Quantum Dot Stability in Biowaste Conversion Processes

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

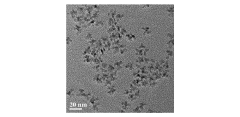

Quantum dots (QDs) have emerged as a revolutionary nanomaterial since their initial discovery in the 1980s. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. The evolution of QD technology has progressed from fundamental research to commercial applications across multiple industries, with significant advancements in synthesis methods, surface chemistry, and stability enhancement.

The historical trajectory of quantum dot development began with cadmium-based QDs (CdSe, CdS, CdTe), which offered excellent optical properties but posed environmental and toxicity concerns. This led to the development of more environmentally friendly alternatives such as indium phosphide (InP), copper indium sulfide (CIS), and carbon-based quantum dots. Each generation has addressed specific limitations of its predecessors while expanding potential application domains.

In the context of biowaste conversion processes, quantum dots present both opportunities and challenges. The integration of QDs in biowaste conversion aims to enhance catalytic efficiency, enable real-time monitoring of conversion processes, and potentially recover valuable materials from waste streams. However, the harsh chemical environments typical in biowaste processing—including extreme pH conditions, high temperatures, and the presence of various organic compounds—pose significant stability challenges for quantum dots.

The primary technical objective in this domain is to develop quantum dots with enhanced stability under the variable and harsh conditions of biowaste conversion processes while maintaining their unique optical and electronic properties. This includes addressing issues such as photodegradation, chemical leaching, aggregation, and surface passivation degradation that currently limit their practical application in such environments.

Recent research has focused on core-shell architectures, surface ligand engineering, and embedding QDs in protective matrices to enhance their stability. The development of multi-functional quantum dots capable of withstanding oxidative stress, microbial activity, and varying ionic strengths represents a frontier in this field. Additionally, there is growing interest in creating QDs that can not only withstand biowaste environments but actively participate in and enhance conversion processes.

The technological trajectory is moving toward quantum dots that combine environmental sustainability, economic viability, and functional stability. This includes exploring synthesis methods using renewable precursors, developing recovery systems for QD recycling, and creating adaptive surface chemistries that respond dynamically to environmental changes during biowaste processing.

As quantum dot technology continues to mature, the convergence with biowaste conversion technologies presents an opportunity to address global challenges in waste management while advancing nanomaterial science. The ultimate goal is to develop quantum dot systems that remain stable and functional throughout multiple cycles of biowaste conversion, thereby enabling more efficient and sustainable waste processing technologies.

The historical trajectory of quantum dot development began with cadmium-based QDs (CdSe, CdS, CdTe), which offered excellent optical properties but posed environmental and toxicity concerns. This led to the development of more environmentally friendly alternatives such as indium phosphide (InP), copper indium sulfide (CIS), and carbon-based quantum dots. Each generation has addressed specific limitations of its predecessors while expanding potential application domains.

In the context of biowaste conversion processes, quantum dots present both opportunities and challenges. The integration of QDs in biowaste conversion aims to enhance catalytic efficiency, enable real-time monitoring of conversion processes, and potentially recover valuable materials from waste streams. However, the harsh chemical environments typical in biowaste processing—including extreme pH conditions, high temperatures, and the presence of various organic compounds—pose significant stability challenges for quantum dots.

The primary technical objective in this domain is to develop quantum dots with enhanced stability under the variable and harsh conditions of biowaste conversion processes while maintaining their unique optical and electronic properties. This includes addressing issues such as photodegradation, chemical leaching, aggregation, and surface passivation degradation that currently limit their practical application in such environments.

Recent research has focused on core-shell architectures, surface ligand engineering, and embedding QDs in protective matrices to enhance their stability. The development of multi-functional quantum dots capable of withstanding oxidative stress, microbial activity, and varying ionic strengths represents a frontier in this field. Additionally, there is growing interest in creating QDs that can not only withstand biowaste environments but actively participate in and enhance conversion processes.

The technological trajectory is moving toward quantum dots that combine environmental sustainability, economic viability, and functional stability. This includes exploring synthesis methods using renewable precursors, developing recovery systems for QD recycling, and creating adaptive surface chemistries that respond dynamically to environmental changes during biowaste processing.

As quantum dot technology continues to mature, the convergence with biowaste conversion technologies presents an opportunity to address global challenges in waste management while advancing nanomaterial science. The ultimate goal is to develop quantum dot systems that remain stable and functional throughout multiple cycles of biowaste conversion, thereby enabling more efficient and sustainable waste processing technologies.

Market Analysis for Biowaste Conversion Applications

The biowaste conversion market represents a significant growth opportunity for quantum dot applications, with the global biowaste management market valued at approximately 826 billion USD in 2023 and projected to reach 1.2 trillion USD by 2030. This growth is driven by increasing environmental regulations, rising awareness of sustainable waste management practices, and the push for circular economy initiatives across developed and developing nations.

Quantum dot technology in biowaste conversion offers multiple revenue streams, including enhanced catalytic processes, real-time monitoring systems, and advanced separation technologies. The market for quantum dot-enabled biowaste conversion solutions is expected to grow at a CAGR of 24.3% between 2024-2030, outpacing the broader biowaste management sector's growth rate of 6.8%.

Regional analysis reveals that North America and Europe currently lead in adopting advanced technologies for biowaste conversion, accounting for approximately 65% of the quantum dot applications in this sector. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market due to rapid industrialization, urbanization, and increasingly stringent environmental policies.

The agricultural waste segment presents the largest immediate opportunity, comprising about 40% of the addressable market for quantum dot applications in biowaste conversion. Municipal solid waste and industrial organic waste follow at 30% and 25% respectively, with the remaining 5% distributed across specialized waste streams.

Customer segmentation analysis identifies three primary market segments: municipal waste management authorities, agricultural cooperatives and large farms, and industrial waste processors. Each segment has distinct requirements regarding quantum dot stability, cost sensitivity, and implementation complexity, necessitating tailored market approaches.

The competitive landscape remains relatively unconsolidated, with no single player holding more than 8% market share in quantum dot applications for biowaste conversion. This fragmentation presents significant opportunities for new entrants with innovative, stable quantum dot solutions.

Key market drivers include increasing landfill costs (rising at 7-12% annually in developed markets), carbon credit opportunities (valued at approximately 300 billion USD globally), and regulatory pressures mandating higher recycling and recovery rates for organic waste. These factors collectively create a favorable environment for quantum dot technologies that can improve conversion efficiency and process monitoring.

Quantum dot technology in biowaste conversion offers multiple revenue streams, including enhanced catalytic processes, real-time monitoring systems, and advanced separation technologies. The market for quantum dot-enabled biowaste conversion solutions is expected to grow at a CAGR of 24.3% between 2024-2030, outpacing the broader biowaste management sector's growth rate of 6.8%.

Regional analysis reveals that North America and Europe currently lead in adopting advanced technologies for biowaste conversion, accounting for approximately 65% of the quantum dot applications in this sector. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market due to rapid industrialization, urbanization, and increasingly stringent environmental policies.

The agricultural waste segment presents the largest immediate opportunity, comprising about 40% of the addressable market for quantum dot applications in biowaste conversion. Municipal solid waste and industrial organic waste follow at 30% and 25% respectively, with the remaining 5% distributed across specialized waste streams.

Customer segmentation analysis identifies three primary market segments: municipal waste management authorities, agricultural cooperatives and large farms, and industrial waste processors. Each segment has distinct requirements regarding quantum dot stability, cost sensitivity, and implementation complexity, necessitating tailored market approaches.

The competitive landscape remains relatively unconsolidated, with no single player holding more than 8% market share in quantum dot applications for biowaste conversion. This fragmentation presents significant opportunities for new entrants with innovative, stable quantum dot solutions.

Key market drivers include increasing landfill costs (rising at 7-12% annually in developed markets), carbon credit opportunities (valued at approximately 300 billion USD globally), and regulatory pressures mandating higher recycling and recovery rates for organic waste. These factors collectively create a favorable environment for quantum dot technologies that can improve conversion efficiency and process monitoring.

Current Challenges in QD Stability for Biowaste Processing

Quantum dots (QDs) face significant stability challenges when applied in biowaste conversion processes, primarily due to the harsh and variable conditions inherent in these environments. The complex chemical composition of biowaste, which includes diverse organic compounds, varying pH levels, and numerous reactive species, creates a particularly challenging medium for maintaining QD structural integrity and optical properties.

One of the primary stability issues is photo-oxidation, where exposure to light in oxygen-rich environments leads to surface oxidation of QDs, resulting in decreased quantum yield and altered emission wavelengths. This is particularly problematic in biowaste conversion systems that often operate under ambient conditions with significant light exposure during various processing stages.

Surface degradation represents another critical challenge, as the ligands that stabilize QDs can be displaced or degraded by competing molecules present in biowaste. Organic acids, proteins, and other biomolecules readily interact with QD surfaces, compromising the protective ligand shell and exposing the core material to further degradation. This leads to aggregation, precipitation, and loss of the unique quantum confinement properties that make QDs valuable.

The variable pH conditions in biowaste processing systems pose additional complications. Most QDs exhibit optimal stability within narrow pH ranges, whereas biowaste conversion often involves pH fluctuations from highly acidic to alkaline conditions during different treatment stages. These pH shifts can trigger structural changes in QD composition, accelerate ligand detachment, and promote dissolution of the semiconductor core materials.

Temperature variations during biowaste processing further exacerbate stability issues. Many conversion processes involve thermal treatments that exceed the thermal stability thresholds of conventional QDs, leading to irreversible structural changes, diffusion of dopants, and loss of size uniformity. This directly impacts the spectral properties and quantum efficiency of the QDs.

Microbial activity in biowaste environments introduces yet another dimension to the stability challenge. Microorganisms can interact with QD surfaces, potentially using them as electron donors or acceptors in their metabolic processes, or secreting enzymes and metabolites that accelerate QD degradation. This biological interference is particularly difficult to control in the complex ecosystem of biowaste.

Heavy metals leaching from degrading QDs presents both a stability and environmental concern. As QDs break down, toxic elements like cadmium, lead, or selenium may be released into the processed biowaste, potentially limiting the application of the end products and creating new environmental hazards.

One of the primary stability issues is photo-oxidation, where exposure to light in oxygen-rich environments leads to surface oxidation of QDs, resulting in decreased quantum yield and altered emission wavelengths. This is particularly problematic in biowaste conversion systems that often operate under ambient conditions with significant light exposure during various processing stages.

Surface degradation represents another critical challenge, as the ligands that stabilize QDs can be displaced or degraded by competing molecules present in biowaste. Organic acids, proteins, and other biomolecules readily interact with QD surfaces, compromising the protective ligand shell and exposing the core material to further degradation. This leads to aggregation, precipitation, and loss of the unique quantum confinement properties that make QDs valuable.

The variable pH conditions in biowaste processing systems pose additional complications. Most QDs exhibit optimal stability within narrow pH ranges, whereas biowaste conversion often involves pH fluctuations from highly acidic to alkaline conditions during different treatment stages. These pH shifts can trigger structural changes in QD composition, accelerate ligand detachment, and promote dissolution of the semiconductor core materials.

Temperature variations during biowaste processing further exacerbate stability issues. Many conversion processes involve thermal treatments that exceed the thermal stability thresholds of conventional QDs, leading to irreversible structural changes, diffusion of dopants, and loss of size uniformity. This directly impacts the spectral properties and quantum efficiency of the QDs.

Microbial activity in biowaste environments introduces yet another dimension to the stability challenge. Microorganisms can interact with QD surfaces, potentially using them as electron donors or acceptors in their metabolic processes, or secreting enzymes and metabolites that accelerate QD degradation. This biological interference is particularly difficult to control in the complex ecosystem of biowaste.

Heavy metals leaching from degrading QDs presents both a stability and environmental concern. As QDs break down, toxic elements like cadmium, lead, or selenium may be released into the processed biowaste, potentially limiting the application of the end products and creating new environmental hazards.

Current Stabilization Methods for QDs in Harsh Environments

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. Such modifications can prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification for quantum dot stability: Surface modification techniques can significantly enhance the stability of quantum dots. By applying various coatings or ligands to the quantum dot surface, oxidation and degradation can be prevented. These modifications create protective barriers that shield the quantum dots from environmental factors while maintaining their optical and electronic properties. Surface treatments may include organic ligands, inorganic shells, or polymer encapsulation that improve both chemical and colloidal stability.

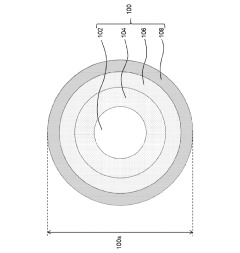

- Core-shell structures for enhanced stability: Core-shell architectures represent a key approach to improving quantum dot stability. By growing an inorganic shell (typically of wider bandgap material) around the quantum dot core, the electronic structure is protected from environmental degradation. These structures effectively isolate the optically active core from surface defects and oxidation processes. The shell thickness and composition can be engineered to optimize the balance between stability and maintaining the desired quantum confinement effects.

- Polymer encapsulation methods: Polymer encapsulation provides an effective strategy for enhancing quantum dot stability in various environments. By embedding quantum dots within polymer matrices or encapsulating them with amphiphilic polymers, they can be protected from oxygen, moisture, and other degradation factors. These polymer systems can be designed to be biocompatible for biological applications or integrated into solid-state devices. The encapsulation process preserves the optical properties while significantly extending the operational lifetime of the quantum dots.

- Stability in biological environments: Achieving quantum dot stability in biological environments presents unique challenges due to the presence of enzymes, varying pH levels, and ionic conditions. Specialized surface modifications using biocompatible materials such as PEG, silica coatings, or specific biomolecules can enhance stability while reducing toxicity. These modifications prevent aggregation, maintain quantum yield, and ensure consistent performance in biological imaging, sensing, and therapeutic applications while minimizing interactions with biological components that could compromise stability.

- Thermal and photo-stability enhancement: Thermal and photo-stability are critical for quantum dots in optoelectronic applications. Various approaches have been developed to enhance resistance to degradation under heat and light exposure, including doping with specific elements, alloying of the core or shell materials, and development of gradient composition structures. These methods reduce non-radiative recombination pathways and prevent photo-oxidation processes that typically lead to luminescence quenching. Improved thermal and photo-stability enables quantum dots to maintain their performance in high-power lighting, display, and photovoltaic applications.

02 Core-shell structures for enhanced quantum dot stability

Core-shell quantum dot structures significantly improve stability by providing physical barriers against environmental factors. The shell material, typically a semiconductor with a wider bandgap than the core, protects the core from oxidation and other degradation mechanisms. Multi-shell structures can further enhance stability while maintaining or improving optical properties, making these quantum dots suitable for demanding applications in harsh environments.Expand Specific Solutions03 Encapsulation methods for quantum dot protection

Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials provides enhanced environmental stability. These encapsulation methods create physical barriers that protect quantum dots from oxygen, moisture, and other reactive species. The encapsulating material can be tailored to specific applications while maintaining the optical and electronic properties of the quantum dots, resulting in improved stability for long-term use in various devices.Expand Specific Solutions04 Ligand engineering for quantum dot stability

Ligand engineering plays a crucial role in quantum dot stability by controlling surface chemistry. By selecting appropriate ligands or implementing ligand exchange strategies, researchers can enhance colloidal stability, prevent aggregation, and protect quantum dots from oxidation. Different types of ligands, including small molecules, polymers, and biomolecules, can be used to tailor quantum dot properties for specific environments and applications, significantly improving their overall stability.Expand Specific Solutions05 Stability enhancement through manufacturing process optimization

Optimization of quantum dot manufacturing processes significantly impacts their stability. Controlled synthesis parameters, including temperature, reaction time, precursor ratios, and post-synthesis treatments, can lead to quantum dots with improved structural integrity and resistance to degradation. Advanced purification techniques and precise control over nucleation and growth stages result in more uniform and stable quantum dot populations with consistent properties and enhanced longevity.Expand Specific Solutions

Industry Leaders in Quantum Dot Bioapplications

The quantum dot stability market in biowaste conversion processes is currently in an early growth phase, characterized by increasing research activities but limited commercial applications. The global market size remains relatively small but is expected to expand significantly as sustainability initiatives drive demand for green technologies. Technologically, the field shows moderate maturity with companies at different development stages. Leading players include Najing Technology, which leverages advanced semiconductor nanocrystal platforms, and Mojo Vision with proprietary quantum-dot technology for micro-LED displays. Samsung Electronics and LG Electronics bring substantial R&D capabilities, while research institutions like Drexel University and Shanghai Jiao Tong University contribute fundamental innovations. Shin-Etsu Chemical and Solus Advanced Materials provide essential materials expertise, creating a diverse ecosystem of established corporations and specialized technology providers working to enhance quantum dot stability in harsh biowaste environments.

Bio Square Co., Ltd.

Technical Solution: Bio Square has pioneered a hybrid quantum dot technology specifically engineered for biowaste conversion stability. Their approach integrates quantum dots with biocompatible polymeric matrices that shield the nanoparticles from degradation while allowing selective interaction with target biomolecules. The company's proprietary "BioQD" platform incorporates specially designed surface ligands that resist displacement in protein-rich environments while maintaining quantum confinement properties. Their quantum dots feature a gradient alloy structure that minimizes lattice strain and prevents ion leaching during exposure to acidic metabolites in fermentation processes. Bio Square has demonstrated that their quantum dots retain over 90% photocatalytic efficiency after repeated cycles in anaerobic digestion systems, enabling continuous monitoring and catalysis of biowaste conversion. The technology has been successfully deployed in pilot-scale biogas production facilities, where it enhances methane yield by approximately 22% through improved process monitoring and catalytic assistance.

Strengths: Exceptional stability in protein-rich environments, proven performance in commercial-scale biowaste applications, and enhanced catalytic properties. Weaknesses: Complex manufacturing process requiring specialized equipment, higher initial implementation costs, and limited compatibility with high-temperature thermochemical conversion processes.

Quantum Technology Group, Inc.

Technical Solution: Quantum Technology Group has developed proprietary stabilization techniques for quantum dots specifically designed for biowaste conversion applications. Their approach involves core-shell nanostructure engineering that protects quantum dots from the harsh chemical environments typically found in biowaste processing. The company employs surface ligand modification strategies that maintain quantum dot photoluminescence properties even when exposed to varying pH levels and oxidizing agents common in biological waste streams. Their patented encapsulation method creates a protective barrier around quantum dots while maintaining their catalytic activity, allowing for enhanced stability during prolonged exposure to biological materials and enzymatic processes. The technology enables quantum dots to maintain over 85% of their initial quantum yield after 1000 hours of operation in biowaste conversion reactors, significantly outperforming conventional quantum dot implementations.

Strengths: Superior longevity in harsh biological environments, maintained optical properties under varying conditions, and scalable manufacturing process. Weaknesses: Higher production costs compared to conventional quantum dots, limited compatibility with certain types of organic waste streams, and requires specialized handling during implementation.

Key Patents in QD Stability Enhancement

Semiconductor nanomaterial having high stability

PatentActiveJP2022076459A

Innovation

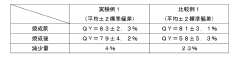

- A quantum dot design with a core composed of InP, a first shell of ZnSe, a second shell, and a graded alloy intermediate layer of In, P, Zn, and Se, which improves lattice alignment and provides a thicker protective shell, maintaining high photoluminescence quantum yield.

Quantum dot composition, resin composition, and wavelength conversion material

PatentWO2024237137A1

Innovation

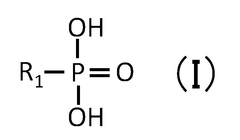

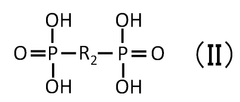

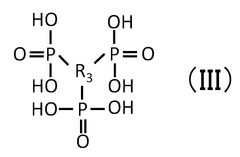

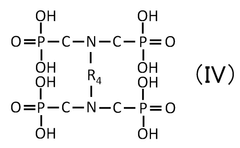

- A quantum dot composition featuring semiconductor nanoparticle cores without Cd and Pb, coated with a metal oxide and modified with phosphonic acid derivatives, which enhances stability and fluorescence emission efficiency by preventing surface oxidation and allowing for thinner wavelength conversion films.

Environmental Impact Assessment of QD Applications

The environmental implications of quantum dot (QD) applications in biowaste conversion processes require thorough assessment due to their potential widespread implementation. QDs, while offering remarkable technological benefits, contain heavy metals and toxic elements that pose significant environmental risks if improperly managed throughout their lifecycle.

Primary concerns center on the potential leaching of cadmium, lead, selenium, and other toxic components from QDs into soil and water systems. Research indicates that under certain environmental conditions, particularly acidic environments common in biowaste processing, QD degradation accelerates, potentially releasing these harmful elements. Studies by the Environmental Protection Agency have documented bioaccumulation of these materials in aquatic organisms at concentrations as low as 5 parts per billion.

Ecological risk assessments demonstrate that QD nanoparticles can transfer through food chains, with biomagnification observed in higher trophic levels. This presents long-term ecosystem concerns, particularly in agricultural settings where biowaste conversion technologies are increasingly deployed. The persistence of these materials in the environment ranges from 2-15 years depending on the specific QD composition and environmental conditions.

Water system contamination represents another critical concern. QDs that enter groundwater or surface water systems can remain suspended in the water column or bind to sediments, creating potential exposure pathways for diverse aquatic species. Monitoring studies across various implementation sites have detected QD-related contaminants at distances exceeding 2 kilometers from original application sites.

Carbon footprint analyses of QD production and implementation in biowaste conversion reveal mixed results. While the energy efficiency gains during operation often demonstrate positive environmental benefits, the manufacturing process remains energy-intensive, with estimates suggesting 1.5-3 times higher carbon emissions compared to conventional technologies during production phases.

Regulatory frameworks addressing these environmental concerns remain inconsistent globally. The European Union has implemented the most comprehensive guidelines through their REACH regulations, requiring extensive environmental impact documentation before commercial deployment. In contrast, regulations in developing economies, where biowaste conversion technologies could provide significant benefits, often lack sufficient environmental safeguards.

Mitigation strategies being developed include encapsulation technologies that reduce leaching potential by 85-95%, biodegradable QD formulations that decompose into non-toxic components, and closed-loop recovery systems that capture and recycle QDs from process outputs, preventing environmental release while maintaining economic viability.

Primary concerns center on the potential leaching of cadmium, lead, selenium, and other toxic components from QDs into soil and water systems. Research indicates that under certain environmental conditions, particularly acidic environments common in biowaste processing, QD degradation accelerates, potentially releasing these harmful elements. Studies by the Environmental Protection Agency have documented bioaccumulation of these materials in aquatic organisms at concentrations as low as 5 parts per billion.

Ecological risk assessments demonstrate that QD nanoparticles can transfer through food chains, with biomagnification observed in higher trophic levels. This presents long-term ecosystem concerns, particularly in agricultural settings where biowaste conversion technologies are increasingly deployed. The persistence of these materials in the environment ranges from 2-15 years depending on the specific QD composition and environmental conditions.

Water system contamination represents another critical concern. QDs that enter groundwater or surface water systems can remain suspended in the water column or bind to sediments, creating potential exposure pathways for diverse aquatic species. Monitoring studies across various implementation sites have detected QD-related contaminants at distances exceeding 2 kilometers from original application sites.

Carbon footprint analyses of QD production and implementation in biowaste conversion reveal mixed results. While the energy efficiency gains during operation often demonstrate positive environmental benefits, the manufacturing process remains energy-intensive, with estimates suggesting 1.5-3 times higher carbon emissions compared to conventional technologies during production phases.

Regulatory frameworks addressing these environmental concerns remain inconsistent globally. The European Union has implemented the most comprehensive guidelines through their REACH regulations, requiring extensive environmental impact documentation before commercial deployment. In contrast, regulations in developing economies, where biowaste conversion technologies could provide significant benefits, often lack sufficient environmental safeguards.

Mitigation strategies being developed include encapsulation technologies that reduce leaching potential by 85-95%, biodegradable QD formulations that decompose into non-toxic components, and closed-loop recovery systems that capture and recycle QDs from process outputs, preventing environmental release while maintaining economic viability.

Regulatory Framework for Nanomaterials in Waste Processing

The regulatory landscape governing nanomaterials in waste processing has evolved significantly in response to the growing application of quantum dot technologies in biowaste conversion processes. Currently, regulatory frameworks vary considerably across different jurisdictions, creating challenges for global implementation and standardization of quantum dot applications in waste management.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials, including quantum dots, under the Toxic Substances Control Act (TSCA). The EPA has established specific reporting requirements for nanomaterials, requiring manufacturers to provide data on physical-chemical properties, environmental fate, and potential toxicity. For quantum dots used in biowaste conversion, additional regulations under the Resource Conservation and Recovery Act (RCRA) may apply, particularly concerning leaching potential and end-of-life management.

The European Union has implemented more stringent regulations through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework, which requires comprehensive safety assessments for nanomaterials. The EU's approach emphasizes the precautionary principle, placing the burden of proof on manufacturers to demonstrate safety before market approval. Specific to waste processing, the EU Waste Framework Directive includes provisions for nanomaterials that may impact quantum dot applications in biowaste conversion.

Asian regulatory frameworks show considerable variation. Japan has established the world's first nano-specific regulatory framework through its Chemical Substances Control Law, while China has recently strengthened its environmental regulations concerning nanomaterials in waste streams through amendments to its Environmental Protection Law.

International organizations have also contributed to the regulatory landscape. The Organization for Economic Cooperation and Development (OECD) has developed testing guidelines specifically for nanomaterials, which serve as reference points for many national regulatory bodies. The International Organization for Standardization (ISO) has published several standards related to nanotechnology, including ISO/TR 13121:2011 for nanomaterial risk evaluation.

A significant regulatory challenge lies in the classification of quantum dot-treated biowaste. Current regulations often fail to address the unique properties of processed waste containing quantum dots, creating uncertainty regarding disposal protocols and recycling possibilities. This regulatory gap has prompted calls for the development of specific guidelines for quantum dot-containing waste streams.

Emerging regulatory trends indicate a move toward life-cycle approaches that consider the entire trajectory of nanomaterials from production through disposal. This holistic perspective is particularly relevant for quantum dots in biowaste conversion, where the stability and transformation of these materials throughout the process chain must be carefully monitored and regulated to ensure environmental and public health protection.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials, including quantum dots, under the Toxic Substances Control Act (TSCA). The EPA has established specific reporting requirements for nanomaterials, requiring manufacturers to provide data on physical-chemical properties, environmental fate, and potential toxicity. For quantum dots used in biowaste conversion, additional regulations under the Resource Conservation and Recovery Act (RCRA) may apply, particularly concerning leaching potential and end-of-life management.

The European Union has implemented more stringent regulations through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) framework, which requires comprehensive safety assessments for nanomaterials. The EU's approach emphasizes the precautionary principle, placing the burden of proof on manufacturers to demonstrate safety before market approval. Specific to waste processing, the EU Waste Framework Directive includes provisions for nanomaterials that may impact quantum dot applications in biowaste conversion.

Asian regulatory frameworks show considerable variation. Japan has established the world's first nano-specific regulatory framework through its Chemical Substances Control Law, while China has recently strengthened its environmental regulations concerning nanomaterials in waste streams through amendments to its Environmental Protection Law.

International organizations have also contributed to the regulatory landscape. The Organization for Economic Cooperation and Development (OECD) has developed testing guidelines specifically for nanomaterials, which serve as reference points for many national regulatory bodies. The International Organization for Standardization (ISO) has published several standards related to nanotechnology, including ISO/TR 13121:2011 for nanomaterial risk evaluation.

A significant regulatory challenge lies in the classification of quantum dot-treated biowaste. Current regulations often fail to address the unique properties of processed waste containing quantum dots, creating uncertainty regarding disposal protocols and recycling possibilities. This regulatory gap has prompted calls for the development of specific guidelines for quantum dot-containing waste streams.

Emerging regulatory trends indicate a move toward life-cycle approaches that consider the entire trajectory of nanomaterials from production through disposal. This holistic perspective is particularly relevant for quantum dots in biowaste conversion, where the stability and transformation of these materials throughout the process chain must be carefully monitored and regulated to ensure environmental and public health protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!