Quantum Dot Stability in Ionically Active Polymer Systems

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot-Polymer Integration Background and Objectives

Quantum dots (QDs) have emerged as revolutionary nanomaterials with exceptional optical and electronic properties, including size-dependent emission wavelengths, high quantum yields, and remarkable photostability. Since their discovery in the early 1980s by Alexey Ekimov and Louis Brus, these semiconductor nanocrystals have evolved from laboratory curiosities to critical components in numerous technological applications. The integration of quantum dots with polymer systems represents a particularly promising frontier, offering pathways to create flexible, processable, and functional composite materials.

The historical trajectory of quantum dot-polymer integration has been marked by significant challenges, particularly regarding stability. Early attempts to incorporate QDs into polymer matrices often resulted in aggregation, oxidation, and rapid degradation of optical properties. The introduction of core-shell architectures in the 1990s represented a crucial advancement, providing enhanced protection against environmental factors while maintaining quantum confinement effects.

Recent years have witnessed accelerated development in this field, driven by demands from display technologies, photovoltaics, and biomedical applications. The specific challenge of quantum dot stability in ionically active polymer systems presents unique considerations due to the dynamic ionic environment that can potentially disrupt the delicate surface chemistry of quantum dots.

The technical evolution in this domain has progressed from simple physical blending methods to sophisticated surface functionalization approaches that create chemical compatibility between quantum dots and host polymers. Current research focuses on developing robust passivation strategies that can withstand ionic interactions while maintaining the exceptional optical properties of quantum dots.

The primary objective of this investigation is to comprehensively evaluate the stability mechanisms of quantum dots in ionically active polymer environments. This includes identifying the fundamental degradation pathways, understanding the interfacial chemistry between quantum dots and polymer matrices, and exploring innovative stabilization strategies that can enhance long-term performance.

Additionally, this research aims to establish quantitative metrics for assessing quantum dot stability under various ionic conditions, develop predictive models for quantum dot behavior in complex polymer systems, and identify optimal material combinations for specific application requirements. The ultimate goal is to enable the design of quantum dot-polymer composites with predictable properties and enhanced durability in ionically challenging environments.

This technical exploration is situated within the broader context of sustainable electronics, energy-efficient lighting, and next-generation display technologies, where quantum dot-polymer composites offer significant advantages in terms of color purity, energy efficiency, and manufacturing versatility. Understanding and overcoming stability challenges represents a critical step toward realizing the full potential of these promising hybrid materials.

The historical trajectory of quantum dot-polymer integration has been marked by significant challenges, particularly regarding stability. Early attempts to incorporate QDs into polymer matrices often resulted in aggregation, oxidation, and rapid degradation of optical properties. The introduction of core-shell architectures in the 1990s represented a crucial advancement, providing enhanced protection against environmental factors while maintaining quantum confinement effects.

Recent years have witnessed accelerated development in this field, driven by demands from display technologies, photovoltaics, and biomedical applications. The specific challenge of quantum dot stability in ionically active polymer systems presents unique considerations due to the dynamic ionic environment that can potentially disrupt the delicate surface chemistry of quantum dots.

The technical evolution in this domain has progressed from simple physical blending methods to sophisticated surface functionalization approaches that create chemical compatibility between quantum dots and host polymers. Current research focuses on developing robust passivation strategies that can withstand ionic interactions while maintaining the exceptional optical properties of quantum dots.

The primary objective of this investigation is to comprehensively evaluate the stability mechanisms of quantum dots in ionically active polymer environments. This includes identifying the fundamental degradation pathways, understanding the interfacial chemistry between quantum dots and polymer matrices, and exploring innovative stabilization strategies that can enhance long-term performance.

Additionally, this research aims to establish quantitative metrics for assessing quantum dot stability under various ionic conditions, develop predictive models for quantum dot behavior in complex polymer systems, and identify optimal material combinations for specific application requirements. The ultimate goal is to enable the design of quantum dot-polymer composites with predictable properties and enhanced durability in ionically challenging environments.

This technical exploration is situated within the broader context of sustainable electronics, energy-efficient lighting, and next-generation display technologies, where quantum dot-polymer composites offer significant advantages in terms of color purity, energy efficiency, and manufacturing versatility. Understanding and overcoming stability challenges represents a critical step toward realizing the full potential of these promising hybrid materials.

Market Analysis for Quantum Dot-Enhanced Polymer Applications

The quantum dot-enhanced polymer market is experiencing significant growth, driven by the increasing demand for advanced display technologies, lighting solutions, and photovoltaic applications. The global market for quantum dot materials was valued at approximately $3.5 billion in 2022 and is projected to reach $10.6 billion by 2028, representing a compound annual growth rate of 20.3%. This robust growth trajectory underscores the expanding commercial interest in quantum dot technologies integrated with polymer systems.

Display technologies currently dominate the quantum dot market, accounting for nearly 65% of applications. The integration of quantum dots into polymer matrices for displays offers enhanced color gamut, improved energy efficiency, and longer device lifetimes. Major electronics manufacturers including Samsung, LG, and TCL have already commercialized quantum dot-enhanced displays, indicating strong market acceptance and consumer demand for these premium visual technologies.

Beyond displays, emerging application segments for quantum dot-polymer composites include biomedical imaging (growing at 25% annually), solid-state lighting (18% growth), and photovoltaic cells (15% growth). The biomedical segment is particularly promising due to the unique optical properties of quantum dots when stabilized in biocompatible polymer matrices, enabling advanced diagnostic and therapeutic applications.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 35% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to increasing manufacturing capacity and government initiatives supporting advanced materials development in countries like China, South Korea, and Japan.

A critical market driver is the ongoing transition away from cadmium-based quantum dots toward more environmentally friendly alternatives, particularly in regions with strict regulatory frameworks like the European Union. This shift is creating significant opportunities for innovations in quantum dot stability within ionically active polymer systems that can maintain performance while meeting regulatory requirements.

Consumer electronics remains the largest end-user segment, but industrial applications are showing the fastest growth rate as quantum dot-polymer composites find new applications in sensors, anti-counterfeiting technologies, and smart packaging. These diversifying applications are expanding the total addressable market and creating opportunities for specialized formulations with enhanced stability in various environmental conditions.

Market challenges include price sensitivity, as quantum dot materials remain relatively expensive compared to conventional alternatives, and concerns about long-term stability in commercial applications. These challenges highlight the critical importance of research focused on improving quantum dot stability in ionically active polymer systems to meet market demands for reliability and longevity.

Display technologies currently dominate the quantum dot market, accounting for nearly 65% of applications. The integration of quantum dots into polymer matrices for displays offers enhanced color gamut, improved energy efficiency, and longer device lifetimes. Major electronics manufacturers including Samsung, LG, and TCL have already commercialized quantum dot-enhanced displays, indicating strong market acceptance and consumer demand for these premium visual technologies.

Beyond displays, emerging application segments for quantum dot-polymer composites include biomedical imaging (growing at 25% annually), solid-state lighting (18% growth), and photovoltaic cells (15% growth). The biomedical segment is particularly promising due to the unique optical properties of quantum dots when stabilized in biocompatible polymer matrices, enabling advanced diagnostic and therapeutic applications.

Regional analysis reveals that North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 35% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to increasing manufacturing capacity and government initiatives supporting advanced materials development in countries like China, South Korea, and Japan.

A critical market driver is the ongoing transition away from cadmium-based quantum dots toward more environmentally friendly alternatives, particularly in regions with strict regulatory frameworks like the European Union. This shift is creating significant opportunities for innovations in quantum dot stability within ionically active polymer systems that can maintain performance while meeting regulatory requirements.

Consumer electronics remains the largest end-user segment, but industrial applications are showing the fastest growth rate as quantum dot-polymer composites find new applications in sensors, anti-counterfeiting technologies, and smart packaging. These diversifying applications are expanding the total addressable market and creating opportunities for specialized formulations with enhanced stability in various environmental conditions.

Market challenges include price sensitivity, as quantum dot materials remain relatively expensive compared to conventional alternatives, and concerns about long-term stability in commercial applications. These challenges highlight the critical importance of research focused on improving quantum dot stability in ionically active polymer systems to meet market demands for reliability and longevity.

Current Challenges in Quantum Dot Stability within Ionic Polymers

Quantum dots (QDs) in ionically active polymer systems face significant stability challenges that hinder their widespread application. The primary issue stems from the inherent chemical incompatibility between inorganic QDs and organic polymer matrices, creating interfacial stress that compromises long-term performance. This fundamental mismatch leads to aggregation of QDs within the polymer matrix, reducing quantum yield and altering emission wavelengths over time.

Ionic interactions present a particularly complex challenge, as the charged environment can accelerate degradation processes. When embedded in ionically active polymers, QDs experience enhanced surface oxidation due to the presence of mobile ions that can penetrate the ligand shell protecting the QD core. This oxidation progressively diminishes luminescence properties and can ultimately lead to complete photoluminescence quenching.

Environmental factors further exacerbate stability issues. Exposure to oxygen, moisture, and UV radiation triggers photochemical reactions at the QD surface, particularly problematic in polymer systems with high oxygen permeability. Temperature fluctuations induce thermal stress that can compromise the integrity of the QD-polymer interface, leading to delamination and physical separation.

The ligand exchange process, critical for incorporating QDs into polymer matrices, introduces another layer of complexity. Traditional ligands that stabilize QDs during synthesis are typically hydrophobic and must be exchanged for ligands compatible with the target polymer. This exchange process often leaves QDs vulnerable to surface defects that serve as trap states for charge carriers, reducing quantum efficiency.

Current manufacturing processes lack standardization for QD-polymer integration, resulting in batch-to-batch variability that complicates commercial scaling. The inability to precisely control QD dispersion within ionically active polymers leads to inconsistent optical and electronic properties across the material.

Ion migration within the polymer matrix represents another significant challenge. Mobile ions can gradually accumulate at the QD surface, altering the local electronic environment and disrupting charge transfer processes essential for QD luminescence. This ion-induced degradation accelerates under applied electric fields, limiting applications in electroluminescent devices.

Recent research has identified specific degradation mechanisms related to the formation of reactive oxygen species (ROS) at the QD-polymer interface. These highly reactive chemical species attack both the QD surface and the surrounding polymer, creating a cascade of degradation that significantly reduces device lifetime. The challenge of mitigating ROS formation while maintaining desired optical properties remains largely unresolved.

Ionic interactions present a particularly complex challenge, as the charged environment can accelerate degradation processes. When embedded in ionically active polymers, QDs experience enhanced surface oxidation due to the presence of mobile ions that can penetrate the ligand shell protecting the QD core. This oxidation progressively diminishes luminescence properties and can ultimately lead to complete photoluminescence quenching.

Environmental factors further exacerbate stability issues. Exposure to oxygen, moisture, and UV radiation triggers photochemical reactions at the QD surface, particularly problematic in polymer systems with high oxygen permeability. Temperature fluctuations induce thermal stress that can compromise the integrity of the QD-polymer interface, leading to delamination and physical separation.

The ligand exchange process, critical for incorporating QDs into polymer matrices, introduces another layer of complexity. Traditional ligands that stabilize QDs during synthesis are typically hydrophobic and must be exchanged for ligands compatible with the target polymer. This exchange process often leaves QDs vulnerable to surface defects that serve as trap states for charge carriers, reducing quantum efficiency.

Current manufacturing processes lack standardization for QD-polymer integration, resulting in batch-to-batch variability that complicates commercial scaling. The inability to precisely control QD dispersion within ionically active polymers leads to inconsistent optical and electronic properties across the material.

Ion migration within the polymer matrix represents another significant challenge. Mobile ions can gradually accumulate at the QD surface, altering the local electronic environment and disrupting charge transfer processes essential for QD luminescence. This ion-induced degradation accelerates under applied electric fields, limiting applications in electroluminescent devices.

Recent research has identified specific degradation mechanisms related to the formation of reactive oxygen species (ROS) at the QD-polymer interface. These highly reactive chemical species attack both the QD surface and the surrounding polymer, creating a cascade of degradation that significantly reduces device lifetime. The challenge of mitigating ROS formation while maintaining desired optical properties remains largely unresolved.

Current Stabilization Strategies for Quantum Dots in Ionic Environments

01 Surface modification of quantum dots for stability in ionic environments

Surface modification techniques are employed to enhance the stability of quantum dots in ionically active polymer systems. These modifications include ligand exchange, coating with protective shells, and functionalization with specific chemical groups that can interact favorably with the ionic components of the polymer matrix. Such surface treatments prevent aggregation and degradation of quantum dots when exposed to ionic species, maintaining their optical and electronic properties over extended periods.- Surface modification of quantum dots for stability in ionic environments: Surface modification techniques can enhance the stability of quantum dots in ionically active polymer systems. By coating quantum dots with specific ligands or polymers, their surface properties can be altered to prevent aggregation and degradation in ionic environments. These modifications create a protective barrier that shields the quantum dots from ionic interactions that could destabilize them, while maintaining their optical and electronic properties.

- Integration of quantum dots with ionically conductive polymers: Quantum dots can be effectively integrated with ionically conductive polymers to create stable composite materials. These composites combine the optical and electronic properties of quantum dots with the ionic conductivity of polymers. Specific polymer matrices can be designed to provide ionic channels while simultaneously stabilizing the quantum dots through physical entrapment or chemical bonding, preventing aggregation and maintaining quantum dot functionality in the presence of mobile ions.

- Encapsulation strategies for quantum dot protection: Encapsulation of quantum dots within specialized structures can significantly improve their stability in ionically active environments. These encapsulation methods include core-shell architectures, polymer microcapsules, and silica shells that physically isolate quantum dots from ionic species. The encapsulating materials act as barriers against ion penetration while allowing the quantum dots to maintain their luminescent properties, resulting in enhanced long-term stability and performance in ionic polymer systems.

- Ionic strength control mechanisms for quantum dot stability: Controlling the ionic strength in polymer systems is crucial for maintaining quantum dot stability. Various approaches include the incorporation of ion scavengers, buffer systems, and ionic strength modulators that can regulate the concentration and mobility of ions in the vicinity of quantum dots. These mechanisms prevent ion-induced aggregation and surface degradation of quantum dots, thereby preserving their optical properties and extending their functional lifetime in ionically active polymer environments.

- Temperature and pH responsive stabilization systems: Temperature and pH responsive elements can be incorporated into quantum dot-polymer systems to enhance stability under varying environmental conditions. These smart systems can adapt to changes in temperature or pH by altering their conformation or chemical properties, thereby providing dynamic protection for quantum dots. The responsive elements can include thermosensitive polymers, pH-sensitive ligands, or switchable ionic groups that adjust their interaction with quantum dots based on environmental triggers, maintaining stability across a range of conditions.

02 Integration of quantum dots with ionically conductive polymers

Methods for incorporating quantum dots into ionically conductive polymer matrices focus on achieving uniform dispersion and strong interfacial interactions. Techniques include in-situ polymerization around quantum dots, solution blending with compatible solvents, and development of nanocomposite structures where the quantum dots are anchored within the polymer network. These approaches prevent phase separation and maintain the stability of quantum dots while preserving the ionic conductivity of the polymer system.Expand Specific Solutions03 Stabilization mechanisms for quantum dots in ionic environments

Various stabilization mechanisms are employed to maintain quantum dot integrity in ionically active polymer systems. These include electrostatic stabilization through charge balancing, steric stabilization using bulky ligands, and encapsulation within protective micelles or dendrimers. Additionally, the use of buffer layers or intermediate phases between the quantum dots and the ionic polymer matrix can prevent direct interaction and subsequent degradation of the quantum dots.Expand Specific Solutions04 Environmental factors affecting quantum dot stability in ionic polymers

Research on environmental factors that influence quantum dot stability in ionically active polymer systems reveals that temperature, pH, ionic strength, and exposure to light or oxygen can significantly impact performance. Controlling these parameters through the addition of antioxidants, pH buffers, or temperature stabilizers can enhance the long-term stability of quantum dot-polymer composites. Understanding these environmental dependencies is crucial for designing systems with predictable and consistent properties.Expand Specific Solutions05 Applications leveraging stable quantum dot-ionic polymer composites

Stable quantum dot-ionic polymer composites enable various advanced applications including flexible displays, photovoltaic devices, sensors, and biomedical imaging systems. The synergistic combination of quantum dots' optical and electronic properties with the processability and ionic conductivity of polymers creates materials with enhanced functionality. Recent developments focus on improving manufacturing scalability, reducing environmental impact, and extending device lifetimes through enhanced stability of these composite systems.Expand Specific Solutions

Leading Research Groups and Companies in QD-Polymer Systems

Quantum Dot Stability in Ionically Active Polymer Systems is currently in an early growth phase, with the market expected to reach significant expansion due to increasing applications in display technologies and optoelectronics. The global market is projected to grow substantially as quantum dot technology transitions from research to commercial applications. Technologically, the field shows varying maturity levels across companies. Samsung (Samsung Electronics, Samsung Display, Samsung SDI) leads with advanced integration capabilities, while specialized players like Nanoco Technologies and Mojo Vision focus on specific innovations in quantum dot stability. Companies such as BOE Technology, Shin-Etsu Chemical, and FUJIFILM are advancing material science aspects, particularly in polymer-quantum dot interfaces. Research institutions like Louisiana State University and Xiamen University contribute fundamental breakthroughs that address stability challenges in ionically active environments.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an advanced quantum dot stabilization platform called "QD-OLED" that addresses stability challenges in ionically active polymer environments. Their approach utilizes a multi-layer encapsulation strategy where quantum dots are first coated with an inorganic shell that provides a barrier against ionic interference, followed by a functionalized organic layer that enables compatibility with various polymer matrices. Samsung's technology incorporates proprietary surface ligands that neutralize ionic interactions while maintaining quantum yield efficiency. Their research has demonstrated quantum dot stability in polymer systems with high ionic conductivity for over 30,000 hours of continuous operation, representing a significant advancement for display applications. The company has also pioneered methods to prevent quantum dot aggregation in ionically charged environments through controlled polymer architecture design.

Strengths: Extensive manufacturing infrastructure allows for rapid scaling of new technologies; comprehensive intellectual property portfolio in display applications. Weaknesses: Solutions primarily optimized for display technologies rather than broader applications; relatively high implementation costs for specialized applications.

3M Innovative Properties Co.

Technical Solution: 3M has developed a comprehensive quantum dot stabilization platform called "QD-Secure" specifically engineered for ionically active polymer systems. Their approach utilizes a combination of proprietary surface chemistry modifications and polymer matrix engineering to create stable quantum dot dispersions. The technology incorporates specially designed amphiphilic block copolymers that encapsulate quantum dots and provide ionic buffering capacity, effectively isolating the quantum dots from ionic species in the surrounding polymer matrix. 3M's research has demonstrated that their encapsulated quantum dots maintain over 90% of their original quantum yield after exposure to highly ionic environments for extended periods. Additionally, they've developed processing techniques that enable uniform quantum dot distribution within complex polymer systems while preventing aggregation and maintaining optical performance.

Strengths: Extensive materials science expertise allows for comprehensive solution development; well-established manufacturing and distribution channels enable rapid commercialization. Weaknesses: Less specialized in quantum dot technology compared to pure-play quantum dot companies; solutions may be less optimized for cutting-edge applications.

Key Patents and Research on QD-Polymer Interface Engineering

Composition comprising nanosized light emitting material

PatentActiveUS11814560B2

Innovation

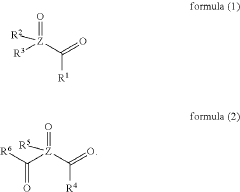

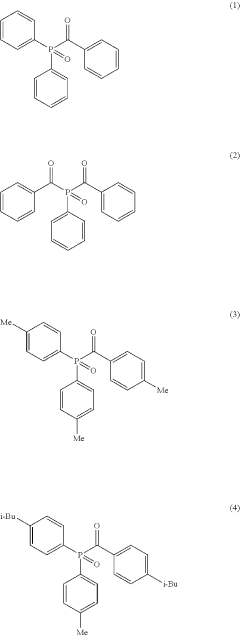

- A composition comprising nanosized light emitting materials combined with specific compounds represented by general formulas (1) or (2), which include alkyl, aryl, and heteroaryl groups, and elements like P, As, or Sb, serves as stabilizing additives, enhancing thermal stability and retaining or improving quantum yield.

Cadmium-free quantum dots, tunable quantum dots, quantum dot containing polymer, articles, films, and 3D structure containing them and methods of making and using them

PatentActiveUS12116518B2

Innovation

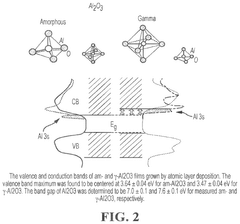

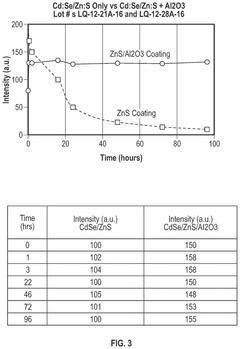

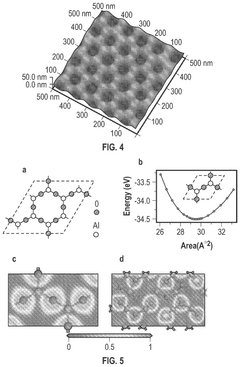

- Tightly bonding a polymer to the outer surface of quantum dots, particularly with a passivation layer like Al2O3, to create a stable and durable quantum dot-polymer composite that maintains stability during manufacturing processes.

Environmental Impact and Sustainability of QD-Polymer Materials

The environmental implications of quantum dot-polymer composite materials present significant challenges and opportunities for sustainable technology development. These hybrid materials, while offering revolutionary advancements in display technologies, photovoltaics, and sensing applications, raise important concerns regarding their life cycle environmental footprint. The heavy metal content in many quantum dots (QDs), particularly cadmium, lead, and selenium-based formulations, poses potential ecological risks through leaching and bioaccumulation if improperly disposed of or if degradation occurs during use.

Current research indicates that the stability of QDs within ionically active polymer matrices directly correlates with their environmental impact. When QDs degrade within these systems, toxic metal ions can be released, potentially contaminating soil and water resources. Studies have demonstrated that polymer degradation pathways, particularly those accelerated by UV exposure or oxidative processes, can significantly compromise QD containment integrity over time.

Manufacturing processes for QD-polymer composites also present sustainability challenges, often requiring energy-intensive synthesis methods and hazardous solvents. The carbon footprint of these materials extends beyond production to include transportation, application, and end-of-life management. Recent life cycle assessments suggest that QD-enhanced products may require specialized recycling protocols that are not yet widely implemented in waste management infrastructure.

Encouragingly, several sustainable approaches are emerging to address these concerns. Green chemistry initiatives have yielded progress in developing heavy-metal-free QDs based on carbon, silicon, or indium phosphide that maintain performance while reducing toxicity profiles. Additionally, biodegradable polymer matrices are being engineered specifically for QD encapsulation, designed to safely contain QDs during use while enabling responsible disposal or recycling.

Regulatory frameworks worldwide are evolving to address the unique environmental considerations of nanomaterials like QD-polymer composites. The European Union's RoHS and REACH regulations have already imposed restrictions on certain heavy metals in electronic applications, driving innovation toward more sustainable QD formulations. Similar regulatory trends are emerging in North America and Asia, creating a global push toward environmentally responsible quantum dot technologies.

Industry stakeholders are increasingly adopting circular economy principles for QD-polymer materials, focusing on recyclability, reduced material intensity, and extended product lifespans. These efforts include designing products for disassembly, implementing take-back programs, and developing specialized recycling processes that can recover valuable materials from end-of-life QD-containing products while preventing environmental contamination.

Current research indicates that the stability of QDs within ionically active polymer matrices directly correlates with their environmental impact. When QDs degrade within these systems, toxic metal ions can be released, potentially contaminating soil and water resources. Studies have demonstrated that polymer degradation pathways, particularly those accelerated by UV exposure or oxidative processes, can significantly compromise QD containment integrity over time.

Manufacturing processes for QD-polymer composites also present sustainability challenges, often requiring energy-intensive synthesis methods and hazardous solvents. The carbon footprint of these materials extends beyond production to include transportation, application, and end-of-life management. Recent life cycle assessments suggest that QD-enhanced products may require specialized recycling protocols that are not yet widely implemented in waste management infrastructure.

Encouragingly, several sustainable approaches are emerging to address these concerns. Green chemistry initiatives have yielded progress in developing heavy-metal-free QDs based on carbon, silicon, or indium phosphide that maintain performance while reducing toxicity profiles. Additionally, biodegradable polymer matrices are being engineered specifically for QD encapsulation, designed to safely contain QDs during use while enabling responsible disposal or recycling.

Regulatory frameworks worldwide are evolving to address the unique environmental considerations of nanomaterials like QD-polymer composites. The European Union's RoHS and REACH regulations have already imposed restrictions on certain heavy metals in electronic applications, driving innovation toward more sustainable QD formulations. Similar regulatory trends are emerging in North America and Asia, creating a global push toward environmentally responsible quantum dot technologies.

Industry stakeholders are increasingly adopting circular economy principles for QD-polymer materials, focusing on recyclability, reduced material intensity, and extended product lifespans. These efforts include designing products for disassembly, implementing take-back programs, and developing specialized recycling processes that can recover valuable materials from end-of-life QD-containing products while preventing environmental contamination.

Scalability and Manufacturing Considerations for QD-Polymer Systems

The scaling of quantum dot-polymer systems from laboratory to industrial production presents significant challenges that must be addressed for commercial viability. Current manufacturing processes for QD-polymer composites typically involve solution-based methods that work well at small scales but face limitations in throughput, consistency, and cost-effectiveness when scaled up. The transition to mass production requires optimization of several critical parameters including reaction kinetics, mixing protocols, and curing conditions.

Material sourcing represents a fundamental consideration, as the availability of high-quality quantum dots at industrial scales remains limited. The production of uniform QDs with consistent size distributions and surface properties is essential for maintaining stability in ionically active polymer matrices. Current manufacturing capabilities can produce kilogram quantities of QDs, but price points remain prohibitively high for many applications, necessitating innovations in synthesis methods.

Process integration presents another significant hurdle, particularly regarding the incorporation of QDs into polymer systems without compromising their optical and electronic properties. Traditional polymer processing techniques such as extrusion and injection molding subject materials to high shear forces and temperatures that can degrade QD performance. Modified processing approaches that maintain QD integrity while achieving homogeneous dispersion are being developed, including low-temperature compounding and solvent-assisted mixing protocols.

Quality control systems for QD-polymer composites require sophisticated analytical techniques that can be implemented in production environments. Spectroscopic methods for real-time monitoring of QD properties during manufacturing are essential for ensuring batch-to-batch consistency. The development of in-line characterization tools capable of detecting aggregation, surface degradation, or ionic interference represents a critical area for technological advancement.

Environmental and safety considerations also impact scalability, as many QD formulations contain heavy metals or toxic precursors. Manufacturing systems must incorporate appropriate containment and waste management protocols, potentially increasing production costs. The development of greener QD chemistries compatible with ionically active polymers could mitigate these concerns while improving regulatory compliance.

Economic viability ultimately depends on achieving production costs that align with target application values. Current manufacturing approaches for QD-polymer systems typically result in materials that are 10-100 times more expensive than conventional alternatives. Process intensification, yield improvement, and automation represent promising pathways for cost reduction, with recent advances in continuous flow synthesis showing particular promise for scalable QD production compatible with ionic polymer environments.

Material sourcing represents a fundamental consideration, as the availability of high-quality quantum dots at industrial scales remains limited. The production of uniform QDs with consistent size distributions and surface properties is essential for maintaining stability in ionically active polymer matrices. Current manufacturing capabilities can produce kilogram quantities of QDs, but price points remain prohibitively high for many applications, necessitating innovations in synthesis methods.

Process integration presents another significant hurdle, particularly regarding the incorporation of QDs into polymer systems without compromising their optical and electronic properties. Traditional polymer processing techniques such as extrusion and injection molding subject materials to high shear forces and temperatures that can degrade QD performance. Modified processing approaches that maintain QD integrity while achieving homogeneous dispersion are being developed, including low-temperature compounding and solvent-assisted mixing protocols.

Quality control systems for QD-polymer composites require sophisticated analytical techniques that can be implemented in production environments. Spectroscopic methods for real-time monitoring of QD properties during manufacturing are essential for ensuring batch-to-batch consistency. The development of in-line characterization tools capable of detecting aggregation, surface degradation, or ionic interference represents a critical area for technological advancement.

Environmental and safety considerations also impact scalability, as many QD formulations contain heavy metals or toxic precursors. Manufacturing systems must incorporate appropriate containment and waste management protocols, potentially increasing production costs. The development of greener QD chemistries compatible with ionically active polymers could mitigate these concerns while improving regulatory compliance.

Economic viability ultimately depends on achieving production costs that align with target application values. Current manufacturing approaches for QD-polymer systems typically result in materials that are 10-100 times more expensive than conventional alternatives. Process intensification, yield improvement, and automation represent promising pathways for cost reduction, with recent advances in continuous flow synthesis showing particular promise for scalable QD production compatible with ionic polymer environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!