Quantum Dot Stability in Lightweight Photovoltaic Modules

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot PV Evolution and Objectives

Quantum dots (QDs) have emerged as a revolutionary material in photovoltaic technology, offering unprecedented potential for enhancing solar energy conversion efficiency. The evolution of quantum dot photovoltaics began in the early 2000s when researchers first demonstrated the quantum confinement effect in semiconductor nanocrystals, allowing for precise tuning of bandgaps to optimize solar spectrum absorption. This fundamental discovery laid the groundwork for subsequent developments in QD-based solar cells.

The progression of quantum dot technology in photovoltaics has followed several distinct phases. Initially, research focused on proof-of-concept demonstrations, establishing that QDs could indeed function as light-harvesting materials. By 2010, attention shifted toward improving quantum dot synthesis methods, with significant breakthroughs in hot-injection techniques and ligand exchange protocols that dramatically enhanced QD quality and stability.

Between 2015 and 2020, the field witnessed remarkable advances in QD surface chemistry, addressing one of the primary challenges in quantum dot stability. Researchers developed core-shell architectures and surface passivation strategies that significantly reduced degradation pathways, extending operational lifetimes from hours to months. This period also saw the first commercial prototypes of QD-enhanced solar modules, though primarily in niche applications.

The current technological landscape is characterized by intensive efforts to integrate quantum dots into lightweight, flexible photovoltaic modules. This direction represents a convergence of two high-potential solar technologies: quantum dot-based light absorption and thin-film manufacturing processes. The primary objective is to develop QD formulations that maintain their exceptional optoelectronic properties while withstanding the mechanical stress inherent in flexible module designs.

Looking forward, the technical objectives for quantum dot stability in lightweight photovoltaic modules are multifaceted. First, researchers aim to extend operational stability under standard testing conditions from the current benchmark of approximately 1,000 hours to over 10,000 hours, approaching the stability of traditional silicon modules. Second, there is a push to develop encapsulation technologies specifically designed for QD protection in flexible form factors, addressing challenges related to oxygen and moisture penetration.

Another critical objective involves reducing the environmental sensitivity of quantum dots without compromising their quantum yield or absorption characteristics. This includes developing synthesis routes for environmentally robust QDs that maintain performance across temperature ranges from -40°C to 85°C and humidity levels up to 85%, essential for real-world deployment. Additionally, researchers are exploring self-healing QD formulations that can recover from photo-induced damage, potentially revolutionizing module longevity.

The progression of quantum dot technology in photovoltaics has followed several distinct phases. Initially, research focused on proof-of-concept demonstrations, establishing that QDs could indeed function as light-harvesting materials. By 2010, attention shifted toward improving quantum dot synthesis methods, with significant breakthroughs in hot-injection techniques and ligand exchange protocols that dramatically enhanced QD quality and stability.

Between 2015 and 2020, the field witnessed remarkable advances in QD surface chemistry, addressing one of the primary challenges in quantum dot stability. Researchers developed core-shell architectures and surface passivation strategies that significantly reduced degradation pathways, extending operational lifetimes from hours to months. This period also saw the first commercial prototypes of QD-enhanced solar modules, though primarily in niche applications.

The current technological landscape is characterized by intensive efforts to integrate quantum dots into lightweight, flexible photovoltaic modules. This direction represents a convergence of two high-potential solar technologies: quantum dot-based light absorption and thin-film manufacturing processes. The primary objective is to develop QD formulations that maintain their exceptional optoelectronic properties while withstanding the mechanical stress inherent in flexible module designs.

Looking forward, the technical objectives for quantum dot stability in lightweight photovoltaic modules are multifaceted. First, researchers aim to extend operational stability under standard testing conditions from the current benchmark of approximately 1,000 hours to over 10,000 hours, approaching the stability of traditional silicon modules. Second, there is a push to develop encapsulation technologies specifically designed for QD protection in flexible form factors, addressing challenges related to oxygen and moisture penetration.

Another critical objective involves reducing the environmental sensitivity of quantum dots without compromising their quantum yield or absorption characteristics. This includes developing synthesis routes for environmentally robust QDs that maintain performance across temperature ranges from -40°C to 85°C and humidity levels up to 85%, essential for real-world deployment. Additionally, researchers are exploring self-healing QD formulations that can recover from photo-induced damage, potentially revolutionizing module longevity.

Market Analysis for Lightweight QD Photovoltaics

The lightweight quantum dot (QD) photovoltaic market is experiencing significant growth, driven by increasing demand for flexible, portable, and building-integrated solar solutions. Current market valuations indicate the global lightweight photovoltaic sector reached approximately $3.5 billion in 2022, with QD-enhanced technologies representing a growing segment estimated at $420 million. Industry analysts project a compound annual growth rate of 24.7% for lightweight QD photovoltaics through 2030, substantially outpacing conventional solar technologies.

Consumer electronics represents the largest current application segment, accounting for 38% of lightweight QD photovoltaic deployments. These applications leverage the technology's flexibility, light weight, and potential for semi-transparency. Building-integrated photovoltaics (BIPV) follows closely at 31%, where QD technology enables novel architectural implementations including solar windows and façade elements that conventional silicon cannot support.

Transportation applications, particularly in automotive and aerospace sectors, constitute 17% of the market. Here, the weight reduction offers significant energy efficiency advantages, with each kilogram reduction in satellite solar arrays estimated to save $10,000-20,000 in launch costs. The remaining market share is distributed across portable charging solutions, military applications, and emerging IoT device integration.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity with 58% market share, led by China, South Korea, and Japan. North America follows with 24%, concentrating on high-efficiency premium applications and advanced research. Europe accounts for 16%, with particular focus on building integration and automotive applications aligned with stringent sustainability regulations.

Customer demand patterns indicate three primary market drivers: efficiency-to-weight ratio, durability under environmental stress, and production scalability. Current lightweight QD photovoltaic products achieve 12-18% efficiency while offering 70-90% weight reduction compared to traditional silicon panels. However, market surveys identify stability concerns as the primary barrier to wider adoption, with 67% of potential industrial customers citing longevity uncertainties as their main hesitation.

Price sensitivity analysis demonstrates market acceptance thresholds at approximately $1.20-1.80 per watt for consumer applications and $0.90-1.40 per watt for industrial implementations. Current production costs range from $1.70-2.30 per watt, indicating the necessity for manufacturing optimization to achieve broader market penetration.

The competitive landscape features both established photovoltaic manufacturers expanding into QD technology and specialized startups focused exclusively on quantum dot innovations. This market structure suggests consolidation is likely as the technology matures, with intellectual property positioning becoming increasingly critical for market participants.

Consumer electronics represents the largest current application segment, accounting for 38% of lightweight QD photovoltaic deployments. These applications leverage the technology's flexibility, light weight, and potential for semi-transparency. Building-integrated photovoltaics (BIPV) follows closely at 31%, where QD technology enables novel architectural implementations including solar windows and façade elements that conventional silicon cannot support.

Transportation applications, particularly in automotive and aerospace sectors, constitute 17% of the market. Here, the weight reduction offers significant energy efficiency advantages, with each kilogram reduction in satellite solar arrays estimated to save $10,000-20,000 in launch costs. The remaining market share is distributed across portable charging solutions, military applications, and emerging IoT device integration.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity with 58% market share, led by China, South Korea, and Japan. North America follows with 24%, concentrating on high-efficiency premium applications and advanced research. Europe accounts for 16%, with particular focus on building integration and automotive applications aligned with stringent sustainability regulations.

Customer demand patterns indicate three primary market drivers: efficiency-to-weight ratio, durability under environmental stress, and production scalability. Current lightweight QD photovoltaic products achieve 12-18% efficiency while offering 70-90% weight reduction compared to traditional silicon panels. However, market surveys identify stability concerns as the primary barrier to wider adoption, with 67% of potential industrial customers citing longevity uncertainties as their main hesitation.

Price sensitivity analysis demonstrates market acceptance thresholds at approximately $1.20-1.80 per watt for consumer applications and $0.90-1.40 per watt for industrial implementations. Current production costs range from $1.70-2.30 per watt, indicating the necessity for manufacturing optimization to achieve broader market penetration.

The competitive landscape features both established photovoltaic manufacturers expanding into QD technology and specialized startups focused exclusively on quantum dot innovations. This market structure suggests consolidation is likely as the technology matures, with intellectual property positioning becoming increasingly critical for market participants.

QD Stability Challenges in Current PV Technology

Quantum dot (QD) technology represents a significant advancement in photovoltaic (PV) module development, offering enhanced light absorption and conversion efficiency through quantum confinement effects. However, stability issues present substantial challenges that currently limit widespread commercial adoption in lightweight PV applications. The primary stability challenge stems from the inherent chemical vulnerability of quantum dots, particularly when exposed to oxygen, moisture, and UV radiation—environmental factors unavoidable in real-world PV deployments.

Core degradation mechanisms include photo-oxidation, where exposure to light and oxygen leads to surface oxidation of QDs, resulting in trap states that diminish quantum yield and reduce overall efficiency. Additionally, ligand detachment represents another critical failure mode, as the organic molecules that provide colloidal stability and passivate surface defects can desorb over time, leading to QD aggregation and performance deterioration.

Temperature fluctuations further exacerbate stability issues, with thermal cycling causing expansion and contraction that disrupts QD arrangements and degrades interfacial contacts. This is particularly problematic in lightweight modules designed for flexible applications, where mechanical stress compounds these effects. Current data indicates that unprotected QD-based devices typically show 20-30% efficiency loss within 1000 hours of operation under standard testing conditions, far below the 25-year lifespan expected of commercial PV technologies.

Material compatibility issues within device architectures present additional challenges. Interactions between QDs and adjacent layers—such as hole transport materials, electron transport layers, and encapsulants—can trigger chemical reactions that accelerate degradation. The migration of ions from these layers can poison QD surfaces, while solvent interactions during processing may strip protective ligands or alter QD surface chemistry.

Manufacturing scalability compounds these stability concerns, as techniques that preserve QD integrity in laboratory settings often prove incompatible with high-throughput industrial processes. Solution-processing methods favorable for lightweight, flexible substrates typically involve solvents and thermal treatments that can compromise QD stability before the module even enters service.

Current encapsulation strategies provide insufficient protection, particularly for flexible modules where traditional rigid glass encapsulation cannot be employed. Polymer-based barriers demonstrate inadequate oxygen and moisture impermeability over extended periods, while more effective barrier technologies significantly increase weight and cost, undermining the core advantages of lightweight PV applications.

Core degradation mechanisms include photo-oxidation, where exposure to light and oxygen leads to surface oxidation of QDs, resulting in trap states that diminish quantum yield and reduce overall efficiency. Additionally, ligand detachment represents another critical failure mode, as the organic molecules that provide colloidal stability and passivate surface defects can desorb over time, leading to QD aggregation and performance deterioration.

Temperature fluctuations further exacerbate stability issues, with thermal cycling causing expansion and contraction that disrupts QD arrangements and degrades interfacial contacts. This is particularly problematic in lightweight modules designed for flexible applications, where mechanical stress compounds these effects. Current data indicates that unprotected QD-based devices typically show 20-30% efficiency loss within 1000 hours of operation under standard testing conditions, far below the 25-year lifespan expected of commercial PV technologies.

Material compatibility issues within device architectures present additional challenges. Interactions between QDs and adjacent layers—such as hole transport materials, electron transport layers, and encapsulants—can trigger chemical reactions that accelerate degradation. The migration of ions from these layers can poison QD surfaces, while solvent interactions during processing may strip protective ligands or alter QD surface chemistry.

Manufacturing scalability compounds these stability concerns, as techniques that preserve QD integrity in laboratory settings often prove incompatible with high-throughput industrial processes. Solution-processing methods favorable for lightweight, flexible substrates typically involve solvents and thermal treatments that can compromise QD stability before the module even enters service.

Current encapsulation strategies provide insufficient protection, particularly for flexible modules where traditional rigid glass encapsulation cannot be employed. Polymer-based barriers demonstrate inadequate oxygen and moisture impermeability over extended periods, while more effective barrier technologies significantly increase weight and cost, undermining the core advantages of lightweight PV applications.

Current Approaches to QD Stability Enhancement

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification for quantum dot stability: Surface modification techniques are employed to enhance the stability of quantum dots by preventing aggregation and oxidation. These methods include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with stabilizing agents. Such modifications create a barrier against environmental factors that could degrade quantum dot performance, thereby extending their operational lifetime and maintaining their optical properties.

- Core-shell structures for improved stability: Core-shell architectures significantly enhance quantum dot stability by providing physical isolation of the core material from environmental factors. The shell material, typically a semiconductor with a wider bandgap than the core, creates a protective barrier that prevents oxidation and leaching of core atoms. These structures also improve quantum yield and reduce surface defects, resulting in more stable photoluminescence properties and extended shelf life under various environmental conditions.

- Polymer encapsulation techniques: Polymer encapsulation provides a robust method for stabilizing quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, these techniques create physical barriers against oxygen, moisture, and other reactive species. The polymer encapsulation also enables dispersion in various solvents, prevents aggregation, and maintains optical properties over extended periods, making the quantum dots suitable for diverse applications including displays and biomedical imaging.

- Stability enhancement through ligand engineering: Ligand engineering plays a crucial role in quantum dot stability by controlling surface chemistry and interactions. By selecting appropriate ligands or implementing ligand exchange processes, researchers can create quantum dots with enhanced resistance to photobleaching, oxidation, and aggregation. Multifunctional ligands can simultaneously provide colloidal stability, surface passivation, and compatibility with target environments. This approach enables fine-tuning of quantum dot properties for specific applications while maintaining long-term stability under operational conditions.

- Environmental stability and aging mechanisms: Understanding the mechanisms of quantum dot degradation under various environmental conditions is essential for developing stabilization strategies. Research focuses on identifying how factors such as temperature, humidity, light exposure, and chemical environment affect quantum dot stability over time. By characterizing aging processes and failure mechanisms, scientists can design quantum dots with improved resistance to specific environmental stressors, implement appropriate storage conditions, and develop accelerated testing protocols to predict long-term stability performance.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing a protective layer around the core material. This architecture helps isolate the optically active core from environmental factors that could cause degradation. Various shell materials and multi-shell designs can be employed to optimize stability while maintaining desired optical and electronic properties of the quantum dots.Expand Specific Solutions03 Environmental factors affecting quantum dot stability

Quantum dot stability is significantly influenced by environmental factors such as temperature, humidity, light exposure, and oxidizing agents. Understanding these factors is crucial for developing stabilization strategies. Research focuses on creating quantum dots that maintain their properties under varying environmental conditions, including methods to prevent photo-oxidation and thermal degradation.Expand Specific Solutions04 Encapsulation methods for quantum dot protection

Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials provides enhanced stability against environmental degradation. These encapsulation methods create physical barriers that protect quantum dots from oxygen, moisture, and other reactive species while potentially allowing for better integration into devices and applications. Various encapsulation techniques have been developed to balance protection with maintaining the optical properties of quantum dots.Expand Specific Solutions05 Stabilization for specific applications

Application-specific stabilization strategies for quantum dots address the unique challenges posed by different usage environments. For biomedical applications, stabilization focuses on maintaining properties in physiological conditions. For display technologies, thermal and photo-stability are prioritized. For energy applications, long-term operational stability under various conditions is essential. These targeted approaches optimize quantum dot performance for specific end uses.Expand Specific Solutions

Leading Companies in QD Photovoltaic Industry

Quantum Dot Stability in Lightweight Photovoltaic Modules is currently in a growth phase, with the market expected to reach significant expansion as quantum dot technology matures. The competitive landscape is characterized by established electronics giants like Samsung Electronics and Samsung Display leading commercial applications, while specialized materials companies such as Shin-Etsu Chemical and Innovalight focus on stability innovations. Research institutions including Korea Electronics Technology Institute and China University of Mining & Technology are advancing fundamental solutions to degradation challenges. The technology is approaching commercial viability, with companies like TCL Research America and 3M Innovative Properties developing proprietary encapsulation methods to extend quantum dot lifespan in photovoltaic applications, though long-term outdoor stability remains a key challenge for widespread adoption.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed an innovative approach to quantum dot stability for lightweight photovoltaic applications through their "QD-Seal" technology. This proprietary system utilizes a multi-layer thin film encapsulation process originally developed for OLED displays but optimized for quantum dot photovoltaics. The technology incorporates alternating layers of inorganic barrier films (typically Al₂O₃ or SiN₄) deposited via atomic layer deposition, and organic planarization layers that together achieve water vapor transmission rates below 10^-6 g/m²/day. Samsung's research has demonstrated that quantum dot solar cells protected with this technology maintain over 90% of their initial efficiency after 2500 hours of accelerated aging under combined high temperature and humidity conditions. Additionally, Samsung Display has pioneered on-chip passivation techniques where quantum dots are individually encapsulated in a thin silica shell before incorporation into the photovoltaic active layer. This approach provides protection at the individual quantum dot level, preventing aggregation and oxidation even if the external barrier is compromised. Their technology also incorporates specialized UV-blocking layers that prevent photo-oxidation while allowing visible light transmission, addressing one of the primary degradation mechanisms in quantum dot materials.

Strengths: Leverages established display manufacturing expertise and infrastructure; ultra-high barrier properties; excellent mechanical flexibility suitable for lightweight applications; comprehensive protection against multiple degradation pathways. Weaknesses: Complex manufacturing process with multiple deposition steps increases production costs; potential optical losses from multiple interface reflections; challenges in scaling to very large area modules.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has pioneered advanced encapsulation techniques for quantum dot stability in lightweight photovoltaic applications. Their multi-layer barrier technology creates an ultra-low oxygen and moisture permeation environment for quantum dots, extending operational lifetime in flexible solar modules. Samsung's approach combines atomic layer deposition (ALD) of metal oxide barriers with specialized polymer interlayers that absorb mechanical stress while maintaining barrier properties. This technology has enabled the development of quantum dot solar cells that retain over 90% of their initial efficiency after 2000 hours of damp heat testing (85°C/85% RH). Additionally, Samsung has developed proprietary surface ligand engineering for their quantum dots, replacing conventional organic ligands with more robust hybrid organic-inorganic structures that significantly improve thermal stability while maintaining high quantum yield. Their research demonstrates that properly engineered quantum dot interfaces can withstand temperatures up to 150°C without significant aggregation or performance degradation.

Strengths: Industry-leading barrier film technology provides exceptional protection against environmental degradation; extensive manufacturing capabilities for scaling production; strong integration potential with existing consumer electronics. Weaknesses: Higher production costs compared to conventional encapsulation methods; added weight from multiple barrier layers can partially offset the lightweight advantages of quantum dot technology.

Key Patents in QD Encapsulation and Protection

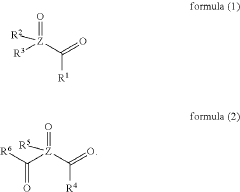

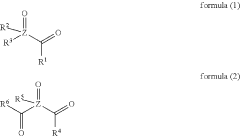

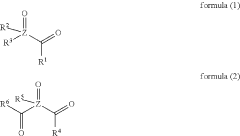

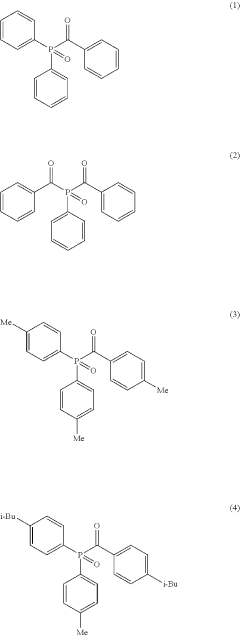

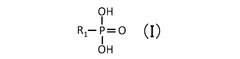

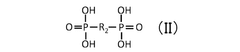

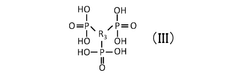

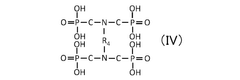

Composition comprising nanosized light emitting material

PatentActiveUS11814560B2

Innovation

- A composition comprising nanosized light emitting materials combined with specific compounds represented by general formulas (1) or (2), which include alkyl, aryl, and heteroaryl groups, and elements like P, As, or Sb, serves as stabilizing additives, enhancing thermal stability and retaining or improving quantum yield.

Quantum dot body, quantum dot composition, and wavelength conversion material and production method thereof

PatentWO2025088985A1

Innovation

- A quantum dot body is developed with a core-shell structure of semiconductor nanoparticles, coated with a metal oxide and modified with a phosphonic acid derivative, and further encapsulated in a polymer coating layer. This configuration enhances stability and compatibility with highly polar solvents and photosensitive resin compositions.

Environmental Impact of QD Photovoltaic Materials

The environmental impact of quantum dot (QD) photovoltaic materials presents significant considerations for sustainable energy development. These nanoscale semiconductor particles, while offering remarkable efficiency improvements in solar energy conversion, introduce complex environmental challenges throughout their lifecycle. The manufacturing process of quantum dots typically involves heavy metals such as cadmium, lead, or indium, which pose potential ecological and health risks if improperly managed or released into the environment.

Production of quantum dots requires energy-intensive processes and specialized chemical treatments, contributing to their initial carbon footprint. However, this environmental cost must be balanced against their potential to significantly improve photovoltaic efficiency over the operational lifetime of solar modules. Life cycle assessments indicate that the environmental payback period for QD-enhanced photovoltaic systems can be substantially shorter than conventional technologies, provided that stability and longevity challenges are adequately addressed.

Disposal and end-of-life management represent critical environmental concerns for QD photovoltaic materials. Without proper recycling infrastructure, these materials risk contributing to electronic waste streams, potentially leaching toxic compounds into soil and water systems. Current recycling technologies for quantum dot materials remain limited and economically challenging, highlighting the need for circular economy approaches in material design and recovery processes.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of nanomaterials, including quantum dots. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impose strict limitations on hazardous materials in electronic products, driving research toward less toxic alternatives such as copper indium sulfide or zinc-based quantum dots that maintain comparable photovoltaic performance.

Recent advancements in green synthesis methods for quantum dots show promise for reducing environmental impact. Approaches utilizing biomolecules as capping agents, aqueous-based synthesis routes, and continuous flow microreactor technologies can significantly reduce solvent usage and hazardous waste generation. These developments align with sustainable chemistry principles and may substantially improve the environmental profile of quantum dot production.

The potential for quantum dots to enable lightweight, flexible photovoltaic modules also carries indirect environmental benefits through expanded deployment opportunities. Building-integrated photovoltaics and mobile energy solutions become more feasible with lightweight designs, potentially accelerating renewable energy adoption in previously unsuitable applications and reducing dependence on fossil fuel energy sources.

Production of quantum dots requires energy-intensive processes and specialized chemical treatments, contributing to their initial carbon footprint. However, this environmental cost must be balanced against their potential to significantly improve photovoltaic efficiency over the operational lifetime of solar modules. Life cycle assessments indicate that the environmental payback period for QD-enhanced photovoltaic systems can be substantially shorter than conventional technologies, provided that stability and longevity challenges are adequately addressed.

Disposal and end-of-life management represent critical environmental concerns for QD photovoltaic materials. Without proper recycling infrastructure, these materials risk contributing to electronic waste streams, potentially leaching toxic compounds into soil and water systems. Current recycling technologies for quantum dot materials remain limited and economically challenging, highlighting the need for circular economy approaches in material design and recovery processes.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of nanomaterials, including quantum dots. The European Union's RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations impose strict limitations on hazardous materials in electronic products, driving research toward less toxic alternatives such as copper indium sulfide or zinc-based quantum dots that maintain comparable photovoltaic performance.

Recent advancements in green synthesis methods for quantum dots show promise for reducing environmental impact. Approaches utilizing biomolecules as capping agents, aqueous-based synthesis routes, and continuous flow microreactor technologies can significantly reduce solvent usage and hazardous waste generation. These developments align with sustainable chemistry principles and may substantially improve the environmental profile of quantum dot production.

The potential for quantum dots to enable lightweight, flexible photovoltaic modules also carries indirect environmental benefits through expanded deployment opportunities. Building-integrated photovoltaics and mobile energy solutions become more feasible with lightweight designs, potentially accelerating renewable energy adoption in previously unsuitable applications and reducing dependence on fossil fuel energy sources.

Scalability and Manufacturing Considerations

The scalability of quantum dot (QD) technology for lightweight photovoltaic modules presents significant manufacturing challenges that must be addressed for commercial viability. Current laboratory-scale synthesis methods for high-quality quantum dots typically yield small quantities, often in the milligram to gram range, which is insufficient for industrial-scale production. Transitioning to mass production requires developing continuous flow reactors and automated synthesis systems capable of maintaining precise control over QD size distribution, composition, and surface chemistry—all critical factors affecting stability and performance.

Manufacturing consistency represents another major hurdle. Batch-to-batch variations in quantum dot properties can significantly impact device performance and stability. Advanced quality control systems incorporating real-time spectroscopic monitoring and machine learning algorithms are being developed to ensure uniformity across production runs. These systems can detect deviations in QD optical properties that might indicate stability issues before integration into modules.

Integration of quantum dots into lightweight module architectures demands specialized deposition techniques. While solution processing methods like spin-coating work well for small-area prototypes, they become inefficient and wasteful for larger modules. Roll-to-roll processing shows promise for flexible substrates, but requires careful optimization of solvent systems and drying conditions to prevent QD aggregation that would compromise stability. Spray coating and inkjet printing technologies are also being adapted for quantum dot deposition, though challenges remain in formulating inks that maintain QD dispersion while enabling uniform film formation.

Environmental considerations in manufacturing cannot be overlooked. Many traditional QD synthesis routes involve toxic precursors and generate hazardous waste. Developing greener synthesis methods using less toxic reagents and aqueous-based processes is essential for sustainable scaling. Additionally, encapsulation technologies must be compatible with high-throughput manufacturing while providing the hermetic sealing necessary to protect quantum dots from oxygen and moisture degradation.

Cost factors significantly influence scalability. Current high-purity QD production costs range from $100-1000 per gram, making large-scale module production economically prohibitive. Material innovations focusing on earth-abundant elements rather than rare metals like indium or cadmium could substantially reduce raw material costs. Process engineering improvements to increase yield and reduce waste will further drive down manufacturing expenses, potentially bringing QD photovoltaic technology within competitive range of conventional solar technologies.

Manufacturing consistency represents another major hurdle. Batch-to-batch variations in quantum dot properties can significantly impact device performance and stability. Advanced quality control systems incorporating real-time spectroscopic monitoring and machine learning algorithms are being developed to ensure uniformity across production runs. These systems can detect deviations in QD optical properties that might indicate stability issues before integration into modules.

Integration of quantum dots into lightweight module architectures demands specialized deposition techniques. While solution processing methods like spin-coating work well for small-area prototypes, they become inefficient and wasteful for larger modules. Roll-to-roll processing shows promise for flexible substrates, but requires careful optimization of solvent systems and drying conditions to prevent QD aggregation that would compromise stability. Spray coating and inkjet printing technologies are also being adapted for quantum dot deposition, though challenges remain in formulating inks that maintain QD dispersion while enabling uniform film formation.

Environmental considerations in manufacturing cannot be overlooked. Many traditional QD synthesis routes involve toxic precursors and generate hazardous waste. Developing greener synthesis methods using less toxic reagents and aqueous-based processes is essential for sustainable scaling. Additionally, encapsulation technologies must be compatible with high-throughput manufacturing while providing the hermetic sealing necessary to protect quantum dots from oxygen and moisture degradation.

Cost factors significantly influence scalability. Current high-purity QD production costs range from $100-1000 per gram, making large-scale module production economically prohibitive. Material innovations focusing on earth-abundant elements rather than rare metals like indium or cadmium could substantially reduce raw material costs. Process engineering improvements to increase yield and reduce waste will further drive down manufacturing expenses, potentially bringing QD photovoltaic technology within competitive range of conventional solar technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!