Research on Quantum Dot Stability with Nanomaterial Blending

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Nanoblending Background and Objectives

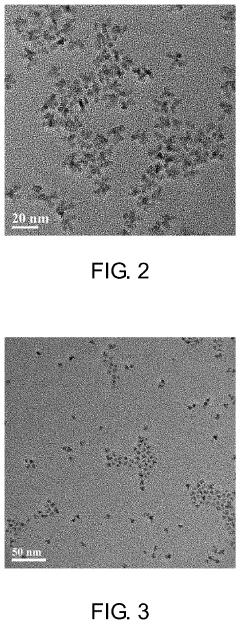

Quantum dots (QDs) have emerged as revolutionary nanomaterials with exceptional optical and electronic properties since their discovery in the early 1980s. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit size-dependent bandgap energies that result in tunable photoluminescence across the visible spectrum. The evolution of QD technology has progressed from fundamental quantum confinement studies to sophisticated applications in displays, lighting, photovoltaics, and biomedical imaging.

Despite their remarkable properties, quantum dots face persistent stability challenges that limit their commercial viability and long-term performance. Environmental factors such as oxygen, moisture, heat, and UV radiation can trigger degradation mechanisms including oxidation, photobleaching, and structural deformation. These degradation pathways lead to diminished quantum yield, color shifts, and ultimately device failure in commercial applications.

The concept of nanomaterial blending represents a promising frontier in addressing these stability issues. By strategically combining quantum dots with complementary nanomaterials such as metal oxides, polymers, or carbon-based structures, researchers aim to create hybrid systems that preserve the optical brilliance of QDs while enhancing their resistance to environmental stressors. This approach leverages synergistic interactions at the nanoscale interface to create protective environments for the quantum dots.

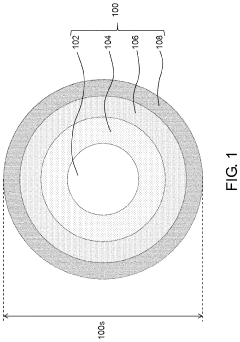

The technical trajectory of quantum dot development has evolved from simple core structures to sophisticated core-shell architectures, and now toward complex nanoblended composites. Each evolutionary step has addressed specific limitations, with nanoblending representing the latest paradigm for comprehensive stability enhancement. This progression reflects the industry's growing understanding of nanoscale interactions and surface chemistry.

The primary objective of this research is to systematically investigate how various nanomaterial blending approaches affect quantum dot stability across multiple degradation vectors. Specifically, we aim to quantify stability improvements under thermal stress (up to 150°C), photostability under continuous illumination, and resistance to oxidative environments. Secondary objectives include maintaining quantum yield above 80% of initial values and preserving spectral characteristics during accelerated aging tests.

This research addresses critical industry needs as quantum dot applications expand into more demanding environments. Display manufacturers require QDs that maintain performance through thousands of operating hours, while lighting applications demand stability under high-flux illumination conditions. Similarly, biomedical applications require QDs that remain stable in physiological environments without leaching toxic components or losing their optical signatures.

By establishing fundamental design principles for quantum dot nanoblending, this research aims to bridge the gap between laboratory demonstrations and commercial implementation, potentially enabling the next generation of stable, high-performance quantum dot technologies across multiple industry sectors.

Despite their remarkable properties, quantum dots face persistent stability challenges that limit their commercial viability and long-term performance. Environmental factors such as oxygen, moisture, heat, and UV radiation can trigger degradation mechanisms including oxidation, photobleaching, and structural deformation. These degradation pathways lead to diminished quantum yield, color shifts, and ultimately device failure in commercial applications.

The concept of nanomaterial blending represents a promising frontier in addressing these stability issues. By strategically combining quantum dots with complementary nanomaterials such as metal oxides, polymers, or carbon-based structures, researchers aim to create hybrid systems that preserve the optical brilliance of QDs while enhancing their resistance to environmental stressors. This approach leverages synergistic interactions at the nanoscale interface to create protective environments for the quantum dots.

The technical trajectory of quantum dot development has evolved from simple core structures to sophisticated core-shell architectures, and now toward complex nanoblended composites. Each evolutionary step has addressed specific limitations, with nanoblending representing the latest paradigm for comprehensive stability enhancement. This progression reflects the industry's growing understanding of nanoscale interactions and surface chemistry.

The primary objective of this research is to systematically investigate how various nanomaterial blending approaches affect quantum dot stability across multiple degradation vectors. Specifically, we aim to quantify stability improvements under thermal stress (up to 150°C), photostability under continuous illumination, and resistance to oxidative environments. Secondary objectives include maintaining quantum yield above 80% of initial values and preserving spectral characteristics during accelerated aging tests.

This research addresses critical industry needs as quantum dot applications expand into more demanding environments. Display manufacturers require QDs that maintain performance through thousands of operating hours, while lighting applications demand stability under high-flux illumination conditions. Similarly, biomedical applications require QDs that remain stable in physiological environments without leaching toxic components or losing their optical signatures.

By establishing fundamental design principles for quantum dot nanoblending, this research aims to bridge the gap between laboratory demonstrations and commercial implementation, potentially enabling the next generation of stable, high-performance quantum dot technologies across multiple industry sectors.

Market Analysis for Stable Quantum Dot Applications

The quantum dot market has witnessed substantial growth in recent years, driven primarily by increasing applications in display technologies. The global quantum dot market was valued at approximately $4.6 billion in 2021 and is projected to reach $25.5 billion by 2030, growing at a CAGR of 21.1% during the forecast period. This remarkable growth trajectory underscores the significant market potential for stable quantum dot applications across various industries.

Display technology currently dominates the quantum dot market, accounting for nearly 65% of the total market share. Major electronics manufacturers including Samsung, LG, and TCL have incorporated quantum dot technology into their premium television and monitor product lines, capitalizing on the superior color gamut and energy efficiency these materials offer. The enhanced stability achieved through nanomaterial blending techniques has been crucial in expanding this market segment.

Healthcare and biomedical applications represent the fastest-growing sector for stable quantum dots, with an estimated growth rate of 24.3% annually. The improved stability of quantum dots through nanomaterial blending has opened new possibilities for in-vivo imaging, drug delivery systems, and diagnostic applications. Market analysts predict this segment could reach $5.8 billion by 2028, driven by increasing investments in precision medicine and advanced diagnostic technologies.

The photovoltaic industry has begun adopting quantum dot technology in next-generation solar cells, with the market expected to grow from $380 million in 2022 to approximately $1.2 billion by 2027. Enhanced stability through nanomaterial blending has addressed previous limitations related to operational lifetime under intense solar radiation, making quantum dot solar cells increasingly viable for commercial applications.

Regionally, North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region is expected to witness the highest growth rate of 23.5% annually, driven by expanding manufacturing capabilities in China, South Korea, and Japan, coupled with increasing adoption across consumer electronics and automotive sectors.

Key market challenges include high production costs, with premium quantum dot materials costing between $10,000 and $30,000 per kilogram, and regulatory concerns regarding heavy metal content in certain quantum dot formulations. These factors have created significant market opportunities for research focused on environmentally friendly, stable quantum dot materials produced through cost-effective methods.

Consumer electronics manufacturers have indicated willingness to pay premium prices for quantum dot materials that demonstrate stability exceeding 10,000 hours under standard operating conditions, highlighting the substantial market value of stability enhancements achieved through nanomaterial blending techniques.

Display technology currently dominates the quantum dot market, accounting for nearly 65% of the total market share. Major electronics manufacturers including Samsung, LG, and TCL have incorporated quantum dot technology into their premium television and monitor product lines, capitalizing on the superior color gamut and energy efficiency these materials offer. The enhanced stability achieved through nanomaterial blending techniques has been crucial in expanding this market segment.

Healthcare and biomedical applications represent the fastest-growing sector for stable quantum dots, with an estimated growth rate of 24.3% annually. The improved stability of quantum dots through nanomaterial blending has opened new possibilities for in-vivo imaging, drug delivery systems, and diagnostic applications. Market analysts predict this segment could reach $5.8 billion by 2028, driven by increasing investments in precision medicine and advanced diagnostic technologies.

The photovoltaic industry has begun adopting quantum dot technology in next-generation solar cells, with the market expected to grow from $380 million in 2022 to approximately $1.2 billion by 2027. Enhanced stability through nanomaterial blending has addressed previous limitations related to operational lifetime under intense solar radiation, making quantum dot solar cells increasingly viable for commercial applications.

Regionally, North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region is expected to witness the highest growth rate of 23.5% annually, driven by expanding manufacturing capabilities in China, South Korea, and Japan, coupled with increasing adoption across consumer electronics and automotive sectors.

Key market challenges include high production costs, with premium quantum dot materials costing between $10,000 and $30,000 per kilogram, and regulatory concerns regarding heavy metal content in certain quantum dot formulations. These factors have created significant market opportunities for research focused on environmentally friendly, stable quantum dot materials produced through cost-effective methods.

Consumer electronics manufacturers have indicated willingness to pay premium prices for quantum dot materials that demonstrate stability exceeding 10,000 hours under standard operating conditions, highlighting the substantial market value of stability enhancements achieved through nanomaterial blending techniques.

Current Challenges in Quantum Dot Stability

Despite significant advancements in quantum dot (QD) technology, stability remains a critical challenge that impedes widespread commercial applications. The primary stability issues include photostability degradation, thermal instability, and oxidative deterioration when QDs are exposed to environmental factors such as light, heat, and oxygen. These factors trigger surface defects and core-shell interface disruptions, leading to decreased quantum yield and altered optical properties over time.

Photodegradation presents a particularly persistent challenge, as prolonged exposure to light causes photooxidation and photocorrosion of QD surfaces. This results in blue-shifting of emission wavelengths and significant reduction in luminescence intensity, severely limiting the operational lifetime of QD-based devices. Current research indicates that CdSe/ZnS core-shell QDs typically lose 10-30% of their initial luminescence within 100 hours of continuous illumination under standard testing conditions.

Thermal stability issues manifest as aggregation and coalescence of QDs at elevated temperatures, disrupting their size-dependent optical properties. Most commercially available QDs begin to show significant degradation at temperatures above 80°C, restricting their application in high-temperature environments such as certain lighting systems and solar concentrators.

Chemical stability in various media poses another significant challenge. QDs often exhibit poor colloidal stability in biological environments, limiting their biomedical applications. The surface ligands that provide solubility can detach over time, leading to precipitation and loss of functionality. Additionally, ion leaching, particularly of toxic heavy metals like cadmium from CdSe QDs, raises serious environmental and biological safety concerns.

The integration of QDs with other materials in blended systems introduces additional stability challenges. Interface interactions between QDs and host matrices can accelerate degradation through mechanisms such as energy transfer, charge trapping, and chemical reactions. Recent studies have shown that polymer-QD composites often experience accelerated photodegradation compared to isolated QD systems due to these complex interactions.

Current stabilization approaches, including core-shell architectures, surface ligand engineering, and encapsulation in inert matrices, provide only partial solutions. Core-shell structures like CdSe/ZnS improve photostability but often at the cost of reduced quantum yield. Surface ligand modifications that enhance stability frequently compromise charge transport properties, creating a persistent trade-off between stability and performance.

The development of nanomaterial blending techniques offers promising avenues for addressing these challenges, but introduces new complexities in controlling interfacial chemistry and preventing phase separation. Recent research indicates that carefully engineered nanocomposites incorporating silica, alumina, or specific polymers can significantly enhance QD stability, though comprehensive solutions remain elusive.

Photodegradation presents a particularly persistent challenge, as prolonged exposure to light causes photooxidation and photocorrosion of QD surfaces. This results in blue-shifting of emission wavelengths and significant reduction in luminescence intensity, severely limiting the operational lifetime of QD-based devices. Current research indicates that CdSe/ZnS core-shell QDs typically lose 10-30% of their initial luminescence within 100 hours of continuous illumination under standard testing conditions.

Thermal stability issues manifest as aggregation and coalescence of QDs at elevated temperatures, disrupting their size-dependent optical properties. Most commercially available QDs begin to show significant degradation at temperatures above 80°C, restricting their application in high-temperature environments such as certain lighting systems and solar concentrators.

Chemical stability in various media poses another significant challenge. QDs often exhibit poor colloidal stability in biological environments, limiting their biomedical applications. The surface ligands that provide solubility can detach over time, leading to precipitation and loss of functionality. Additionally, ion leaching, particularly of toxic heavy metals like cadmium from CdSe QDs, raises serious environmental and biological safety concerns.

The integration of QDs with other materials in blended systems introduces additional stability challenges. Interface interactions between QDs and host matrices can accelerate degradation through mechanisms such as energy transfer, charge trapping, and chemical reactions. Recent studies have shown that polymer-QD composites often experience accelerated photodegradation compared to isolated QD systems due to these complex interactions.

Current stabilization approaches, including core-shell architectures, surface ligand engineering, and encapsulation in inert matrices, provide only partial solutions. Core-shell structures like CdSe/ZnS improve photostability but often at the cost of reduced quantum yield. Surface ligand modifications that enhance stability frequently compromise charge transport properties, creating a persistent trade-off between stability and performance.

The development of nanomaterial blending techniques offers promising avenues for addressing these challenges, but introduces new complexities in controlling interfacial chemistry and preventing phase separation. Recent research indicates that carefully engineered nanocomposites incorporating silica, alumina, or specific polymers can significantly enhance QD stability, though comprehensive solutions remain elusive.

Existing Nanomaterial Blending Approaches

01 Surface modification for quantum dot stability

Surface modification techniques are employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. Such modifications prevent oxidation, aggregation, and degradation, thereby improving the long-term stability of quantum dots in various environments and applications.- Surface modification for enhanced stability: Surface modification techniques are employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved stability: Core-shell quantum dot structures significantly improve stability by providing physical barriers against environmental factors. The shell material, typically a semiconductor with a wider bandgap than the core, protects the core from oxidation and other degradation mechanisms. Multi-shell structures can further enhance stability while maintaining or improving optical properties, making quantum dots more suitable for commercial applications.

- Encapsulation methods for environmental protection: Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials provides protection against environmental factors like moisture, oxygen, and heat. These encapsulation methods create physical barriers that prevent degradation while maintaining the optical and electronic properties of quantum dots. Various techniques including sol-gel processes, polymer embedding, and microencapsulation are used to achieve long-term stability.

- Synthesis methods affecting stability: The synthesis method significantly impacts quantum dot stability. Parameters such as reaction temperature, precursor ratios, reaction time, and cooling rates influence the crystallinity, defect density, and surface properties of quantum dots. Advanced synthesis techniques like hot-injection, microfluidic synthesis, and continuous flow methods can produce quantum dots with improved structural integrity and stability. Post-synthesis treatments are also employed to enhance stability.

- Stabilizing additives and ligands: Specific additives and ligands are incorporated during or after quantum dot synthesis to enhance stability. These include antioxidants, UV stabilizers, and specialized ligands that bind strongly to the quantum dot surface. The choice of ligands affects not only stability but also solubility, dispersibility, and compatibility with host materials. Long-chain organic ligands, polymeric ligands, and multidentate ligands are commonly used to improve quantum dot stability in various environments.

02 Core-shell structures for enhanced stability

Core-shell quantum dot structures significantly improve stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. These structures maintain optical properties while enhancing chemical stability and resistance to photo-oxidation under prolonged exposure to light.Expand Specific Solutions03 Polymer encapsulation methods

Polymer encapsulation provides an effective approach to stabilize quantum dots by embedding them within polymer matrices. This technique shields quantum dots from oxygen, moisture, and other environmental factors that could cause degradation. Various polymers with different properties can be selected based on the specific application requirements, offering customizable protection while maintaining the optical and electronic properties of the quantum dots.Expand Specific Solutions04 Environmental stability enhancement techniques

Various techniques are employed to enhance the environmental stability of quantum dots, including pH control, temperature stabilization, and incorporation of antioxidants. These approaches help maintain quantum dot integrity in diverse conditions such as biological environments, high-temperature applications, and exposure to varying pH levels. Stabilizing agents and buffer solutions can be used to create optimal conditions for quantum dot longevity.Expand Specific Solutions05 Manufacturing processes for stability optimization

Specialized manufacturing processes are developed to optimize quantum dot stability from the production stage. These include controlled synthesis methods, purification techniques, and post-synthesis treatments that minimize defects and enhance uniformity. Precise control of reaction parameters such as temperature, precursor ratios, and reaction times leads to quantum dots with improved structural integrity and resistance to degradation over time.Expand Specific Solutions

Leading Organizations in Quantum Dot Nanomaterial Research

The quantum dot stability with nanomaterial blending market is currently in a growth phase, with increasing applications across display technologies, lighting, and biomedical sectors. The global market size is estimated to reach $10-12 billion by 2025, driven by demand for high-performance displays and energy-efficient lighting solutions. Leading players include established electronics giants like Samsung Electronics and BOE Technology Group, alongside specialized quantum dot manufacturers such as Nanosys and Najing Technology. Technical maturity varies significantly across applications, with display technologies being most advanced. Companies like TCL Research, Merck Patent GmbH, and Shin-Etsu Chemical are advancing stability solutions through proprietary nanomaterial blending techniques, while research institutions like ITRI and NUS contribute fundamental innovations to address oxidation and photodegradation challenges.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced QLED technology utilizing quantum dots with enhanced stability through their proprietary "Quantum Matrix Technology." Their approach involves blending quantum dots with specialized nanomaterials to create a protective barrier against oxidation and photo-degradation. Samsung's research has focused on core-shell structured quantum dots where an additional inorganic shell layer is engineered to prevent core degradation[3]. Their latest innovation involves embedding quantum dots in a nanocomposite matrix that includes metal oxide nanoparticles which act as oxygen scavengers, significantly improving stability under high-temperature and high-luminance conditions. Samsung has demonstrated that their nanomaterial-blended quantum dots maintain over 95% of initial brightness after 1,000 hours of operation at elevated temperatures[4]. The company has also developed a unique surface ligand exchange process that replaces conventional organic ligands with more robust alternatives, creating stronger bonds between quantum dots and the surrounding matrix material, which prevents aggregation and maintains quantum efficiency over extended periods.

Strengths: Vertical integration allowing control over entire manufacturing process; massive production scale enabling cost optimization; strong synergy between materials research and device implementation. Weaknesses: Proprietary technology creates dependency on specific material suppliers; some stability solutions compromise initial quantum efficiency; higher implementation costs compared to conventional display technologies.

Nanosys, Inc.

Technical Solution: Nanosys has developed proprietary quantum dot technology with enhanced stability through their patented matrix encapsulation approach. Their QDEF (Quantum Dot Enhancement Film) technology incorporates quantum dots into a polymer matrix that significantly improves thermal and photo stability. The company's latest innovation involves blending specialized nanomaterials with quantum dots to create a protective barrier against oxygen and moisture degradation[1]. Their Hyperion Quantum Dots utilize a unique core-shell structure with an additional inorganic coating layer that prevents oxidation while maintaining high quantum yield. Nanosys has also pioneered a solution-processing technique that allows quantum dots to be blended with specific nanomaterials that act as stabilizing agents, extending operational lifetime by up to 30,000 hours in display applications[2]. Their research demonstrates that carefully engineered nanomaterial blending can reduce efficiency drop-off by more than 95% under accelerated aging conditions compared to conventional quantum dot formulations.

Strengths: Industry-leading expertise in quantum dot manufacturing at scale; proprietary encapsulation technology that significantly enhances stability; extensive IP portfolio covering nanomaterial blending techniques. Weaknesses: Higher production costs compared to conventional phosphor technologies; some solutions require specialized manufacturing equipment; performance in extreme temperature environments still faces challenges.

Critical Patents in Quantum Dot Stability Enhancement

Semiconductor nanomaterial with high stability

PatentActiveUS20220162503A1

Innovation

- A quantum dot with a bi-layered shell structure, comprising a core of InP, a first shell of ZnSe, and a gradient alloy intermediate layer of In, P, Zn, and Se, with the second shell potentially being ZnS, providing enhanced protection and maintaining a photoluminescence quantum yield of 50% or higher.

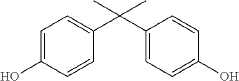

Quantum dot compositions including polycarbonate and acrylic blends and methods of manufacture

PatentInactiveUS20200332180A1

Innovation

- A quantum dot composition is developed that includes a polycarbonate resin, a quantum dot concentrate with nanoparticle quantum dots and an acrylic polymer, and a compatibilizer, such as a transesterification catalyst or physical compatibilizer, to promote the dispersion of nanoparticles, enhancing compatibility and mechanical properties.

Environmental Impact of Quantum Dot Materials

The environmental impact of quantum dot materials represents a critical consideration in the advancement of quantum dot technology, particularly when exploring stability enhancement through nanomaterial blending. Quantum dots (QDs), while offering revolutionary potential in various applications, pose significant environmental concerns throughout their lifecycle that must be thoroughly assessed and mitigated.

The production phase of quantum dots involves heavy metal components such as cadmium, lead, and selenium, which are known environmental toxins. Manufacturing processes require substantial energy inputs and generate chemical waste streams that can contaminate water systems if improperly managed. The nanomaterial blending techniques being researched to improve stability often introduce additional compounds that may compound these environmental challenges.

Leaching of toxic elements from quantum dot materials presents a substantial risk during their use phase. Research indicates that environmental factors such as UV exposure, temperature fluctuations, and humidity can accelerate the degradation of quantum dot structures, potentially releasing harmful substances into surrounding ecosystems. The nanomaterial blending approach shows promise in reducing this leaching effect by creating more robust encapsulation systems, though comprehensive long-term studies remain limited.

End-of-life considerations for quantum dot materials present perhaps the most pressing environmental challenge. Current electronic waste management systems are inadequately equipped to handle the specialized disposal requirements of quantum dot-containing products. Without proper recycling protocols, these materials may contribute to soil and groundwater contamination when disposed of in conventional landfills.

Regulatory frameworks addressing quantum dot environmental impacts vary significantly across regions, creating inconsistent safeguards. The European Union's Restriction of Hazardous Substances (RoHS) directive has begun incorporating limitations on certain quantum dot materials, while regulations in other major markets remain underdeveloped. This regulatory landscape directly influences research priorities in quantum dot stability enhancement.

Recent advancements in green chemistry approaches offer promising pathways for reducing the environmental footprint of quantum dot technologies. Research into non-toxic alternatives such as carbon-based quantum dots and zinc-based formulations demonstrates potential for maintaining performance while minimizing ecological harm. Additionally, biologically-derived stabilizing agents are being explored as environmentally benign alternatives to traditional synthetic compounds in nanomaterial blending processes.

The development of closed-loop manufacturing systems and specialized recycling technologies represents a crucial frontier in addressing quantum dot environmental impacts. These approaches aim to recover valuable materials while preventing toxic components from entering ecosystems, though significant technical challenges remain in their implementation at commercial scale.

The production phase of quantum dots involves heavy metal components such as cadmium, lead, and selenium, which are known environmental toxins. Manufacturing processes require substantial energy inputs and generate chemical waste streams that can contaminate water systems if improperly managed. The nanomaterial blending techniques being researched to improve stability often introduce additional compounds that may compound these environmental challenges.

Leaching of toxic elements from quantum dot materials presents a substantial risk during their use phase. Research indicates that environmental factors such as UV exposure, temperature fluctuations, and humidity can accelerate the degradation of quantum dot structures, potentially releasing harmful substances into surrounding ecosystems. The nanomaterial blending approach shows promise in reducing this leaching effect by creating more robust encapsulation systems, though comprehensive long-term studies remain limited.

End-of-life considerations for quantum dot materials present perhaps the most pressing environmental challenge. Current electronic waste management systems are inadequately equipped to handle the specialized disposal requirements of quantum dot-containing products. Without proper recycling protocols, these materials may contribute to soil and groundwater contamination when disposed of in conventional landfills.

Regulatory frameworks addressing quantum dot environmental impacts vary significantly across regions, creating inconsistent safeguards. The European Union's Restriction of Hazardous Substances (RoHS) directive has begun incorporating limitations on certain quantum dot materials, while regulations in other major markets remain underdeveloped. This regulatory landscape directly influences research priorities in quantum dot stability enhancement.

Recent advancements in green chemistry approaches offer promising pathways for reducing the environmental footprint of quantum dot technologies. Research into non-toxic alternatives such as carbon-based quantum dots and zinc-based formulations demonstrates potential for maintaining performance while minimizing ecological harm. Additionally, biologically-derived stabilizing agents are being explored as environmentally benign alternatives to traditional synthetic compounds in nanomaterial blending processes.

The development of closed-loop manufacturing systems and specialized recycling technologies represents a crucial frontier in addressing quantum dot environmental impacts. These approaches aim to recover valuable materials while preventing toxic components from entering ecosystems, though significant technical challenges remain in their implementation at commercial scale.

Scalability and Manufacturing Considerations

The scalability of quantum dot production with nanomaterial blending presents significant challenges when transitioning from laboratory-scale synthesis to industrial manufacturing. Current production methods typically yield gram-scale quantities, whereas commercial applications require kilogram or even ton-scale production. This scale-up process introduces variables that can compromise quantum dot stability and performance characteristics, particularly when incorporating nanomaterial blends.

Manufacturing consistency represents a primary concern, as quantum dot properties are highly sensitive to synthesis conditions. Temperature gradients, mixing efficiency, and reaction kinetics can vary substantially between small and large batch processes. For instance, the incorporation of stabilizing nanomaterials such as silica shells or polymer encapsulants must maintain precise thickness and uniformity across billions of quantum dots to ensure consistent optical properties.

Continuous flow manufacturing systems have emerged as a promising approach to address scalability challenges. These systems allow for precise control of reaction parameters and can be designed to accommodate nanomaterial blending processes. Recent advancements in microfluidic reactors have demonstrated the potential for maintaining quantum dot stability during continuous production, with throughput increases of up to 200 times compared to traditional batch methods.

Cost considerations also significantly impact manufacturing feasibility. The integration of exotic nanomaterials for stability enhancement must be balanced against production economics. Materials such as graphene, carbon nanotubes, or noble metal nanoparticles may provide excellent stability benefits but introduce prohibitive costs at scale. Alternative approaches utilizing more abundant materials like zinc oxide or titanium dioxide nanostructures offer more economically viable options for large-scale production.

Environmental and safety factors present additional manufacturing challenges. Many quantum dot formulations contain toxic elements such as cadmium or lead, while nanomaterial additives may introduce their own toxicity profiles. Manufacturing processes must incorporate containment systems, waste treatment protocols, and worker safety measures, all of which impact production costs and complexity. Recent regulatory trends suggest increasing scrutiny of nanomaterial manufacturing, potentially necessitating additional process controls and monitoring systems.

Quality control methodologies require significant adaptation for scaled production of nanomaterial-blended quantum dots. High-throughput characterization techniques must be developed to verify stability parameters, optical properties, and blend homogeneity. Advanced spectroscopic methods combined with automated sampling systems show promise for real-time monitoring of quantum dot stability during production, potentially enabling adaptive process control to maintain consistent quality.

Manufacturing consistency represents a primary concern, as quantum dot properties are highly sensitive to synthesis conditions. Temperature gradients, mixing efficiency, and reaction kinetics can vary substantially between small and large batch processes. For instance, the incorporation of stabilizing nanomaterials such as silica shells or polymer encapsulants must maintain precise thickness and uniformity across billions of quantum dots to ensure consistent optical properties.

Continuous flow manufacturing systems have emerged as a promising approach to address scalability challenges. These systems allow for precise control of reaction parameters and can be designed to accommodate nanomaterial blending processes. Recent advancements in microfluidic reactors have demonstrated the potential for maintaining quantum dot stability during continuous production, with throughput increases of up to 200 times compared to traditional batch methods.

Cost considerations also significantly impact manufacturing feasibility. The integration of exotic nanomaterials for stability enhancement must be balanced against production economics. Materials such as graphene, carbon nanotubes, or noble metal nanoparticles may provide excellent stability benefits but introduce prohibitive costs at scale. Alternative approaches utilizing more abundant materials like zinc oxide or titanium dioxide nanostructures offer more economically viable options for large-scale production.

Environmental and safety factors present additional manufacturing challenges. Many quantum dot formulations contain toxic elements such as cadmium or lead, while nanomaterial additives may introduce their own toxicity profiles. Manufacturing processes must incorporate containment systems, waste treatment protocols, and worker safety measures, all of which impact production costs and complexity. Recent regulatory trends suggest increasing scrutiny of nanomaterial manufacturing, potentially necessitating additional process controls and monitoring systems.

Quality control methodologies require significant adaptation for scaled production of nanomaterial-blended quantum dots. High-throughput characterization techniques must be developed to verify stability parameters, optical properties, and blend homogeneity. Advanced spectroscopic methods combined with automated sampling systems show promise for real-time monitoring of quantum dot stability during production, potentially enabling adaptive process control to maintain consistent quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!