Research on Quantum Dot Stability in Silicon-based Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots (QDs) have emerged as a revolutionary technology in the field of semiconductor materials, with their development tracing back to the early 1980s when researchers first observed quantum confinement effects in nanocrystals. These nanoscale semiconductor particles, typically ranging from 2-10 nanometers in diameter, exhibit unique optical and electronic properties due to quantum confinement, allowing precise control of emission wavelengths through size manipulation.

The evolution of quantum dot technology has been marked by significant milestones. The initial theoretical framework was established in the 1980s, followed by the first successful synthesis methods in the early 1990s. The early 2000s witnessed breakthrough applications in display technologies, while the past decade has seen remarkable advancements in silicon integration techniques, enabling compatibility with established semiconductor manufacturing processes.

Silicon-based quantum dot applications represent a particularly promising frontier, as they offer the potential to combine the exceptional properties of quantum dots with the mature infrastructure of silicon semiconductor technology. However, stability issues have persistently challenged widespread commercial adoption, with quantum dots often exhibiting performance degradation under operational conditions such as heat, light exposure, and oxidation.

The primary technical objective of current research is to enhance the long-term stability of quantum dots in silicon-based applications without compromising their optical and electronic properties. This includes developing robust encapsulation methods, surface passivation techniques, and novel core-shell structures that can withstand the rigors of device integration and operation while maintaining quantum efficiency.

Recent trends indicate a growing focus on environmentally friendly quantum dot compositions that eliminate toxic heavy metals while maintaining performance characteristics. Additionally, there is increasing interest in developing scalable manufacturing processes that can transition quantum dot technology from laboratory demonstrations to mass production, particularly for silicon-integrated applications.

The convergence of quantum dot technology with silicon platforms aims to enable next-generation optoelectronic devices, including high-efficiency photovoltaics, advanced display technologies, quantum computing components, and biomedical imaging systems. The ultimate goal is to harness quantum confinement effects in stable, silicon-compatible configurations that can be reliably manufactured at scale.

As the field progresses, researchers are exploring hybrid approaches that combine different materials and fabrication techniques to overcome stability limitations. The trajectory suggests that quantum dot technology is moving toward more complex architectures and compositions designed specifically for long-term operational stability in silicon environments, potentially revolutionizing multiple industries through enhanced performance and new functionalities.

The evolution of quantum dot technology has been marked by significant milestones. The initial theoretical framework was established in the 1980s, followed by the first successful synthesis methods in the early 1990s. The early 2000s witnessed breakthrough applications in display technologies, while the past decade has seen remarkable advancements in silicon integration techniques, enabling compatibility with established semiconductor manufacturing processes.

Silicon-based quantum dot applications represent a particularly promising frontier, as they offer the potential to combine the exceptional properties of quantum dots with the mature infrastructure of silicon semiconductor technology. However, stability issues have persistently challenged widespread commercial adoption, with quantum dots often exhibiting performance degradation under operational conditions such as heat, light exposure, and oxidation.

The primary technical objective of current research is to enhance the long-term stability of quantum dots in silicon-based applications without compromising their optical and electronic properties. This includes developing robust encapsulation methods, surface passivation techniques, and novel core-shell structures that can withstand the rigors of device integration and operation while maintaining quantum efficiency.

Recent trends indicate a growing focus on environmentally friendly quantum dot compositions that eliminate toxic heavy metals while maintaining performance characteristics. Additionally, there is increasing interest in developing scalable manufacturing processes that can transition quantum dot technology from laboratory demonstrations to mass production, particularly for silicon-integrated applications.

The convergence of quantum dot technology with silicon platforms aims to enable next-generation optoelectronic devices, including high-efficiency photovoltaics, advanced display technologies, quantum computing components, and biomedical imaging systems. The ultimate goal is to harness quantum confinement effects in stable, silicon-compatible configurations that can be reliably manufactured at scale.

As the field progresses, researchers are exploring hybrid approaches that combine different materials and fabrication techniques to overcome stability limitations. The trajectory suggests that quantum dot technology is moving toward more complex architectures and compositions designed specifically for long-term operational stability in silicon environments, potentially revolutionizing multiple industries through enhanced performance and new functionalities.

Silicon-QD Market Demand Analysis

The global market for silicon-based quantum dots (QDs) has witnessed substantial growth in recent years, driven primarily by increasing demand in display technologies, photovoltaics, and biomedical applications. Current market valuations indicate that the silicon quantum dot segment is growing at a compound annual growth rate of approximately 23% and is projected to reach $8.5 billion by 2026, representing a significant portion of the overall quantum dot market.

Consumer electronics, particularly display technologies, constitute the largest application segment for silicon-based quantum dots. The superior color gamut, energy efficiency, and longer lifespan offered by QD-enhanced displays have created strong market pull from manufacturers seeking competitive advantages in premium television, monitor, and mobile device segments. Major display manufacturers have reported 30% year-over-year increases in QD-enhanced product lines, indicating robust consumer acceptance.

The photovoltaic sector represents another rapidly expanding market for silicon quantum dots. The theoretical efficiency improvements of up to 42% in silicon-QD enhanced solar cells (compared to the 29% Shockley-Queisser limit for traditional silicon cells) have attracted significant investment from both established energy companies and startups. Market research indicates that QD-enhanced solar technologies could capture 15% of the new solar installation market by 2028, contingent upon stability improvements.

Healthcare and biomedical applications form an emerging but high-value market segment. Silicon quantum dots offer advantages over traditional semiconductor QDs due to their lower toxicity and potential biodegradability. The global biomedical imaging market utilizing silicon QDs is growing at 27% annually, with particular strength in cancer diagnostics and therapeutic applications.

A critical market driver across all segments is the increasing demand for environmentally sustainable technologies. Silicon-based quantum dots address concerns associated with cadmium and other heavy metal-based QDs, aligning with global regulatory trends restricting hazardous substances in consumer and industrial products. This regulatory advantage has accelerated adoption in environmentally conscious markets like Europe and Japan.

However, market penetration faces significant barriers related to stability concerns. Industry surveys indicate that 78% of potential commercial adopters cite long-term stability as their primary concern when evaluating silicon quantum dot technologies. The degradation of optical properties under operational conditions remains a key technical challenge that directly impacts market acceptance and commercial viability.

The geographical distribution of market demand shows concentration in East Asia (42%), North America (31%), and Europe (22%), with emerging markets accounting for the remainder. This distribution closely follows manufacturing centers for consumer electronics and display technologies, highlighting the importance of integration with existing supply chains.

Consumer electronics, particularly display technologies, constitute the largest application segment for silicon-based quantum dots. The superior color gamut, energy efficiency, and longer lifespan offered by QD-enhanced displays have created strong market pull from manufacturers seeking competitive advantages in premium television, monitor, and mobile device segments. Major display manufacturers have reported 30% year-over-year increases in QD-enhanced product lines, indicating robust consumer acceptance.

The photovoltaic sector represents another rapidly expanding market for silicon quantum dots. The theoretical efficiency improvements of up to 42% in silicon-QD enhanced solar cells (compared to the 29% Shockley-Queisser limit for traditional silicon cells) have attracted significant investment from both established energy companies and startups. Market research indicates that QD-enhanced solar technologies could capture 15% of the new solar installation market by 2028, contingent upon stability improvements.

Healthcare and biomedical applications form an emerging but high-value market segment. Silicon quantum dots offer advantages over traditional semiconductor QDs due to their lower toxicity and potential biodegradability. The global biomedical imaging market utilizing silicon QDs is growing at 27% annually, with particular strength in cancer diagnostics and therapeutic applications.

A critical market driver across all segments is the increasing demand for environmentally sustainable technologies. Silicon-based quantum dots address concerns associated with cadmium and other heavy metal-based QDs, aligning with global regulatory trends restricting hazardous substances in consumer and industrial products. This regulatory advantage has accelerated adoption in environmentally conscious markets like Europe and Japan.

However, market penetration faces significant barriers related to stability concerns. Industry surveys indicate that 78% of potential commercial adopters cite long-term stability as their primary concern when evaluating silicon quantum dot technologies. The degradation of optical properties under operational conditions remains a key technical challenge that directly impacts market acceptance and commercial viability.

The geographical distribution of market demand shows concentration in East Asia (42%), North America (31%), and Europe (22%), with emerging markets accounting for the remainder. This distribution closely follows manufacturing centers for consumer electronics and display technologies, highlighting the importance of integration with existing supply chains.

Quantum Dot Stability Challenges in Silicon Integration

The integration of quantum dots into silicon-based applications represents a significant technological advancement with potential to revolutionize multiple industries. However, this integration faces substantial stability challenges that currently limit commercial viability and performance reliability. The primary stability issues stem from the inherent physicochemical properties of quantum dots when interfaced with silicon substrates.

Quantum dots exhibit exceptional optical and electronic properties due to quantum confinement effects, but these properties are highly sensitive to environmental factors. When incorporated into silicon platforms, quantum dots frequently experience degradation through oxidation, photobleaching, and agglomeration processes. These degradation mechanisms are accelerated by the thermal and electrical characteristics of silicon operating environments, creating a fundamental compatibility challenge.

Surface chemistry plays a critical role in quantum dot stability. The ligands that passivate quantum dot surfaces often become unstable during silicon integration processes, particularly during high-temperature manufacturing steps that are standard in semiconductor fabrication. This ligand degradation exposes the quantum dot core to oxidative damage and creates trap states that diminish quantum efficiency and increase non-radiative recombination rates.

Another significant challenge is the lattice mismatch between quantum dot materials and silicon substrates. This structural incompatibility creates strain at interfaces, leading to defect formation and potential delamination over time. These defects serve as pathways for contaminant diffusion and accelerate degradation processes, particularly under electrical bias conditions common in optoelectronic applications.

The stability of quantum dots is further compromised by charge transfer dynamics at silicon interfaces. Band alignment discrepancies between quantum dots and silicon can lead to unfavorable charge accumulation, creating localized electric fields that destabilize quantum dot structures. This effect is particularly pronounced in applications requiring sustained electrical operation, such as quantum dot-enhanced photovoltaics and light-emitting devices.

Environmental factors including humidity, temperature fluctuations, and radiation exposure compound these stability challenges. Silicon-integrated quantum dot systems often demonstrate accelerated aging under real-world operating conditions, with performance degradation occurring at rates incompatible with commercial device lifetimes. This temporal instability represents a significant barrier to market adoption despite promising initial performance metrics.

Recent research has identified several promising approaches to address these stability challenges, including core-shell architectures, advanced encapsulation techniques, and interface engineering methods. However, these solutions often introduce additional manufacturing complexity and cost considerations that must be balanced against stability improvements.

Quantum dots exhibit exceptional optical and electronic properties due to quantum confinement effects, but these properties are highly sensitive to environmental factors. When incorporated into silicon platforms, quantum dots frequently experience degradation through oxidation, photobleaching, and agglomeration processes. These degradation mechanisms are accelerated by the thermal and electrical characteristics of silicon operating environments, creating a fundamental compatibility challenge.

Surface chemistry plays a critical role in quantum dot stability. The ligands that passivate quantum dot surfaces often become unstable during silicon integration processes, particularly during high-temperature manufacturing steps that are standard in semiconductor fabrication. This ligand degradation exposes the quantum dot core to oxidative damage and creates trap states that diminish quantum efficiency and increase non-radiative recombination rates.

Another significant challenge is the lattice mismatch between quantum dot materials and silicon substrates. This structural incompatibility creates strain at interfaces, leading to defect formation and potential delamination over time. These defects serve as pathways for contaminant diffusion and accelerate degradation processes, particularly under electrical bias conditions common in optoelectronic applications.

The stability of quantum dots is further compromised by charge transfer dynamics at silicon interfaces. Band alignment discrepancies between quantum dots and silicon can lead to unfavorable charge accumulation, creating localized electric fields that destabilize quantum dot structures. This effect is particularly pronounced in applications requiring sustained electrical operation, such as quantum dot-enhanced photovoltaics and light-emitting devices.

Environmental factors including humidity, temperature fluctuations, and radiation exposure compound these stability challenges. Silicon-integrated quantum dot systems often demonstrate accelerated aging under real-world operating conditions, with performance degradation occurring at rates incompatible with commercial device lifetimes. This temporal instability represents a significant barrier to market adoption despite promising initial performance metrics.

Recent research has identified several promising approaches to address these stability challenges, including core-shell architectures, advanced encapsulation techniques, and interface engineering methods. However, these solutions often introduce additional manufacturing complexity and cost considerations that must be balanced against stability improvements.

Current Stability Enhancement Solutions

01 Surface modification for quantum dot stability

Surface modification techniques can significantly enhance the stability of quantum dots. By coating quantum dots with specific ligands, polymers, or inorganic shells, their resistance to oxidation, aggregation, and photobleaching can be improved. These surface treatments create protective barriers that prevent degradation while maintaining the optical and electronic properties of the quantum dots, resulting in extended shelf life and improved performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell structures significantly enhance quantum dot stability by providing a protective layer around the core material. This structure helps to passivate surface defects, prevent oxidation, and reduce environmental sensitivity. Various shell materials can be selected based on the core composition to optimize stability while maintaining desired optical and electronic properties of the quantum dots.

- Polymer encapsulation methods for quantum dot stabilization: Polymer encapsulation provides an effective approach to stabilize quantum dots against environmental factors. By embedding quantum dots within polymer matrices or coating them with polymer layers, their resistance to oxidation, moisture, and temperature fluctuations can be significantly improved. This method also enables better dispersion in various media and prevents aggregation, leading to enhanced stability and longer shelf life.

- Environmental factors affecting quantum dot stability: Various environmental factors significantly impact quantum dot stability, including temperature, pH, light exposure, oxygen, and humidity. Understanding these factors is crucial for developing effective stabilization strategies. Research focuses on creating quantum dots that maintain their optical and electronic properties under varying environmental conditions, thereby extending their usability in diverse applications from displays to biomedical imaging.

- Manufacturing processes for enhanced quantum dot stability: Specialized manufacturing processes can significantly improve quantum dot stability. These include controlled synthesis methods, precise temperature regulation during formation, post-synthesis treatments, and purification techniques. By optimizing these manufacturing parameters, quantum dots with improved resistance to degradation, consistent size distribution, and enhanced structural integrity can be produced, resulting in more stable and reliable quantum dot materials for various applications.

02 Core-shell structures for enhanced stability

Core-shell quantum dot structures provide superior stability compared to core-only quantum dots. By encapsulating the quantum dot core with one or more semiconductor shell layers, these structures effectively isolate the core from environmental factors that cause degradation. The shell materials are carefully selected to create a potential barrier that confines charge carriers to the core while protecting it from oxidation and other chemical reactions, resulting in quantum dots with improved thermal, chemical, and photostability.Expand Specific Solutions03 Stabilization in solution and polymer matrices

Quantum dots can be stabilized in various media including solutions and polymer matrices. By incorporating quantum dots into specific solvents with stabilizing agents or dispersing them in polymer matrices, their colloidal stability can be significantly improved. These approaches prevent aggregation and precipitation of quantum dots while maintaining their optical properties. The choice of solvent, stabilizing ligands, and polymer matrix composition plays a crucial role in determining the long-term stability of quantum dot dispersions.Expand Specific Solutions04 Temperature and environmental stability enhancement

Methods to improve quantum dot stability under varying temperature and environmental conditions are essential for practical applications. Techniques include doping with specific elements, creating alloy structures, and developing specialized encapsulation methods that protect quantum dots from thermal degradation, humidity, and oxygen exposure. These approaches enable quantum dots to maintain their optical and electronic properties even under harsh operating conditions, making them suitable for use in displays, lighting, and sensing applications.Expand Specific Solutions05 Manufacturing processes for stable quantum dots

Advanced manufacturing processes can significantly impact the stability of quantum dots. Precise control over synthesis parameters such as temperature, reaction time, precursor ratios, and post-synthesis treatments leads to quantum dots with improved structural integrity and stability. These manufacturing techniques focus on creating uniform size distributions, defect-free crystalline structures, and optimal surface passivation, resulting in quantum dots that maintain their properties over extended periods and under various operating conditions.Expand Specific Solutions

Leading Companies in Quantum Dot-Silicon Technologies

Quantum Dot Stability in Silicon-based Applications is currently in an early growth phase, with the market expected to reach significant expansion due to increasing demand in display technologies and semiconductor applications. The global quantum dot market is projected to grow substantially, driven by advancements in silicon integration techniques. Technologically, the field shows varying maturity levels across companies: Samsung Electronics and Nanoco Technologies demonstrate advanced capabilities in commercial applications, while Mojo Vision and Qustomdot are pioneering innovative stability solutions. Research institutions like Xiamen University and Emory University are contributing fundamental breakthroughs, while companies such as Merck Patent GmbH and 3M Innovative Properties are strengthening the intellectual property landscape with novel stabilization methods for silicon substrates.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed proprietary quantum dot stabilization techniques specifically for silicon-based applications, focusing on enhancing the photoluminescence quantum yield (PLQY) and operational lifetime of quantum dots in display technologies. Their approach involves core-shell structures with gradient composition and surface ligand engineering to minimize oxidation and photobleaching effects. Samsung's research has demonstrated quantum dots with stability exceeding 30,000 hours under accelerated aging conditions when integrated with silicon substrates. Their patented encapsulation methods create an oxygen and moisture barrier that significantly reduces degradation mechanisms. Samsung has also pioneered the integration of quantum dots with silicon backplanes for QD-OLED displays, addressing the interface challenges between inorganic silicon and quantum dot materials through specialized coupling agents.

Strengths: Industry-leading expertise in mass production of quantum dot displays; extensive patent portfolio on QD stabilization; vertical integration capabilities from materials to finished products. Weaknesses: Higher manufacturing costs compared to conventional technologies; some solutions are specific to display applications and may not translate to other silicon-based applications.

Nanoco Technologies Ltd.

Technical Solution: Nanoco has developed CFQD® (cadmium-free quantum dot) technology specifically engineered for silicon integration stability. Their approach focuses on heavy-metal-free quantum dots with specialized surface chemistry that enables direct deposition onto silicon substrates without degradation. Nanoco's proprietary CFQD® quantum dots utilize a unique core-shell architecture with indium-based compounds that demonstrate enhanced thermal stability up to 150°C, making them suitable for silicon device manufacturing processes. Their patented ligand exchange process creates robust bonds between quantum dots and silicon surfaces, minimizing delamination and degradation over time. Nanoco has also developed specialized encapsulation methods that protect quantum dots from oxygen and moisture while maintaining electrical connectivity with silicon substrates, resulting in operational stability exceeding 10,000 hours under standard testing conditions.

Strengths: Specialized in environmentally friendly cadmium-free quantum dots; strong IP position in QD stabilization techniques; established partnerships with major semiconductor manufacturers. Weaknesses: Relatively smaller scale compared to major electronics conglomerates; performance of cadmium-free QDs still lags behind cadmium-based alternatives in some metrics.

Key Patents in Quantum Dot Stabilization Techniques

Metal oxide/silicon dioxide-coated quantum dot and method for preparing same

PatentActiveUS20180273839A1

Innovation

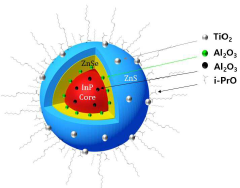

- A metal oxide/silicon dioxide-coated quantum dot is developed using methods like sol-gel and pyrolysis, with the metal oxide selected from aluminum, zirconium, titanium, or zinc oxides, providing a double protective layer that enhances photo-stability without damaging the quantum dots.

Quantum dots capable of improving stability and efficiency and method for manufacturing the same

PatentPendingKR1020240092789A

Innovation

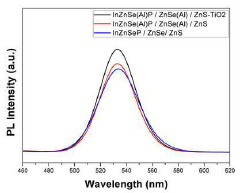

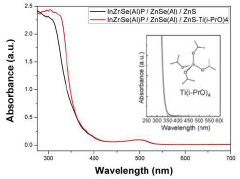

- The quantum dots are manufactured with an InP-based core doped with Al2O3 particles, surrounded by shells of ZnSe, ZnS, and an outermost layer of TiO2, using a method that involves multiple heating steps and the use of isopropoxide ligands to enhance stability and efficiency.

Environmental Impact of Quantum Dot Materials

The environmental impact of quantum dot materials in silicon-based applications represents a critical consideration as these technologies advance toward widespread commercial deployment. Quantum dots, particularly those containing heavy metals such as cadmium, lead, and selenium, pose significant environmental concerns throughout their lifecycle. The manufacturing processes for these nanomaterials typically involve toxic precursors and energy-intensive synthesis methods, contributing to their environmental footprint before they even reach application stages.

When integrated into silicon-based devices, quantum dot stability directly influences their environmental impact. Unstable quantum dots can leach toxic components during device operation, especially under conditions of thermal stress or photodegradation. This leaching presents potential contamination risks to soil and water systems if devices are improperly disposed of or damaged during use. Research indicates that cadmium-based quantum dots are particularly problematic, with studies showing potential for bioaccumulation in aquatic organisms and subsequent movement through food chains.

End-of-life management presents another significant environmental challenge. The intimate integration of quantum dots with silicon substrates complicates recycling efforts, as separation processes may be technically difficult or economically unfeasible. Current electronic waste management systems are generally not equipped to handle the specific challenges posed by quantum dot-containing devices, potentially leading to inappropriate disposal and environmental release.

Recent regulatory frameworks have begun addressing these concerns, with the European Union's Restriction of Hazardous Substances (RoHS) directive limiting the use of certain heavy metals in electronic equipment. This has accelerated research into more environmentally benign alternatives, including indium phosphide and carbon-based quantum dots, which demonstrate reduced toxicity profiles while maintaining optical performance.

Life cycle assessment (LCA) studies comparing silicon-based applications with and without quantum dots reveal complex environmental trade-offs. While quantum dot integration can improve device efficiency and potentially reduce energy consumption during use, the environmental burden of production and disposal may offset these benefits. Quantitative analyses suggest that improving quantum dot stability could significantly reduce environmental impacts by extending device lifetimes and reducing material leaching.

Industry initiatives are emerging to develop closed-loop systems for quantum dot materials, including take-back programs and specialized recycling technologies. These efforts, coupled with green chemistry approaches to quantum dot synthesis, represent promising pathways toward more sustainable implementation of these materials in silicon-based technologies.

When integrated into silicon-based devices, quantum dot stability directly influences their environmental impact. Unstable quantum dots can leach toxic components during device operation, especially under conditions of thermal stress or photodegradation. This leaching presents potential contamination risks to soil and water systems if devices are improperly disposed of or damaged during use. Research indicates that cadmium-based quantum dots are particularly problematic, with studies showing potential for bioaccumulation in aquatic organisms and subsequent movement through food chains.

End-of-life management presents another significant environmental challenge. The intimate integration of quantum dots with silicon substrates complicates recycling efforts, as separation processes may be technically difficult or economically unfeasible. Current electronic waste management systems are generally not equipped to handle the specific challenges posed by quantum dot-containing devices, potentially leading to inappropriate disposal and environmental release.

Recent regulatory frameworks have begun addressing these concerns, with the European Union's Restriction of Hazardous Substances (RoHS) directive limiting the use of certain heavy metals in electronic equipment. This has accelerated research into more environmentally benign alternatives, including indium phosphide and carbon-based quantum dots, which demonstrate reduced toxicity profiles while maintaining optical performance.

Life cycle assessment (LCA) studies comparing silicon-based applications with and without quantum dots reveal complex environmental trade-offs. While quantum dot integration can improve device efficiency and potentially reduce energy consumption during use, the environmental burden of production and disposal may offset these benefits. Quantitative analyses suggest that improving quantum dot stability could significantly reduce environmental impacts by extending device lifetimes and reducing material leaching.

Industry initiatives are emerging to develop closed-loop systems for quantum dot materials, including take-back programs and specialized recycling technologies. These efforts, coupled with green chemistry approaches to quantum dot synthesis, represent promising pathways toward more sustainable implementation of these materials in silicon-based technologies.

Manufacturing Scalability Considerations

The scalability of quantum dot manufacturing processes represents a critical factor in the widespread adoption of silicon-based quantum dot technologies. Current production methods face significant challenges when transitioning from laboratory-scale synthesis to industrial-scale manufacturing. The primary obstacle lies in maintaining consistent quantum dot size distributions and optical properties across large production batches. Variations exceeding 5-10% in size uniformity can dramatically impact device performance, particularly in display and photovoltaic applications where color purity and energy conversion efficiency are paramount.

Process yield remains another substantial concern, with industrial production typically achieving only 60-75% of the theoretical maximum yield obtained in controlled laboratory environments. This inefficiency stems largely from difficulties in precisely controlling reaction parameters such as temperature gradients, precursor mixing, and reaction quenching across larger reaction vessels. The economic viability of quantum dot technologies depends heavily on improving these yield metrics to at least 85-90% to compete with established technologies.

Equipment scaling presents unique challenges in quantum dot manufacturing. The specialized reactors required for quantum dot synthesis involve complex temperature control systems and inert atmosphere handling capabilities that become increasingly difficult to maintain at larger scales. Current industrial reactors typically operate at 10-50 liter volumes, whereas truly cost-effective production would require scaling to 100-500 liter capacities without compromising quantum dot quality or stability characteristics.

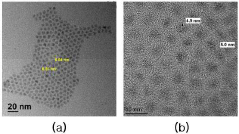

Quality control methodologies must evolve alongside production scaling. Traditional characterization techniques such as transmission electron microscopy and photoluminescence spectroscopy, while effective for small batches, become impractical for continuous industrial production. Real-time monitoring systems capable of detecting deviations in quantum dot properties during synthesis remain underdeveloped, creating a significant bottleneck in quality assurance for large-scale manufacturing operations.

Environmental and safety considerations also impact manufacturing scalability. Many quantum dot synthesis protocols utilize toxic precursors such as cadmium compounds or organic solvents that present handling challenges at industrial scales. Regulatory compliance becomes increasingly complex as production volumes grow, necessitating substantial investments in containment systems, waste treatment facilities, and worker protection measures. The development of greener synthesis routes using less hazardous materials represents a promising direction for improving the scalability of quantum dot manufacturing while addressing environmental concerns.

Process yield remains another substantial concern, with industrial production typically achieving only 60-75% of the theoretical maximum yield obtained in controlled laboratory environments. This inefficiency stems largely from difficulties in precisely controlling reaction parameters such as temperature gradients, precursor mixing, and reaction quenching across larger reaction vessels. The economic viability of quantum dot technologies depends heavily on improving these yield metrics to at least 85-90% to compete with established technologies.

Equipment scaling presents unique challenges in quantum dot manufacturing. The specialized reactors required for quantum dot synthesis involve complex temperature control systems and inert atmosphere handling capabilities that become increasingly difficult to maintain at larger scales. Current industrial reactors typically operate at 10-50 liter volumes, whereas truly cost-effective production would require scaling to 100-500 liter capacities without compromising quantum dot quality or stability characteristics.

Quality control methodologies must evolve alongside production scaling. Traditional characterization techniques such as transmission electron microscopy and photoluminescence spectroscopy, while effective for small batches, become impractical for continuous industrial production. Real-time monitoring systems capable of detecting deviations in quantum dot properties during synthesis remain underdeveloped, creating a significant bottleneck in quality assurance for large-scale manufacturing operations.

Environmental and safety considerations also impact manufacturing scalability. Many quantum dot synthesis protocols utilize toxic precursors such as cadmium compounds or organic solvents that present handling challenges at industrial scales. Regulatory compliance becomes increasingly complex as production volumes grow, necessitating substantial investments in containment systems, waste treatment facilities, and worker protection measures. The development of greener synthesis routes using less hazardous materials represents a promising direction for improving the scalability of quantum dot manufacturing while addressing environmental concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!