Notable Regulatory Frameworks for Quantum Dot Stability

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Stability Regulatory Background and Objectives

Quantum dots (QDs) have emerged as revolutionary nanomaterials with applications spanning from biomedical imaging to next-generation display technologies. The evolution of quantum dot technology began in the early 1980s with theoretical work by Alexey Ekimov and Louis Brus, followed by significant experimental breakthroughs in the 1990s. Over the past decade, quantum dots have transitioned from laboratory curiosities to commercial products, highlighting the importance of establishing comprehensive regulatory frameworks to ensure their stability and safety.

The primary technical objective in quantum dot stability regulation is to establish standardized protocols for assessing and ensuring the long-term physical, chemical, and optical stability of quantum dots across diverse environmental conditions. This includes developing metrics for evaluating photostability, colloidal stability, and resistance to oxidation—factors critical to maintaining quantum dot performance in real-world applications.

Regulatory interest in quantum dot stability has intensified as these nanomaterials increasingly enter consumer markets. The unique properties that make quantum dots valuable—their size-dependent optical properties, high quantum yield, and tunable emission spectra—also present novel regulatory challenges. Traditional regulatory frameworks designed for bulk materials often prove inadequate for nanoscale materials whose properties can change dramatically with minor alterations in size, shape, or surface chemistry.

Global regulatory bodies, including the FDA in the United States, the European Chemicals Agency, and similar organizations in Asia, have begun developing specialized guidelines addressing quantum dot stability. These efforts aim to establish safety standards while simultaneously fostering innovation in this rapidly evolving field. The technical trajectory suggests movement toward performance-based regulatory approaches rather than prescriptive standards, allowing flexibility as the technology continues to mature.

A significant trend in quantum dot regulation involves the transition from heavy metal-based quantum dots (containing cadmium, lead, or mercury) toward more environmentally benign alternatives. This shift reflects growing awareness of potential environmental and health impacts, driving research into indium phosphide, zinc selenide, and carbon-based quantum dots with comparable optical properties but reduced toxicity concerns.

The regulatory landscape must also address the diverse applications of quantum dots, from consumer electronics to medical diagnostics, each presenting unique stability requirements. For instance, quantum dots in biological applications must maintain stability in physiological environments, while those in display technologies must withstand high-energy blue light exposure without degradation.

Looking forward, the technical goals for quantum dot stability regulation include developing accelerated aging protocols that can reliably predict long-term stability, establishing international harmonization of testing standards, and creating specialized frameworks for emerging quantum dot variants such as perovskite quantum dots and quantum dot-polymer composites.

The primary technical objective in quantum dot stability regulation is to establish standardized protocols for assessing and ensuring the long-term physical, chemical, and optical stability of quantum dots across diverse environmental conditions. This includes developing metrics for evaluating photostability, colloidal stability, and resistance to oxidation—factors critical to maintaining quantum dot performance in real-world applications.

Regulatory interest in quantum dot stability has intensified as these nanomaterials increasingly enter consumer markets. The unique properties that make quantum dots valuable—their size-dependent optical properties, high quantum yield, and tunable emission spectra—also present novel regulatory challenges. Traditional regulatory frameworks designed for bulk materials often prove inadequate for nanoscale materials whose properties can change dramatically with minor alterations in size, shape, or surface chemistry.

Global regulatory bodies, including the FDA in the United States, the European Chemicals Agency, and similar organizations in Asia, have begun developing specialized guidelines addressing quantum dot stability. These efforts aim to establish safety standards while simultaneously fostering innovation in this rapidly evolving field. The technical trajectory suggests movement toward performance-based regulatory approaches rather than prescriptive standards, allowing flexibility as the technology continues to mature.

A significant trend in quantum dot regulation involves the transition from heavy metal-based quantum dots (containing cadmium, lead, or mercury) toward more environmentally benign alternatives. This shift reflects growing awareness of potential environmental and health impacts, driving research into indium phosphide, zinc selenide, and carbon-based quantum dots with comparable optical properties but reduced toxicity concerns.

The regulatory landscape must also address the diverse applications of quantum dots, from consumer electronics to medical diagnostics, each presenting unique stability requirements. For instance, quantum dots in biological applications must maintain stability in physiological environments, while those in display technologies must withstand high-energy blue light exposure without degradation.

Looking forward, the technical goals for quantum dot stability regulation include developing accelerated aging protocols that can reliably predict long-term stability, establishing international harmonization of testing standards, and creating specialized frameworks for emerging quantum dot variants such as perovskite quantum dots and quantum dot-polymer composites.

Market Demand Analysis for Stable Quantum Dot Applications

The quantum dot market has witnessed substantial growth in recent years, driven primarily by increasing demand for high-performance display technologies. The global quantum dot market was valued at approximately $4.6 billion in 2021 and is projected to reach $16.0 billion by 2028, representing a compound annual growth rate (CAGR) of 19.8%. This remarkable growth trajectory underscores the expanding market potential for stable quantum dot applications across various industries.

Display technology remains the dominant application segment, accounting for nearly 65% of the total market share. Consumer electronics manufacturers are increasingly incorporating quantum dot technology into their product lines to enhance color accuracy, brightness, and energy efficiency. Major players like Samsung, LG, and Sony have already commercialized quantum dot displays, signaling strong market acceptance and consumer demand for this technology.

Healthcare and biomedical applications represent the fastest-growing segment for quantum dot technology, with a CAGR exceeding 22%. The demand for stable quantum dots in bioimaging, diagnostics, and drug delivery systems has surged due to their superior optical properties and biocompatibility when properly stabilized. Regulatory frameworks ensuring quantum dot stability are particularly crucial in this sector, as they directly impact product safety and efficacy.

The energy sector presents another significant market opportunity, particularly in photovoltaics and solid-state lighting. Quantum dot solar cells have demonstrated theoretical efficiency limits exceeding traditional silicon-based cells, driving research investment in this area. However, market penetration remains limited by stability challenges under operational conditions, highlighting the critical need for regulatory frameworks addressing long-term stability requirements.

Regional analysis reveals North America and Asia-Pacific as the leading markets for stable quantum dot applications, collectively accounting for over 70% of global market share. Stringent regulatory environments in these regions have accelerated the development of stabilization technologies, creating market entry barriers but also ensuring higher product quality and reliability.

Industry surveys indicate that 78% of end-users cite stability and reliability as the primary concerns when adopting quantum dot technology, outranking cost considerations. This consumer preference has created a premium market segment for demonstrably stable quantum dot products that comply with established regulatory frameworks, particularly in consumer electronics and medical applications.

The market landscape is further shaped by emerging applications in security and anti-counterfeiting measures, where stable quantum dots serve as authentication markers. This segment is projected to grow at 25% annually, driven by increasing concerns about product authenticity and intellectual property protection across global supply chains.

Display technology remains the dominant application segment, accounting for nearly 65% of the total market share. Consumer electronics manufacturers are increasingly incorporating quantum dot technology into their product lines to enhance color accuracy, brightness, and energy efficiency. Major players like Samsung, LG, and Sony have already commercialized quantum dot displays, signaling strong market acceptance and consumer demand for this technology.

Healthcare and biomedical applications represent the fastest-growing segment for quantum dot technology, with a CAGR exceeding 22%. The demand for stable quantum dots in bioimaging, diagnostics, and drug delivery systems has surged due to their superior optical properties and biocompatibility when properly stabilized. Regulatory frameworks ensuring quantum dot stability are particularly crucial in this sector, as they directly impact product safety and efficacy.

The energy sector presents another significant market opportunity, particularly in photovoltaics and solid-state lighting. Quantum dot solar cells have demonstrated theoretical efficiency limits exceeding traditional silicon-based cells, driving research investment in this area. However, market penetration remains limited by stability challenges under operational conditions, highlighting the critical need for regulatory frameworks addressing long-term stability requirements.

Regional analysis reveals North America and Asia-Pacific as the leading markets for stable quantum dot applications, collectively accounting for over 70% of global market share. Stringent regulatory environments in these regions have accelerated the development of stabilization technologies, creating market entry barriers but also ensuring higher product quality and reliability.

Industry surveys indicate that 78% of end-users cite stability and reliability as the primary concerns when adopting quantum dot technology, outranking cost considerations. This consumer preference has created a premium market segment for demonstrably stable quantum dot products that comply with established regulatory frameworks, particularly in consumer electronics and medical applications.

The market landscape is further shaped by emerging applications in security and anti-counterfeiting measures, where stable quantum dots serve as authentication markers. This segment is projected to grow at 25% annually, driven by increasing concerns about product authenticity and intellectual property protection across global supply chains.

Global Regulatory Landscape and Technical Challenges

The regulatory landscape for quantum dot technology is characterized by a complex interplay of regional frameworks, with significant variations in approach and stringency. In the United States, the Environmental Protection Agency (EPA) regulates quantum dots primarily through the Toxic Substances Control Act (TSCA), which requires manufacturers to submit premanufacture notices for new chemical substances. The FDA also maintains oversight for quantum dots in biomedical applications, imposing rigorous stability and biocompatibility requirements.

The European Union employs a more precautionary approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which places the burden of proof on companies to demonstrate safety. Additionally, the EU's Restriction of Hazardous Substances (RoHS) directive specifically limits the use of certain heavy metals commonly found in quantum dots, such as cadmium, lead, and mercury, presenting significant technical challenges for manufacturers.

In Asia, regulatory frameworks show considerable diversity. Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances both require extensive stability testing and environmental impact assessments. South Korea has implemented the K-REACH system, closely modeled after the EU approach but with distinct reporting requirements and thresholds.

A critical technical challenge emerging from these regulatory frameworks is the need to develop standardized stability testing protocols. Current methodologies vary significantly across jurisdictions, creating compliance difficulties for global manufacturers. The lack of harmonized testing standards for quantum dot degradation under various environmental conditions represents a substantial barrier to market entry.

Another major challenge is the cadmium conundrum. While cadmium-based quantum dots offer superior optical properties and stability, their toxic nature has led to severe restrictions in many markets. This has accelerated research into cadmium-free alternatives, though these generally exhibit lower quantum yields and reduced stability, particularly under prolonged light exposure and elevated temperatures.

The bioaccumulation potential of quantum dots presents both regulatory and technical challenges. Long-term environmental fate studies are increasingly required by regulatory bodies, yet standardized methodologies for assessing the persistence, bioaccumulation, and toxicity (PBT) properties of quantum dots remain underdeveloped.

Emerging regulations are also beginning to address end-of-life considerations, with extended producer responsibility frameworks requiring manufacturers to account for the entire lifecycle of quantum dot products. This necessitates the development of recycling technologies capable of safely recovering and processing these nanomaterials, an area where technical solutions remain limited.

The European Union employs a more precautionary approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which places the burden of proof on companies to demonstrate safety. Additionally, the EU's Restriction of Hazardous Substances (RoHS) directive specifically limits the use of certain heavy metals commonly found in quantum dots, such as cadmium, lead, and mercury, presenting significant technical challenges for manufacturers.

In Asia, regulatory frameworks show considerable diversity. Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances both require extensive stability testing and environmental impact assessments. South Korea has implemented the K-REACH system, closely modeled after the EU approach but with distinct reporting requirements and thresholds.

A critical technical challenge emerging from these regulatory frameworks is the need to develop standardized stability testing protocols. Current methodologies vary significantly across jurisdictions, creating compliance difficulties for global manufacturers. The lack of harmonized testing standards for quantum dot degradation under various environmental conditions represents a substantial barrier to market entry.

Another major challenge is the cadmium conundrum. While cadmium-based quantum dots offer superior optical properties and stability, their toxic nature has led to severe restrictions in many markets. This has accelerated research into cadmium-free alternatives, though these generally exhibit lower quantum yields and reduced stability, particularly under prolonged light exposure and elevated temperatures.

The bioaccumulation potential of quantum dots presents both regulatory and technical challenges. Long-term environmental fate studies are increasingly required by regulatory bodies, yet standardized methodologies for assessing the persistence, bioaccumulation, and toxicity (PBT) properties of quantum dots remain underdeveloped.

Emerging regulations are also beginning to address end-of-life considerations, with extended producer responsibility frameworks requiring manufacturers to account for the entire lifecycle of quantum dot products. This necessitates the development of recycling technologies capable of safely recovering and processing these nanomaterials, an area where technical solutions remain limited.

Current Compliance Solutions and Testing Methodologies

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help to prevent oxidation, photo-degradation, and aggregation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help to prevent oxidation, photo-degradation, and aggregation of quantum dots, thereby improving their long-term stability and performance in various applications.

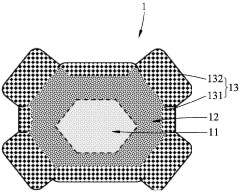

- Core-shell structures for improved quantum dot stability: Core-shell structured quantum dots offer enhanced stability compared to core-only quantum dots. The shell material, typically a semiconductor with a wider bandgap than the core, provides physical and chemical protection to the core. This structure effectively passivates surface defects, reduces non-radiative recombination, and shields the core from environmental factors that could cause degradation, resulting in quantum dots with improved stability and optical properties.

- Encapsulation methods for quantum dot protection: Encapsulation of quantum dots within matrices such as polymers, silica, or other inorganic materials significantly enhances their stability. These encapsulation methods create a physical barrier that protects quantum dots from oxygen, moisture, and other environmental factors that can cause degradation. Additionally, encapsulation can prevent leaching of toxic components from quantum dots, making them safer for various applications while maintaining their optical and electronic properties.

- Ligand engineering for quantum dot stability enhancement: Ligand engineering plays a crucial role in improving quantum dot stability. By carefully selecting and designing ligands that bind to the quantum dot surface, researchers can control surface chemistry, prevent aggregation, and enhance resistance to environmental degradation. Long-chain organic ligands, multidentate ligands, and cross-linkable ligands are among the strategies used to improve colloidal stability, photostability, and thermal stability of quantum dots for various applications.

- Environmental stability factors for quantum dots: Understanding and controlling environmental factors is essential for maintaining quantum dot stability. These factors include temperature, humidity, light exposure, pH, and the presence of oxidizing agents. Research focuses on developing quantum dots that remain stable across a wide range of environmental conditions, enabling their use in diverse applications such as displays, lighting, biomedical imaging, and photovoltaics. Stability testing protocols and standardization methods are also being developed to assess quantum dot performance under various environmental stresses.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically a semiconductor with a wider bandgap than the core, protects the core from oxidation and other degradation mechanisms. Multi-shell structures can further improve stability while maintaining or enhancing the optical properties of quantum dots, making them suitable for applications requiring prolonged stability under harsh conditions.Expand Specific Solutions03 Polymer encapsulation for quantum dot protection

Encapsulating quantum dots within polymer matrices provides excellent protection against environmental factors that cause degradation. Polymers create physical barriers that prevent oxygen and moisture from reaching the quantum dot surface. Additionally, specific polymers can be selected to enhance compatibility with target applications, improve dispersibility in various media, and reduce toxicity concerns, all while maintaining the optical properties of the quantum dots.Expand Specific Solutions04 Stabilization additives and ligand engineering

Specific additives and carefully engineered ligands can significantly improve quantum dot stability. Antioxidants, UV stabilizers, and certain metal ions can be incorporated into quantum dot formulations to prevent degradation. Ligand engineering focuses on designing and attaching molecules that provide both electronic passivation of surface defects and steric protection against environmental factors, resulting in quantum dots with enhanced stability for various applications.Expand Specific Solutions05 Environmental control and device integration strategies

Controlling the environment in which quantum dots operate is crucial for their stability. This includes strategies such as hermetic sealing, oxygen and moisture barriers, and temperature management systems. When integrating quantum dots into devices, specific design considerations can enhance stability, such as embedding them in protective matrices, using barrier layers, and optimizing device architectures to minimize stress factors that could lead to quantum dot degradation.Expand Specific Solutions

Key Regulatory Bodies and Industry Stakeholders

The regulatory landscape for quantum dot stability is evolving as the technology matures, with market growth accelerating despite being in early commercialization stages. Key frameworks include the EU's REACH regulation, FDA guidelines for biomedical applications, and ISO standards for nanomaterials safety. Leading companies like Samsung, Google, and Microsoft are advancing stability solutions through proprietary technologies, while research institutions such as Duke University and INRIA contribute fundamental innovations. Mojo Vision and TCL Research America are developing commercial applications with enhanced stability profiles. The competitive landscape is characterized by cross-sector collaboration between academic institutions and industry players, with increasing focus on environmental safety and biocompatibility as quantum dot applications expand beyond displays into healthcare and energy sectors.

Suzhou Xingshuo Nanotechnology Co Ltd.

Technical Solution: Suzhou Xingshuo Nanotechnology has developed a comprehensive regulatory compliance framework for quantum dot stability that addresses both environmental and health concerns. Their approach includes implementing strict quality control measures during manufacturing to ensure consistent quantum dot properties and stability. The company has established a proprietary encapsulation technology that significantly reduces heavy metal leaching from quantum dots, meeting the stringent requirements of RoHS (Restriction of Hazardous Substances) regulations in multiple jurisdictions. Their framework also incorporates regular stability testing protocols that align with ISO standards for nanomaterials, ensuring long-term performance reliability while maintaining regulatory compliance. Suzhou Xingshuo has additionally developed documentation systems that track quantum dot materials throughout their lifecycle, enabling full traceability required by emerging regulations in China and internationally.

Strengths: Strong focus on heavy metal containment technologies that exceed current regulatory requirements; established testing protocols specifically designed for quantum dot applications. Weaknesses: Framework primarily optimized for Chinese regulatory environment, potentially requiring adaptation for full compliance with emerging EU and US standards.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has implemented a multi-tiered regulatory compliance framework for quantum dot stability in their display technologies. Their approach integrates both international and regional regulatory requirements, with particular attention to the EU's RoHS and REACH regulations. Samsung's framework includes a specialized cadmium-free quantum dot technology that maintains stability while eliminating toxic heavy metals, addressing one of the primary regulatory concerns worldwide. The company has established comprehensive stability testing protocols that evaluate quantum dot performance under various environmental conditions, including temperature fluctuations, humidity exposure, and prolonged light exposure - all critical factors in regulatory assessments. Samsung also maintains a dedicated regulatory affairs team that continuously monitors evolving global standards for nanomaterials and quantum dots, allowing them to proactively adapt their compliance framework. Their approach includes detailed documentation of material composition, manufacturing processes, and stability test results to satisfy regulatory reporting requirements across different markets.

Strengths: Comprehensive global regulatory compliance strategy; advanced cadmium-free technology that preemptively addresses stricter future regulations; robust stability testing protocols. Weaknesses: Higher production costs associated with premium materials used to achieve regulatory compliance; potential performance trade-offs compared to less regulated quantum dot formulations.

Critical Regulatory Standards and Scientific Literature

Quantum dot with excellent stability and method for making the same

PatentActiveTW202233803A

Innovation

- A quantum dot structure with a core-shell configuration, where a non-oxidized core is protected by a selectively grown inner shell, followed by etching and ligand exchange to stabilize the core, allowing for uniform particle size and improved yield.

Quantum dot and method for producing same, resin composition, wavelength converting material, and light-emitting element

PatentWO2019111617A1

Innovation

- Modifying the surface of semiconductor crystal particles with ligands that coordinate in a bidentate or more manner, followed by coating with inorganic oxides or polymers to enhance stability and compatibility with resins.

Environmental Impact Assessment of Quantum Dot Materials

The environmental impact assessment of quantum dot materials has become increasingly critical as regulatory frameworks for quantum dot stability continue to evolve globally. Quantum dots (QDs), while offering revolutionary technological applications, present significant environmental concerns due to their composition often including heavy metals such as cadmium, lead, and selenium.

Regulatory bodies worldwide have established frameworks specifically addressing the environmental implications of quantum dot production, usage, and disposal. The European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation imposes strict requirements on quantum dot manufacturers to assess and mitigate environmental risks. Similarly, the EU's Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous substances in electrical and electronic equipment, directly affecting quantum dot applications in consumer electronics.

In the United States, the Environmental Protection Agency (EPA) regulates quantum dots under the Toxic Substances Control Act (TSCA), requiring comprehensive environmental impact assessments before commercial deployment. The EPA has established specific guidelines for nanomaterials, including quantum dots, focusing on their potential for bioaccumulation and persistence in ecosystems.

Life cycle assessment (LCA) methodologies have been developed specifically for quantum dot materials, evaluating environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. These assessments reveal that quantum dot production processes can be energy-intensive and generate hazardous waste streams that require specialized treatment protocols to prevent environmental contamination.

Aquatic toxicity studies have demonstrated that certain quantum dot compositions can release toxic ions when exposed to environmental conditions, potentially affecting aquatic organisms at various trophic levels. Research indicates bioaccumulation potential in aquatic food chains, raising concerns about long-term ecosystem effects. Terrestrial impact assessments have similarly identified risks associated with soil contamination from improper disposal of quantum dot-containing products.

Recent regulatory developments have focused on promoting "green" quantum dot alternatives, encouraging the development of cadmium-free and heavy metal-free quantum dots with reduced environmental footprints. Countries including Japan, South Korea, and China have implemented specialized regulatory frameworks addressing nanomaterial environmental impacts, with specific provisions for quantum dot technologies.

Industry response has included the development of comprehensive environmental management systems for quantum dot manufacturing facilities, implementing closed-loop production processes to minimize waste generation and environmental releases. Third-party certification programs have emerged to verify environmental performance claims and ensure regulatory compliance across global supply chains.

Regulatory bodies worldwide have established frameworks specifically addressing the environmental implications of quantum dot production, usage, and disposal. The European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation imposes strict requirements on quantum dot manufacturers to assess and mitigate environmental risks. Similarly, the EU's Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous substances in electrical and electronic equipment, directly affecting quantum dot applications in consumer electronics.

In the United States, the Environmental Protection Agency (EPA) regulates quantum dots under the Toxic Substances Control Act (TSCA), requiring comprehensive environmental impact assessments before commercial deployment. The EPA has established specific guidelines for nanomaterials, including quantum dots, focusing on their potential for bioaccumulation and persistence in ecosystems.

Life cycle assessment (LCA) methodologies have been developed specifically for quantum dot materials, evaluating environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. These assessments reveal that quantum dot production processes can be energy-intensive and generate hazardous waste streams that require specialized treatment protocols to prevent environmental contamination.

Aquatic toxicity studies have demonstrated that certain quantum dot compositions can release toxic ions when exposed to environmental conditions, potentially affecting aquatic organisms at various trophic levels. Research indicates bioaccumulation potential in aquatic food chains, raising concerns about long-term ecosystem effects. Terrestrial impact assessments have similarly identified risks associated with soil contamination from improper disposal of quantum dot-containing products.

Recent regulatory developments have focused on promoting "green" quantum dot alternatives, encouraging the development of cadmium-free and heavy metal-free quantum dots with reduced environmental footprints. Countries including Japan, South Korea, and China have implemented specialized regulatory frameworks addressing nanomaterial environmental impacts, with specific provisions for quantum dot technologies.

Industry response has included the development of comprehensive environmental management systems for quantum dot manufacturing facilities, implementing closed-loop production processes to minimize waste generation and environmental releases. Third-party certification programs have emerged to verify environmental performance claims and ensure regulatory compliance across global supply chains.

Cross-Border Regulatory Harmonization Strategies

The harmonization of quantum dot stability regulations across international borders represents a critical challenge for the global advancement of this technology. Currently, major regulatory bodies including the U.S. Food and Drug Administration (FDA), European Chemicals Agency (ECHA), and various Asian regulatory authorities maintain distinct frameworks for quantum dot safety assessment, creating significant market entry barriers for manufacturers and researchers.

A multi-tiered approach to regulatory harmonization is emerging as the most viable strategy. At the foundational level, establishing internationally recognized testing protocols for quantum dot stability assessment would create a common technical language. The International Organization for Standardization (ISO) has begun developing such standards through its Technical Committee 229 on Nanotechnologies, which could serve as a baseline for global regulatory alignment.

Mutual recognition agreements (MRAs) between key regulatory jurisdictions offer a pragmatic intermediate solution. The existing MRA framework between the FDA and European Medicines Agency provides a potential template for quantum dot applications, particularly in biomedical contexts. These agreements would allow stability data generated in one jurisdiction to be accepted in another, significantly reducing redundant testing requirements.

Regional harmonization initiatives present another promising pathway. The Association of Southeast Asian Nations (ASEAN) Cosmetic Directive demonstrates how regional alignment can streamline regulatory processes while maintaining appropriate safety standards. Similar approaches could be implemented for quantum dot technologies in electronics, energy, and healthcare applications across economic blocs.

Data sharing mechanisms between regulatory authorities represent a critical enabler for cross-border harmonization. The establishment of secure international databases containing non-proprietary stability data would facilitate evidence-based regulatory convergence while protecting intellectual property. The OECD's existing frameworks for chemical safety data sharing could be expanded to specifically address quantum dot stability parameters.

Industry consortia and public-private partnerships are increasingly driving harmonization efforts through voluntary standards development. The International Quantum Dot Industry Consortium, comprising major manufacturers and research institutions, has proposed a unified stability assessment framework that is gaining traction among regulatory authorities as a reference point for formal regulations.

A multi-tiered approach to regulatory harmonization is emerging as the most viable strategy. At the foundational level, establishing internationally recognized testing protocols for quantum dot stability assessment would create a common technical language. The International Organization for Standardization (ISO) has begun developing such standards through its Technical Committee 229 on Nanotechnologies, which could serve as a baseline for global regulatory alignment.

Mutual recognition agreements (MRAs) between key regulatory jurisdictions offer a pragmatic intermediate solution. The existing MRA framework between the FDA and European Medicines Agency provides a potential template for quantum dot applications, particularly in biomedical contexts. These agreements would allow stability data generated in one jurisdiction to be accepted in another, significantly reducing redundant testing requirements.

Regional harmonization initiatives present another promising pathway. The Association of Southeast Asian Nations (ASEAN) Cosmetic Directive demonstrates how regional alignment can streamline regulatory processes while maintaining appropriate safety standards. Similar approaches could be implemented for quantum dot technologies in electronics, energy, and healthcare applications across economic blocs.

Data sharing mechanisms between regulatory authorities represent a critical enabler for cross-border harmonization. The establishment of secure international databases containing non-proprietary stability data would facilitate evidence-based regulatory convergence while protecting intellectual property. The OECD's existing frameworks for chemical safety data sharing could be expanded to specifically address quantum dot stability parameters.

Industry consortia and public-private partnerships are increasingly driving harmonization efforts through voluntary standards development. The International Quantum Dot Industry Consortium, comprising major manufacturers and research institutions, has proposed a unified stability assessment framework that is gaining traction among regulatory authorities as a reference point for formal regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!