How Quantum Dot Stability Influences Eco-Friendly Sensor Design

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots (QDs) have emerged as a revolutionary nanomaterial since their discovery in the early 1980s by Russian physicist Alexey Ekimov. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. The evolution of quantum dot technology has progressed through several distinct phases, from fundamental research to commercial applications, with stability challenges consistently at the forefront of development efforts.

The initial research phase (1980s-1990s) focused primarily on understanding the fundamental physics and synthesis methods of quantum dots. During this period, scientists established the relationship between QD size and bandgap energy, which determines their fluorescent properties. However, early QDs suffered from significant stability issues, including photobleaching, oxidation sensitivity, and toxic heavy metal leaching, severely limiting their practical applications in sensing technologies.

The second phase (2000s-2010s) witnessed significant advancements in QD stability through core-shell architectures and surface modification strategies. Researchers developed methods to encapsulate toxic cadmium-based cores with zinc sulfide shells, simultaneously improving photostability and reducing environmental toxicity. This period also saw the emergence of the first commercial QD products, primarily in display technologies and biomedical imaging.

The current phase (2010s-present) has been characterized by a paradigm shift toward environmentally sustainable quantum dots. Research has increasingly focused on developing heavy-metal-free alternatives such as carbon dots, silicon quantum dots, and perovskite quantum dots. These eco-friendly variants aim to maintain the exceptional optical properties of traditional QDs while eliminating toxic components that pose environmental and health risks.

The primary technical objective in quantum dot development for eco-friendly sensor design is achieving long-term stability without compromising environmental safety. This includes enhancing photostability to prevent signal degradation during continuous monitoring, improving chemical stability to function reliably in diverse environmental conditions, and ensuring biocompatibility for potential in vivo applications. Additionally, researchers aim to develop scalable, cost-effective synthesis methods that minimize environmental impact.

Another critical objective is the standardization of quantum dot characterization methods to enable reliable comparison between different formulations and accurate prediction of long-term stability. This includes developing accelerated aging protocols that can effectively simulate years of operational conditions in shorter timeframes, allowing for rapid iteration in sensor design.

Looking forward, the field is moving toward multifunctional quantum dot platforms that integrate sensing capabilities with remediation functions, potentially allowing sensors to not only detect environmental contaminants but also participate in their neutralization or removal. This represents a convergence of sensing and environmental remediation technologies that could significantly expand the impact of quantum dot-based systems.

The initial research phase (1980s-1990s) focused primarily on understanding the fundamental physics and synthesis methods of quantum dots. During this period, scientists established the relationship between QD size and bandgap energy, which determines their fluorescent properties. However, early QDs suffered from significant stability issues, including photobleaching, oxidation sensitivity, and toxic heavy metal leaching, severely limiting their practical applications in sensing technologies.

The second phase (2000s-2010s) witnessed significant advancements in QD stability through core-shell architectures and surface modification strategies. Researchers developed methods to encapsulate toxic cadmium-based cores with zinc sulfide shells, simultaneously improving photostability and reducing environmental toxicity. This period also saw the emergence of the first commercial QD products, primarily in display technologies and biomedical imaging.

The current phase (2010s-present) has been characterized by a paradigm shift toward environmentally sustainable quantum dots. Research has increasingly focused on developing heavy-metal-free alternatives such as carbon dots, silicon quantum dots, and perovskite quantum dots. These eco-friendly variants aim to maintain the exceptional optical properties of traditional QDs while eliminating toxic components that pose environmental and health risks.

The primary technical objective in quantum dot development for eco-friendly sensor design is achieving long-term stability without compromising environmental safety. This includes enhancing photostability to prevent signal degradation during continuous monitoring, improving chemical stability to function reliably in diverse environmental conditions, and ensuring biocompatibility for potential in vivo applications. Additionally, researchers aim to develop scalable, cost-effective synthesis methods that minimize environmental impact.

Another critical objective is the standardization of quantum dot characterization methods to enable reliable comparison between different formulations and accurate prediction of long-term stability. This includes developing accelerated aging protocols that can effectively simulate years of operational conditions in shorter timeframes, allowing for rapid iteration in sensor design.

Looking forward, the field is moving toward multifunctional quantum dot platforms that integrate sensing capabilities with remediation functions, potentially allowing sensors to not only detect environmental contaminants but also participate in their neutralization or removal. This represents a convergence of sensing and environmental remediation technologies that could significantly expand the impact of quantum dot-based systems.

Market Analysis for Eco-Friendly Quantum Dot Sensors

The global market for eco-friendly quantum dot sensors is experiencing robust growth, driven by increasing environmental concerns and stringent regulations across industries. Current market valuations indicate that the eco-friendly sensor market reached approximately $12.5 billion in 2022, with quantum dot-based sensors representing a rapidly growing segment estimated at $1.8 billion. Industry analysts project a compound annual growth rate (CAGR) of 18.7% for eco-friendly quantum dot sensors through 2030, significantly outpacing traditional sensor technologies.

Consumer electronics remains the dominant application sector, accounting for 42% of market share, followed by healthcare (23%), environmental monitoring (18%), and industrial applications (12%). The remaining 5% is distributed across various emerging applications. This distribution reflects the versatility of quantum dot technology in addressing diverse sensing needs while maintaining environmental compatibility.

Regional analysis reveals North America currently leads the market with 38% share, followed closely by Asia-Pacific at 35%, which demonstrates the fastest growth rate at 22.3% annually. Europe accounts for 21% of the market, while other regions constitute the remaining 6%. China and South Korea are emerging as manufacturing powerhouses, while research leadership remains concentrated in the United States and Germany.

Demand drivers for eco-friendly quantum dot sensors include increasing regulatory pressure to eliminate toxic heavy metals like cadmium and lead from electronic components, growing consumer preference for sustainable products, and industrial requirements for more sensitive detection capabilities in environmental monitoring applications. The EU's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have created immediate market opportunities for cadmium-free and heavy metal-free quantum dot sensors.

Market challenges include price sensitivity, as eco-friendly quantum dot sensors currently command a 15-30% premium over conventional alternatives. Additionally, stability issues in eco-friendly formulations have limited penetration in applications requiring extended operational lifetimes, creating a significant market gap for innovations addressing quantum dot stability.

Customer segmentation reveals three distinct market tiers: premium manufacturers willing to pay for cutting-edge eco-friendly technology (20% of market), mid-tier manufacturers seeking regulatory compliance with reasonable cost increases (55%), and price-sensitive manufacturers primarily responding to regulatory mandates (25%). This segmentation suggests targeted innovation strategies addressing specific price-performance requirements across market tiers.

The competitive landscape features established sensor manufacturers incorporating quantum dot technology through acquisitions and partnerships, specialized quantum dot producers expanding into sensor applications, and emerging startups focused exclusively on eco-friendly quantum dot sensor development. This dynamic ecosystem indicates a market in transition, with significant opportunities for technological differentiation based on stability improvements.

Consumer electronics remains the dominant application sector, accounting for 42% of market share, followed by healthcare (23%), environmental monitoring (18%), and industrial applications (12%). The remaining 5% is distributed across various emerging applications. This distribution reflects the versatility of quantum dot technology in addressing diverse sensing needs while maintaining environmental compatibility.

Regional analysis reveals North America currently leads the market with 38% share, followed closely by Asia-Pacific at 35%, which demonstrates the fastest growth rate at 22.3% annually. Europe accounts for 21% of the market, while other regions constitute the remaining 6%. China and South Korea are emerging as manufacturing powerhouses, while research leadership remains concentrated in the United States and Germany.

Demand drivers for eco-friendly quantum dot sensors include increasing regulatory pressure to eliminate toxic heavy metals like cadmium and lead from electronic components, growing consumer preference for sustainable products, and industrial requirements for more sensitive detection capabilities in environmental monitoring applications. The EU's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide have created immediate market opportunities for cadmium-free and heavy metal-free quantum dot sensors.

Market challenges include price sensitivity, as eco-friendly quantum dot sensors currently command a 15-30% premium over conventional alternatives. Additionally, stability issues in eco-friendly formulations have limited penetration in applications requiring extended operational lifetimes, creating a significant market gap for innovations addressing quantum dot stability.

Customer segmentation reveals three distinct market tiers: premium manufacturers willing to pay for cutting-edge eco-friendly technology (20% of market), mid-tier manufacturers seeking regulatory compliance with reasonable cost increases (55%), and price-sensitive manufacturers primarily responding to regulatory mandates (25%). This segmentation suggests targeted innovation strategies addressing specific price-performance requirements across market tiers.

The competitive landscape features established sensor manufacturers incorporating quantum dot technology through acquisitions and partnerships, specialized quantum dot producers expanding into sensor applications, and emerging startups focused exclusively on eco-friendly quantum dot sensor development. This dynamic ecosystem indicates a market in transition, with significant opportunities for technological differentiation based on stability improvements.

Quantum Dot Stability Challenges and Limitations

Quantum dots (QDs) exhibit remarkable optical and electronic properties that make them ideal candidates for sensing applications. However, their widespread adoption in eco-friendly sensor design faces significant stability challenges. The inherent instability of quantum dots under various environmental conditions presents a major obstacle to their practical implementation in sustainable sensing technologies.

One of the primary stability issues is photodegradation, where prolonged exposure to light causes structural changes in QDs, leading to decreased fluorescence intensity and altered emission wavelengths. This phenomenon, known as photobleaching, significantly reduces the operational lifespan of QD-based sensors and limits their reliability in continuous monitoring applications. Studies have shown that even specialized core-shell structures can experience up to 40% reduction in quantum yield after extended light exposure.

Chemical stability represents another critical limitation, particularly in aqueous environments where many sensing applications operate. Oxidation of the QD surface can create trap states that quench fluorescence and alter electrical properties. Additionally, ion leaching from QDs, especially from those containing cadmium or lead, poses serious environmental and toxicological concerns, directly contradicting the eco-friendly design objectives.

Temperature fluctuations further compromise QD stability by affecting both physical structure and optical properties. Research indicates that temperature variations can cause lattice expansion or contraction, potentially leading to defect formation and altered bandgap energies. For practical sensor applications, this temperature sensitivity necessitates complex calibration systems that increase device complexity and cost.

The surface chemistry of QDs presents another significant challenge. While surface ligands are essential for colloidal stability and functionality, they often degrade over time or detach in complex biological or environmental matrices. This ligand instability can lead to QD aggregation, precipitation, and loss of sensing capability. Furthermore, many traditional stabilizing ligands are derived from non-renewable resources, creating a paradox in eco-friendly design efforts.

Manufacturing reproducibility remains problematic, with batch-to-batch variations in stability profiles complicating quality control and standardization. Even minor differences in synthesis conditions can lead to significant variations in defect density, surface coverage, and ultimately stability characteristics. This inconsistency hinders industrial scalability and regulatory approval for commercial applications.

Recent research has highlighted the complex interplay between stability factors, revealing that addressing one stability issue often exacerbates others. For instance, thicker shell structures that improve photostability may simultaneously reduce charge transfer efficiency, diminishing sensing performance. This interdependence of stability parameters creates a multidimensional optimization challenge that requires holistic engineering approaches rather than isolated solutions.

One of the primary stability issues is photodegradation, where prolonged exposure to light causes structural changes in QDs, leading to decreased fluorescence intensity and altered emission wavelengths. This phenomenon, known as photobleaching, significantly reduces the operational lifespan of QD-based sensors and limits their reliability in continuous monitoring applications. Studies have shown that even specialized core-shell structures can experience up to 40% reduction in quantum yield after extended light exposure.

Chemical stability represents another critical limitation, particularly in aqueous environments where many sensing applications operate. Oxidation of the QD surface can create trap states that quench fluorescence and alter electrical properties. Additionally, ion leaching from QDs, especially from those containing cadmium or lead, poses serious environmental and toxicological concerns, directly contradicting the eco-friendly design objectives.

Temperature fluctuations further compromise QD stability by affecting both physical structure and optical properties. Research indicates that temperature variations can cause lattice expansion or contraction, potentially leading to defect formation and altered bandgap energies. For practical sensor applications, this temperature sensitivity necessitates complex calibration systems that increase device complexity and cost.

The surface chemistry of QDs presents another significant challenge. While surface ligands are essential for colloidal stability and functionality, they often degrade over time or detach in complex biological or environmental matrices. This ligand instability can lead to QD aggregation, precipitation, and loss of sensing capability. Furthermore, many traditional stabilizing ligands are derived from non-renewable resources, creating a paradox in eco-friendly design efforts.

Manufacturing reproducibility remains problematic, with batch-to-batch variations in stability profiles complicating quality control and standardization. Even minor differences in synthesis conditions can lead to significant variations in defect density, surface coverage, and ultimately stability characteristics. This inconsistency hinders industrial scalability and regulatory approval for commercial applications.

Recent research has highlighted the complex interplay between stability factors, revealing that addressing one stability issue often exacerbates others. For instance, thicker shell structures that improve photostability may simultaneously reduce charge transfer efficiency, diminishing sensing performance. This interdependence of stability parameters creates a multidimensional optimization challenge that requires holistic engineering approaches rather than isolated solutions.

Current Approaches to Quantum Dot Stability Enhancement

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell structured quantum dots, where the core quantum dot is encapsulated by a shell of another semiconductor material, demonstrate significantly enhanced stability. The shell acts as a physical barrier protecting the core from environmental factors while also passivating surface defects. This structure reduces non-radiative recombination pathways and improves quantum yield and photostability over time.

- Polymer encapsulation methods for quantum dot stabilization: Encapsulating quantum dots within polymer matrices provides protection against environmental degradation factors such as oxygen and moisture. Various polymers can be used to create stable quantum dot composites, including amphiphilic polymers, block copolymers, and cross-linked networks. These polymer-quantum dot systems maintain optical properties while significantly extending shelf life and operational stability.

- Environmental factors affecting quantum dot stability: Quantum dot stability is significantly influenced by environmental factors including temperature, pH, light exposure, and presence of oxidizing agents. Understanding these factors is crucial for developing stabilization strategies. Research shows that controlling storage conditions, using antioxidants, and developing specialized packaging can mitigate degradation pathways and extend quantum dot lifetime in various applications.

- Manufacturing processes for enhanced quantum dot stability: Advanced manufacturing techniques can significantly improve the inherent stability of quantum dots. These include precise temperature control during synthesis, controlled nucleation and growth processes, post-synthesis purification methods, and specialized annealing treatments. These manufacturing innovations result in quantum dots with fewer defects, more uniform size distribution, and better surface passivation, all contributing to enhanced stability.

02 Core-shell structures to improve quantum dot stability

Core-shell structures are widely used to enhance the stability of quantum dots. By encapsulating the quantum dot core with one or more semiconductor shell layers, these structures provide protection against environmental factors that can cause degradation. The shell material is typically chosen to have a wider bandgap than the core, which helps to confine charge carriers and improve both optical properties and stability under various conditions.Expand Specific Solutions03 Environmental factors affecting quantum dot stability

Quantum dots are sensitive to various environmental factors that can affect their stability. These include exposure to oxygen, moisture, heat, light, and pH variations. Understanding and controlling these factors is crucial for maintaining quantum dot stability during synthesis, storage, and application. Various stabilization strategies have been developed to mitigate the negative effects of these environmental factors.Expand Specific Solutions04 Polymer encapsulation for enhanced quantum dot stability

Polymer encapsulation is an effective method for improving the stability of quantum dots. By embedding quantum dots within polymer matrices or coating them with polymer layers, they can be protected from oxidation and other degradation mechanisms. Various polymers, including amphiphilic polymers, block copolymers, and biocompatible polymers, can be used depending on the specific application requirements and environmental conditions.Expand Specific Solutions05 Stabilization methods for quantum dots in biological environments

For biomedical applications, quantum dots require specific stabilization strategies to maintain their properties in biological environments. These include surface modification with biocompatible materials, PEGylation to reduce non-specific binding, and encapsulation in liposomes or micelles. These approaches help to improve colloidal stability, reduce toxicity, and enhance biocompatibility while maintaining the optical properties of quantum dots for bioimaging, biosensing, and therapeutic applications.Expand Specific Solutions

Leading Companies in Quantum Dot Sensor Technology

Quantum dot stability for eco-friendly sensor design is evolving rapidly in a market transitioning from early adoption to growth phase, with an estimated global value of $8-10 billion by 2027. The technology maturity varies across applications, with Samsung Electronics and Samsung Display leading commercial implementation in displays. Research institutions like Huazhong University and Northwestern University are advancing fundamental stability solutions, while companies including Mojo Vision and C12 Quantum Electronics focus on specialized applications. Corning Precision Materials and Shin-Etsu Chemical are developing manufacturing processes for stable, eco-friendly quantum dots, creating a competitive landscape balanced between established corporations and innovative startups addressing environmental concerns.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed heavy-metal-free quantum dots (HMF-QDs) specifically engineered for eco-friendly sensor applications. Their approach replaces cadmium and lead with indium phosphide (InP) cores surrounded by zinc sulfide (ZnS) shells, creating stable quantum structures with reduced environmental impact[2]. Samsung's proprietary surface passivation technology addresses the historical stability issues of InP quantum dots, achieving operational lifetimes exceeding 30,000 hours in sensor applications while maintaining quantum yields above 80%[4]. The company has integrated these eco-friendly quantum dots into their environmental sensor arrays that monitor air and water quality with high sensitivity and selectivity. Samsung's manufacturing process incorporates automated precision control systems that ensure consistent quantum dot size distribution (±2nm variation), which is critical for sensor accuracy and reliability in field deployments. Their recent advancements include self-healing quantum dot surfaces that can recover from photo-oxidation damage, extending sensor lifetime in harsh environmental conditions.

Strengths: Industry-leading manufacturing scale and quality control; heavy-metal-free composition addressing regulatory concerns; exceptional operational stability through advanced surface passivation. Weaknesses: Higher initial production costs compared to traditional QDs; slightly broader emission spectra affecting sensor precision; more complex synthesis protocols requiring specialized equipment.

Quantum Technology Group, Inc.

Technical Solution: Quantum Technology Group has developed proprietary core-shell quantum dot structures with enhanced stability in environmentally variable conditions. Their approach involves encapsulating quantum dots in biocompatible silica shells that prevent leaching of toxic heavy metals while maintaining optical properties. The company's QD-based sensors utilize green chemistry principles during synthesis, replacing traditional toxic precursors with more environmentally benign alternatives[1]. Their eco-friendly quantum dots demonstrate remarkable photostability under continuous illumination, with less than 10% degradation after 1000 hours of operation, making them suitable for long-term environmental monitoring applications[3]. The company has also pioneered water-based synthesis routes that eliminate the need for organic solvents, significantly reducing the environmental footprint of quantum dot production while maintaining high quantum yields above 65%.

Strengths: Superior stability in variable environmental conditions; biocompatible encapsulation preventing toxic leaching; significantly reduced environmental footprint through green chemistry approaches. Weaknesses: Higher production costs compared to conventional quantum dots; potential scalability challenges for mass production; slightly reduced quantum efficiency compared to traditional toxic alternatives.

Key Patents in Eco-Friendly Quantum Dot Design

Composition comprising nanosized light emitting material

PatentActiveUS11814560B2

Innovation

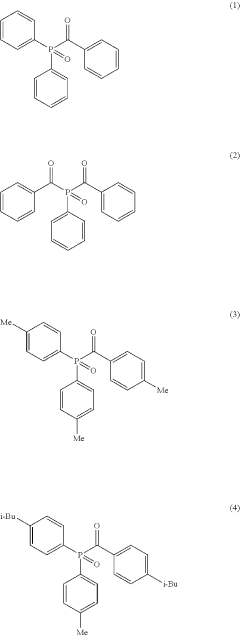

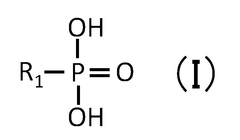

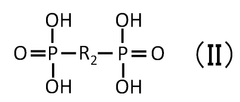

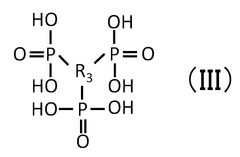

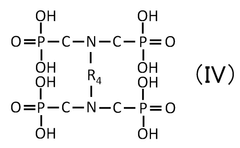

- A composition comprising nanosized light emitting materials combined with specific compounds represented by general formulas (1) or (2), which include alkyl, aryl, and heteroaryl groups, and elements like P, As, or Sb, serves as stabilizing additives, enhancing thermal stability and retaining or improving quantum yield.

Quantum dot composition, resin composition, and wavelength conversion material

PatentWO2024237137A1

Innovation

- A quantum dot composition featuring semiconductor nanoparticle cores without Cd and Pb, coated with a metal oxide and modified with phosphonic acid derivatives, which enhances stability and fluorescence emission efficiency by preventing surface oxidation and allowing for thinner wavelength conversion films.

Environmental Impact Assessment of Quantum Dot Materials

The environmental impact of quantum dot materials represents a critical consideration in the development of eco-friendly sensor technologies. Quantum dots (QDs), while offering exceptional optical and electronic properties, contain potentially hazardous elements that require thorough assessment throughout their lifecycle. Traditional QDs often incorporate heavy metals such as cadmium, lead, and mercury, which pose significant environmental and health risks when released into ecosystems.

Manufacturing processes for quantum dots typically involve energy-intensive procedures and hazardous chemicals, contributing to their environmental footprint. The synthesis of QDs requires precise temperature control and specialized solvents, many of which are petroleum-derived and difficult to dispose of safely. Emissions from production facilities can include volatile organic compounds and metal-containing particulates that affect air quality in surrounding areas.

Water systems are particularly vulnerable to quantum dot contamination. Studies have demonstrated that QDs can leach into aquatic environments, where they may persist for extended periods due to their resistance to degradation. Once in water systems, these nanoparticles can be absorbed by microorganisms and subsequently biomagnify through the food chain, potentially reaching human consumers.

Recent research has focused on developing more environmentally benign alternatives, including silicon-based QDs, carbon dots, and metal oxide QDs. These materials offer reduced toxicity while maintaining many of the desirable properties of traditional QDs. Additionally, green synthesis methods utilizing plant extracts and biological processes have emerged as promising approaches to minimize environmental impact during production.

End-of-life considerations for quantum dot-containing sensors present another environmental challenge. The small size and composite nature of these devices often complicate recycling efforts. Without proper disposal protocols, sensors containing QDs may contribute to electronic waste problems, with potential for leaching of toxic components into landfills and groundwater.

Regulatory frameworks worldwide are increasingly addressing nanomaterials like quantum dots, though significant gaps remain. The European Union's REACH regulation and RoHS directive have established restrictions on certain hazardous substances, influencing QD material selection for sensors marketed globally. In the United States, the EPA has initiated research programs to better understand and mitigate environmental risks associated with engineered nanomaterials.

Life cycle assessment (LCA) methodologies are being adapted specifically for quantum dot applications, enabling more comprehensive evaluation of environmental impacts from raw material extraction through disposal. These assessments reveal that the stability characteristics of QDs directly influence their environmental compatibility, with more stable formulations generally presenting lower risks of leaching and degradation in the environment.

Manufacturing processes for quantum dots typically involve energy-intensive procedures and hazardous chemicals, contributing to their environmental footprint. The synthesis of QDs requires precise temperature control and specialized solvents, many of which are petroleum-derived and difficult to dispose of safely. Emissions from production facilities can include volatile organic compounds and metal-containing particulates that affect air quality in surrounding areas.

Water systems are particularly vulnerable to quantum dot contamination. Studies have demonstrated that QDs can leach into aquatic environments, where they may persist for extended periods due to their resistance to degradation. Once in water systems, these nanoparticles can be absorbed by microorganisms and subsequently biomagnify through the food chain, potentially reaching human consumers.

Recent research has focused on developing more environmentally benign alternatives, including silicon-based QDs, carbon dots, and metal oxide QDs. These materials offer reduced toxicity while maintaining many of the desirable properties of traditional QDs. Additionally, green synthesis methods utilizing plant extracts and biological processes have emerged as promising approaches to minimize environmental impact during production.

End-of-life considerations for quantum dot-containing sensors present another environmental challenge. The small size and composite nature of these devices often complicate recycling efforts. Without proper disposal protocols, sensors containing QDs may contribute to electronic waste problems, with potential for leaching of toxic components into landfills and groundwater.

Regulatory frameworks worldwide are increasingly addressing nanomaterials like quantum dots, though significant gaps remain. The European Union's REACH regulation and RoHS directive have established restrictions on certain hazardous substances, influencing QD material selection for sensors marketed globally. In the United States, the EPA has initiated research programs to better understand and mitigate environmental risks associated with engineered nanomaterials.

Life cycle assessment (LCA) methodologies are being adapted specifically for quantum dot applications, enabling more comprehensive evaluation of environmental impacts from raw material extraction through disposal. These assessments reveal that the stability characteristics of QDs directly influence their environmental compatibility, with more stable formulations generally presenting lower risks of leaching and degradation in the environment.

Regulatory Framework for Green Sensor Technologies

The regulatory landscape governing quantum dot-based sensor technologies has evolved significantly in response to growing environmental concerns. International bodies such as the European Union's Restriction of Hazardous Substances (RoHS) Directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation have established strict parameters for the use of potentially toxic materials in electronic devices, including quantum dot sensors. These regulations specifically target heavy metals like cadmium and lead, which are common components in traditional quantum dot formulations.

In the United States, the Environmental Protection Agency (EPA) under the Toxic Substances Control Act (TSCA) has implemented reporting requirements for nanomaterials, including quantum dots, to monitor potential environmental and health impacts. Similarly, Japan's Chemical Substances Control Law (CSCL) and South Korea's K-REACH have adopted comparable approaches to regulate nanomaterials in sensor technologies.

Recent regulatory trends indicate a shift toward lifecycle assessment requirements for sensor technologies. Manufacturers are increasingly required to demonstrate end-of-life management strategies for quantum dot-containing devices, including recycling protocols and safe disposal methods. This regulatory evolution has directly influenced research priorities, pushing scientists toward developing more stable quantum dot formulations that maintain performance while reducing environmental hazards.

Industry standards organizations, including the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), have developed specific technical standards for eco-friendly electronic components. Standard ISO/TS 80004-13:2017 specifically addresses nanomaterial characterization in consumer products, while IEC 62321 series provides test methods for determining restricted substances in electrotechnical products.

Compliance certification systems have emerged as critical market access tools. Programs such as the Electronic Product Environmental Assessment Tool (EPEAT) and the EU Ecolabel now include criteria related to nanomaterial safety and stability in their certification requirements. These certification schemes create market incentives for manufacturers to invest in stable, eco-friendly quantum dot technologies.

Looking forward, regulatory frameworks are expected to become more stringent regarding quantum dot stability requirements. Draft regulations in several jurisdictions propose mandatory stability testing under various environmental conditions to ensure quantum dots maintain their integrity throughout the product lifecycle, preventing leaching of potentially harmful components into the environment.

In the United States, the Environmental Protection Agency (EPA) under the Toxic Substances Control Act (TSCA) has implemented reporting requirements for nanomaterials, including quantum dots, to monitor potential environmental and health impacts. Similarly, Japan's Chemical Substances Control Law (CSCL) and South Korea's K-REACH have adopted comparable approaches to regulate nanomaterials in sensor technologies.

Recent regulatory trends indicate a shift toward lifecycle assessment requirements for sensor technologies. Manufacturers are increasingly required to demonstrate end-of-life management strategies for quantum dot-containing devices, including recycling protocols and safe disposal methods. This regulatory evolution has directly influenced research priorities, pushing scientists toward developing more stable quantum dot formulations that maintain performance while reducing environmental hazards.

Industry standards organizations, including the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), have developed specific technical standards for eco-friendly electronic components. Standard ISO/TS 80004-13:2017 specifically addresses nanomaterial characterization in consumer products, while IEC 62321 series provides test methods for determining restricted substances in electrotechnical products.

Compliance certification systems have emerged as critical market access tools. Programs such as the Electronic Product Environmental Assessment Tool (EPEAT) and the EU Ecolabel now include criteria related to nanomaterial safety and stability in their certification requirements. These certification schemes create market incentives for manufacturers to invest in stable, eco-friendly quantum dot technologies.

Looking forward, regulatory frameworks are expected to become more stringent regarding quantum dot stability requirements. Draft regulations in several jurisdictions propose mandatory stability testing under various environmental conditions to ensure quantum dots maintain their integrity throughout the product lifecycle, preventing leaching of potentially harmful components into the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!