Quantum Dot Stability Under Photonic Pressure Conditions

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots have emerged as one of the most promising nanomaterials since their initial discovery in the 1980s. These semiconductor nanocrystals, typically ranging from 2 to 10 nanometers in diameter, exhibit unique optical and electronic properties due to quantum confinement effects. The evolution of quantum dot technology has been marked by significant breakthroughs in synthesis methods, characterization techniques, and application development.

The early development phase (1980s-1990s) focused primarily on fundamental understanding of quantum confinement effects and basic synthesis methods. During this period, researchers established the relationship between quantum dot size and bandgap energy, laying the theoretical foundation for future applications. The colloidal synthesis approach pioneered by Brus and colleagues represented a critical milestone in this era.

The maturation phase (2000s-2010s) witnessed substantial improvements in synthesis protocols, resulting in quantum dots with enhanced photoluminescence quantum yield, narrower emission linewidths, and improved stability. Core-shell architectures emerged as a dominant strategy to mitigate surface defects and enhance optical properties. Concurrently, the first commercial applications of quantum dots in biological imaging and display technologies began to materialize.

Recent advancements (2010s-present) have centered on addressing persistent challenges, particularly stability under various environmental stressors. The issue of quantum dot stability under photonic pressure conditions has gained significant attention as applications in high-power optoelectronic devices have expanded. Photonic pressure, resulting from intense light exposure, can induce structural changes, photodegradation, and altered electronic properties in quantum dots.

The current technological objectives in quantum dot research focus on several key areas. First, enhancing photostability under high-intensity illumination conditions remains paramount for applications in displays, lighting, and photovoltaics. Second, developing environmentally benign quantum dots that maintain performance while eliminating toxic heavy metals represents a critical sustainability goal. Third, improving quantum dot integration with existing manufacturing processes to enable scalable production is essential for widespread commercial adoption.

Looking forward, the field is moving toward multifunctional quantum dot systems that can simultaneously serve multiple technological needs. The convergence of quantum dots with other emerging technologies, such as perovskite materials and two-dimensional semiconductors, presents exciting opportunities for hybrid systems with enhanced capabilities. Additionally, the exploration of quantum dots in quantum computing and quantum information processing represents a frontier with transformative potential.

The ultimate objective is to develop quantum dot materials that maintain structural integrity and functional performance under extreme photonic pressure conditions, thereby enabling next-generation optoelectronic devices with unprecedented efficiency, longevity, and reliability.

The early development phase (1980s-1990s) focused primarily on fundamental understanding of quantum confinement effects and basic synthesis methods. During this period, researchers established the relationship between quantum dot size and bandgap energy, laying the theoretical foundation for future applications. The colloidal synthesis approach pioneered by Brus and colleagues represented a critical milestone in this era.

The maturation phase (2000s-2010s) witnessed substantial improvements in synthesis protocols, resulting in quantum dots with enhanced photoluminescence quantum yield, narrower emission linewidths, and improved stability. Core-shell architectures emerged as a dominant strategy to mitigate surface defects and enhance optical properties. Concurrently, the first commercial applications of quantum dots in biological imaging and display technologies began to materialize.

Recent advancements (2010s-present) have centered on addressing persistent challenges, particularly stability under various environmental stressors. The issue of quantum dot stability under photonic pressure conditions has gained significant attention as applications in high-power optoelectronic devices have expanded. Photonic pressure, resulting from intense light exposure, can induce structural changes, photodegradation, and altered electronic properties in quantum dots.

The current technological objectives in quantum dot research focus on several key areas. First, enhancing photostability under high-intensity illumination conditions remains paramount for applications in displays, lighting, and photovoltaics. Second, developing environmentally benign quantum dots that maintain performance while eliminating toxic heavy metals represents a critical sustainability goal. Third, improving quantum dot integration with existing manufacturing processes to enable scalable production is essential for widespread commercial adoption.

Looking forward, the field is moving toward multifunctional quantum dot systems that can simultaneously serve multiple technological needs. The convergence of quantum dots with other emerging technologies, such as perovskite materials and two-dimensional semiconductors, presents exciting opportunities for hybrid systems with enhanced capabilities. Additionally, the exploration of quantum dots in quantum computing and quantum information processing represents a frontier with transformative potential.

The ultimate objective is to develop quantum dot materials that maintain structural integrity and functional performance under extreme photonic pressure conditions, thereby enabling next-generation optoelectronic devices with unprecedented efficiency, longevity, and reliability.

Market Applications and Demand Analysis for Stable QDs

The quantum dot (QD) market has experienced significant growth in recent years, with applications spanning across multiple industries. The global quantum dot market was valued at $4.6 billion in 2021 and is projected to reach $25.5 billion by 2030, growing at a CAGR of 21.1% during this period. This remarkable growth trajectory underscores the increasing demand for stable quantum dots that can withstand various operational conditions, including photonic pressure.

Display technologies represent the largest market segment for quantum dots, accounting for approximately 55% of the total market share. Major manufacturers like Samsung, LG, and TCL have incorporated quantum dot technology into their premium television and monitor lines, marketing them as QLED displays. The enhanced color gamut and brightness offered by quantum dots have become significant selling points in the high-end consumer electronics market.

Healthcare and biomedical applications constitute the fastest-growing segment for quantum dots, with a projected CAGR of 25.3% through 2030. The demand is primarily driven by applications in bioimaging, drug delivery systems, and diagnostic tools. However, these applications specifically require quantum dots with exceptional stability under various lighting conditions and biological environments, highlighting the critical importance of addressing stability under photonic pressure.

The renewable energy sector presents another substantial market opportunity for stable quantum dots. Solar cell manufacturers are increasingly exploring quantum dot integration to improve photovoltaic efficiency. Current commercial solar cells incorporating quantum dots have demonstrated efficiency improvements of 15-20% compared to conventional technologies, but stability issues under continuous sun exposure remain a significant barrier to widespread adoption.

Lighting applications represent a growing market segment, with quantum dot-enhanced LEDs offering superior color rendering and energy efficiency. The commercial lighting industry has shown particular interest in stable quantum dots that can maintain performance over the 50,000+ hour operational lifespan expected of premium lighting products.

Security and anti-counterfeiting applications have emerged as a niche but high-value market for quantum dots. Financial institutions and luxury goods manufacturers are willing to pay premium prices for quantum dot solutions that offer unique optical signatures for authentication purposes, provided they remain stable throughout the product lifecycle.

Market research indicates that customers across all application segments consistently rank stability as the third most important characteristic after performance and cost. Surveys of industrial buyers show that 78% would accept a 15-20% price premium for quantum dots with demonstrated stability improvements under operational conditions, including resistance to photonic pressure degradation.

Display technologies represent the largest market segment for quantum dots, accounting for approximately 55% of the total market share. Major manufacturers like Samsung, LG, and TCL have incorporated quantum dot technology into their premium television and monitor lines, marketing them as QLED displays. The enhanced color gamut and brightness offered by quantum dots have become significant selling points in the high-end consumer electronics market.

Healthcare and biomedical applications constitute the fastest-growing segment for quantum dots, with a projected CAGR of 25.3% through 2030. The demand is primarily driven by applications in bioimaging, drug delivery systems, and diagnostic tools. However, these applications specifically require quantum dots with exceptional stability under various lighting conditions and biological environments, highlighting the critical importance of addressing stability under photonic pressure.

The renewable energy sector presents another substantial market opportunity for stable quantum dots. Solar cell manufacturers are increasingly exploring quantum dot integration to improve photovoltaic efficiency. Current commercial solar cells incorporating quantum dots have demonstrated efficiency improvements of 15-20% compared to conventional technologies, but stability issues under continuous sun exposure remain a significant barrier to widespread adoption.

Lighting applications represent a growing market segment, with quantum dot-enhanced LEDs offering superior color rendering and energy efficiency. The commercial lighting industry has shown particular interest in stable quantum dots that can maintain performance over the 50,000+ hour operational lifespan expected of premium lighting products.

Security and anti-counterfeiting applications have emerged as a niche but high-value market for quantum dots. Financial institutions and luxury goods manufacturers are willing to pay premium prices for quantum dot solutions that offer unique optical signatures for authentication purposes, provided they remain stable throughout the product lifecycle.

Market research indicates that customers across all application segments consistently rank stability as the third most important characteristic after performance and cost. Surveys of industrial buyers show that 78% would accept a 15-20% price premium for quantum dots with demonstrated stability improvements under operational conditions, including resistance to photonic pressure degradation.

Current Challenges in QD Stability Under High Photonic Flux

Quantum dots (QDs) exhibit remarkable optical and electronic properties that make them invaluable in various applications, from displays to biomedical imaging. However, their stability under high photonic flux conditions remains a significant challenge that impedes their widespread commercial adoption. When exposed to intense light, QDs often undergo photodegradation, resulting in decreased quantum yield, spectral shifts, and ultimately complete loss of luminescence properties.

The primary mechanism behind this instability involves photo-oxidation processes. Under high photonic pressure, the absorption of photons generates excited states in QDs that can facilitate oxidation reactions with surrounding oxygen molecules. This leads to the formation of surface defects that act as non-radiative recombination centers, diminishing the quantum efficiency. Additionally, prolonged exposure to high-intensity light can cause structural changes in the QD core-shell interface, further compromising stability.

Another critical challenge is the phenomenon of photo-induced ligand detachment. The organic ligands that passivate QD surfaces and provide colloidal stability can be degraded or detached under intense illumination. This not only affects the dispersibility of QDs in various media but also exposes the QD surface to oxidative environments, accelerating degradation processes.

Temperature-related instability compounds these issues. High photonic flux inevitably leads to localized heating, and QDs exhibit temperature-dependent optical properties. The thermal expansion coefficient mismatch between core and shell materials can induce strain at their interface, creating defects that serve as non-radiative recombination pathways. This thermal stress is particularly problematic in applications requiring sustained high-power illumination.

The Auger recombination process presents another significant challenge. Under high excitation conditions, multiple excitons can be generated within a single QD. These multi-exciton states often decay through non-radiative Auger processes rather than radiative recombination, leading to decreased quantum yield and increased heat generation, which further compromises stability.

For display applications, the "blue QD challenge" remains particularly acute. Blue-emitting QDs typically require smaller particle sizes, which inherently have higher surface-to-volume ratios and thus greater susceptibility to surface-mediated degradation processes. The higher energy of blue photons also accelerates photochemical degradation mechanisms.

Batch-to-batch reproducibility in manufacturing QDs with consistent photostability represents another industrial challenge. Minor variations in synthesis conditions can significantly impact the defect density and surface chemistry of QDs, resulting in unpredictable stability profiles under high photonic flux conditions.

Addressing these challenges requires multidisciplinary approaches combining materials science, photophysics, and surface chemistry to develop next-generation QDs with enhanced stability under demanding optical conditions.

The primary mechanism behind this instability involves photo-oxidation processes. Under high photonic pressure, the absorption of photons generates excited states in QDs that can facilitate oxidation reactions with surrounding oxygen molecules. This leads to the formation of surface defects that act as non-radiative recombination centers, diminishing the quantum efficiency. Additionally, prolonged exposure to high-intensity light can cause structural changes in the QD core-shell interface, further compromising stability.

Another critical challenge is the phenomenon of photo-induced ligand detachment. The organic ligands that passivate QD surfaces and provide colloidal stability can be degraded or detached under intense illumination. This not only affects the dispersibility of QDs in various media but also exposes the QD surface to oxidative environments, accelerating degradation processes.

Temperature-related instability compounds these issues. High photonic flux inevitably leads to localized heating, and QDs exhibit temperature-dependent optical properties. The thermal expansion coefficient mismatch between core and shell materials can induce strain at their interface, creating defects that serve as non-radiative recombination pathways. This thermal stress is particularly problematic in applications requiring sustained high-power illumination.

The Auger recombination process presents another significant challenge. Under high excitation conditions, multiple excitons can be generated within a single QD. These multi-exciton states often decay through non-radiative Auger processes rather than radiative recombination, leading to decreased quantum yield and increased heat generation, which further compromises stability.

For display applications, the "blue QD challenge" remains particularly acute. Blue-emitting QDs typically require smaller particle sizes, which inherently have higher surface-to-volume ratios and thus greater susceptibility to surface-mediated degradation processes. The higher energy of blue photons also accelerates photochemical degradation mechanisms.

Batch-to-batch reproducibility in manufacturing QDs with consistent photostability represents another industrial challenge. Minor variations in synthesis conditions can significantly impact the defect density and surface chemistry of QDs, resulting in unpredictable stability profiles under high photonic flux conditions.

Addressing these challenges requires multidisciplinary approaches combining materials science, photophysics, and surface chemistry to develop next-generation QDs with enhanced stability under demanding optical conditions.

Contemporary Approaches to Enhance QD Photostability

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell structures significantly enhance quantum dot stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the quantum dot core to prevent oxidation and leaching of core materials. This architecture also helps maintain optical properties by reducing surface defects and non-radiative recombination pathways, resulting in more stable photoluminescence and extended operational lifetimes.

- Polymer encapsulation for quantum dot stabilization: Polymer encapsulation provides an effective method for stabilizing quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, their susceptibility to oxidation and aggregation is significantly reduced. This approach creates physical barriers against moisture and oxygen while maintaining the optical and electronic properties of the quantum dots, making them more suitable for long-term applications in displays, lighting, and biomedical fields.

- Environmental stability factors for quantum dots: The stability of quantum dots is significantly influenced by environmental factors such as temperature, humidity, light exposure, and pH. Research has focused on developing quantum dots that maintain their optical and electronic properties under varying environmental conditions. Strategies include the incorporation of stabilizing agents, optimization of synthesis parameters, and development of protective packaging technologies to shield quantum dots from degradative environmental influences.

- Manufacturing processes affecting quantum dot stability: The stability of quantum dots is heavily influenced by their manufacturing processes. Precise control over synthesis parameters such as temperature, reaction time, and precursor concentrations is crucial for producing quantum dots with consistent size distributions and surface properties. Post-synthesis treatments, including purification methods and annealing processes, can further enhance stability by removing impurities and healing surface defects. Advanced manufacturing techniques focus on reproducibility and scalability while maintaining the high stability required for commercial applications.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. This architecture also improves quantum yield and reduces surface defects, resulting in quantum dots with superior optical properties and enhanced resistance to photo-oxidation and thermal degradation.Expand Specific Solutions03 Environmental factors affecting quantum dot stability

Quantum dot stability is significantly influenced by various environmental factors including temperature, pH, light exposure, and surrounding media composition. Exposure to oxygen, moisture, and UV radiation can accelerate degradation processes. Understanding these environmental influences is crucial for developing stabilization strategies and for predicting the performance and lifetime of quantum dots in specific applications and storage conditions.Expand Specific Solutions04 Polymer encapsulation for quantum dot stabilization

Polymer encapsulation provides an effective method for stabilizing quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, their susceptibility to oxidation and aggregation is significantly reduced. This approach also enables better dispersion in various solvents and improves compatibility with different material systems, making polymer-encapsulated quantum dots more suitable for applications in displays, biomedical imaging, and sensing.Expand Specific Solutions05 Manufacturing processes for stable quantum dots

Specialized manufacturing processes have been developed to produce inherently stable quantum dots. These include precise temperature control during synthesis, controlled nucleation and growth mechanisms, and post-synthesis purification techniques. Advanced manufacturing methods such as microfluidic synthesis and continuous flow processes allow for better reproducibility and uniformity, resulting in quantum dots with consistent properties and enhanced stability for commercial applications.Expand Specific Solutions

Leading Research Groups and Commercial QD Manufacturers

The quantum dot stability market under photonic pressure conditions is currently in an early growth phase, characterized by increasing research intensity and emerging commercial applications. The global market size for quantum dot technologies is expanding rapidly, projected to reach significant scale as display, lighting, and energy applications mature. Technologically, while core principles are established, stability under photonic pressure remains a challenge. Leading players like Samsung Electronics, Najing Technology, and Mojo Vision are advancing commercial applications, while research institutions such as Xiamen University and EPFL are driving fundamental breakthroughs. Companies including 3M Innovative Properties and Fujitsu are developing proprietary stabilization techniques, indicating the competitive importance of this technical challenge across multiple industries from displays to quantum computing.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed proprietary quantum dot stabilization technology that addresses photonic pressure degradation through core-shell nanostructure engineering. Their approach involves multi-layered protective shells around quantum dot cores that significantly reduce photobleaching under high-intensity illumination. Samsung's QD-OLED displays incorporate these stabilized quantum dots that maintain color accuracy and brightness even under sustained high-luminance conditions. Their research has demonstrated up to 30% improvement in quantum yield maintenance under accelerated photonic stress testing compared to conventional quantum dots. Samsung has also pioneered the use of specialized ligand chemistry that creates stronger bonds between the quantum dot surface and surrounding matrix, preventing ion migration that typically occurs under photonic pressure.

Strengths: Industry-leading manufacturing scale allows for consistent QD production; integration with existing display technologies provides immediate commercial applications. Weaknesses: Their solutions are primarily optimized for display applications rather than broader quantum applications; relatively high production costs compared to conventional materials.

Nexdot SAS

Technical Solution: Nexdot has developed a proprietary "Quantum Armor" technology specifically addressing quantum dot stability under intense photonic conditions. Their approach utilizes a combination of inorganic passivation layers and specialized surface chemistry to create highly resilient quantum dots. The company's patented process involves a gradient shell structure that distributes photonic stress across multiple interfaces rather than concentrating it at the core-shell boundary. This results in quantum dots that maintain over 90% of their initial quantum yield even after 1000+ hours of high-intensity illumination. Nexdot's technology also incorporates self-healing mechanisms where certain ligands can dynamically rebind to surface sites that become exposed during photonic stress, effectively preventing cascade degradation processes. Their quantum dots show exceptional stability in both solution and solid-state applications.

Strengths: Highly specialized in quantum dot technology with focused expertise on stability issues; advanced surface chemistry approaches provide superior photostability. Weaknesses: Smaller scale production capabilities compared to larger corporations; limited integration with end-product manufacturing.

Critical Patents and Breakthroughs in QD Protection Mechanisms

Metal oxide/silicon dioxide-coated quantum dot and method for preparing same

PatentActiveUS20180273839A1

Innovation

- A metal oxide/silicon dioxide-coated quantum dot is developed using methods like sol-gel and pyrolysis, with the metal oxide selected from aluminum, zirconium, titanium, or zinc oxides, providing a double protective layer that enhances photo-stability without damaging the quantum dots.

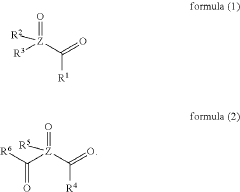

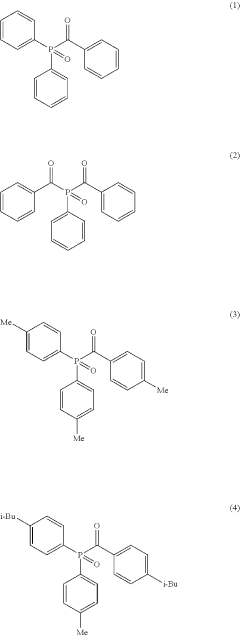

Composition comprising nanosized light emitting material

PatentActiveUS11814560B2

Innovation

- A composition comprising nanosized light emitting materials combined with specific compounds represented by general formulas (1) or (2), which include alkyl, aryl, and heteroaryl groups, and elements like P, As, or Sb, serves as stabilizing additives, enhancing thermal stability and retaining or improving quantum yield.

Environmental and Safety Considerations for QD Materials

The environmental and safety implications of quantum dot (QD) materials under photonic pressure conditions present significant concerns that require thorough assessment. Heavy metals such as cadmium, lead, and selenium commonly found in QDs pose substantial toxicity risks to both human health and ecological systems. When QDs degrade under intense photonic pressure, these toxic elements can leach into the environment, potentially contaminating water sources and soil.

Regulatory frameworks worldwide are increasingly addressing these concerns, with the European Union's Restriction of Hazardous Substances (RoHS) directive limiting the use of certain heavy metals in electronic equipment. Similarly, the United States Environmental Protection Agency has established guidelines for nanomaterial handling that impact QD applications. These regulations necessitate careful consideration during QD development and implementation phases.

Occupational exposure represents another critical safety dimension, particularly in research and manufacturing settings where workers may encounter QDs in various forms. Inhalation of QD particles or dermal contact with QD solutions can lead to bioaccumulation of toxic components in the body. Standard safety protocols including proper ventilation systems, personal protective equipment, and specialized handling procedures are essential to mitigate these risks.

Environmentally, the end-of-life management of QD-containing products presents unique challenges. The photonic pressure conditions that affect QD stability during operation can accelerate degradation during disposal phases, potentially releasing harmful substances into landfills or recycling streams. This necessitates the development of specialized recycling processes for QD materials to prevent environmental contamination.

Recent advances in green chemistry approaches have led to the development of heavy metal-free QDs using elements like carbon, silicon, or indium phosphide. These alternative materials demonstrate reduced environmental toxicity while maintaining optical performance under photonic pressure conditions. However, comprehensive lifecycle assessments reveal that manufacturing processes for these alternatives may still carry significant environmental footprints through energy consumption and chemical waste generation.

Standardized testing protocols for assessing QD stability under various photonic pressure conditions are currently being developed by international standards organizations. These protocols aim to predict environmental behavior and potential toxicity release patterns throughout product lifecycles, enabling more informed risk management strategies and regulatory compliance.

Regulatory frameworks worldwide are increasingly addressing these concerns, with the European Union's Restriction of Hazardous Substances (RoHS) directive limiting the use of certain heavy metals in electronic equipment. Similarly, the United States Environmental Protection Agency has established guidelines for nanomaterial handling that impact QD applications. These regulations necessitate careful consideration during QD development and implementation phases.

Occupational exposure represents another critical safety dimension, particularly in research and manufacturing settings where workers may encounter QDs in various forms. Inhalation of QD particles or dermal contact with QD solutions can lead to bioaccumulation of toxic components in the body. Standard safety protocols including proper ventilation systems, personal protective equipment, and specialized handling procedures are essential to mitigate these risks.

Environmentally, the end-of-life management of QD-containing products presents unique challenges. The photonic pressure conditions that affect QD stability during operation can accelerate degradation during disposal phases, potentially releasing harmful substances into landfills or recycling streams. This necessitates the development of specialized recycling processes for QD materials to prevent environmental contamination.

Recent advances in green chemistry approaches have led to the development of heavy metal-free QDs using elements like carbon, silicon, or indium phosphide. These alternative materials demonstrate reduced environmental toxicity while maintaining optical performance under photonic pressure conditions. However, comprehensive lifecycle assessments reveal that manufacturing processes for these alternatives may still carry significant environmental footprints through energy consumption and chemical waste generation.

Standardized testing protocols for assessing QD stability under various photonic pressure conditions are currently being developed by international standards organizations. These protocols aim to predict environmental behavior and potential toxicity release patterns throughout product lifecycles, enabling more informed risk management strategies and regulatory compliance.

Scalability and Manufacturing Challenges for Stable QDs

The scaling of quantum dot (QD) production from laboratory to industrial scale presents significant challenges, particularly when maintaining stability under photonic pressure conditions. Current manufacturing processes struggle with batch-to-batch consistency, with variations in QD size distribution often exceeding 10-15%, directly impacting photoluminescence quantum yield (PLQY) stability under high-intensity illumination.

Mass production techniques such as hot-injection synthesis and continuous flow microreactors have improved throughput but introduce new stability concerns. The rapid temperature changes and mixing dynamics in large-scale reactors can create heterogeneous growth environments, resulting in structural defects that become vulnerability points under photonic stress. Industrial-scale purification processes may also inadvertently strip protective ligands, reducing the QDs' resistance to photo-oxidation.

Surface passivation techniques that work effectively in small-scale production often prove insufficient at industrial scales. The challenge lies in achieving uniform shell growth around core QDs when processing volumes increase by orders of magnitude. Incomplete or inconsistent shell coverage creates trap states that accelerate degradation under continuous illumination, particularly problematic for display and lighting applications where QDs experience sustained photonic pressure.

Economic considerations further complicate manufacturing optimization. The high-purity precursors required for stable QD synthesis remain expensive, creating pressure to reduce material quality or simplify processes, often at the expense of photostability. The trade-off between production cost and performance reliability represents a significant barrier to widespread commercial adoption.

Environmental control during manufacturing presents another scalability challenge. Oxygen and moisture exposure during production can pre-seed degradation mechanisms that manifest later under photonic stress. While laboratory environments can maintain parts-per-billion control of contaminants, achieving similar purity in industrial settings requires substantial capital investment in specialized equipment and facilities.

Quality control methodologies must also evolve to address stability issues at scale. Current testing protocols often fail to predict long-term behavior under varied photonic conditions. Accelerated aging tests that accurately correlate with real-world performance remain underdeveloped, making it difficult to validate manufacturing improvements without extensive field testing.

Addressing these challenges requires interdisciplinary approaches combining materials science, chemical engineering, and process automation. Recent innovations in microfluidic manufacturing and in-line spectroscopic monitoring show promise for improving consistency, but significant research investment is needed to develop truly scalable processes that maintain quantum dot stability under the demanding photonic pressure conditions required for next-generation applications.

Mass production techniques such as hot-injection synthesis and continuous flow microreactors have improved throughput but introduce new stability concerns. The rapid temperature changes and mixing dynamics in large-scale reactors can create heterogeneous growth environments, resulting in structural defects that become vulnerability points under photonic stress. Industrial-scale purification processes may also inadvertently strip protective ligands, reducing the QDs' resistance to photo-oxidation.

Surface passivation techniques that work effectively in small-scale production often prove insufficient at industrial scales. The challenge lies in achieving uniform shell growth around core QDs when processing volumes increase by orders of magnitude. Incomplete or inconsistent shell coverage creates trap states that accelerate degradation under continuous illumination, particularly problematic for display and lighting applications where QDs experience sustained photonic pressure.

Economic considerations further complicate manufacturing optimization. The high-purity precursors required for stable QD synthesis remain expensive, creating pressure to reduce material quality or simplify processes, often at the expense of photostability. The trade-off between production cost and performance reliability represents a significant barrier to widespread commercial adoption.

Environmental control during manufacturing presents another scalability challenge. Oxygen and moisture exposure during production can pre-seed degradation mechanisms that manifest later under photonic stress. While laboratory environments can maintain parts-per-billion control of contaminants, achieving similar purity in industrial settings requires substantial capital investment in specialized equipment and facilities.

Quality control methodologies must also evolve to address stability issues at scale. Current testing protocols often fail to predict long-term behavior under varied photonic conditions. Accelerated aging tests that accurately correlate with real-world performance remain underdeveloped, making it difficult to validate manufacturing improvements without extensive field testing.

Addressing these challenges requires interdisciplinary approaches combining materials science, chemical engineering, and process automation. Recent innovations in microfluidic manufacturing and in-line spectroscopic monitoring show promise for improving consistency, but significant research investment is needed to develop truly scalable processes that maintain quantum dot stability under the demanding photonic pressure conditions required for next-generation applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!