Quantum Dot Stability in Rare-Earth Element Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots (QDs) have emerged as a revolutionary nanomaterial technology since their initial discovery in the 1980s. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. The evolution of quantum dot technology has been marked by significant breakthroughs in synthesis methods, composition engineering, and surface chemistry modifications aimed at enhancing their stability and performance.

The early development phase focused primarily on cadmium-based quantum dots (CdSe, CdS, CdTe), which demonstrated exceptional luminescence properties but posed environmental and toxicity concerns. This led to the exploration of alternative compositions, including indium phosphide, zinc selenide, and rare-earth element incorporated quantum dots, which offer improved biocompatibility and reduced environmental impact while maintaining desirable optical properties.

A critical milestone in quantum dot evolution was the development of core-shell structures in the 1990s, where a semiconductor shell (typically ZnS) encapsulates the core material, significantly improving quantum yield and photostability. This advancement paved the way for practical applications in displays, lighting, and biological imaging. The integration of rare-earth elements with quantum dots represents a more recent technological convergence, combining the sharp emission lines and long luminescence lifetimes of rare-earth elements with the tunable absorption and high quantum yield of quantum dots.

The stability challenges of quantum dots in rare-earth element applications have become increasingly apparent as commercial implementation has expanded. These challenges include photo-oxidation, thermal degradation, and ligand detachment, all of which compromise long-term performance. The technological trajectory has thus shifted toward developing robust encapsulation strategies, surface passivation techniques, and novel hybrid structures to enhance stability while preserving the unique optical properties that make these materials valuable.

Current research objectives in quantum dot stability for rare-earth element applications focus on several key areas: developing synthesis protocols that yield consistent size distribution and composition; engineering surface chemistry that maintains colloidal stability while preventing oxidation; creating effective encapsulation methods that shield quantum dots from environmental stressors; and designing hybrid structures that synergistically combine the advantages of both quantum dots and rare-earth elements.

The long-term technological goal is to achieve quantum dot-rare earth element systems with operational lifetimes exceeding 50,000 hours under standard application conditions, maintaining at least 95% of initial luminescence efficiency. This would enable their widespread adoption in high-value applications including next-generation displays, solid-state lighting, solar concentrators, and advanced biomedical imaging systems.

The early development phase focused primarily on cadmium-based quantum dots (CdSe, CdS, CdTe), which demonstrated exceptional luminescence properties but posed environmental and toxicity concerns. This led to the exploration of alternative compositions, including indium phosphide, zinc selenide, and rare-earth element incorporated quantum dots, which offer improved biocompatibility and reduced environmental impact while maintaining desirable optical properties.

A critical milestone in quantum dot evolution was the development of core-shell structures in the 1990s, where a semiconductor shell (typically ZnS) encapsulates the core material, significantly improving quantum yield and photostability. This advancement paved the way for practical applications in displays, lighting, and biological imaging. The integration of rare-earth elements with quantum dots represents a more recent technological convergence, combining the sharp emission lines and long luminescence lifetimes of rare-earth elements with the tunable absorption and high quantum yield of quantum dots.

The stability challenges of quantum dots in rare-earth element applications have become increasingly apparent as commercial implementation has expanded. These challenges include photo-oxidation, thermal degradation, and ligand detachment, all of which compromise long-term performance. The technological trajectory has thus shifted toward developing robust encapsulation strategies, surface passivation techniques, and novel hybrid structures to enhance stability while preserving the unique optical properties that make these materials valuable.

Current research objectives in quantum dot stability for rare-earth element applications focus on several key areas: developing synthesis protocols that yield consistent size distribution and composition; engineering surface chemistry that maintains colloidal stability while preventing oxidation; creating effective encapsulation methods that shield quantum dots from environmental stressors; and designing hybrid structures that synergistically combine the advantages of both quantum dots and rare-earth elements.

The long-term technological goal is to achieve quantum dot-rare earth element systems with operational lifetimes exceeding 50,000 hours under standard application conditions, maintaining at least 95% of initial luminescence efficiency. This would enable their widespread adoption in high-value applications including next-generation displays, solid-state lighting, solar concentrators, and advanced biomedical imaging systems.

Market Analysis for Rare-Earth Quantum Dot Applications

The global market for quantum dot technologies incorporating rare-earth elements is experiencing significant growth, projected to reach $8.6 billion by 2025, with a compound annual growth rate of approximately 27.3% from 2020. This remarkable expansion is primarily driven by increasing demand across multiple high-tech sectors, particularly in display technologies, where rare-earth quantum dots offer superior color gamut and energy efficiency compared to conventional materials.

Consumer electronics represents the largest market segment, accounting for nearly 43% of current applications. Major manufacturers including Samsung, LG, and Sony have already commercialized quantum dot-enhanced displays, with rare-earth stabilized variants gaining traction due to their enhanced durability and performance characteristics. The premium pricing of these displays reflects consumer willingness to pay for superior visual experiences.

Healthcare applications constitute the fastest-growing segment, with an anticipated growth rate of 32.5% through 2025. Rare-earth quantum dots show particular promise in bioimaging, drug delivery, and diagnostic applications due to their unique photoluminescent properties and improved biocompatibility when properly stabilized. The development of non-toxic, stable quantum dot formulations has been crucial in opening this market.

Regionally, Asia-Pacific dominates the market landscape, representing approximately 51% of global consumption, followed by North America (27%) and Europe (18%). China's strategic position in rare-earth element production creates significant advantages for domestic manufacturers, though concerns about supply chain stability have prompted research into alternative formulations in other regions.

Market barriers include persistent concerns about long-term stability, particularly in harsh environmental conditions, regulatory uncertainties regarding nanomaterials, and relatively high production costs. The average manufacturing cost for high-quality rare-earth quantum dots remains 3-5 times higher than conventional semiconductor quantum dots, limiting mass-market adoption in price-sensitive applications.

Industry surveys indicate that end-users prioritize stability and reliability over marginal performance improvements, suggesting that innovations addressing quantum dot degradation could unlock substantial market value. Manufacturers capable of demonstrating extended operational lifetimes under variable conditions stand to capture premium positioning in this rapidly evolving marketplace.

Consumer electronics represents the largest market segment, accounting for nearly 43% of current applications. Major manufacturers including Samsung, LG, and Sony have already commercialized quantum dot-enhanced displays, with rare-earth stabilized variants gaining traction due to their enhanced durability and performance characteristics. The premium pricing of these displays reflects consumer willingness to pay for superior visual experiences.

Healthcare applications constitute the fastest-growing segment, with an anticipated growth rate of 32.5% through 2025. Rare-earth quantum dots show particular promise in bioimaging, drug delivery, and diagnostic applications due to their unique photoluminescent properties and improved biocompatibility when properly stabilized. The development of non-toxic, stable quantum dot formulations has been crucial in opening this market.

Regionally, Asia-Pacific dominates the market landscape, representing approximately 51% of global consumption, followed by North America (27%) and Europe (18%). China's strategic position in rare-earth element production creates significant advantages for domestic manufacturers, though concerns about supply chain stability have prompted research into alternative formulations in other regions.

Market barriers include persistent concerns about long-term stability, particularly in harsh environmental conditions, regulatory uncertainties regarding nanomaterials, and relatively high production costs. The average manufacturing cost for high-quality rare-earth quantum dots remains 3-5 times higher than conventional semiconductor quantum dots, limiting mass-market adoption in price-sensitive applications.

Industry surveys indicate that end-users prioritize stability and reliability over marginal performance improvements, suggesting that innovations addressing quantum dot degradation could unlock substantial market value. Manufacturers capable of demonstrating extended operational lifetimes under variable conditions stand to capture premium positioning in this rapidly evolving marketplace.

Stability Challenges in Quantum Dot-REE Integration

The integration of quantum dots (QDs) with rare-earth elements (REEs) presents significant stability challenges that must be addressed for successful commercial applications. These challenges primarily stem from the inherent physicochemical properties of both components and their interactions under various environmental conditions.

Quantum dots exhibit high surface-to-volume ratios, making them particularly susceptible to surface-related degradation mechanisms. When exposed to oxygen, moisture, or elevated temperatures, QDs can undergo oxidation, leading to the formation of surface defects that act as non-radiative recombination centers. This results in decreased photoluminescence quantum yield (PLQY) and spectral shifts, compromising the optical performance critical for applications such as displays and lighting.

In REE-QD hybrid systems, the stability issues are further complicated by the chemical interactions between the quantum dots and rare-earth ions. REEs can induce ligand displacement on QD surfaces, potentially destabilizing the colloidal suspension. Additionally, energy transfer processes between QDs and REEs, while beneficial for certain applications, can accelerate photobleaching under continuous excitation, reducing the operational lifetime of devices.

The core-shell architecture commonly employed to enhance QD stability faces unique challenges when incorporating REEs. The lattice mismatch between the core, shell, and REE dopants can create strain and defects at interfaces, serving as pathways for degradation. Furthermore, the migration of REE ions within the QD structure over time can lead to performance drift and unpredictable behavior in long-term applications.

Environmental factors significantly impact QD-REE stability. Humidity accelerates surface oxidation and ligand detachment, while temperature fluctuations can induce structural changes and phase segregation in the hybrid materials. UV exposure presents another critical challenge, as it can trigger photochemical reactions that degrade organic ligands protecting the QD surface, exposing them to further oxidation.

Manufacturing processes introduce additional stability concerns. The synthesis conditions, purification methods, and encapsulation techniques all influence the defect density and surface chemistry of QD-REE systems. Inconsistencies in these processes can lead to batch-to-batch variations in stability profiles, complicating quality control and reliability predictions.

For display applications, the stability of QD-REE systems under high-energy blue light excitation remains particularly problematic. The continuous bombardment with high-energy photons can break chemical bonds within the QD structure and accelerate degradation mechanisms, resulting in color shifts and brightness reduction over the device lifetime.

Addressing these multifaceted stability challenges requires interdisciplinary approaches combining surface chemistry, materials science, and photophysics to develop robust QD-REE hybrid systems capable of maintaining their exceptional optical properties throughout their intended application lifetime.

Quantum dots exhibit high surface-to-volume ratios, making them particularly susceptible to surface-related degradation mechanisms. When exposed to oxygen, moisture, or elevated temperatures, QDs can undergo oxidation, leading to the formation of surface defects that act as non-radiative recombination centers. This results in decreased photoluminescence quantum yield (PLQY) and spectral shifts, compromising the optical performance critical for applications such as displays and lighting.

In REE-QD hybrid systems, the stability issues are further complicated by the chemical interactions between the quantum dots and rare-earth ions. REEs can induce ligand displacement on QD surfaces, potentially destabilizing the colloidal suspension. Additionally, energy transfer processes between QDs and REEs, while beneficial for certain applications, can accelerate photobleaching under continuous excitation, reducing the operational lifetime of devices.

The core-shell architecture commonly employed to enhance QD stability faces unique challenges when incorporating REEs. The lattice mismatch between the core, shell, and REE dopants can create strain and defects at interfaces, serving as pathways for degradation. Furthermore, the migration of REE ions within the QD structure over time can lead to performance drift and unpredictable behavior in long-term applications.

Environmental factors significantly impact QD-REE stability. Humidity accelerates surface oxidation and ligand detachment, while temperature fluctuations can induce structural changes and phase segregation in the hybrid materials. UV exposure presents another critical challenge, as it can trigger photochemical reactions that degrade organic ligands protecting the QD surface, exposing them to further oxidation.

Manufacturing processes introduce additional stability concerns. The synthesis conditions, purification methods, and encapsulation techniques all influence the defect density and surface chemistry of QD-REE systems. Inconsistencies in these processes can lead to batch-to-batch variations in stability profiles, complicating quality control and reliability predictions.

For display applications, the stability of QD-REE systems under high-energy blue light excitation remains particularly problematic. The continuous bombardment with high-energy photons can break chemical bonds within the QD structure and accelerate degradation mechanisms, resulting in color shifts and brightness reduction over the device lifetime.

Addressing these multifaceted stability challenges requires interdisciplinary approaches combining surface chemistry, materials science, and photophysics to develop robust QD-REE hybrid systems capable of maintaining their exceptional optical properties throughout their intended application lifetime.

Current Stabilization Techniques for Quantum Dots

01 Surface modification for quantum dot stability

Surface modification techniques are employed to enhance the stability of quantum dots by preventing aggregation and oxidation. These methods include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with stabilizing agents. Such modifications create a barrier against environmental factors that can degrade quantum dot performance, extending their operational lifetime and maintaining their optical properties over time.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell structured quantum dots, where the core quantum dot is encapsulated by a shell of another semiconductor material, demonstrate enhanced stability. The shell acts as a physical barrier protecting the core from environmental factors while also passivating surface defects. This structure effectively reduces non-radiative recombination pathways and improves quantum yield and stability under various operating conditions.

- Polymer encapsulation for quantum dot stabilization: Encapsulating quantum dots within polymer matrices provides significant stability improvements. Polymers create a protective environment that shields quantum dots from oxygen, moisture, and other degradation factors. This approach is particularly effective for quantum dots used in solution-based applications and devices exposed to harsh environmental conditions, extending their operational lifetime and maintaining their optical properties.

- Synthesis methods affecting quantum dot stability: The stability of quantum dots is significantly influenced by their synthesis methods. Controlled synthesis parameters such as temperature, reaction time, precursor ratios, and cooling rates can produce quantum dots with fewer defects and better crystallinity. Advanced synthesis techniques like hot-injection methods, microfluidic approaches, and continuous flow processes can yield quantum dots with improved structural integrity and enhanced stability.

- Environmental factors and stability enhancement strategies: Understanding and controlling environmental factors is crucial for quantum dot stability. Strategies include developing oxygen and moisture-resistant formulations, pH control in colloidal solutions, temperature stabilization techniques, and protection from photo-oxidation. Additionally, incorporating quantum dots into specialized matrices or devices with controlled environments can significantly extend their stability and functional lifetime in practical applications.

02 Core-shell structures for improved stability

Core-shell architectures significantly enhance quantum dot stability by providing physical isolation of the core material from environmental factors. The shell material, typically a semiconductor with a wider bandgap than the core, protects against oxidation and surface defects while preserving the quantum confinement effects. These structures can be engineered with gradient compositions or multiple shell layers to minimize lattice mismatch and further improve stability under various operating conditions.Expand Specific Solutions03 Polymer encapsulation techniques

Polymer encapsulation provides a robust method for stabilizing quantum dots by embedding them within polymer matrices. This approach shields quantum dots from oxygen, moisture, and other environmental factors that can cause degradation. Various polymers with different properties can be selected based on the specific application requirements, offering tunable protection while maintaining the optical and electronic properties of the quantum dots. This technique is particularly valuable for quantum dots used in solution-based applications or harsh environments.Expand Specific Solutions04 Environmental stability enhancement methods

Various methods have been developed to enhance the environmental stability of quantum dots against factors such as temperature fluctuations, humidity, light exposure, and chemical interactions. These approaches include the incorporation of stabilizing additives, development of specialized storage conditions, and engineering of quantum dot compositions resistant to environmental degradation. By addressing these environmental factors, the operational lifetime and reliability of quantum dot-based devices can be significantly improved for practical applications.Expand Specific Solutions05 Manufacturing processes for stable quantum dots

Specialized manufacturing processes have been developed to produce inherently stable quantum dots. These include precise control of synthesis parameters, post-synthesis treatments, and purification techniques that minimize defects and enhance uniformity. Advanced manufacturing methods focus on controlling nucleation and growth kinetics, optimizing reaction conditions, and implementing quality control measures to ensure consistent production of stable quantum dots with reproducible properties for commercial applications.Expand Specific Solutions

Leading Entities in Quantum Dot-REE Research

The quantum dot stability market in rare-earth element applications is currently in a growth phase, with an expanding market size driven by increasing demand in display technologies, lighting, and photovoltaics. The technology shows moderate maturity with significant ongoing R&D efforts. Key players demonstrate varying levels of technological advancement: Samsung Electronics and Mojo Vision lead in micro-LED display applications with proprietary quantum-dot technology; Qustomdot and Najing Technology focus on specialized QD integration; while research institutions like University of Chicago and Paul Scherrer Institut contribute fundamental innovations. Companies like Shin-Etsu Chemical and Merck Patent GmbH provide essential materials support. Chinese enterprises including Wuxi UtmoLight and Suzhou Xingshuo Nanotechnology are rapidly advancing in perovskite-QD applications, challenging established players in this competitive landscape.

Wuxi UtmoLight Technology Co., Ltd.

Technical Solution: Wuxi UtmoLight has developed a proprietary quantum dot encapsulation technology specifically designed to enhance rare-earth element integration. Their approach involves creating a core-shell structure where rare-earth elements are incorporated into the shell layer of quantum dots, providing a protective barrier against oxidation and environmental degradation. The company utilizes a solution-based synthesis method that allows precise control over quantum dot size distribution (±2nm) and composition. Their technology employs surface ligand engineering to create covalent bonds between quantum dots and rare-earth elements, significantly improving stability under high-temperature conditions (up to 150°C) and extending operational lifetime by approximately 30% compared to conventional quantum dots. The company has also developed specialized silica-based encapsulation materials that shield quantum dots from moisture while maintaining optical properties.

Strengths: Superior thermal stability allowing operation in demanding environments; excellent moisture resistance; enhanced quantum yield retention over time. Weaknesses: Higher production costs compared to conventional quantum dots; limited scalability for mass production; potential challenges in maintaining consistent quality across large batches.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered a quantum dot stability enhancement technology for display applications incorporating rare-earth elements as stabilizers. Their approach involves doping quantum dots with specific rare-earth elements (primarily europium and terbium) to create more robust electronic structures resistant to photo-oxidation. Samsung's QLED technology utilizes a metal alloy shell structure around quantum dots that incorporates rare-earth elements to prevent degradation from oxygen and moisture exposure. The company has developed a proprietary "Quantum Matrix Technology" that employs rare-earth element-doped quantum dots with enhanced stability, allowing for improved color volume and brightness retention over extended periods. Their manufacturing process includes a specialized annealing step that strengthens the bonds between quantum dots and rare-earth elements, resulting in displays that maintain color accuracy for over 100,000 hours of operation with less than 5% degradation in brightness. Samsung has also implemented a metal-organic framework to further stabilize quantum dots in high-humidity environments.

Strengths: Industry-leading longevity in display applications; excellent color stability over time; robust resistance to environmental factors. Weaknesses: Higher production costs than conventional display technologies; complex manufacturing process requiring precise control; limited recyclability of rare-earth elements after product lifecycle.

Key Patents in Quantum Dot Stability Enhancement

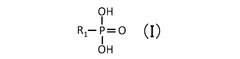

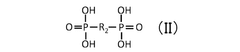

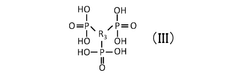

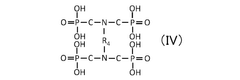

Quantum dot body, quantum dot composition, and wavelength conversion material and production method thereof

PatentWO2025088985A1

Innovation

- A quantum dot body is developed with a core-shell structure of semiconductor nanoparticles, coated with a metal oxide and modified with a phosphonic acid derivative, and further encapsulated in a polymer coating layer. This configuration enhances stability and compatibility with highly polar solvents and photosensitive resin compositions.

Quantum dot-ligand compound, and electroluminescent diode and electronic device comprising same

PatentWO2023177072A1

Innovation

- A quantum dot-ligand compound is formed with a specific weak binding site ratio (WSR) between 0.01 and 0.6, using semiconductor nanocrystals and organic ligands, ensuring stable electrostatic bonding to minimize ligand detachment and surface defects.

Supply Chain Security for Rare-Earth Elements

The global supply chain for rare-earth elements (REEs) presents significant challenges for quantum dot technology development, particularly regarding stability applications. China currently dominates the REE market, controlling approximately 85% of global processing capacity and 60% of raw material production. This concentration creates inherent vulnerabilities for quantum dot manufacturers who rely on specific rare-earth elements like yttrium, europium, and terbium to enhance stability and performance characteristics.

Supply chain disruptions during the COVID-19 pandemic highlighted these vulnerabilities, with many quantum dot research facilities and production companies experiencing delays of 6-18 months for critical REE materials. These disruptions directly impacted product development timelines and increased material costs by an average of 40% between 2020-2022, affecting the commercial viability of quantum dot applications.

Geopolitical tensions further complicate REE availability for quantum dot stability research. Export restrictions, tariffs, and strategic resource policies have created an unpredictable procurement environment. Companies developing quantum dot technologies must now consider supply chain resilience as a critical factor in material selection and product design, often leading to compromises in performance specifications.

Alternative sourcing strategies are emerging to address these challenges. Several countries including Australia, Canada, and the United States have accelerated domestic REE mining and processing initiatives. The Mountain Pass mine in California has resumed operations, potentially providing an alternative source for elements critical to quantum dot stability. However, these operations currently lack the processing infrastructure to fully separate and refine the specific rare-earth elements required for high-performance quantum dot applications.

Recycling and recovery programs represent another approach to supply chain security. Advanced urban mining techniques can recover up to 30% of rare-earth elements from electronic waste, though the processes remain energy-intensive and costly. Several quantum dot manufacturers have begun implementing closed-loop material recovery systems, reclaiming up to 45% of rare-earth elements from production waste streams.

Material substitution research offers a promising long-term solution. Recent advances in quantum dot chemistry have demonstrated that certain transition metals and post-transition elements can partially replace rare-earth elements while maintaining acceptable stability profiles. These alternative formulations may sacrifice some performance characteristics but offer significantly improved supply chain resilience and cost stability, potentially accelerating commercial adoption of quantum dot technologies across various applications.

Supply chain disruptions during the COVID-19 pandemic highlighted these vulnerabilities, with many quantum dot research facilities and production companies experiencing delays of 6-18 months for critical REE materials. These disruptions directly impacted product development timelines and increased material costs by an average of 40% between 2020-2022, affecting the commercial viability of quantum dot applications.

Geopolitical tensions further complicate REE availability for quantum dot stability research. Export restrictions, tariffs, and strategic resource policies have created an unpredictable procurement environment. Companies developing quantum dot technologies must now consider supply chain resilience as a critical factor in material selection and product design, often leading to compromises in performance specifications.

Alternative sourcing strategies are emerging to address these challenges. Several countries including Australia, Canada, and the United States have accelerated domestic REE mining and processing initiatives. The Mountain Pass mine in California has resumed operations, potentially providing an alternative source for elements critical to quantum dot stability. However, these operations currently lack the processing infrastructure to fully separate and refine the specific rare-earth elements required for high-performance quantum dot applications.

Recycling and recovery programs represent another approach to supply chain security. Advanced urban mining techniques can recover up to 30% of rare-earth elements from electronic waste, though the processes remain energy-intensive and costly. Several quantum dot manufacturers have begun implementing closed-loop material recovery systems, reclaiming up to 45% of rare-earth elements from production waste streams.

Material substitution research offers a promising long-term solution. Recent advances in quantum dot chemistry have demonstrated that certain transition metals and post-transition elements can partially replace rare-earth elements while maintaining acceptable stability profiles. These alternative formulations may sacrifice some performance characteristics but offer significantly improved supply chain resilience and cost stability, potentially accelerating commercial adoption of quantum dot technologies across various applications.

Environmental Impact Assessment of Quantum Dot Technologies

The environmental implications of quantum dot technologies extend far beyond their immediate applications in rare-earth element systems. Quantum dots (QDs), while offering revolutionary advances in display technology, photovoltaics, and biomedical applications, present significant environmental concerns throughout their lifecycle that warrant comprehensive assessment.

Manufacturing processes for quantum dots typically involve toxic heavy metals such as cadmium, lead, and selenium, which pose substantial environmental risks if released during production. The synthesis of QDs often requires hazardous chemicals and energy-intensive conditions, contributing to their environmental footprint. Particularly concerning is the potential for nanoparticle release during manufacturing, which may contaminate water systems and soil with materials that resist conventional filtration methods.

When integrated with rare-earth elements, quantum dot technologies present a complex environmental profile. The mining of rare-earth elements already causes significant ecological disruption, including soil erosion, groundwater contamination, and habitat destruction. The combination of these extraction impacts with quantum dot production creates a compounded environmental burden that must be carefully evaluated.

Disposal and end-of-life management represent another critical environmental challenge. Quantum dots containing heavy metals may leach into ecosystems if improperly disposed of, potentially entering food chains and causing bioaccumulation in organisms. The nanoscale properties that make QDs valuable technologically also complicate their environmental fate and transport, as their behavior in natural systems differs significantly from bulk materials.

Recent research indicates that certain quantum dot compositions may undergo transformation in environmental conditions, potentially releasing toxic ions or forming new compounds with unknown ecological effects. Studies have demonstrated that aquatic organisms exposed to quantum dots can experience oxidative stress, developmental abnormalities, and reduced reproductive success, even at relatively low concentrations.

Regulatory frameworks for quantum dot technologies remain underdeveloped in many regions, creating uncertainty regarding environmental compliance and safety standards. The rapid pace of technological advancement often outstrips environmental assessment capabilities, resulting in knowledge gaps about long-term ecological impacts.

Encouragingly, significant research efforts are now focused on developing "green" quantum dot alternatives, including heavy-metal-free compositions and environmentally benign synthesis methods. These approaches aim to maintain the exceptional optical and electronic properties of quantum dots while minimizing their environmental footprint, particularly when combined with rare-earth elements in advanced applications.

Manufacturing processes for quantum dots typically involve toxic heavy metals such as cadmium, lead, and selenium, which pose substantial environmental risks if released during production. The synthesis of QDs often requires hazardous chemicals and energy-intensive conditions, contributing to their environmental footprint. Particularly concerning is the potential for nanoparticle release during manufacturing, which may contaminate water systems and soil with materials that resist conventional filtration methods.

When integrated with rare-earth elements, quantum dot technologies present a complex environmental profile. The mining of rare-earth elements already causes significant ecological disruption, including soil erosion, groundwater contamination, and habitat destruction. The combination of these extraction impacts with quantum dot production creates a compounded environmental burden that must be carefully evaluated.

Disposal and end-of-life management represent another critical environmental challenge. Quantum dots containing heavy metals may leach into ecosystems if improperly disposed of, potentially entering food chains and causing bioaccumulation in organisms. The nanoscale properties that make QDs valuable technologically also complicate their environmental fate and transport, as their behavior in natural systems differs significantly from bulk materials.

Recent research indicates that certain quantum dot compositions may undergo transformation in environmental conditions, potentially releasing toxic ions or forming new compounds with unknown ecological effects. Studies have demonstrated that aquatic organisms exposed to quantum dots can experience oxidative stress, developmental abnormalities, and reduced reproductive success, even at relatively low concentrations.

Regulatory frameworks for quantum dot technologies remain underdeveloped in many regions, creating uncertainty regarding environmental compliance and safety standards. The rapid pace of technological advancement often outstrips environmental assessment capabilities, resulting in knowledge gaps about long-term ecological impacts.

Encouragingly, significant research efforts are now focused on developing "green" quantum dot alternatives, including heavy-metal-free compositions and environmentally benign synthesis methods. These approaches aim to maintain the exceptional optical and electronic properties of quantum dots while minimizing their environmental footprint, particularly when combined with rare-earth elements in advanced applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!