays, lighting, and biomedical sectors. The global market is projected to reach several billion dollars by 2028, driven by demand for high-performance materials with enhanced stability. Technologically, the field remains in development with key players at different maturity levels. Samsung Electronics and TCL Research lead in display applications, while Nanosys and Mojo Vision have made significant advances in quantum dot stability. Companies like 3M and LG Chem are leveraging their materials expertise to address manufacturing challenges, while emerging players such as Qustomdot and Emberion are developing specialized solutions for stability in additive manufacturing environments.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive quantum dot stabilization platform for additive manufacturing called QD-Print. This technology incorporates heavy-metal-free quantum dots with specially engineered surface ligands that maintain colloidal stability during high-shear printing processes. Their approach includes a dual-layer passivation system where an inorganic shell protects the quantum dot core, while a secondary organic layer provides compatibility with various printing media. Samsung's research has demonstrated that their stabilized QDs retain over 85% luminescence efficiency after being subjected to the thermal stresses of extrusion-based 3D printing processes (temperatures up to 230°C). The company has also pioneered photo-curable QD-polymer composites that enable direct digital light processing (DLP) printing of quantum dot-embedded structures with sub-micron resolution.

Strengths: Exceptional thermal stability during high-temperature printing processes; seamless integration with existing manufacturing infrastructure; comprehensive IP protection. Weaknesses: Technology primarily optimized for display applications rather than broader additive manufacturing uses; higher implementation costs compared to conventional materials; limited publicly available performance data in non-display applications.

Suzhou Xingshuo Nanotechnology Co Ltd.

Technical Solution: Suzhou Xingshuo has developed a proprietary "shell-gradient" quantum dot technology specifically engineered for stability in additive manufacturing environments. Their approach features progressively changing shell composition that transitions from rigid inner layers to flexible outer layers, creating quantum dots that can withstand the mechanical stresses of printing processes while maintaining optical performance. The company's XS-Stable QD series incorporates proprietary surface ligands that form strong covalent bonds with printing media, preventing aggregation and phase separation during curing processes. Their research demonstrates that these quantum dots maintain over 80% quantum yield after 500 thermal cycles between 25-200°C, making them suitable for repeated processing in additive manufacturing applications. Suzhou Xingshuo has also pioneered solvent-resistant QD formulations that can be incorporated into a wide range of printing materials including photopolymers, thermoplastics, and ceramic slurries.

Strengths: Exceptional mechanical stability during printing processes; versatile compatibility with multiple additive manufacturing technologies; cost-effective manufacturing process. Weaknesses: Limited global market presence compared to larger competitors; narrower emission spectrum options; less extensive testing data in extreme environmental conditions.

Key Patents and Research on QD Degradation Prevention

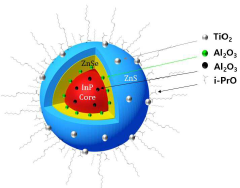

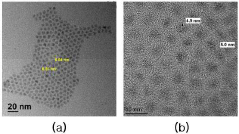

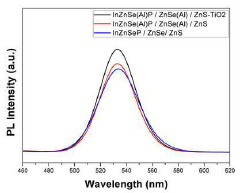

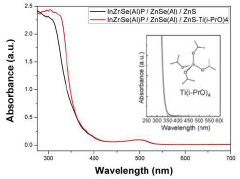

Quantum dots capable of improving stability and efficiency and method for manufacturing the same

PatentPendingKR1020240092789A

Innovation

- The quantum dots are manufactured with an InP-based core doped with Al2O3 particles, surrounded by shells of ZnSe, ZnS, and an outermost layer of TiO2, using a method that involves multiple heating steps and the use of isopropoxide ligands to enhance stability and efficiency.

Semiconductor nanomaterial having high stability

PatentActiveJP2022076459A

Innovation

- A quantum dot design with a core composed of InP, a first shell of ZnSe, a second shell, and a graded alloy intermediate layer of In, P, Zn, and Se, which improves lattice alignment and provides a thicker protective shell, maintaining high photoluminescence quantum yield.

Environmental Impact and Sustainability Considerations

The integration of quantum dots in additive manufacturing processes raises significant environmental and sustainability concerns that must be addressed for responsible technology development. Quantum dots typically contain heavy metals such as cadmium, lead, or indium, which pose potential ecological risks throughout their lifecycle. When incorporated into 3D printing materials, these nanoparticles may leach into the environment during manufacturing, product use, or disposal phases, potentially contaminating water systems and soil.

Manufacturing processes involving quantum dots require careful consideration of energy consumption and resource efficiency. Current production methods often involve high-temperature synthesis and purification steps that demand substantial energy inputs. The environmental footprint of quantum dot-enhanced additive manufacturing can be reduced through the development of room-temperature synthesis routes and more efficient production techniques that minimize waste generation and energy requirements.

End-of-life management presents another critical sustainability challenge. Quantum dot-containing printed products may not integrate seamlessly into existing recycling streams, potentially creating new waste management issues. Research into biodegradable quantum dot formulations and recovery systems is essential to mitigate these concerns. Some promising approaches include the development of core-shell structures that encapsulate toxic elements and the exploration of heavy-metal-free alternatives based on carbon, silicon, or graphene quantum dots.

Regulatory frameworks worldwide are increasingly addressing nanomaterial safety, with implications for quantum dot applications in additive manufacturing. The European Union's REACH regulations and similar initiatives in other regions require thorough risk assessment and may restrict certain quantum dot compositions. Companies investing in this technology must navigate these evolving regulatory landscapes while demonstrating commitment to environmental stewardship.

Life cycle assessment (LCA) studies specific to quantum dot-enhanced 3D printed products remain limited but are essential for quantifying environmental impacts. Preliminary research indicates that while quantum dots may increase certain environmental burdens during production, their potential to enhance product longevity and functionality could offset these impacts through extended product lifecycles and improved performance characteristics.

Industry stakeholders are increasingly exploring green chemistry principles in quantum dot synthesis, including aqueous-based production methods and the use of environmentally benign precursors. These approaches, combined with closed-loop manufacturing systems that capture and reuse materials, represent promising pathways toward more sustainable quantum dot integration in additive manufacturing applications.

Manufacturing processes involving quantum dots require careful consideration of energy consumption and resource efficiency. Current production methods often involve high-temperature synthesis and purification steps that demand substantial energy inputs. The environmental footprint of quantum dot-enhanced additive manufacturing can be reduced through the development of room-temperature synthesis routes and more efficient production techniques that minimize waste generation and energy requirements.

End-of-life management presents another critical sustainability challenge. Quantum dot-containing printed products may not integrate seamlessly into existing recycling streams, potentially creating new waste management issues. Research into biodegradable quantum dot formulations and recovery systems is essential to mitigate these concerns. Some promising approaches include the development of core-shell structures that encapsulate toxic elements and the exploration of heavy-metal-free alternatives based on carbon, silicon, or graphene quantum dots.

Regulatory frameworks worldwide are increasingly addressing nanomaterial safety, with implications for quantum dot applications in additive manufacturing. The European Union's REACH regulations and similar initiatives in other regions require thorough risk assessment and may restrict certain quantum dot compositions. Companies investing in this technology must navigate these evolving regulatory landscapes while demonstrating commitment to environmental stewardship.

Life cycle assessment (LCA) studies specific to quantum dot-enhanced 3D printed products remain limited but are essential for quantifying environmental impacts. Preliminary research indicates that while quantum dots may increase certain environmental burdens during production, their potential to enhance product longevity and functionality could offset these impacts through extended product lifecycles and improved performance characteristics.

Industry stakeholders are increasingly exploring green chemistry principles in quantum dot synthesis, including aqueous-based production methods and the use of environmentally benign precursors. These approaches, combined with closed-loop manufacturing systems that capture and reuse materials, represent promising pathways toward more sustainable quantum dot integration in additive manufacturing applications.

Regulatory Framework for QD-Based Manufacturing Materials

The regulatory landscape for quantum dot (QD) materials in additive manufacturing remains complex and evolving, with significant variations across different jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates QDs primarily under the Toxic Substances Control Act (TSCA), requiring manufacturers to submit premanufacture notices for new QD formulations. The FDA also maintains oversight when QDs are incorporated into medical devices or products with potential human exposure, with particular emphasis on leaching and degradation concerns.

The European Union applies more stringent controls through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Restriction of Hazardous Substances (RoHS) Directive. These frameworks mandate comprehensive safety assessments and place limitations on heavy metal content—particularly relevant for cadmium-based QDs which face severe restrictions under EU law. Manufacturers must provide detailed documentation on QD stability throughout the product lifecycle, including degradation pathways and potential environmental release scenarios.

In Asia, regulatory approaches vary significantly. Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances both require extensive testing for novel nanomaterials including QDs. South Korea has implemented the K-REACH system, closely modeled after European standards but with specific provisions for nanomaterials used in manufacturing processes.

International standardization efforts are gradually emerging through organizations like the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM), which have developed specific protocols for characterizing nanoparticle stability and release patterns. ISO/TR 13014 and ASTM E2456 provide guidelines for physicochemical characterization of engineered nanomaterials, though specific standards for QDs in additive manufacturing remain under development.

Compliance challenges are particularly acute for QD-based materials due to their novel properties and potential for transformation during the manufacturing process. The high temperatures and mechanical stresses typical in additive manufacturing can alter QD stability profiles, potentially creating regulatory classification challenges. Most regulatory frameworks currently lack specific provisions addressing these transformation scenarios, creating uncertainty for manufacturers.

Looking forward, regulatory trends indicate movement toward lifecycle-based approaches that consider QD stability from raw material through manufacturing, use, and disposal phases. Several jurisdictions are developing nanomaterial-specific registries and monitoring requirements that will likely impact QD applications in additive manufacturing, with particular focus on workplace exposure limits and waste management protocols.

The European Union applies more stringent controls through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Restriction of Hazardous Substances (RoHS) Directive. These frameworks mandate comprehensive safety assessments and place limitations on heavy metal content—particularly relevant for cadmium-based QDs which face severe restrictions under EU law. Manufacturers must provide detailed documentation on QD stability throughout the product lifecycle, including degradation pathways and potential environmental release scenarios.

In Asia, regulatory approaches vary significantly. Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances both require extensive testing for novel nanomaterials including QDs. South Korea has implemented the K-REACH system, closely modeled after European standards but with specific provisions for nanomaterials used in manufacturing processes.

International standardization efforts are gradually emerging through organizations like the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM), which have developed specific protocols for characterizing nanoparticle stability and release patterns. ISO/TR 13014 and ASTM E2456 provide guidelines for physicochemical characterization of engineered nanomaterials, though specific standards for QDs in additive manufacturing remain under development.

Compliance challenges are particularly acute for QD-based materials due to their novel properties and potential for transformation during the manufacturing process. The high temperatures and mechanical stresses typical in additive manufacturing can alter QD stability profiles, potentially creating regulatory classification challenges. Most regulatory frameworks currently lack specific provisions addressing these transformation scenarios, creating uncertainty for manufacturers.

Looking forward, regulatory trends indicate movement toward lifecycle-based approaches that consider QD stability from raw material through manufacturing, use, and disposal phases. Several jurisdictions are developing nanomaterial-specific registries and monitoring requirements that will likely impact QD applications in additive manufacturing, with particular focus on workplace exposure limits and waste management protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!