Quantum Dot Stability in Flexible Substrate Applications

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots (QDs) have emerged as a revolutionary technology in the field of optoelectronics since their initial discovery in the 1980s. These semiconductor nanocrystals, typically ranging from 2 to 10 nanometers in diameter, exhibit unique quantum confinement effects that allow precise tuning of their optical and electronic properties by simply adjusting their size. The evolution of quantum dot technology has progressed through several distinct phases, from fundamental research to commercial applications, particularly in display technologies.

The early development phase (1980s-1990s) focused primarily on synthesis methods and understanding the fundamental physics of these nanostructures. During this period, researchers established the relationship between quantum dot size and bandgap energy, laying the groundwork for future applications. The second phase (2000s) saw significant advancements in surface chemistry and core-shell structures, which dramatically improved quantum yield and stability.

The integration phase (2010s) marked the beginning of quantum dots' incorporation into commercial products, particularly in display technologies. This period witnessed the emergence of quantum dot-enhanced LCD displays (QLED), offering superior color gamut and energy efficiency compared to conventional displays. The current phase (2020s) is characterized by the expansion of quantum dots into flexible and wearable electronics, which presents new challenges regarding stability and performance under mechanical stress.

When applied to flexible substrates, quantum dots face unique stability challenges that differ significantly from their application in rigid structures. Mechanical stress, substrate deformation, and increased exposure to environmental factors can accelerate degradation processes. The primary stability issues include photo-oxidation, aggregation under mechanical stress, and interfacial delamination between quantum dots and flexible substrate materials.

The objectives of current research on quantum dot stability in flexible substrate applications are multifaceted. First, to develop robust encapsulation methods that can maintain quantum dot optical properties while accommodating substrate flexibility. Second, to engineer quantum dot surface chemistry that enhances adhesion to flexible substrates without compromising quantum yield. Third, to establish accelerated testing protocols that can accurately predict long-term stability under various mechanical and environmental conditions.

Future technological goals include achieving quantum dot-based flexible displays with operational lifetimes exceeding 50,000 hours, developing self-healing quantum dot composites that can recover from mechanical damage, and creating manufacturing processes compatible with roll-to-roll production for cost-effective scaling. Additionally, research aims to reduce or eliminate toxic heavy metals in quantum dot compositions while maintaining performance, addressing both environmental concerns and regulatory requirements in consumer electronics.

The early development phase (1980s-1990s) focused primarily on synthesis methods and understanding the fundamental physics of these nanostructures. During this period, researchers established the relationship between quantum dot size and bandgap energy, laying the groundwork for future applications. The second phase (2000s) saw significant advancements in surface chemistry and core-shell structures, which dramatically improved quantum yield and stability.

The integration phase (2010s) marked the beginning of quantum dots' incorporation into commercial products, particularly in display technologies. This period witnessed the emergence of quantum dot-enhanced LCD displays (QLED), offering superior color gamut and energy efficiency compared to conventional displays. The current phase (2020s) is characterized by the expansion of quantum dots into flexible and wearable electronics, which presents new challenges regarding stability and performance under mechanical stress.

When applied to flexible substrates, quantum dots face unique stability challenges that differ significantly from their application in rigid structures. Mechanical stress, substrate deformation, and increased exposure to environmental factors can accelerate degradation processes. The primary stability issues include photo-oxidation, aggregation under mechanical stress, and interfacial delamination between quantum dots and flexible substrate materials.

The objectives of current research on quantum dot stability in flexible substrate applications are multifaceted. First, to develop robust encapsulation methods that can maintain quantum dot optical properties while accommodating substrate flexibility. Second, to engineer quantum dot surface chemistry that enhances adhesion to flexible substrates without compromising quantum yield. Third, to establish accelerated testing protocols that can accurately predict long-term stability under various mechanical and environmental conditions.

Future technological goals include achieving quantum dot-based flexible displays with operational lifetimes exceeding 50,000 hours, developing self-healing quantum dot composites that can recover from mechanical damage, and creating manufacturing processes compatible with roll-to-roll production for cost-effective scaling. Additionally, research aims to reduce or eliminate toxic heavy metals in quantum dot compositions while maintaining performance, addressing both environmental concerns and regulatory requirements in consumer electronics.

Market Analysis for Flexible Quantum Dot Displays

The flexible quantum dot display market is experiencing unprecedented growth, driven by increasing consumer demand for bendable, foldable, and rollable display technologies. Current market valuations place this sector at approximately 4.5 billion USD in 2023, with projections indicating a compound annual growth rate of 21.7% through 2028. This remarkable expansion is primarily fueled by the integration of quantum dot technology into next-generation flexible displays for smartphones, wearables, and automotive applications.

Consumer electronics represents the largest market segment, accounting for nearly 65% of the total market share. Within this segment, smartphone manufacturers are increasingly adopting flexible quantum dot displays to differentiate their premium product lines. Samsung Electronics and BOE Technology have emerged as frontrunners, collectively controlling over 40% of the market supply chain.

Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring flexible quantum dot displays, citing enhanced color accuracy, brightness, and energy efficiency as primary motivators. This consumer preference has created a significant value proposition for manufacturers, despite the higher production costs associated with quantum dot integration in flexible substrates.

Regional analysis reveals that Asia-Pacific dominates the market with 58% share, followed by North America (22%) and Europe (17%). China, South Korea, and Japan lead manufacturing capacity, while North American and European markets drive high-end consumption. Emerging markets in India and Brazil are showing accelerated adoption rates, growing at 27% annually.

The automotive sector represents the fastest-growing application segment, expanding at 29% annually as vehicle manufacturers incorporate flexible quantum dot displays into dashboard systems and entertainment consoles. This trend is particularly pronounced in electric vehicles, where energy-efficient display technologies offer tangible benefits for battery conservation.

Market challenges primarily revolve around production costs and stability concerns. The price premium for flexible quantum dot displays currently stands at 30-40% above conventional OLED alternatives, though this gap is narrowing by approximately 5-7% annually as manufacturing processes mature. Stability issues in flexible applications remain a significant market barrier, with consumers reporting concerns about display degradation after repeated folding or exposure to environmental stressors.

Industry forecasts suggest that technological breakthroughs in quantum dot stability could potentially double the addressable market within three years, particularly if durability metrics can match or exceed those of conventional flexible OLED displays.

Consumer electronics represents the largest market segment, accounting for nearly 65% of the total market share. Within this segment, smartphone manufacturers are increasingly adopting flexible quantum dot displays to differentiate their premium product lines. Samsung Electronics and BOE Technology have emerged as frontrunners, collectively controlling over 40% of the market supply chain.

Market research indicates that consumers are willing to pay a premium of 15-20% for devices featuring flexible quantum dot displays, citing enhanced color accuracy, brightness, and energy efficiency as primary motivators. This consumer preference has created a significant value proposition for manufacturers, despite the higher production costs associated with quantum dot integration in flexible substrates.

Regional analysis reveals that Asia-Pacific dominates the market with 58% share, followed by North America (22%) and Europe (17%). China, South Korea, and Japan lead manufacturing capacity, while North American and European markets drive high-end consumption. Emerging markets in India and Brazil are showing accelerated adoption rates, growing at 27% annually.

The automotive sector represents the fastest-growing application segment, expanding at 29% annually as vehicle manufacturers incorporate flexible quantum dot displays into dashboard systems and entertainment consoles. This trend is particularly pronounced in electric vehicles, where energy-efficient display technologies offer tangible benefits for battery conservation.

Market challenges primarily revolve around production costs and stability concerns. The price premium for flexible quantum dot displays currently stands at 30-40% above conventional OLED alternatives, though this gap is narrowing by approximately 5-7% annually as manufacturing processes mature. Stability issues in flexible applications remain a significant market barrier, with consumers reporting concerns about display degradation after repeated folding or exposure to environmental stressors.

Industry forecasts suggest that technological breakthroughs in quantum dot stability could potentially double the addressable market within three years, particularly if durability metrics can match or exceed those of conventional flexible OLED displays.

Stability Challenges in Quantum Dot Flexible Applications

Quantum dots (QDs) integrated into flexible substrates face significant stability challenges that currently limit their widespread commercial adoption. The inherent physical and chemical properties of QDs make them susceptible to degradation under various environmental conditions, particularly when incorporated into flexible applications that introduce additional stress factors.

The primary stability challenge stems from the core-shell structure of quantum dots, which can be compromised during the integration process with flexible materials. When QDs are embedded in polymeric substrates that undergo repeated bending, twisting, or stretching, the mechanical stress can disrupt the protective shell layer, exposing the core to oxidation and other degradation mechanisms. This structural vulnerability is particularly pronounced in applications requiring high flexibility, such as wearable displays or conformable lighting solutions.

Environmental factors pose another significant challenge to QD stability in flexible applications. Oxygen and moisture penetration through flexible substrates occurs more readily than through rigid alternatives, accelerating photo-oxidation processes that lead to luminescence quenching and color shifts. Temperature fluctuations, which are common in wearable and portable applications, further exacerbate these effects by promoting diffusion of oxygen and water molecules to the QD surface.

The interface between quantum dots and flexible substrate materials presents additional stability concerns. Chemical incompatibility between QDs' surface ligands and polymer matrices can lead to phase separation over time, resulting in aggregation that diminishes optical performance. The dynamic nature of flexible substrates means that even initially well-dispersed QDs may gradually migrate and cluster during repeated mechanical deformation cycles.

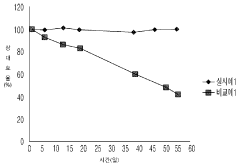

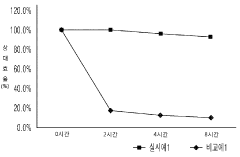

Photostability represents another critical challenge, particularly for display and lighting applications. The combination of mechanical stress from flexibility and photoinduced degradation creates a compound effect that accelerates performance deterioration. Studies have shown that QDs in flexible substrates typically exhibit faster photoluminescence decay rates compared to those in rigid encapsulation under identical illumination conditions.

Manufacturing processes for flexible QD applications introduce their own stability challenges. The solvents and processing conditions required for flexible substrate production can adversely affect QD surface chemistry, while the lower processing temperature limits compared to rigid substrates restrict the use of high-temperature annealing techniques that might otherwise enhance stability.

Long-term reliability testing reveals that QDs in flexible applications typically demonstrate accelerated aging compared to their rigid counterparts, with performance metrics declining more rapidly under standard testing protocols. This accelerated degradation significantly impacts product lifetime expectations and creates barriers to commercialization in applications where extended durability is essential.

The primary stability challenge stems from the core-shell structure of quantum dots, which can be compromised during the integration process with flexible materials. When QDs are embedded in polymeric substrates that undergo repeated bending, twisting, or stretching, the mechanical stress can disrupt the protective shell layer, exposing the core to oxidation and other degradation mechanisms. This structural vulnerability is particularly pronounced in applications requiring high flexibility, such as wearable displays or conformable lighting solutions.

Environmental factors pose another significant challenge to QD stability in flexible applications. Oxygen and moisture penetration through flexible substrates occurs more readily than through rigid alternatives, accelerating photo-oxidation processes that lead to luminescence quenching and color shifts. Temperature fluctuations, which are common in wearable and portable applications, further exacerbate these effects by promoting diffusion of oxygen and water molecules to the QD surface.

The interface between quantum dots and flexible substrate materials presents additional stability concerns. Chemical incompatibility between QDs' surface ligands and polymer matrices can lead to phase separation over time, resulting in aggregation that diminishes optical performance. The dynamic nature of flexible substrates means that even initially well-dispersed QDs may gradually migrate and cluster during repeated mechanical deformation cycles.

Photostability represents another critical challenge, particularly for display and lighting applications. The combination of mechanical stress from flexibility and photoinduced degradation creates a compound effect that accelerates performance deterioration. Studies have shown that QDs in flexible substrates typically exhibit faster photoluminescence decay rates compared to those in rigid encapsulation under identical illumination conditions.

Manufacturing processes for flexible QD applications introduce their own stability challenges. The solvents and processing conditions required for flexible substrate production can adversely affect QD surface chemistry, while the lower processing temperature limits compared to rigid substrates restrict the use of high-temperature annealing techniques that might otherwise enhance stability.

Long-term reliability testing reveals that QDs in flexible applications typically demonstrate accelerated aging compared to their rigid counterparts, with performance metrics declining more rapidly under standard testing protocols. This accelerated degradation significantly impacts product lifetime expectations and creates barriers to commercialization in applications where extended durability is essential.

Current Stability Enhancement Techniques

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification for quantum dot stability: Surface modification techniques can significantly enhance the stability of quantum dots. These methods involve coating the quantum dots with protective layers such as ligands, polymers, or inorganic shells that prevent oxidation and degradation. The modified surface chemistry improves colloidal stability, prevents aggregation, and protects the quantum dots from environmental factors that could affect their optical and electronic properties. These approaches are crucial for maintaining long-term stability in various applications.

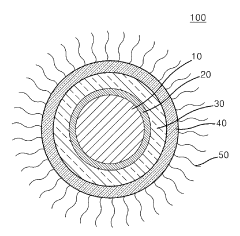

- Core-shell structures for enhanced stability: Core-shell quantum dot structures significantly improve stability by providing physical isolation of the core material from the surrounding environment. The shell, typically composed of a wider bandgap semiconductor material, protects the optically active core from oxidation and other degradation mechanisms. This architecture not only enhances chemical stability but also improves quantum yield and reduces surface defects, resulting in more stable photoluminescence properties over time and under various environmental conditions.

- Stability in device integration and manufacturing: Ensuring quantum dot stability during device integration and manufacturing processes presents unique challenges. Techniques such as encapsulation, matrix embedding, and specialized deposition methods help maintain quantum dot properties during exposure to high temperatures, solvents, and other processing conditions. These approaches are essential for incorporating quantum dots into electronic devices, displays, and sensors while preserving their optical and electronic characteristics throughout the manufacturing process and device lifetime.

- Environmental stability enhancement methods: Methods to improve quantum dot stability against environmental factors such as oxygen, moisture, heat, and light exposure are critical for practical applications. These include hermetic sealing techniques, incorporation of oxygen scavengers, UV blockers, and specialized packaging materials. Advanced formulations may also include stabilizing additives that neutralize reactive species or prevent degradation pathways, significantly extending the operational lifetime of quantum dot-based materials and devices under real-world conditions.

- Colloidal stability in solution and dispersions: Maintaining colloidal stability of quantum dots in solutions and dispersions is essential for many applications, particularly in biological systems and solution-processed electronics. This involves controlling surface charge, steric hindrance, and solvent interactions to prevent aggregation and precipitation. Techniques include ligand exchange processes, polymer coating, and pH control to create stable dispersions that maintain their optical properties and size distribution over extended periods, even in complex media or under changing environmental conditions.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. Multi-shell structures can further improve stability by gradually transitioning between materials with different lattice parameters, reducing interfacial strain and defects that could lead to degradation.Expand Specific Solutions03 Environmental stability factors for quantum dots

Quantum dots are sensitive to various environmental factors that affect their stability. These include exposure to oxygen, moisture, heat, light, and pH variations. Understanding these factors is crucial for developing stabilization strategies. Research focuses on creating quantum dots that maintain their optical and electronic properties under challenging environmental conditions through innovative formulation and encapsulation methods.Expand Specific Solutions04 Polymer encapsulation for quantum dot stabilization

Polymer encapsulation provides an effective approach to enhance quantum dot stability. By embedding quantum dots within polymer matrices or coating them with polymer layers, they are protected from environmental degradation factors. Various polymers with different properties can be selected based on the specific application requirements. This technique not only improves stability but also enables better processability and integration of quantum dots into devices.Expand Specific Solutions05 Stabilization methods for quantum dots in solution

Maintaining the stability of quantum dots in solution presents unique challenges that require specific stabilization strategies. These include the use of appropriate solvents, surfactants, and dispersing agents to prevent aggregation. Controlling the ionic strength and pH of the solution is also critical. Advanced colloidal stabilization techniques help maintain quantum dots in stable dispersions for extended periods, which is essential for many biological applications and solution-processing methods.Expand Specific Solutions

Leading Companies in Quantum Dot Flexible Technology

The quantum dot stability in flexible substrate applications market is currently in a growth phase, characterized by increasing R&D investments and expanding commercial applications. The global market is projected to grow significantly as quantum dot technology advances from research labs to commercial products. Leading players include Samsung Display and BOE Technology Group, who are integrating quantum dots into flexible displays, while specialized materials companies like Najing Technology and Mojo Vision are developing proprietary quantum dot technologies with enhanced stability characteristics. Research institutions such as Southern University of Science & Technology and University of Basel are contributing fundamental breakthroughs in quantum dot stability, while established chemical companies like Shin-Etsu Chemical and 3M Innovative Properties provide essential substrate materials and manufacturing solutions for the emerging flexible quantum dot ecosystem.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive quantum dot stabilization system specifically designed for flexible display applications. Their approach centers on a dual-protection strategy that addresses both chemical and mechanical stability challenges. For chemical stability, BOE employs proprietary surface ligand engineering that creates strong covalent bonds between QDs and surrounding polymer matrices, significantly reducing oxidation vulnerability[1]. The company has pioneged a gradient-density encapsulation technique where QDs are embedded in polymer layers with varying elastic properties, allowing for stress distribution during flexing while maintaining optical performance. BOE's research includes specialized silica-based shells with modified surface chemistry that improves compatibility with flexible substrates while providing robust environmental protection. Their technology incorporates self-healing polymer components that can repair microfractures formed during repeated bending cycles, extending the operational lifetime of QD-enhanced flexible displays[3]. Recent advancements include temperature-stabilized QD formulations that maintain performance across wide operating temperature ranges.

Strengths: Their gradient-density encapsulation approach provides excellent mechanical stability during repeated flexing cycles. The self-healing polymer technology addresses a critical failure point in flexible QD applications. Weaknesses: The complex multi-layer structure may increase manufacturing complexity and production costs compared to simpler approaches. Some of their stabilization techniques may slightly reduce initial quantum yield.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced quantum dot (QD) stabilization techniques for flexible displays, focusing on core-shell structures that protect QDs from environmental degradation. Their approach involves encapsulating QDs in specialized polymer matrices that maintain optical properties while allowing mechanical flexibility. Samsung's research includes novel ligand exchange processes that improve QD-polymer compatibility and reduce aggregation during substrate flexing[1]. They've pioneered multi-layer encapsulation technology that creates oxygen and moisture barriers around QDs, significantly extending operational lifetime in flexible applications. Recent developments include temperature-resistant QD formulations that maintain stability through the high-temperature processes required for flexible substrate manufacturing[2]. Samsung has also developed proprietary surface treatment methods that enhance adhesion between QDs and flexible substrates while minimizing stress-induced degradation during bending cycles.

Strengths: Industry-leading encapsulation technology provides superior protection against oxygen and moisture penetration. Extensive manufacturing infrastructure enables rapid commercialization of research breakthroughs. Weaknesses: Their solutions often require complex multi-layer structures that increase production costs and may limit ultimate flexibility compared to simpler approaches.

Key Patents in Quantum Dot Encapsulation Methods

Method and device for surface treatment of quantum dots

PatentWO2022124127A1

Innovation

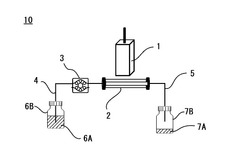

- A surface treatment method involving a silicone compound with substituents that can be photopolymerized onto quantum dots, using a reaction channel that allows continuous light irradiation to ensure uniform coating, even with large solution volumes, enhancing stability and compatibility with resin materials.

Quantum dot and method for producing same

PatentWO2017116013A1

Innovation

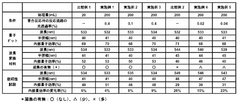

- The development of quantum dots with a core-shell structure and additional stability layers, along with a ligand layer, enhances stability and efficiency, featuring a stability index of 90% or more and quantum efficiency of 80% or more, and allowing for conversion efficiency of 100% or more when switching from lipid-soluble to water-soluble ligands.

Environmental Impact of Quantum Dot Materials

The environmental impact of quantum dot materials represents a critical consideration in the development and deployment of quantum dot technologies in flexible substrates. Quantum dots (QDs), while offering exceptional optical and electronic properties, contain heavy metals such as cadmium, lead, selenium, and indium that pose significant environmental and health concerns throughout their lifecycle.

Manufacturing processes for quantum dots involve energy-intensive methods and potentially hazardous chemicals. The synthesis typically requires high temperatures and organic solvents, resulting in considerable energy consumption and chemical waste generation. Purification steps further compound these environmental impacts through additional solvent usage and waste production. Recent life cycle assessments indicate that the carbon footprint of quantum dot production can be 10-15 times higher per unit mass compared to conventional semiconductor materials.

During the operational phase, quantum dot stability directly correlates with environmental impact. Unstable QDs in flexible substrates may leach toxic heavy metals when exposed to environmental stressors such as moisture, heat, or mechanical stress. Studies have shown that cadmium-based quantum dots can release up to 10% of their cadmium content within 30 days under simulated environmental conditions, particularly when encapsulation methods are compromised by substrate flexing.

End-of-life considerations present perhaps the most significant environmental challenge. The composite nature of flexible QD devices complicates recycling efforts, often resulting in improper disposal. When landfilled, degrading quantum dot materials can potentially contaminate soil and groundwater systems. Research indicates that heavy metals from improperly disposed QDs can remain bioavailable in soil for decades, with potential for bioaccumulation in ecosystems.

Regulatory frameworks worldwide are increasingly addressing these concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive limits the use of certain heavy metals in electronic equipment, while the U.S. Environmental Protection Agency has established reporting requirements for nanomaterials including quantum dots. These regulations are driving research toward more environmentally benign alternatives.

Recent innovations focus on developing "green" quantum dots using less toxic materials. Silicon-based, carbon-based, and certain metal oxide quantum dots show promise as environmentally friendly alternatives. Additionally, improved encapsulation technologies and substrate materials are being developed to enhance QD stability and reduce leaching potential, with some recent designs demonstrating up to 95% reduction in heavy metal release under environmental stress conditions.

Manufacturing processes for quantum dots involve energy-intensive methods and potentially hazardous chemicals. The synthesis typically requires high temperatures and organic solvents, resulting in considerable energy consumption and chemical waste generation. Purification steps further compound these environmental impacts through additional solvent usage and waste production. Recent life cycle assessments indicate that the carbon footprint of quantum dot production can be 10-15 times higher per unit mass compared to conventional semiconductor materials.

During the operational phase, quantum dot stability directly correlates with environmental impact. Unstable QDs in flexible substrates may leach toxic heavy metals when exposed to environmental stressors such as moisture, heat, or mechanical stress. Studies have shown that cadmium-based quantum dots can release up to 10% of their cadmium content within 30 days under simulated environmental conditions, particularly when encapsulation methods are compromised by substrate flexing.

End-of-life considerations present perhaps the most significant environmental challenge. The composite nature of flexible QD devices complicates recycling efforts, often resulting in improper disposal. When landfilled, degrading quantum dot materials can potentially contaminate soil and groundwater systems. Research indicates that heavy metals from improperly disposed QDs can remain bioavailable in soil for decades, with potential for bioaccumulation in ecosystems.

Regulatory frameworks worldwide are increasingly addressing these concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive limits the use of certain heavy metals in electronic equipment, while the U.S. Environmental Protection Agency has established reporting requirements for nanomaterials including quantum dots. These regulations are driving research toward more environmentally benign alternatives.

Recent innovations focus on developing "green" quantum dots using less toxic materials. Silicon-based, carbon-based, and certain metal oxide quantum dots show promise as environmentally friendly alternatives. Additionally, improved encapsulation technologies and substrate materials are being developed to enhance QD stability and reduce leaching potential, with some recent designs demonstrating up to 95% reduction in heavy metal release under environmental stress conditions.

Manufacturing Scalability Considerations

The transition from laboratory-scale production to industrial manufacturing of quantum dot-enhanced flexible substrates presents significant challenges that must be addressed to ensure commercial viability. Current manufacturing processes for quantum dots typically involve batch synthesis methods that produce limited quantities with variable quality. For flexible substrate applications, where uniformity and consistency are paramount, these limitations become particularly problematic. The industry requires scalable production techniques that maintain quantum dot stability while enabling high-throughput manufacturing.

Roll-to-roll processing emerges as a promising approach for large-scale production of quantum dot-integrated flexible substrates. This continuous manufacturing method allows for significant increases in production volume compared to traditional batch processes. However, implementing quantum dots within roll-to-roll systems introduces challenges related to deposition uniformity, curing conditions, and encapsulation integrity. The speed of the substrate movement through the production line directly impacts quantum dot arrangement and stability, requiring precise engineering controls.

Material compatibility issues also affect manufacturing scalability. The solvents and processing conditions used in large-scale production may differ from laboratory environments, potentially altering quantum dot surface chemistry and stability. Industrial manufacturing typically involves higher temperatures, mechanical stresses, and exposure to various chemicals that can compromise quantum dot performance. Developing robust quantum dot formulations that withstand these manufacturing conditions without degradation represents a critical research priority.

Cost considerations play a decisive role in scaling production. Current high-purity quantum dot synthesis methods involve expensive precursors and energy-intensive processes. For mass market applications in flexible electronics, production costs must decrease substantially. Research into alternative precursors, more efficient synthesis routes, and recovery/recycling systems for valuable materials could significantly improve economic feasibility. Additionally, yield optimization becomes increasingly important at scale, as even small percentages of defective product translate to substantial financial losses.

Quality control systems present another manufacturing challenge. Inline monitoring of quantum dot properties during high-speed production requires sophisticated sensing technologies that do not currently exist at industrial scale. Developing rapid, non-destructive testing methods to verify quantum dot stability and performance characteristics throughout the manufacturing process will be essential for maintaining consistent product quality. This may involve advanced spectroscopic techniques adapted for production environments or machine learning algorithms that can detect subtle variations in optical properties.

Environmental and safety considerations also impact scalability. Many quantum dot formulations contain heavy metals or toxic components that require careful handling during mass production. Developing greener synthesis methods and implementing appropriate containment systems will be necessary to meet regulatory requirements while scaling up manufacturing operations. These factors must be addressed holistically to enable truly scalable production of quantum dot-enhanced flexible substrates.

Roll-to-roll processing emerges as a promising approach for large-scale production of quantum dot-integrated flexible substrates. This continuous manufacturing method allows for significant increases in production volume compared to traditional batch processes. However, implementing quantum dots within roll-to-roll systems introduces challenges related to deposition uniformity, curing conditions, and encapsulation integrity. The speed of the substrate movement through the production line directly impacts quantum dot arrangement and stability, requiring precise engineering controls.

Material compatibility issues also affect manufacturing scalability. The solvents and processing conditions used in large-scale production may differ from laboratory environments, potentially altering quantum dot surface chemistry and stability. Industrial manufacturing typically involves higher temperatures, mechanical stresses, and exposure to various chemicals that can compromise quantum dot performance. Developing robust quantum dot formulations that withstand these manufacturing conditions without degradation represents a critical research priority.

Cost considerations play a decisive role in scaling production. Current high-purity quantum dot synthesis methods involve expensive precursors and energy-intensive processes. For mass market applications in flexible electronics, production costs must decrease substantially. Research into alternative precursors, more efficient synthesis routes, and recovery/recycling systems for valuable materials could significantly improve economic feasibility. Additionally, yield optimization becomes increasingly important at scale, as even small percentages of defective product translate to substantial financial losses.

Quality control systems present another manufacturing challenge. Inline monitoring of quantum dot properties during high-speed production requires sophisticated sensing technologies that do not currently exist at industrial scale. Developing rapid, non-destructive testing methods to verify quantum dot stability and performance characteristics throughout the manufacturing process will be essential for maintaining consistent product quality. This may involve advanced spectroscopic techniques adapted for production environments or machine learning algorithms that can detect subtle variations in optical properties.

Environmental and safety considerations also impact scalability. Many quantum dot formulations contain heavy metals or toxic components that require careful handling during mass production. Developing greener synthesis methods and implementing appropriate containment systems will be necessary to meet regulatory requirements while scaling up manufacturing operations. These factors must be addressed holistically to enable truly scalable production of quantum dot-enhanced flexible substrates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!