Developing Low-Maintenance Plate Heat Exchanger Systems

JUL 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat Exchanger Evolution and Objectives

Plate heat exchangers have undergone significant evolution since their inception in the 1920s. Initially designed for the dairy industry, these devices have expanded their applications across various sectors due to their efficiency and compact design. The progression of plate heat exchanger technology has been driven by the need for improved heat transfer rates, reduced fouling, and enhanced durability.

In the early stages, plate heat exchangers were primarily constructed with simple, flat plates. As research advanced, corrugated patterns were introduced to increase turbulence and improve heat transfer efficiency. This innovation marked a crucial milestone in the technology's development, significantly boosting performance while maintaining a compact form factor.

The materials used in plate heat exchangers have also evolved considerably. Early models relied heavily on stainless steel, but modern designs incorporate a wide range of materials including titanium, nickel alloys, and specialized polymers. This diversification has enabled plate heat exchangers to handle more corrosive fluids and operate in more demanding environments, expanding their utility across industries.

Recent advancements have focused on optimizing plate geometry and channel configuration. Computer-aided design and computational fluid dynamics have played pivotal roles in this process, allowing engineers to fine-tune plate designs for specific applications. These improvements have led to enhanced heat transfer coefficients and reduced pressure drops, further increasing overall system efficiency.

The primary objective in developing low-maintenance plate heat exchanger systems is to address the persistent challenge of fouling. Fouling not only reduces heat transfer efficiency but also necessitates frequent cleaning and maintenance, leading to increased operational costs and downtime. Innovations in this area aim to create surfaces that resist deposit formation and facilitate easier cleaning processes.

Another key goal is to improve the overall lifespan of plate heat exchangers. This involves developing more robust sealing technologies to prevent leaks and enhance the durability of plate materials. By extending the operational life of these systems, manufacturers can significantly reduce the total cost of ownership for end-users.

Energy efficiency remains a critical objective in the evolution of plate heat exchangers. Current research is focused on maximizing heat recovery and minimizing energy losses. This includes exploring novel plate designs that can handle wider temperature ranges and higher operating pressures, allowing for more versatile and efficient heat exchange processes.

As industries move towards more sustainable practices, there is a growing emphasis on developing plate heat exchangers that are not only energy-efficient but also environmentally friendly. This encompasses the use of recyclable materials, reduction of raw material consumption in manufacturing, and designs that facilitate easy disassembly and recycling at the end of the product's life cycle.

In the early stages, plate heat exchangers were primarily constructed with simple, flat plates. As research advanced, corrugated patterns were introduced to increase turbulence and improve heat transfer efficiency. This innovation marked a crucial milestone in the technology's development, significantly boosting performance while maintaining a compact form factor.

The materials used in plate heat exchangers have also evolved considerably. Early models relied heavily on stainless steel, but modern designs incorporate a wide range of materials including titanium, nickel alloys, and specialized polymers. This diversification has enabled plate heat exchangers to handle more corrosive fluids and operate in more demanding environments, expanding their utility across industries.

Recent advancements have focused on optimizing plate geometry and channel configuration. Computer-aided design and computational fluid dynamics have played pivotal roles in this process, allowing engineers to fine-tune plate designs for specific applications. These improvements have led to enhanced heat transfer coefficients and reduced pressure drops, further increasing overall system efficiency.

The primary objective in developing low-maintenance plate heat exchanger systems is to address the persistent challenge of fouling. Fouling not only reduces heat transfer efficiency but also necessitates frequent cleaning and maintenance, leading to increased operational costs and downtime. Innovations in this area aim to create surfaces that resist deposit formation and facilitate easier cleaning processes.

Another key goal is to improve the overall lifespan of plate heat exchangers. This involves developing more robust sealing technologies to prevent leaks and enhance the durability of plate materials. By extending the operational life of these systems, manufacturers can significantly reduce the total cost of ownership for end-users.

Energy efficiency remains a critical objective in the evolution of plate heat exchangers. Current research is focused on maximizing heat recovery and minimizing energy losses. This includes exploring novel plate designs that can handle wider temperature ranges and higher operating pressures, allowing for more versatile and efficient heat exchange processes.

As industries move towards more sustainable practices, there is a growing emphasis on developing plate heat exchangers that are not only energy-efficient but also environmentally friendly. This encompasses the use of recyclable materials, reduction of raw material consumption in manufacturing, and designs that facilitate easy disassembly and recycling at the end of the product's life cycle.

Market Demand Analysis for Low-Maintenance Heat Exchangers

The market demand for low-maintenance plate heat exchanger systems has been steadily increasing across various industries. This growth is primarily driven by the need for more efficient and cost-effective heat transfer solutions in industrial processes. The global plate heat exchanger market is expected to expand significantly in the coming years, with a particular focus on low-maintenance systems.

One of the key factors fueling this demand is the rising emphasis on energy efficiency and sustainability in industrial operations. Low-maintenance plate heat exchangers offer improved heat transfer efficiency, reduced energy consumption, and lower operational costs compared to traditional heat exchange systems. This aligns well with the growing global focus on reducing carbon footprints and implementing environmentally friendly technologies.

The food and beverage industry has emerged as a major consumer of low-maintenance plate heat exchangers. These systems are crucial for maintaining product quality and safety while ensuring efficient heating and cooling processes. The pharmaceutical sector also shows a strong demand for these systems, particularly in applications requiring strict temperature control and hygiene standards.

In the chemical processing industry, there is a growing need for corrosion-resistant and fouling-resistant heat exchangers. Low-maintenance plate heat exchangers, with their advanced materials and designs, are well-positioned to meet these requirements. This has led to increased adoption in chemical plants and refineries worldwide.

The HVAC sector represents another significant market for low-maintenance heat exchangers. As building energy efficiency standards become more stringent, there is a rising demand for heat recovery systems that can operate efficiently with minimal maintenance. This trend is particularly pronounced in commercial and industrial buildings, where energy costs form a substantial part of operational expenses.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for low-maintenance plate heat exchangers. This is attributed to rapid industrialization, increasing energy costs, and stringent environmental regulations in countries like China and India. North America and Europe also show strong market potential, driven by the need to upgrade aging industrial infrastructure with more efficient and sustainable technologies.

The market is also seeing a shift towards customized solutions. End-users are increasingly seeking heat exchanger systems tailored to their specific process requirements, which presents both opportunities and challenges for manufacturers. This trend is likely to drive innovation in design and materials, further expanding the market for low-maintenance plate heat exchangers.

As industries continue to prioritize operational efficiency and sustainability, the demand for low-maintenance plate heat exchanger systems is expected to grow consistently. Manufacturers who can offer reliable, efficient, and truly low-maintenance solutions are likely to gain a significant competitive advantage in this expanding market.

One of the key factors fueling this demand is the rising emphasis on energy efficiency and sustainability in industrial operations. Low-maintenance plate heat exchangers offer improved heat transfer efficiency, reduced energy consumption, and lower operational costs compared to traditional heat exchange systems. This aligns well with the growing global focus on reducing carbon footprints and implementing environmentally friendly technologies.

The food and beverage industry has emerged as a major consumer of low-maintenance plate heat exchangers. These systems are crucial for maintaining product quality and safety while ensuring efficient heating and cooling processes. The pharmaceutical sector also shows a strong demand for these systems, particularly in applications requiring strict temperature control and hygiene standards.

In the chemical processing industry, there is a growing need for corrosion-resistant and fouling-resistant heat exchangers. Low-maintenance plate heat exchangers, with their advanced materials and designs, are well-positioned to meet these requirements. This has led to increased adoption in chemical plants and refineries worldwide.

The HVAC sector represents another significant market for low-maintenance heat exchangers. As building energy efficiency standards become more stringent, there is a rising demand for heat recovery systems that can operate efficiently with minimal maintenance. This trend is particularly pronounced in commercial and industrial buildings, where energy costs form a substantial part of operational expenses.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for low-maintenance plate heat exchangers. This is attributed to rapid industrialization, increasing energy costs, and stringent environmental regulations in countries like China and India. North America and Europe also show strong market potential, driven by the need to upgrade aging industrial infrastructure with more efficient and sustainable technologies.

The market is also seeing a shift towards customized solutions. End-users are increasingly seeking heat exchanger systems tailored to their specific process requirements, which presents both opportunities and challenges for manufacturers. This trend is likely to drive innovation in design and materials, further expanding the market for low-maintenance plate heat exchangers.

As industries continue to prioritize operational efficiency and sustainability, the demand for low-maintenance plate heat exchanger systems is expected to grow consistently. Manufacturers who can offer reliable, efficient, and truly low-maintenance solutions are likely to gain a significant competitive advantage in this expanding market.

Current Challenges in Plate Heat Exchanger Maintenance

Plate heat exchangers (PHEs) have become integral components in various industrial processes due to their efficiency and compact design. However, maintaining these systems presents several challenges that impact their performance and longevity. One of the primary issues is fouling, which occurs when deposits accumulate on heat transfer surfaces, reducing thermal efficiency and increasing pressure drop. This problem is particularly prevalent in applications involving high-temperature fluids or those with suspended particles.

Corrosion is another significant challenge, especially in environments with aggressive chemicals or high-temperature operations. The thin plates used in PHEs are susceptible to corrosion, which can lead to leaks and compromised structural integrity. This issue is exacerbated by the difficulty in detecting early-stage corrosion due to the compact nature of PHE designs.

Gasket degradation poses a persistent maintenance concern. The elastomeric gaskets used to seal plate interfaces are prone to deterioration over time, leading to leaks and reduced system efficiency. Factors such as temperature fluctuations, chemical exposure, and mechanical stress contribute to accelerated gasket wear, necessitating frequent replacements.

The complexity of PHE designs also presents challenges in terms of cleaning and inspection. The narrow channels between plates can be difficult to access, making thorough cleaning a time-consuming and labor-intensive process. This complexity often requires specialized cleaning equipment and techniques, which can increase maintenance costs and downtime.

Uneven flow distribution is another issue that affects PHE performance and maintenance requirements. Improper flow patterns can lead to localized fouling, thermal stress, and reduced heat transfer efficiency. Addressing this challenge often involves careful design considerations and periodic flow adjustments, which add to the overall maintenance burden.

The need for regular disassembly and reassembly of PHEs for cleaning and inspection introduces risks of mechanical damage to plates and gaskets. This process requires skilled technicians and can be time-consuming, particularly for large systems with numerous plates. The potential for improper reassembly can lead to leaks and reduced performance, necessitating additional maintenance interventions.

Scaling, particularly in water-based applications, remains a persistent challenge. Mineral deposits can accumulate rapidly, reducing heat transfer efficiency and increasing pressure drop. While chemical treatments can mitigate scaling, they introduce additional maintenance requirements and potential environmental concerns.

As industrial processes demand higher efficiency and reliability, addressing these maintenance challenges becomes increasingly critical. The development of low-maintenance PHE systems must focus on innovative materials, advanced surface treatments, and intelligent monitoring systems to mitigate these issues and enhance overall system performance and longevity.

Corrosion is another significant challenge, especially in environments with aggressive chemicals or high-temperature operations. The thin plates used in PHEs are susceptible to corrosion, which can lead to leaks and compromised structural integrity. This issue is exacerbated by the difficulty in detecting early-stage corrosion due to the compact nature of PHE designs.

Gasket degradation poses a persistent maintenance concern. The elastomeric gaskets used to seal plate interfaces are prone to deterioration over time, leading to leaks and reduced system efficiency. Factors such as temperature fluctuations, chemical exposure, and mechanical stress contribute to accelerated gasket wear, necessitating frequent replacements.

The complexity of PHE designs also presents challenges in terms of cleaning and inspection. The narrow channels between plates can be difficult to access, making thorough cleaning a time-consuming and labor-intensive process. This complexity often requires specialized cleaning equipment and techniques, which can increase maintenance costs and downtime.

Uneven flow distribution is another issue that affects PHE performance and maintenance requirements. Improper flow patterns can lead to localized fouling, thermal stress, and reduced heat transfer efficiency. Addressing this challenge often involves careful design considerations and periodic flow adjustments, which add to the overall maintenance burden.

The need for regular disassembly and reassembly of PHEs for cleaning and inspection introduces risks of mechanical damage to plates and gaskets. This process requires skilled technicians and can be time-consuming, particularly for large systems with numerous plates. The potential for improper reassembly can lead to leaks and reduced performance, necessitating additional maintenance interventions.

Scaling, particularly in water-based applications, remains a persistent challenge. Mineral deposits can accumulate rapidly, reducing heat transfer efficiency and increasing pressure drop. While chemical treatments can mitigate scaling, they introduce additional maintenance requirements and potential environmental concerns.

As industrial processes demand higher efficiency and reliability, addressing these maintenance challenges becomes increasingly critical. The development of low-maintenance PHE systems must focus on innovative materials, advanced surface treatments, and intelligent monitoring systems to mitigate these issues and enhance overall system performance and longevity.

Existing Low-Maintenance Heat Exchanger Solutions

01 Cleaning and descaling methods

Various techniques for cleaning and descaling plate heat exchangers are essential for maintaining their efficiency. These methods may include chemical cleaning, high-pressure water jetting, or ultrasonic cleaning to remove fouling and scale buildup. Regular cleaning helps prevent performance degradation and extends the lifespan of the heat exchanger.- Cleaning and descaling methods: Various techniques for cleaning and descaling plate heat exchangers are essential for maintaining their efficiency. These methods include chemical cleaning, high-pressure water jetting, and ultrasonic cleaning. Regular cleaning helps prevent fouling and scaling, which can reduce heat transfer efficiency and increase pressure drop across the exchanger.

- Monitoring and diagnostic systems: Advanced monitoring and diagnostic systems are employed to detect performance issues in plate heat exchangers. These systems use sensors, data analysis, and predictive algorithms to identify potential problems before they escalate. Real-time monitoring helps in scheduling maintenance activities and optimizing system performance.

- Gasket replacement and plate restoration: Proper maintenance of gaskets and plates is crucial for preventing leaks and ensuring optimal heat transfer. Techniques for gasket replacement and plate restoration include careful removal of old gaskets, cleaning of plate surfaces, and precise installation of new gaskets. Some methods also involve reconditioning of damaged plates to extend their service life.

- Corrosion prevention and treatment: Strategies for preventing and treating corrosion in plate heat exchangers are vital for prolonging equipment life. These include the use of corrosion-resistant materials, protective coatings, and cathodic protection systems. Regular inspection and timely treatment of corroded areas help maintain the integrity of the heat exchanger components.

- Optimization of flow distribution: Techniques for optimizing flow distribution within plate heat exchangers are important for maintaining efficiency. These include the design of flow channels, use of flow distributors, and adjustment of plate configurations. Proper flow distribution ensures even heat transfer across the exchanger and reduces the risk of localized fouling or scaling.

02 Monitoring and diagnostic systems

Advanced monitoring and diagnostic systems are implemented to detect issues in plate heat exchangers early. These systems may use sensors, data analytics, and predictive maintenance algorithms to identify potential problems before they escalate. Real-time monitoring helps optimize maintenance schedules and prevent unexpected failures.Expand Specific Solutions03 Gasket replacement and plate restoration

Proper maintenance of gaskets and plates is crucial for preventing leaks and ensuring optimal heat transfer. Techniques for gasket replacement and plate restoration may include specialized tools, adhesive applications, and surface treatments. Regular inspection and timely replacement of worn components help maintain system integrity.Expand Specific Solutions04 Corrosion prevention and treatment

Methods for preventing and treating corrosion in plate heat exchangers are vital for prolonging their service life. These may include the use of corrosion-resistant materials, protective coatings, and chemical treatments. Regular inspection and maintenance procedures help identify and address corrosion issues early.Expand Specific Solutions05 Optimization of flow distribution

Techniques for optimizing flow distribution within plate heat exchangers are important for maintaining efficiency. These may include modifications to plate designs, flow channel configurations, or the use of flow distributors. Proper flow distribution helps prevent uneven fouling and ensures consistent heat transfer across the exchanger.Expand Specific Solutions

Key Players in Heat Exchanger Manufacturing

The development of low-maintenance plate heat exchanger systems is in a mature phase, with a competitive landscape dominated by established players. The market size is substantial, driven by increasing demand for energy-efficient heat transfer solutions across various industries. Companies like Alfa Laval, MAHLE International, and Vahterus Oy are at the forefront of technological advancements, focusing on improving efficiency and reducing maintenance requirements. The technology's maturity is evident in the diverse applications and continuous innovations from key players such as Air Liquide and Mitsubishi Electric, who are investing in R&D to enhance performance and durability. This competitive environment fosters ongoing improvements in plate heat exchanger technology, benefiting end-users across multiple sectors.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed innovative plate heat exchanger systems with a focus on low maintenance. Their AlfaNova fusion-bonded plate heat exchangers use a patented fusion technology to create an all-stainless steel construction[1]. This design eliminates gaskets, reducing maintenance needs and increasing durability. They've also introduced the RefTight service concept, which uses predictive maintenance algorithms to optimize cleaning intervals and reduce downtime[2]. Additionally, their DuroShell plate-and-shell heat exchanger features a patented plate pattern that enhances heat transfer efficiency while minimizing fouling, thus extending maintenance intervals[3].

Strengths: Innovative fusion technology eliminates gaskets, reducing maintenance. Predictive maintenance algorithms optimize cleaning schedules. Patented plate designs enhance efficiency and reduce fouling. Weaknesses: Higher initial cost compared to traditional designs. May require specialized technicians for repairs.

A-HEAT Allied Heat Exchange Technology AG

Technical Solution: A-HEAT has focused on developing low-maintenance plate heat exchanger systems through their subsidiary, Kelvion (formerly GEA Heat Exchangers). Their NX series of gasketed plate heat exchangers features an optimized plate geometry that enhances turbulence and reduces fouling[10]. The OptiWave plate pattern improves flow distribution and heat transfer efficiency, extending the time between cleaning cycles. A-HEAT has also introduced a novel gasket-free laser-welded technology for their plate heat exchangers, significantly reducing maintenance related to gasket replacement[11]. Their latest innovation includes a smart monitoring system that uses IoT sensors and machine learning algorithms to predict maintenance needs and optimize performance in real-time[12].

Strengths: OptiWave plate pattern reduces fouling and improves efficiency. Laser-welded technology eliminates gasket maintenance. Smart monitoring system enables predictive maintenance. Weaknesses: Laser-welded units have less flexibility for capacity adjustments. Smart monitoring system may require additional investment in IoT infrastructure.

Innovative Materials and Coatings for Fouling Reduction

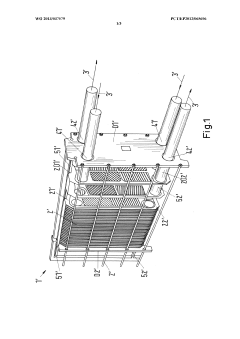

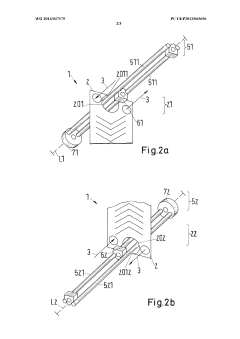

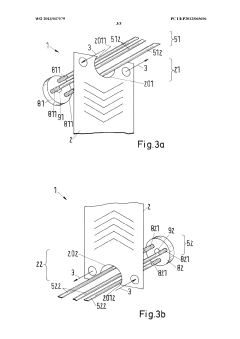

Plate heat exchanger

PatentInactiveEP2756254A1

Innovation

- The introduction of support and guide devices with recessed openings and multi-part configurations, allowing for easy locking and unlocking, enabling individual heat exchange plates to be swapped without disassembling the entire package, using fastening discs, spacers, and wire ropes for secure and flexible attachment.

Plate heat exchanger

PatentWO2013037579A1

Innovation

- The design incorporates support and guide devices with recessed openings that allow for easy locking and unlocking, enabling individual heat exchange plates to be swapped without disassembling the entire package, using multi-part support and guide devices with rotatable components and wire ropes for secure yet removable attachments.

Environmental Impact and Energy Efficiency Considerations

Plate heat exchanger systems play a crucial role in various industries, and their environmental impact and energy efficiency are of paramount importance in today's sustainability-focused world. These systems, when designed and operated efficiently, can significantly reduce energy consumption and minimize environmental footprint.

The primary environmental consideration for plate heat exchangers is their potential to reduce overall energy consumption in industrial processes. By facilitating efficient heat transfer between fluids, these systems can recover waste heat and reduce the need for additional heating or cooling, thereby lowering the overall energy demand. This reduction in energy consumption directly translates to decreased greenhouse gas emissions and a smaller carbon footprint for industrial operations.

Material selection is another critical factor in the environmental impact of plate heat exchangers. The use of corrosion-resistant materials, such as titanium or high-grade stainless steel, can extend the lifespan of these systems, reducing the need for frequent replacements and minimizing waste generation. Additionally, the compact design of plate heat exchangers requires less raw material compared to traditional shell-and-tube heat exchangers, further reducing the environmental impact associated with manufacturing and transportation.

Energy efficiency in plate heat exchanger systems is primarily achieved through their design characteristics. The corrugated plates create turbulent flow, enhancing heat transfer efficiency and reducing the required heat transfer surface area. This design allows for closer temperature approaches between fluids, maximizing the overall system efficiency. Furthermore, the modular nature of plate heat exchangers enables easy scalability and optimization for specific process requirements, ensuring optimal energy utilization across various applications.

Maintenance practices also play a significant role in the long-term energy efficiency of these systems. Regular cleaning and inspection can prevent fouling and scaling, which can severely impact heat transfer efficiency. Implementing advanced monitoring systems and predictive maintenance strategies can help maintain peak performance, ensuring consistent energy efficiency throughout the system's lifecycle.

Water conservation is another important aspect of environmental consideration for plate heat exchangers. These systems often require less cooling water compared to traditional heat exchangers, contributing to water conservation efforts in industrial settings. Additionally, the ability to use lower-grade heat sources in plate heat exchangers can reduce the demand for high-quality energy inputs, further enhancing overall resource efficiency.

As industries strive for more sustainable operations, the development of low-maintenance plate heat exchanger systems must prioritize both environmental impact and energy efficiency. This involves not only improving the design and materials used but also considering the entire lifecycle of the system, from manufacturing to end-of-life disposal. By focusing on these aspects, manufacturers can create systems that not only meet the immediate needs of industries but also contribute to long-term environmental sustainability goals.

The primary environmental consideration for plate heat exchangers is their potential to reduce overall energy consumption in industrial processes. By facilitating efficient heat transfer between fluids, these systems can recover waste heat and reduce the need for additional heating or cooling, thereby lowering the overall energy demand. This reduction in energy consumption directly translates to decreased greenhouse gas emissions and a smaller carbon footprint for industrial operations.

Material selection is another critical factor in the environmental impact of plate heat exchangers. The use of corrosion-resistant materials, such as titanium or high-grade stainless steel, can extend the lifespan of these systems, reducing the need for frequent replacements and minimizing waste generation. Additionally, the compact design of plate heat exchangers requires less raw material compared to traditional shell-and-tube heat exchangers, further reducing the environmental impact associated with manufacturing and transportation.

Energy efficiency in plate heat exchanger systems is primarily achieved through their design characteristics. The corrugated plates create turbulent flow, enhancing heat transfer efficiency and reducing the required heat transfer surface area. This design allows for closer temperature approaches between fluids, maximizing the overall system efficiency. Furthermore, the modular nature of plate heat exchangers enables easy scalability and optimization for specific process requirements, ensuring optimal energy utilization across various applications.

Maintenance practices also play a significant role in the long-term energy efficiency of these systems. Regular cleaning and inspection can prevent fouling and scaling, which can severely impact heat transfer efficiency. Implementing advanced monitoring systems and predictive maintenance strategies can help maintain peak performance, ensuring consistent energy efficiency throughout the system's lifecycle.

Water conservation is another important aspect of environmental consideration for plate heat exchangers. These systems often require less cooling water compared to traditional heat exchangers, contributing to water conservation efforts in industrial settings. Additionally, the ability to use lower-grade heat sources in plate heat exchangers can reduce the demand for high-quality energy inputs, further enhancing overall resource efficiency.

As industries strive for more sustainable operations, the development of low-maintenance plate heat exchanger systems must prioritize both environmental impact and energy efficiency. This involves not only improving the design and materials used but also considering the entire lifecycle of the system, from manufacturing to end-of-life disposal. By focusing on these aspects, manufacturers can create systems that not only meet the immediate needs of industries but also contribute to long-term environmental sustainability goals.

Cost-Benefit Analysis of Low-Maintenance Heat Exchangers

The cost-benefit analysis of low-maintenance heat exchangers reveals significant advantages for businesses across various industries. Initial investment in these advanced systems may be higher compared to traditional heat exchangers, but the long-term savings and operational benefits often outweigh the upfront costs.

One of the primary benefits is the reduction in maintenance expenses. Low-maintenance plate heat exchangers require less frequent cleaning and servicing, resulting in decreased downtime and lower labor costs. This improved efficiency translates to substantial savings over the system's lifetime, particularly in industries with continuous operations.

Energy efficiency is another crucial factor in the cost-benefit equation. Low-maintenance heat exchangers often incorporate advanced designs and materials that enhance heat transfer efficiency. This improved performance leads to reduced energy consumption, contributing to lower operational costs and a smaller carbon footprint.

The extended lifespan of low-maintenance heat exchangers also plays a significant role in their cost-effectiveness. With reduced wear and tear due to less frequent maintenance interventions, these systems tend to have longer operational lives compared to conventional alternatives. This longevity translates to delayed replacement costs and improved return on investment.

In terms of operational reliability, low-maintenance heat exchangers offer enhanced stability and reduced risk of unexpected failures. This increased reliability minimizes production disruptions and associated financial losses, particularly in critical processes where downtime can be extremely costly.

The analysis also considers the impact on product quality. In industries such as food and beverage or pharmaceuticals, where maintaining precise temperature control is crucial, low-maintenance heat exchangers can provide more consistent performance. This consistency can lead to improved product quality, reduced waste, and potentially higher market value for the end products.

Environmental considerations further enhance the cost-benefit profile of low-maintenance heat exchangers. Their improved energy efficiency and reduced need for cleaning chemicals contribute to a lower environmental impact. This aspect can be particularly valuable for companies aiming to meet sustainability goals or comply with increasingly stringent environmental regulations.

When evaluating the total cost of ownership, it's essential to consider factors beyond direct financial metrics. The reduced complexity of maintenance procedures can lead to simplified training requirements for operational staff and potentially lower insurance premiums due to decreased risk of equipment failure.

In conclusion, while the initial investment in low-maintenance plate heat exchanger systems may be higher, the long-term benefits in terms of reduced operational costs, improved efficiency, extended lifespan, and environmental advantages often result in a favorable cost-benefit ratio for many applications.

One of the primary benefits is the reduction in maintenance expenses. Low-maintenance plate heat exchangers require less frequent cleaning and servicing, resulting in decreased downtime and lower labor costs. This improved efficiency translates to substantial savings over the system's lifetime, particularly in industries with continuous operations.

Energy efficiency is another crucial factor in the cost-benefit equation. Low-maintenance heat exchangers often incorporate advanced designs and materials that enhance heat transfer efficiency. This improved performance leads to reduced energy consumption, contributing to lower operational costs and a smaller carbon footprint.

The extended lifespan of low-maintenance heat exchangers also plays a significant role in their cost-effectiveness. With reduced wear and tear due to less frequent maintenance interventions, these systems tend to have longer operational lives compared to conventional alternatives. This longevity translates to delayed replacement costs and improved return on investment.

In terms of operational reliability, low-maintenance heat exchangers offer enhanced stability and reduced risk of unexpected failures. This increased reliability minimizes production disruptions and associated financial losses, particularly in critical processes where downtime can be extremely costly.

The analysis also considers the impact on product quality. In industries such as food and beverage or pharmaceuticals, where maintaining precise temperature control is crucial, low-maintenance heat exchangers can provide more consistent performance. This consistency can lead to improved product quality, reduced waste, and potentially higher market value for the end products.

Environmental considerations further enhance the cost-benefit profile of low-maintenance heat exchangers. Their improved energy efficiency and reduced need for cleaning chemicals contribute to a lower environmental impact. This aspect can be particularly valuable for companies aiming to meet sustainability goals or comply with increasingly stringent environmental regulations.

When evaluating the total cost of ownership, it's essential to consider factors beyond direct financial metrics. The reduced complexity of maintenance procedures can lead to simplified training requirements for operational staff and potentially lower insurance premiums due to decreased risk of equipment failure.

In conclusion, while the initial investment in low-maintenance plate heat exchanger systems may be higher, the long-term benefits in terms of reduced operational costs, improved efficiency, extended lifespan, and environmental advantages often result in a favorable cost-benefit ratio for many applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!