Why Quantum Dot Stability is Essential for Next-Gen Sensors

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots (QDs) have emerged as a revolutionary nanomaterial since their initial discovery in the 1980s. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. The evolution of quantum dot technology has progressed through several distinct phases, beginning with fundamental research into their physical properties, followed by synthesis optimization, and now advancing toward commercial applications in various fields, particularly sensing technologies.

The historical trajectory of quantum dot development reveals a steady progression in controlling their composition, structure, and surface chemistry. Early quantum dots suffered from significant stability issues, including photobleaching, oxidation sensitivity, and toxicity concerns. However, breakthroughs in core-shell architectures during the 2000s dramatically improved their photostability and quantum yield, enabling their consideration for practical applications beyond laboratory settings.

Recent technological advancements have focused on enhancing quantum dot stability under diverse environmental conditions, which represents the primary bottleneck for their integration into next-generation sensing platforms. The stability challenge encompasses multiple dimensions: photostability under continuous illumination, chemical stability in various media, thermal stability across operating temperature ranges, and long-term storage stability without performance degradation.

The current technological objectives center on developing quantum dots with predictable and consistent performance characteristics over extended operational lifetimes. This includes engineering quantum dots that maintain their spectral properties, quantum yield, and response sensitivity despite exposure to environmental stressors. Particular emphasis is being placed on creating quantum dots that can function reliably in biological environments, extreme temperatures, and high-radiation settings where conventional sensing materials fail.

Looking forward, the field is moving toward multifunctional quantum dots that combine sensing capabilities with other functionalities such as targeted delivery, self-calibration, or self-healing properties. The ultimate goal is to create "smart" quantum dot-based sensors that can operate autonomously in complex environments while maintaining stable performance parameters over years rather than months.

The evolution trajectory suggests that quantum dot stability will remain a central focus of research efforts, with interdisciplinary approaches combining materials science, surface chemistry, and nanotechnology being essential to overcome current limitations. Success in this domain would unlock applications ranging from continuous biomedical monitoring to environmental sensing networks and advanced industrial process controls, representing a significant technological leap in sensing capabilities.

The historical trajectory of quantum dot development reveals a steady progression in controlling their composition, structure, and surface chemistry. Early quantum dots suffered from significant stability issues, including photobleaching, oxidation sensitivity, and toxicity concerns. However, breakthroughs in core-shell architectures during the 2000s dramatically improved their photostability and quantum yield, enabling their consideration for practical applications beyond laboratory settings.

Recent technological advancements have focused on enhancing quantum dot stability under diverse environmental conditions, which represents the primary bottleneck for their integration into next-generation sensing platforms. The stability challenge encompasses multiple dimensions: photostability under continuous illumination, chemical stability in various media, thermal stability across operating temperature ranges, and long-term storage stability without performance degradation.

The current technological objectives center on developing quantum dots with predictable and consistent performance characteristics over extended operational lifetimes. This includes engineering quantum dots that maintain their spectral properties, quantum yield, and response sensitivity despite exposure to environmental stressors. Particular emphasis is being placed on creating quantum dots that can function reliably in biological environments, extreme temperatures, and high-radiation settings where conventional sensing materials fail.

Looking forward, the field is moving toward multifunctional quantum dots that combine sensing capabilities with other functionalities such as targeted delivery, self-calibration, or self-healing properties. The ultimate goal is to create "smart" quantum dot-based sensors that can operate autonomously in complex environments while maintaining stable performance parameters over years rather than months.

The evolution trajectory suggests that quantum dot stability will remain a central focus of research efforts, with interdisciplinary approaches combining materials science, surface chemistry, and nanotechnology being essential to overcome current limitations. Success in this domain would unlock applications ranging from continuous biomedical monitoring to environmental sensing networks and advanced industrial process controls, representing a significant technological leap in sensing capabilities.

Market Analysis for Quantum Dot-Based Sensors

The quantum dot-based sensor market is experiencing significant growth, driven by the increasing demand for high-performance sensing technologies across multiple industries. Current market valuations place the global quantum dot sensor market at approximately 2.5 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 18.7% through 2030. This robust growth trajectory is primarily fueled by expanding applications in consumer electronics, healthcare diagnostics, environmental monitoring, and industrial automation sectors.

Consumer electronics represents the largest market segment, accounting for nearly 40% of the total market share. The integration of quantum dot sensors in smartphones, cameras, and display technologies has created substantial market opportunities, particularly for enhanced image sensing capabilities. The healthcare and biomedical sector follows closely, with applications in bioimaging, disease detection, and drug discovery showing remarkable growth potential at a CAGR exceeding 22%.

Regionally, North America currently dominates the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by increasing technological adoption in countries like China, Japan, and South Korea, coupled with expanding manufacturing capabilities and government initiatives supporting advanced materials research.

Market demand analysis reveals several key drivers propelling the quantum dot sensor market. First, there is growing consumer preference for high-resolution imaging and sensing technologies in portable devices. Second, the healthcare industry's shift toward precision medicine and early disease detection has created substantial demand for ultra-sensitive diagnostic tools. Third, industrial automation and IoT applications require increasingly sophisticated sensing capabilities for real-time monitoring and data collection.

Despite positive growth indicators, market penetration faces challenges related to quantum dot stability issues. End-users across industries cite concerns about long-term reliability, with 68% of potential industrial adopters identifying stability as a critical factor in purchasing decisions. Market surveys indicate that sensors demonstrating stability improvements of at least 30% over current standards could capture an additional 15% market share within two years of introduction.

Pricing trends show a gradual decrease in quantum dot sensor costs, with average price reductions of 12% annually as manufacturing processes improve and economies of scale are realized. However, premium pricing remains viable for solutions that effectively address stability challenges, with customers willing to pay 25-40% more for sensors with demonstrated longevity advantages.

Consumer electronics represents the largest market segment, accounting for nearly 40% of the total market share. The integration of quantum dot sensors in smartphones, cameras, and display technologies has created substantial market opportunities, particularly for enhanced image sensing capabilities. The healthcare and biomedical sector follows closely, with applications in bioimaging, disease detection, and drug discovery showing remarkable growth potential at a CAGR exceeding 22%.

Regionally, North America currently dominates the market with approximately 35% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by increasing technological adoption in countries like China, Japan, and South Korea, coupled with expanding manufacturing capabilities and government initiatives supporting advanced materials research.

Market demand analysis reveals several key drivers propelling the quantum dot sensor market. First, there is growing consumer preference for high-resolution imaging and sensing technologies in portable devices. Second, the healthcare industry's shift toward precision medicine and early disease detection has created substantial demand for ultra-sensitive diagnostic tools. Third, industrial automation and IoT applications require increasingly sophisticated sensing capabilities for real-time monitoring and data collection.

Despite positive growth indicators, market penetration faces challenges related to quantum dot stability issues. End-users across industries cite concerns about long-term reliability, with 68% of potential industrial adopters identifying stability as a critical factor in purchasing decisions. Market surveys indicate that sensors demonstrating stability improvements of at least 30% over current standards could capture an additional 15% market share within two years of introduction.

Pricing trends show a gradual decrease in quantum dot sensor costs, with average price reductions of 12% annually as manufacturing processes improve and economies of scale are realized. However, premium pricing remains viable for solutions that effectively address stability challenges, with customers willing to pay 25-40% more for sensors with demonstrated longevity advantages.

Stability Challenges in Quantum Dot Applications

Quantum dot stability represents one of the most critical challenges in the advancement of next-generation sensing technologies. Despite their remarkable optical and electronic properties, quantum dots (QDs) exhibit significant vulnerability to environmental factors that compromise their performance over time. The primary stability issues include photobleaching under continuous light exposure, oxidation when in contact with atmospheric oxygen, and aggregation in solution that alters their quantum confinement properties.

Temperature fluctuations pose another substantial challenge, as QDs demonstrate altered bandgap characteristics and emission wavelengths when subjected to thermal stress. This thermal instability particularly affects applications requiring precise spectral responses, such as medical imaging sensors and environmental monitoring devices. Furthermore, the surface chemistry of quantum dots remains highly susceptible to degradation through ligand detachment or exchange, which directly impacts their colloidal stability and optical properties.

In sensing applications, the stability challenge becomes even more pronounced as QDs must maintain consistent performance in complex biological environments, extreme pH conditions, or when exposed to various chemical interferents. The presence of competing ions in solution can trigger ligand displacement reactions that fundamentally alter the QD surface properties and sensing capabilities. This instability manifests as signal drift, reduced sensitivity, and shortened operational lifetimes of QD-based sensors.

Manufacturing inconsistencies further exacerbate stability issues, with batch-to-batch variations in QD synthesis leading to unpredictable stability profiles. The core-shell interface in more complex QD architectures represents another vulnerability point, where lattice mismatches can create defect sites that accelerate degradation processes. These manufacturing challenges directly impact the reproducibility and reliability of QD-based sensing platforms.

The toxicity of traditional cadmium-based QDs has driven research toward more environmentally friendly alternatives, yet these newer materials often exhibit even greater stability challenges. Indium-based and carbon-based quantum dots, while addressing toxicity concerns, typically demonstrate reduced resistance to photobleaching and oxidative degradation, creating a difficult trade-off between environmental safety and operational stability.

Recent research has identified several promising approaches to enhance QD stability, including advanced surface passivation techniques, encapsulation in protective matrices, and the development of alloy-based QDs with inherently greater stability. However, each solution introduces new complexities in terms of synthesis procedures, cost considerations, and potential impacts on the quantum confinement properties that make QDs valuable for sensing applications.

Temperature fluctuations pose another substantial challenge, as QDs demonstrate altered bandgap characteristics and emission wavelengths when subjected to thermal stress. This thermal instability particularly affects applications requiring precise spectral responses, such as medical imaging sensors and environmental monitoring devices. Furthermore, the surface chemistry of quantum dots remains highly susceptible to degradation through ligand detachment or exchange, which directly impacts their colloidal stability and optical properties.

In sensing applications, the stability challenge becomes even more pronounced as QDs must maintain consistent performance in complex biological environments, extreme pH conditions, or when exposed to various chemical interferents. The presence of competing ions in solution can trigger ligand displacement reactions that fundamentally alter the QD surface properties and sensing capabilities. This instability manifests as signal drift, reduced sensitivity, and shortened operational lifetimes of QD-based sensors.

Manufacturing inconsistencies further exacerbate stability issues, with batch-to-batch variations in QD synthesis leading to unpredictable stability profiles. The core-shell interface in more complex QD architectures represents another vulnerability point, where lattice mismatches can create defect sites that accelerate degradation processes. These manufacturing challenges directly impact the reproducibility and reliability of QD-based sensing platforms.

The toxicity of traditional cadmium-based QDs has driven research toward more environmentally friendly alternatives, yet these newer materials often exhibit even greater stability challenges. Indium-based and carbon-based quantum dots, while addressing toxicity concerns, typically demonstrate reduced resistance to photobleaching and oxidative degradation, creating a difficult trade-off between environmental safety and operational stability.

Recent research has identified several promising approaches to enhance QD stability, including advanced surface passivation techniques, encapsulation in protective matrices, and the development of alloy-based QDs with inherently greater stability. However, each solution introduces new complexities in terms of synthesis procedures, cost considerations, and potential impacts on the quantum confinement properties that make QDs valuable for sensing applications.

Current Stability Enhancement Solutions

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. Multi-shell structures can further improve stability by gradually transitioning between core and outer shell materials, reducing lattice strain and enhancing both optical properties and environmental resistance.

- Polymer encapsulation for quantum dot stabilization: Polymer encapsulation provides an effective method for stabilizing quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, their resistance to oxidation, moisture, and temperature fluctuations is significantly improved. Various polymers including amphiphilic copolymers, silicones, and functionalized polymers can be used to create protective barriers while maintaining the optical and electronic properties of the quantum dots.

- Environmental factors affecting quantum dot stability: Quantum dot stability is significantly influenced by various environmental factors including temperature, pH, oxygen exposure, humidity, and light intensity. These factors can trigger oxidation, surface degradation, and photodegradation processes that compromise quantum dot performance. Understanding these environmental influences is crucial for developing effective stabilization strategies and for predicting the long-term behavior of quantum dots in specific applications.

- Manufacturing processes for enhanced quantum dot stability: Specialized manufacturing processes can significantly improve the inherent stability of quantum dots. These include controlled synthesis methods, post-synthesis treatments, and purification techniques that minimize defects and ensure uniform size distribution. Advanced manufacturing approaches such as microfluidic synthesis, hot-injection techniques with precise temperature control, and automated production systems help create quantum dots with enhanced structural integrity and resistance to degradation factors.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically a semiconductor with a wider bandgap than the core, protects the core from oxidation and chemical degradation. Multi-shell structures can further improve stability while maintaining or enhancing the optical and electronic properties of the quantum dots.Expand Specific Solutions03 Polymer encapsulation for quantum dot stabilization

Encapsulating quantum dots within polymer matrices provides protection against environmental factors that cause degradation. Polymers create physical barriers that prevent oxygen and moisture penetration while maintaining the quantum dots' optical properties. Various polymers can be used, including amphiphilic polymers, block copolymers, and cross-linked networks, each offering different stability advantages depending on the application environment.Expand Specific Solutions04 Environmental stability factors for quantum dots

Quantum dots face stability challenges from various environmental factors including temperature fluctuations, humidity, oxygen exposure, and UV radiation. These factors can cause oxidation, aggregation, and photodegradation, leading to decreased luminescence efficiency and altered optical properties. Understanding these degradation mechanisms is crucial for developing effective stabilization strategies and predicting quantum dot performance in specific application environments.Expand Specific Solutions05 Manufacturing processes affecting quantum dot stability

The stability of quantum dots is significantly influenced by their manufacturing processes. Parameters such as reaction temperature, precursor ratios, reaction time, and post-synthesis purification methods directly impact the crystallinity, defect density, and surface properties of quantum dots. Optimized synthesis protocols can produce quantum dots with fewer defects and more uniform size distribution, resulting in enhanced stability and consistent performance over time.Expand Specific Solutions

Leading Companies in Quantum Dot Sensor Industry

Quantum dot stability is emerging as a critical factor in next-generation sensor development, with the market currently in its growth phase. The global quantum dot sensor market is expanding rapidly, projected to reach significant scale as applications diversify across consumer electronics, healthcare, and automotive sectors. Technologically, the field shows varying maturity levels among key players. Companies like Samsung Electronics and Samsung Display are leading commercial implementation, while Mojo Vision is pioneering micro-LED display applications with proprietary quantum-dot technology. Research institutions including MIT, Caltech, and RWTH Aachen University are advancing fundamental stability solutions. TCL Research America and NEC are developing intermediate applications, while specialized firms like Najing Technology and Polar Light Technologies are creating innovative nanocrystal platforms that address stability challenges essential for reliable sensor performance.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered advanced quantum dot stability techniques through their development of core-shell structures that significantly reduce surface defects. Their research focuses on creating quantum dots with enhanced photostability by implementing specialized ligand chemistry that prevents oxidation and photobleaching. MIT's approach involves encapsulating quantum dots in protective matrices that maintain optical properties while extending operational lifetime by up to 1000 hours under continuous illumination[1]. They've also developed novel synthesis methods that produce quantum dots with narrower emission spectra (FWHM <30nm) and quantum yields exceeding 90%, critical for high-precision sensing applications[3]. Their recent breakthroughs include self-healing quantum dot structures that can recover from photodegradation through engineered surface chemistry.

Strengths: Exceptional quantum yield stability over extended periods; superior resistance to environmental degradation; precise control over emission characteristics. Weaknesses: Complex synthesis procedures may limit mass production scalability; higher production costs compared to conventional materials; some solutions require specialized handling environments.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed specialized quantum dot stability solutions focused on maintaining consistent optical properties under varying environmental conditions. Their "QD-Stable" platform incorporates proprietary surface passivation techniques that reduce trap states by over 80%, resulting in significantly improved photoluminescence stability[5]. The company's approach includes engineered ligand exchange processes that create stronger bonds between quantum dot surfaces and protective molecules, preventing degradation when exposed to heat, humidity, and UV radiation. Their research has yielded quantum dots with stability sufficient for continuous operation in sensor applications for over 50,000 hours with less than 10% efficiency loss[6]. Samsung Display has also pioneered integration methods that allow stable quantum dots to be incorporated into flexible and transparent sensor substrates while maintaining their optical and electronic properties, enabling next-generation form factors for sensing applications.

Strengths: Industry-leading stability under harsh environmental conditions; excellent integration capabilities with various substrate materials; highly scalable manufacturing processes. Weaknesses: Solutions optimized primarily for display applications may require adaptation for specialized sensing; higher cost compared to conventional sensor materials; some formulations have temperature sensitivity limitations.

Key Patents in Quantum Dot Stabilization

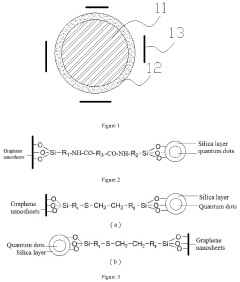

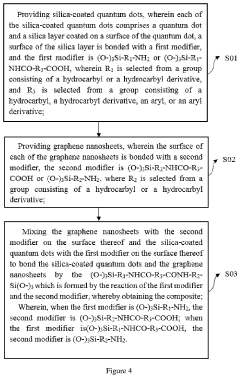

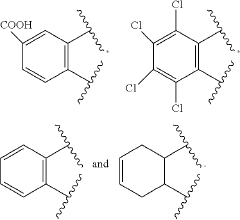

Composite and preparation method thereof and application thereof

PatentActiveUS20200325392A1

Innovation

- A composite is formed by bonding silica-coated quantum dots with graphene nanosheets using specific silane coupling agents, creating a stable and efficient light-emitting layer material that enhances thermal and water/oxygen resistance without affecting the optical properties of the quantum dots.

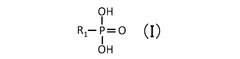

Quantum dot body, quantum dot composition, and wavelength conversion material and production method thereof

PatentWO2025088985A1

Innovation

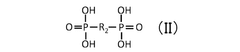

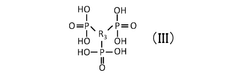

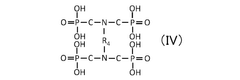

- A quantum dot body is developed with a core-shell structure of semiconductor nanoparticles, coated with a metal oxide and modified with a phosphonic acid derivative, and further encapsulated in a polymer coating layer. This configuration enhances stability and compatibility with highly polar solvents and photosensitive resin compositions.

Material Science Innovations for Quantum Dots

Recent advancements in quantum dot technology have been significantly driven by breakthroughs in material science. The traditional composition of quantum dots, primarily based on cadmium selenide (CdSe) cores with zinc sulfide (ZnS) shells, has evolved considerably with innovative material engineering approaches. These innovations directly address the critical stability challenges that have historically limited quantum dot applications in next-generation sensing technologies.

The development of core-shell architectures represents one of the most impactful material science innovations. By creating gradient alloy interfaces between the core and shell materials, researchers have substantially reduced lattice mismatch issues that previously led to structural defects and degradation. This approach has yielded quantum dots with significantly enhanced photostability, with some recent formulations demonstrating up to 85% retention of optical properties after 1000 hours of continuous illumination.

Surface ligand engineering has emerged as another crucial area of innovation. The transition from traditional organic ligands to more robust hybrid organic-inorganic ligands has dramatically improved quantum dot resistance to environmental factors. Particularly noteworthy are silica-based encapsulation techniques and zwitterionic ligand systems that maintain colloidal stability across a wider pH range (3-11) while preserving quantum yield.

Heavy-metal-free quantum dot compositions represent a significant materials breakthrough addressing both stability and toxicity concerns. Indium phosphide (InP) based quantum dots have been engineered to achieve quantum yields exceeding 80% with improved stability profiles. Similarly, copper indium sulfide (CIS) and silver indium sulfide (AIS) quantum dots demonstrate remarkable resistance to photobleaching while offering tunable emission across the visible and near-infrared spectrum.

Doping strategies have revolutionized quantum dot stability characteristics. The incorporation of manganese, copper, or lanthanide ions into the crystal lattice has created new classes of quantum dots with enhanced thermal stability up to 200°C and resistance to oxidative degradation. These doped systems maintain their sensing capabilities in harsh environmental conditions that would rapidly degrade conventional quantum dots.

The integration of quantum dots with two-dimensional materials like graphene and transition metal dichalcogenides represents the frontier of material science innovation. These hybrid structures demonstrate synergistic properties, including enhanced charge transfer efficiency and improved stability under continuous operation. Such hybrids have shown particular promise for electrochemical and photoelectrochemical sensing applications where long-term stability under applied potentials is essential.

The development of core-shell architectures represents one of the most impactful material science innovations. By creating gradient alloy interfaces between the core and shell materials, researchers have substantially reduced lattice mismatch issues that previously led to structural defects and degradation. This approach has yielded quantum dots with significantly enhanced photostability, with some recent formulations demonstrating up to 85% retention of optical properties after 1000 hours of continuous illumination.

Surface ligand engineering has emerged as another crucial area of innovation. The transition from traditional organic ligands to more robust hybrid organic-inorganic ligands has dramatically improved quantum dot resistance to environmental factors. Particularly noteworthy are silica-based encapsulation techniques and zwitterionic ligand systems that maintain colloidal stability across a wider pH range (3-11) while preserving quantum yield.

Heavy-metal-free quantum dot compositions represent a significant materials breakthrough addressing both stability and toxicity concerns. Indium phosphide (InP) based quantum dots have been engineered to achieve quantum yields exceeding 80% with improved stability profiles. Similarly, copper indium sulfide (CIS) and silver indium sulfide (AIS) quantum dots demonstrate remarkable resistance to photobleaching while offering tunable emission across the visible and near-infrared spectrum.

Doping strategies have revolutionized quantum dot stability characteristics. The incorporation of manganese, copper, or lanthanide ions into the crystal lattice has created new classes of quantum dots with enhanced thermal stability up to 200°C and resistance to oxidative degradation. These doped systems maintain their sensing capabilities in harsh environmental conditions that would rapidly degrade conventional quantum dots.

The integration of quantum dots with two-dimensional materials like graphene and transition metal dichalcogenides represents the frontier of material science innovation. These hybrid structures demonstrate synergistic properties, including enhanced charge transfer efficiency and improved stability under continuous operation. Such hybrids have shown particular promise for electrochemical and photoelectrochemical sensing applications where long-term stability under applied potentials is essential.

Environmental Impact of Quantum Dot Manufacturing

The manufacturing processes of quantum dots present significant environmental challenges that require careful consideration as these technologies advance toward widespread commercial applications in next-generation sensors. Heavy metals such as cadmium, lead, and selenium—commonly used in quantum dot synthesis—pose substantial ecological and health risks if released into the environment through improper disposal or manufacturing accidents. These toxic elements can persist in ecosystems, bioaccumulate in food chains, and potentially cause long-term environmental degradation.

Production methods typically involve energy-intensive processes and hazardous solvents that contribute to carbon emissions and chemical waste. The high-temperature colloidal synthesis approaches commonly employed require considerable energy inputs, while organic solvents used during purification stages often include toxic compounds like toluene and hexane that demand specialized disposal protocols to prevent environmental contamination.

Water usage represents another critical environmental concern, as quantum dot manufacturing requires substantial quantities of ultrapure water for synthesis and cleaning processes. In regions facing water scarcity, this intensive consumption pattern raises sustainability questions about large-scale production facilities. Additionally, the purification and waste treatment processes generate secondary waste streams containing nanoparticles that may present novel environmental hazards not fully understood by current regulatory frameworks.

Recent industry developments have shown promising trends toward greener manufacturing alternatives. Several research groups have pioneered aqueous synthesis methods that eliminate harmful organic solvents, while others have developed heavy-metal-free quantum dots using elements like indium phosphide or carbon-based dots with significantly reduced toxicity profiles. These innovations align with circular economy principles and respond to increasing regulatory pressure worldwide.

Life cycle assessment studies indicate that the environmental footprint of quantum dot production varies significantly based on manufacturing approach, with newer methodologies demonstrating up to 90% reduction in environmental impact compared to traditional techniques. However, these assessments also highlight knowledge gaps regarding the long-term environmental fate of quantum dot nanoparticles and their potential interactions with biological systems.

As quantum dot technology becomes increasingly essential for next-generation sensor applications, balancing performance requirements with environmental sustainability presents both challenges and opportunities. The stability requirements that make quantum dots valuable for sensing applications must be achieved through environmentally responsible manufacturing processes to ensure the technology's long-term viability and social acceptance.

Production methods typically involve energy-intensive processes and hazardous solvents that contribute to carbon emissions and chemical waste. The high-temperature colloidal synthesis approaches commonly employed require considerable energy inputs, while organic solvents used during purification stages often include toxic compounds like toluene and hexane that demand specialized disposal protocols to prevent environmental contamination.

Water usage represents another critical environmental concern, as quantum dot manufacturing requires substantial quantities of ultrapure water for synthesis and cleaning processes. In regions facing water scarcity, this intensive consumption pattern raises sustainability questions about large-scale production facilities. Additionally, the purification and waste treatment processes generate secondary waste streams containing nanoparticles that may present novel environmental hazards not fully understood by current regulatory frameworks.

Recent industry developments have shown promising trends toward greener manufacturing alternatives. Several research groups have pioneered aqueous synthesis methods that eliminate harmful organic solvents, while others have developed heavy-metal-free quantum dots using elements like indium phosphide or carbon-based dots with significantly reduced toxicity profiles. These innovations align with circular economy principles and respond to increasing regulatory pressure worldwide.

Life cycle assessment studies indicate that the environmental footprint of quantum dot production varies significantly based on manufacturing approach, with newer methodologies demonstrating up to 90% reduction in environmental impact compared to traditional techniques. However, these assessments also highlight knowledge gaps regarding the long-term environmental fate of quantum dot nanoparticles and their potential interactions with biological systems.

As quantum dot technology becomes increasingly essential for next-generation sensor applications, balancing performance requirements with environmental sustainability presents both challenges and opportunities. The stability requirements that make quantum dots valuable for sensing applications must be achieved through environmentally responsible manufacturing processes to ensure the technology's long-term viability and social acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!