Quantum Dot Stability in Wide Bandgap Semiconductors

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Stability Background and Objectives

Quantum dots (QDs) have emerged as revolutionary nanomaterials in semiconductor technology over the past three decades, evolving from theoretical concepts to practical applications across multiple industries. These nanoscale semiconductor crystals, typically ranging from 2-10 nanometers in diameter, exhibit unique quantum confinement effects that enable precise tuning of their optical and electronic properties through size manipulation. The integration of quantum dots with wide bandgap semiconductors represents a particularly promising frontier, offering potential breakthroughs in optoelectronics, photovoltaics, and quantum computing.

The historical trajectory of quantum dot research began with theoretical predictions in the 1970s, followed by successful synthesis methods developed in the 1980s and 1990s. Early challenges in stability and reproducibility have gradually given way to more sophisticated fabrication techniques, enabling greater control over size distribution, surface chemistry, and integration with host materials. Despite this progress, quantum dot stability within wide bandgap semiconductor matrices remains a critical challenge limiting commercial viability and performance reliability.

Wide bandgap semiconductors, including materials such as GaN, SiC, ZnO, and diamond, offer exceptional thermal conductivity, breakdown strength, and operational capabilities under extreme conditions. The marriage of quantum dots with these materials presents unique opportunities for next-generation devices operating at high temperatures, high frequencies, and high power densities. However, this integration introduces complex stability challenges at the interface between quantum dots and host materials.

The primary objective of this research is to comprehensively investigate the fundamental mechanisms affecting quantum dot stability in wide bandgap semiconductor environments. Specifically, we aim to identify and characterize the physical and chemical processes that lead to degradation, including photo-oxidation, Ostwald ripening, surface defect formation, and charge carrier dynamics at interfaces. Understanding these mechanisms is essential for developing strategies to enhance long-term stability and performance reliability.

Secondary objectives include developing novel passivation techniques to mitigate degradation pathways, establishing standardized protocols for accelerated lifetime testing, and creating predictive models for quantum dot behavior under various operational conditions. The research also seeks to explore the relationship between quantum dot composition, size, and surface chemistry on overall stability metrics within different wide bandgap semiconductor matrices.

The technological significance of this research extends beyond academic interest, addressing critical barriers to commercialization in emerging fields such as quantum computing, high-efficiency solid-state lighting, next-generation display technologies, and advanced photovoltaics. By establishing a fundamental understanding of stability mechanisms, this work aims to enable engineering solutions that can extend device lifetimes from months to years, thereby unlocking the full potential of quantum dot integration with wide bandgap semiconductors.

The historical trajectory of quantum dot research began with theoretical predictions in the 1970s, followed by successful synthesis methods developed in the 1980s and 1990s. Early challenges in stability and reproducibility have gradually given way to more sophisticated fabrication techniques, enabling greater control over size distribution, surface chemistry, and integration with host materials. Despite this progress, quantum dot stability within wide bandgap semiconductor matrices remains a critical challenge limiting commercial viability and performance reliability.

Wide bandgap semiconductors, including materials such as GaN, SiC, ZnO, and diamond, offer exceptional thermal conductivity, breakdown strength, and operational capabilities under extreme conditions. The marriage of quantum dots with these materials presents unique opportunities for next-generation devices operating at high temperatures, high frequencies, and high power densities. However, this integration introduces complex stability challenges at the interface between quantum dots and host materials.

The primary objective of this research is to comprehensively investigate the fundamental mechanisms affecting quantum dot stability in wide bandgap semiconductor environments. Specifically, we aim to identify and characterize the physical and chemical processes that lead to degradation, including photo-oxidation, Ostwald ripening, surface defect formation, and charge carrier dynamics at interfaces. Understanding these mechanisms is essential for developing strategies to enhance long-term stability and performance reliability.

Secondary objectives include developing novel passivation techniques to mitigate degradation pathways, establishing standardized protocols for accelerated lifetime testing, and creating predictive models for quantum dot behavior under various operational conditions. The research also seeks to explore the relationship between quantum dot composition, size, and surface chemistry on overall stability metrics within different wide bandgap semiconductor matrices.

The technological significance of this research extends beyond academic interest, addressing critical barriers to commercialization in emerging fields such as quantum computing, high-efficiency solid-state lighting, next-generation display technologies, and advanced photovoltaics. By establishing a fundamental understanding of stability mechanisms, this work aims to enable engineering solutions that can extend device lifetimes from months to years, thereby unlocking the full potential of quantum dot integration with wide bandgap semiconductors.

Market Analysis for Quantum Dot Semiconductor Applications

The quantum dot semiconductor market has experienced significant growth in recent years, driven by increasing applications in display technologies, lighting solutions, and emerging quantum computing systems. The global quantum dot market was valued at approximately 4.5 billion USD in 2022 and is projected to reach 25 billion USD by 2030, representing a compound annual growth rate (CAGR) of 23.8% during this forecast period.

Display technology currently dominates the quantum dot application landscape, accounting for nearly 60% of market share. This segment is primarily fueled by the superior color performance and energy efficiency that quantum dot-enhanced displays offer compared to traditional LCD and OLED technologies. Major electronics manufacturers including Samsung, LG, and TCL have already commercialized quantum dot displays, with Samsung's QLED technology leading market penetration.

The lighting sector represents the second-largest application area, with quantum dot-enhanced LED lighting solutions gaining traction due to their tunable color temperature and improved energy efficiency. This segment is expected to grow at a CAGR of 21.3% through 2030, as commercial and residential lighting markets increasingly adopt these advanced solutions.

Healthcare and biomedical applications constitute an emerging but rapidly growing segment. Quantum dots are increasingly utilized in bioimaging, diagnostics, and drug delivery systems due to their unique optical properties and biocompatibility when properly encapsulated. This sector is projected to witness the highest growth rate among all application segments, with a CAGR exceeding 27% over the next decade.

Regionally, North America currently leads the quantum dot market with approximately 38% market share, followed by Asia-Pacific at 35% and Europe at 22%. However, the Asia-Pacific region is expected to overtake North America by 2026, driven by massive investments in display manufacturing infrastructure and government initiatives supporting semiconductor research in countries like China, South Korea, and Japan.

A critical market challenge remains the stability and reliability of quantum dot materials, particularly in wide bandgap semiconductor applications. Current commercial solutions often suffer from degradation under prolonged exposure to heat, light, and oxygen, limiting their operational lifespan. This technical challenge represents a significant market opportunity, as solutions addressing quantum dot stability could unlock additional applications in automotive displays, outdoor signage, and industrial monitoring systems where environmental robustness is paramount.

The competitive landscape features both established semiconductor companies and specialized quantum dot manufacturers. Key players include Nanosys, QD Vision, Quantum Materials Corp, and Nanoco Group, alongside major electronics manufacturers who have developed proprietary quantum dot technologies. Recent market consolidation through acquisitions indicates the strategic importance of quantum dot technology in the broader semiconductor industry's future roadmap.

Display technology currently dominates the quantum dot application landscape, accounting for nearly 60% of market share. This segment is primarily fueled by the superior color performance and energy efficiency that quantum dot-enhanced displays offer compared to traditional LCD and OLED technologies. Major electronics manufacturers including Samsung, LG, and TCL have already commercialized quantum dot displays, with Samsung's QLED technology leading market penetration.

The lighting sector represents the second-largest application area, with quantum dot-enhanced LED lighting solutions gaining traction due to their tunable color temperature and improved energy efficiency. This segment is expected to grow at a CAGR of 21.3% through 2030, as commercial and residential lighting markets increasingly adopt these advanced solutions.

Healthcare and biomedical applications constitute an emerging but rapidly growing segment. Quantum dots are increasingly utilized in bioimaging, diagnostics, and drug delivery systems due to their unique optical properties and biocompatibility when properly encapsulated. This sector is projected to witness the highest growth rate among all application segments, with a CAGR exceeding 27% over the next decade.

Regionally, North America currently leads the quantum dot market with approximately 38% market share, followed by Asia-Pacific at 35% and Europe at 22%. However, the Asia-Pacific region is expected to overtake North America by 2026, driven by massive investments in display manufacturing infrastructure and government initiatives supporting semiconductor research in countries like China, South Korea, and Japan.

A critical market challenge remains the stability and reliability of quantum dot materials, particularly in wide bandgap semiconductor applications. Current commercial solutions often suffer from degradation under prolonged exposure to heat, light, and oxygen, limiting their operational lifespan. This technical challenge represents a significant market opportunity, as solutions addressing quantum dot stability could unlock additional applications in automotive displays, outdoor signage, and industrial monitoring systems where environmental robustness is paramount.

The competitive landscape features both established semiconductor companies and specialized quantum dot manufacturers. Key players include Nanosys, QD Vision, Quantum Materials Corp, and Nanoco Group, alongside major electronics manufacturers who have developed proprietary quantum dot technologies. Recent market consolidation through acquisitions indicates the strategic importance of quantum dot technology in the broader semiconductor industry's future roadmap.

Current Challenges in Quantum Dot Stability

Despite significant advancements in quantum dot (QD) technology for wide bandgap semiconductors, several critical challenges persist regarding their stability. The foremost issue is photo-oxidation, where exposure to light and oxygen leads to surface degradation of QDs, resulting in decreased luminescence efficiency and altered optical properties. This phenomenon is particularly pronounced in wide bandgap semiconductor environments where high-energy photons can accelerate oxidative processes.

Thermal instability represents another major challenge, as quantum dots exhibit significant property changes at elevated temperatures. In wide bandgap semiconductor applications, which often operate at higher power densities and temperatures, QDs can experience structural reorganization, diffusion of core/shell materials, and even complete decomposition. These thermal effects dramatically reduce device lifetime and reliability in real-world applications.

Surface chemistry complications further exacerbate stability issues. The high surface-to-volume ratio of QDs makes their properties heavily dependent on surface conditions. Inadequate passivation leads to surface trap states that quench luminescence and reduce quantum yield. Additionally, ligand detachment over time creates new surface defects, particularly problematic in wide bandgap environments where interface quality is critical for charge transfer processes.

Integration challenges with host semiconductor materials present significant hurdles. The lattice mismatch between QDs and wide bandgap semiconductors creates strain and defects at interfaces, compromising electrical and optical performance. Moreover, charge carrier dynamics at these interfaces often suffer from non-radiative recombination pathways that reduce overall efficiency.

Environmental sensitivity poses ongoing difficulties, as humidity, oxygen, and various chemical species can penetrate protective layers and interact with QD surfaces. This is especially problematic in wide bandgap semiconductor applications that may be deployed in harsh or variable environments, where encapsulation technologies have not kept pace with QD development.

Manufacturing reproducibility remains an industrial challenge. Current synthesis methods struggle to produce QDs with consistent size distributions, composition, and surface properties at scale. This variability translates directly to inconsistent performance in devices, hampering commercial viability and widespread adoption in wide bandgap semiconductor applications.

Lastly, long-term aging effects continue to plague QD implementations. Even under optimal storage conditions, QDs experience gradual property changes over time, including spectral shifts, efficiency decreases, and increased blinking behavior. These aging mechanisms are not fully understood, particularly regarding the complex interactions between QDs and wide bandgap semiconductor matrices over extended operational periods.

Thermal instability represents another major challenge, as quantum dots exhibit significant property changes at elevated temperatures. In wide bandgap semiconductor applications, which often operate at higher power densities and temperatures, QDs can experience structural reorganization, diffusion of core/shell materials, and even complete decomposition. These thermal effects dramatically reduce device lifetime and reliability in real-world applications.

Surface chemistry complications further exacerbate stability issues. The high surface-to-volume ratio of QDs makes their properties heavily dependent on surface conditions. Inadequate passivation leads to surface trap states that quench luminescence and reduce quantum yield. Additionally, ligand detachment over time creates new surface defects, particularly problematic in wide bandgap environments where interface quality is critical for charge transfer processes.

Integration challenges with host semiconductor materials present significant hurdles. The lattice mismatch between QDs and wide bandgap semiconductors creates strain and defects at interfaces, compromising electrical and optical performance. Moreover, charge carrier dynamics at these interfaces often suffer from non-radiative recombination pathways that reduce overall efficiency.

Environmental sensitivity poses ongoing difficulties, as humidity, oxygen, and various chemical species can penetrate protective layers and interact with QD surfaces. This is especially problematic in wide bandgap semiconductor applications that may be deployed in harsh or variable environments, where encapsulation technologies have not kept pace with QD development.

Manufacturing reproducibility remains an industrial challenge. Current synthesis methods struggle to produce QDs with consistent size distributions, composition, and surface properties at scale. This variability translates directly to inconsistent performance in devices, hampering commercial viability and widespread adoption in wide bandgap semiconductor applications.

Lastly, long-term aging effects continue to plague QD implementations. Even under optimal storage conditions, QDs experience gradual property changes over time, including spectral shifts, efficiency decreases, and increased blinking behavior. These aging mechanisms are not fully understood, particularly regarding the complex interactions between QDs and wide bandgap semiconductor matrices over extended operational periods.

Current Stabilization Methods for Quantum Dots

01 Stability enhancement methods for quantum dots in wide bandgap semiconductors

Various methods can be employed to enhance the stability of quantum dots in wide bandgap semiconductors. These include surface passivation techniques, core-shell structures, and ligand engineering. Surface passivation reduces defect states at the quantum dot surface, while core-shell structures provide physical barriers against environmental degradation. Ligand engineering can improve both colloidal stability and electronic properties, resulting in quantum dots with improved thermal and chemical stability for use in wide bandgap semiconductor applications.- Stability enhancement methods for quantum dots in wide bandgap semiconductors: Various methods can be employed to enhance the stability of quantum dots in wide bandgap semiconductor materials. These include surface passivation techniques, core-shell structures, and ligand engineering. Surface passivation reduces defect states at the quantum dot interfaces, while core-shell structures provide physical barriers against environmental degradation. Ligand engineering can improve both colloidal stability and electronic properties, resulting in quantum dots with improved thermal and chemical stability when integrated with wide bandgap semiconductors.

- Integration of quantum dots with wide bandgap semiconductor devices: Quantum dots can be effectively integrated with wide bandgap semiconductor devices such as LEDs, solar cells, and photodetectors. Integration techniques include direct growth, embedding in matrices, and surface attachment methods. These approaches must address lattice matching, thermal expansion differences, and interface quality to maintain quantum dot stability. Proper integration enables enhanced device performance while preserving the optical and electronic properties of the quantum dots within the wide bandgap semiconductor environment.

- Environmental and operational stability factors: Quantum dots in wide bandgap semiconductors face stability challenges under various environmental and operational conditions. Factors affecting stability include temperature fluctuations, humidity, oxygen exposure, and high-energy radiation. Research focuses on developing quantum dot compositions and protective structures that maintain performance under extreme conditions. Encapsulation technologies and composite materials can significantly improve long-term stability by isolating quantum dots from degradation factors while maintaining their functional properties within wide bandgap semiconductor systems.

- Material composition for enhanced stability: The composition of quantum dots plays a crucial role in their stability when incorporated into wide bandgap semiconductors. Alloying quantum dots with specific elements can reduce defects and improve crystalline quality. Heavy metal-free quantum dots using elements like indium, zinc, and gallium show improved environmental stability. Additionally, doping strategies can enhance both electronic properties and structural stability, resulting in quantum dot systems that maintain their performance characteristics over extended operational periods in wide bandgap semiconductor environments.

- Characterization and testing methods for stability assessment: Advanced characterization and testing methodologies are essential for evaluating the stability of quantum dots in wide bandgap semiconductors. Techniques include accelerated aging tests, spectroscopic monitoring of optical properties over time, and in-situ electron microscopy for structural analysis. Computational modeling helps predict degradation mechanisms and design more stable systems. These methods enable quantitative assessment of quantum dot stability under various conditions, facilitating the development of more robust quantum dot-semiconductor composites with enhanced longevity for practical applications.

02 Integration of quantum dots with wide bandgap semiconductor materials

Quantum dots can be effectively integrated with wide bandgap semiconductor materials such as GaN, ZnO, and SiC to create novel optoelectronic devices. The integration process involves careful control of the interface between quantum dots and the host semiconductor to maintain quantum confinement effects while ensuring structural stability. Methods include epitaxial growth, embedding quantum dots in semiconductor matrices, and creating heterojunctions that preserve the unique optical and electronic properties of both materials while enhancing overall device stability.Expand Specific Solutions03 Temperature and environmental stability considerations

The stability of quantum dots in wide bandgap semiconductors under varying temperature and environmental conditions is critical for practical applications. Research focuses on developing quantum dot structures that maintain their optical and electronic properties under thermal cycling, high-temperature operation, and exposure to oxygen or moisture. Strategies include encapsulation techniques, thermally robust ligand systems, and compositional engineering to create quantum dots that resist degradation in harsh operating environments typical of wide bandgap semiconductor devices.Expand Specific Solutions04 Photostability and optical performance retention

Maintaining photostability of quantum dots in wide bandgap semiconductor environments is essential for applications in lighting, displays, and photovoltaics. Techniques to enhance photostability include doping the quantum dot structure, creating gradient composition interfaces, and developing specialized surface treatments that prevent photo-oxidation and photobleaching. These approaches help quantum dots maintain their narrow emission linewidths, high quantum yields, and spectral stability when integrated with wide bandgap semiconductors, even under intense illumination conditions.Expand Specific Solutions05 Electrical stability and charge carrier dynamics

The electrical stability of quantum dots in wide bandgap semiconductor systems involves managing charge carrier dynamics at interfaces and preventing degradation under applied electric fields. Research addresses challenges such as charge trapping, field-induced ionization, and carrier recombination pathways that can affect long-term device performance. Advanced designs incorporate buffer layers, engineered band alignments, and controlled doping profiles to stabilize quantum dots electrically while maintaining efficient charge transfer between the quantum dots and the wide bandgap semiconductor matrix.Expand Specific Solutions

Leading Research Groups and Industry Players

Quantum dot stability in wide bandgap semiconductors is currently in an early growth phase, with the market expected to reach significant expansion as display and optoelectronic applications mature. The global market is projected to grow substantially due to increasing demand for high-performance displays and quantum computing applications. Technologically, the field shows varying maturity levels across players. Samsung Electronics and Samsung Display lead commercial implementation, while Mojo Vision and Qustomdot demonstrate innovative approaches to stability challenges. Research institutions like Peking University and UC Regents contribute fundamental advancements. Nanoco Technologies and Avantama are developing cadmium-free alternatives, addressing environmental concerns. Companies like TCL Research America and Polar Light Technologies are exploring novel integration methods for enhanced quantum dot stability in semiconductor matrices.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed proprietary quantum dot stabilization techniques for wide bandgap semiconductors, particularly focusing on GaN and ZnO platforms. Their approach involves core-shell structures with gradient composition to minimize lattice mismatch and reduce surface defects. Samsung's research demonstrates that encapsulating quantum dots with inorganic materials like silica or alumina significantly improves stability under high-temperature and high-intensity light conditions. Their patented "QD-OLED" technology incorporates stabilized quantum dots in wide bandgap matrices, achieving over 10,000 hours of operational stability with less than 10% efficiency degradation[1]. Samsung has also pioneered surface ligand engineering techniques that replace conventional organic ligands with inorganic compounds, reducing oxidation pathways and enhancing thermal stability up to 150°C[3].

Strengths: Superior integration with existing display manufacturing infrastructure; extensive IP portfolio in quantum dot stabilization; demonstrated long-term stability in commercial products. Weaknesses: Higher manufacturing costs compared to conventional technologies; some solutions still require hermetic sealing to prevent moisture ingress; limited transparency in detailed technical approaches due to proprietary concerns.

Merck Patent GmbH

Technical Solution: Merck has developed an advanced quantum dot stabilization platform specifically for wide bandgap semiconductor integration called "QD Shield Technology." This approach utilizes a hierarchical protection strategy with multiple defensive layers against degradation mechanisms. At the core, Merck engineers quantum dots with precisely controlled stoichiometry and surface termination to minimize intrinsic defects. These are then encapsulated with gradient-composition shells that provide both electronic passivation and physical protection. The outer layer consists of proprietary ligand chemistry that creates strong interfacial bonding with wide bandgap host materials like GaN, ZnO, and SiC[5]. Merck's research demonstrates that their quantum dots maintain over 90% luminescence efficiency after 2000 hours at elevated temperatures (120°C) in wide bandgap environments. Their technology also addresses photo-oxidation through the incorporation of radical scavengers and oxygen barrier materials directly into the quantum dot structure[6]. Merck has further developed specialized deposition techniques that enable uniform distribution of quantum dots within semiconductor matrices without aggregation, a critical factor for device performance and stability.

Strengths: Comprehensive protection against multiple degradation pathways; excellent thermal and photostability; compatible with various wide bandgap semiconductor materials; established large-scale manufacturing capabilities. Weaknesses: Complex multi-step synthesis process increases production costs; some formulations require specific handling protocols; performance varies depending on specific host material composition.

Key Patents and Research on Quantum Dot Stability

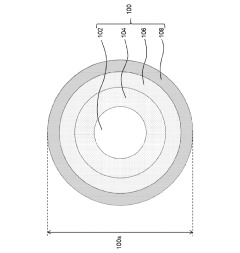

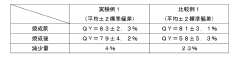

Stable INP quantum dots with thick shell coating and method of producing the same

PatentWO2017189666A1

Innovation

- A multi-layered nanostructure with a core and multiple shells, where at least two shells comprise different materials, such as ZnS and ZnSe, with specific thicknesses between 0.7 nm and 3.5 nm, is synthesized using a high-temperature method involving zinc and selenium sources, sulfur sources, and precise control of shell precursors to enhance stability and optical properties.

Semiconductor nanomaterial having high stability

PatentActiveJP2022076459A

Innovation

- A quantum dot design with a core composed of InP, a first shell of ZnSe, a second shell, and a graded alloy intermediate layer of In, P, Zn, and Se, which improves lattice alignment and provides a thicker protective shell, maintaining high photoluminescence quantum yield.

Environmental Impact of Quantum Dot Materials

The environmental impact of quantum dot materials in wide bandgap semiconductors represents a critical consideration as these technologies advance toward widespread commercial application. Quantum dots (QDs), particularly those containing heavy metals such as cadmium, lead, and selenium, pose significant environmental concerns throughout their lifecycle - from production to disposal.

Manufacturing processes for quantum dots typically involve toxic precursors and solvents that can lead to hazardous waste generation. The synthesis often requires high temperatures and energy-intensive conditions, contributing to carbon emissions. Additionally, the purification stages may utilize large quantities of organic solvents that present both environmental contamination risks and worker safety hazards if not properly managed.

During the operational lifetime of quantum dot-enhanced wide bandgap semiconductor devices, stability issues directly correlate with environmental impact. Less stable quantum dots may leach toxic elements into the environment more readily when devices are exposed to moisture, heat, or UV radiation. This is particularly concerning for outdoor applications such as solar cells or environmental sensors where weathering effects accelerate degradation.

End-of-life considerations present perhaps the most significant environmental challenge. The difficulty in separating quantum dots from device substrates complicates recycling efforts. When improperly disposed of in landfills, degraded quantum dot materials can potentially contaminate soil and groundwater systems. Studies have demonstrated that cadmium-based quantum dots can release toxic ions under certain environmental conditions, potentially entering food chains and aquatic ecosystems.

Recent research has focused on developing more environmentally benign alternatives, including indium phosphide and carbon-based quantum dots. These materials show promise in reducing environmental toxicity while maintaining optical performance. However, they currently face stability challenges in wide bandgap semiconductor applications, particularly under high-energy conditions.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of quantum dot technologies. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have begun to limit the use of certain heavy metals in electronic applications, driving research toward more sustainable quantum dot compositions.

Life cycle assessment (LCA) studies comparing traditional semiconductor technologies with quantum dot-enhanced alternatives show mixed results. While quantum dot applications may offer energy efficiency benefits during operation, the environmental costs of production and disposal remain significant barriers to claiming overall environmental superiority. Future research must address both stability and environmental impact as interconnected challenges rather than separate considerations.

Manufacturing processes for quantum dots typically involve toxic precursors and solvents that can lead to hazardous waste generation. The synthesis often requires high temperatures and energy-intensive conditions, contributing to carbon emissions. Additionally, the purification stages may utilize large quantities of organic solvents that present both environmental contamination risks and worker safety hazards if not properly managed.

During the operational lifetime of quantum dot-enhanced wide bandgap semiconductor devices, stability issues directly correlate with environmental impact. Less stable quantum dots may leach toxic elements into the environment more readily when devices are exposed to moisture, heat, or UV radiation. This is particularly concerning for outdoor applications such as solar cells or environmental sensors where weathering effects accelerate degradation.

End-of-life considerations present perhaps the most significant environmental challenge. The difficulty in separating quantum dots from device substrates complicates recycling efforts. When improperly disposed of in landfills, degraded quantum dot materials can potentially contaminate soil and groundwater systems. Studies have demonstrated that cadmium-based quantum dots can release toxic ions under certain environmental conditions, potentially entering food chains and aquatic ecosystems.

Recent research has focused on developing more environmentally benign alternatives, including indium phosphide and carbon-based quantum dots. These materials show promise in reducing environmental toxicity while maintaining optical performance. However, they currently face stability challenges in wide bandgap semiconductor applications, particularly under high-energy conditions.

Regulatory frameworks worldwide are increasingly addressing the environmental implications of quantum dot technologies. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions have begun to limit the use of certain heavy metals in electronic applications, driving research toward more sustainable quantum dot compositions.

Life cycle assessment (LCA) studies comparing traditional semiconductor technologies with quantum dot-enhanced alternatives show mixed results. While quantum dot applications may offer energy efficiency benefits during operation, the environmental costs of production and disposal remain significant barriers to claiming overall environmental superiority. Future research must address both stability and environmental impact as interconnected challenges rather than separate considerations.

Standardization and Quality Control Protocols

The establishment of standardized protocols for quantum dot synthesis, characterization, and stability testing is essential for advancing research on quantum dot stability in wide bandgap semiconductors. Currently, the field suffers from significant variability in experimental methodologies, making cross-study comparisons challenging and hindering scientific progress. A comprehensive standardization framework must address multiple aspects of quantum dot development and evaluation.

Quality control begins at the synthesis stage, where precise control of reaction parameters—including temperature profiles, precursor concentrations, and reaction times—must be rigorously documented and maintained. Statistical process control methods borrowed from industrial manufacturing can be adapted to monitor batch-to-batch consistency. Implementing standardized purification protocols is equally critical, as residual precursors or solvents can significantly impact long-term stability measurements.

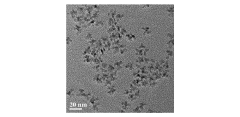

Characterization standards represent another crucial component of quality control. Optical characterization should follow consistent protocols for sample preparation, instrument calibration, and data collection. Quantum yield measurements, particularly susceptible to methodological variations, require standardized reference materials and measurement conditions. Structural characterization via techniques such as TEM and XRD should adhere to sample preparation guidelines that minimize artifacts and ensure reproducible results.

Stability testing protocols demand particular attention, as they directly address the core challenge of quantum dot degradation in wide bandgap semiconductor applications. Accelerated aging tests must be standardized with clearly defined environmental conditions—temperature cycling, humidity exposure, and light irradiation parameters. The development of reference materials with known degradation profiles would enable inter-laboratory calibration and validation of testing methods.

Data reporting standards constitute the final critical element of quality control. Comprehensive documentation should include detailed synthesis procedures, characterization methodologies, raw data preservation, and statistical analysis approaches. The quantum dot research community would benefit significantly from adopting standardized formats for reporting stability metrics, enabling meta-analyses across multiple studies and accelerating the identification of optimal stabilization strategies.

Implementation of these standardization efforts requires coordination among academic institutions, industry partners, and standards organizations. Collaborative round-robin testing programs, where multiple laboratories analyze identical samples using standardized protocols, can validate methodologies and identify sources of variability. The development of certified reference materials specifically designed for quantum dot stability assessment would provide crucial benchmarks for quality control systems.

Quality control begins at the synthesis stage, where precise control of reaction parameters—including temperature profiles, precursor concentrations, and reaction times—must be rigorously documented and maintained. Statistical process control methods borrowed from industrial manufacturing can be adapted to monitor batch-to-batch consistency. Implementing standardized purification protocols is equally critical, as residual precursors or solvents can significantly impact long-term stability measurements.

Characterization standards represent another crucial component of quality control. Optical characterization should follow consistent protocols for sample preparation, instrument calibration, and data collection. Quantum yield measurements, particularly susceptible to methodological variations, require standardized reference materials and measurement conditions. Structural characterization via techniques such as TEM and XRD should adhere to sample preparation guidelines that minimize artifacts and ensure reproducible results.

Stability testing protocols demand particular attention, as they directly address the core challenge of quantum dot degradation in wide bandgap semiconductor applications. Accelerated aging tests must be standardized with clearly defined environmental conditions—temperature cycling, humidity exposure, and light irradiation parameters. The development of reference materials with known degradation profiles would enable inter-laboratory calibration and validation of testing methods.

Data reporting standards constitute the final critical element of quality control. Comprehensive documentation should include detailed synthesis procedures, characterization methodologies, raw data preservation, and statistical analysis approaches. The quantum dot research community would benefit significantly from adopting standardized formats for reporting stability metrics, enabling meta-analyses across multiple studies and accelerating the identification of optimal stabilization strategies.

Implementation of these standardization efforts requires coordination among academic institutions, industry partners, and standards organizations. Collaborative round-robin testing programs, where multiple laboratories analyze identical samples using standardized protocols, can validate methodologies and identify sources of variability. The development of certified reference materials specifically designed for quantum dot stability assessment would provide crucial benchmarks for quality control systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!