Directed Energy Deposition: Precision Fabrication in Aerospace

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Technology Evolution and Aerospace Applications

Directed Energy Deposition (DED) technology has undergone significant evolution since its inception in the 1990s, transforming from experimental additive manufacturing processes to sophisticated precision fabrication methods. The initial DED systems utilized basic powder feeding mechanisms with limited control parameters, resulting in components with inconsistent material properties and dimensional accuracy. These early systems primarily focused on rapid prototyping rather than production of flight-critical aerospace components.

By the early 2000s, DED technology experienced its first major advancement with the integration of closed-loop control systems that monitored and adjusted process parameters in real-time. This development marked a crucial turning point, enabling manufacturers to achieve more consistent material deposition and improved mechanical properties. Concurrently, the aerospace industry began recognizing DED's potential for repair applications, particularly for high-value turbine components.

The period between 2010 and 2015 witnessed the emergence of multi-material DED capabilities, allowing for functionally graded materials and strategic material placement within a single component. This innovation addressed the aerospace industry's demand for components with location-specific material properties, such as heat resistance at specific areas while maintaining overall structural integrity. During this phase, aerospace manufacturers began implementing DED for limited production of non-critical components and repair operations.

Recent technological breakthroughs (2016-present) have centered on precision enhancement through advanced monitoring systems incorporating machine learning algorithms. These systems analyze thermal signatures, melt pool dynamics, and deposition patterns to predict and prevent defects before they occur. The integration of five-axis motion systems with DED has further expanded geometric capabilities, enabling the fabrication of complex aerospace components with internal features previously impossible to manufacture.

In contemporary aerospace applications, DED technology has found particular success in three key areas: repair and refurbishment of high-value components like turbine blades and structural elements; rapid prototyping of complex geometries for testing and validation; and production of specialized components with gradient material properties. Leading aerospace manufacturers have reported 30-50% reductions in lead times for certain components and up to 60% material savings compared to traditional manufacturing methods.

The trajectory of DED technology continues toward higher precision, multi-material capabilities, and integration with complementary manufacturing processes. As aerospace requirements become increasingly demanding, DED systems are evolving to incorporate higher energy efficiency, finer resolution deposition, and expanded material compatibility, particularly with high-performance alloys and composites essential to next-generation aircraft and spacecraft designs.

By the early 2000s, DED technology experienced its first major advancement with the integration of closed-loop control systems that monitored and adjusted process parameters in real-time. This development marked a crucial turning point, enabling manufacturers to achieve more consistent material deposition and improved mechanical properties. Concurrently, the aerospace industry began recognizing DED's potential for repair applications, particularly for high-value turbine components.

The period between 2010 and 2015 witnessed the emergence of multi-material DED capabilities, allowing for functionally graded materials and strategic material placement within a single component. This innovation addressed the aerospace industry's demand for components with location-specific material properties, such as heat resistance at specific areas while maintaining overall structural integrity. During this phase, aerospace manufacturers began implementing DED for limited production of non-critical components and repair operations.

Recent technological breakthroughs (2016-present) have centered on precision enhancement through advanced monitoring systems incorporating machine learning algorithms. These systems analyze thermal signatures, melt pool dynamics, and deposition patterns to predict and prevent defects before they occur. The integration of five-axis motion systems with DED has further expanded geometric capabilities, enabling the fabrication of complex aerospace components with internal features previously impossible to manufacture.

In contemporary aerospace applications, DED technology has found particular success in three key areas: repair and refurbishment of high-value components like turbine blades and structural elements; rapid prototyping of complex geometries for testing and validation; and production of specialized components with gradient material properties. Leading aerospace manufacturers have reported 30-50% reductions in lead times for certain components and up to 60% material savings compared to traditional manufacturing methods.

The trajectory of DED technology continues toward higher precision, multi-material capabilities, and integration with complementary manufacturing processes. As aerospace requirements become increasingly demanding, DED systems are evolving to incorporate higher energy efficiency, finer resolution deposition, and expanded material compatibility, particularly with high-performance alloys and composites essential to next-generation aircraft and spacecraft designs.

Aerospace Market Demand for Advanced Additive Manufacturing

The aerospace industry is experiencing a significant shift towards advanced manufacturing technologies, with additive manufacturing (AM) emerging as a critical enabler for next-generation aircraft and spacecraft components. Market analysis indicates that the global aerospace AM market is projected to grow at a compound annual growth rate of 20.3% through 2028, reaching approximately 9.5 billion USD by that time.

This robust growth is primarily driven by increasing demand for lightweight components that can enhance fuel efficiency and reduce emissions in commercial aviation. Airlines and aircraft manufacturers face mounting pressure to meet stringent environmental regulations while optimizing operational costs. Advanced AM technologies like Directed Energy Deposition (DED) directly address these challenges by enabling the production of complex geometries with reduced material waste.

Defense aerospace applications represent another substantial market segment, with military contractors seeking rapid prototyping capabilities and on-demand manufacturing solutions for critical components. The ability to quickly produce replacement parts in remote locations using DED technology offers strategic advantages that traditional manufacturing cannot match.

Space exploration presents perhaps the most promising frontier for advanced AM adoption. Companies like SpaceX, Blue Origin, and established players such as Boeing and Lockheed Martin are investing heavily in AM capabilities to produce rocket engines, propulsion systems, and structural components. The extreme operating conditions of space applications demand materials and manufacturing processes that can deliver exceptional performance while minimizing weight—precisely the value proposition that DED technology offers.

Market research indicates that approximately 70% of aerospace manufacturers have already implemented some form of additive manufacturing in their operations, with 35% specifically utilizing directed energy processes. This adoption rate is expected to accelerate as the technology matures and demonstrates consistent quality and reliability in flight-critical applications.

Regional analysis shows North America leading the aerospace AM market with 42% market share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region is experiencing the fastest growth rate as countries like China, Japan, and Singapore make strategic investments in advanced manufacturing capabilities for their aerospace sectors.

Customer requirements driving market demand include shorter lead times for complex components, ability to produce parts with integrated functionality, material optimization for specific performance characteristics, and cost reduction through design optimization and reduced material waste. DED technology specifically addresses these needs through its ability to create near-net-shape components with excellent mechanical properties and material efficiency.

This robust growth is primarily driven by increasing demand for lightweight components that can enhance fuel efficiency and reduce emissions in commercial aviation. Airlines and aircraft manufacturers face mounting pressure to meet stringent environmental regulations while optimizing operational costs. Advanced AM technologies like Directed Energy Deposition (DED) directly address these challenges by enabling the production of complex geometries with reduced material waste.

Defense aerospace applications represent another substantial market segment, with military contractors seeking rapid prototyping capabilities and on-demand manufacturing solutions for critical components. The ability to quickly produce replacement parts in remote locations using DED technology offers strategic advantages that traditional manufacturing cannot match.

Space exploration presents perhaps the most promising frontier for advanced AM adoption. Companies like SpaceX, Blue Origin, and established players such as Boeing and Lockheed Martin are investing heavily in AM capabilities to produce rocket engines, propulsion systems, and structural components. The extreme operating conditions of space applications demand materials and manufacturing processes that can deliver exceptional performance while minimizing weight—precisely the value proposition that DED technology offers.

Market research indicates that approximately 70% of aerospace manufacturers have already implemented some form of additive manufacturing in their operations, with 35% specifically utilizing directed energy processes. This adoption rate is expected to accelerate as the technology matures and demonstrates consistent quality and reliability in flight-critical applications.

Regional analysis shows North America leading the aerospace AM market with 42% market share, followed by Europe at 31% and Asia-Pacific at 22%. However, the Asia-Pacific region is experiencing the fastest growth rate as countries like China, Japan, and Singapore make strategic investments in advanced manufacturing capabilities for their aerospace sectors.

Customer requirements driving market demand include shorter lead times for complex components, ability to produce parts with integrated functionality, material optimization for specific performance characteristics, and cost reduction through design optimization and reduced material waste. DED technology specifically addresses these needs through its ability to create near-net-shape components with excellent mechanical properties and material efficiency.

Current DED Capabilities and Technical Limitations

Directed Energy Deposition (DED) technology has evolved significantly in recent years, establishing itself as a viable manufacturing process for aerospace applications. Current DED systems can achieve deposition rates ranging from 0.5 to 4 kg/hour, significantly faster than powder bed fusion processes, making it suitable for larger aerospace components. The dimensional accuracy of modern DED systems typically ranges from ±0.2mm to ±0.5mm, with surface roughness values between 10-25 μm Ra, depending on process parameters and materials.

Material versatility represents one of DED's key strengths in aerospace applications. Contemporary systems can process a wide range of aerospace-grade materials including titanium alloys (Ti-6Al-4V), nickel-based superalloys (Inconel 718, 625), aluminum alloys, and specialized steels. Multi-material capabilities have also emerged, allowing for functionally graded components that optimize weight, strength, and thermal properties simultaneously.

Despite these advancements, DED technology faces several significant technical limitations. Thermal management remains a critical challenge, as the high-energy input creates residual stresses and potential distortion in aerospace components. Current thermal monitoring systems provide feedback but often lack the predictive capabilities needed for aerospace-grade quality assurance. The resulting microstructural variations can lead to inconsistent mechanical properties throughout a single component.

Resolution and surface finish limitations persist as obstacles to wider adoption. While DED excels at building larger structures, it struggles with fine features below 0.5mm, necessitating post-processing operations that add time and cost to production. Surface roughness often requires extensive machining to meet aerospace specifications, reducing the net material efficiency advantage of the additive approach.

Process stability and repeatability present ongoing challenges for aerospace certification. Current DED systems exhibit parameter sensitivity that can lead to build-to-build variations, particularly problematic for safety-critical aerospace components. In-process monitoring capabilities, while improving, still lack the comprehensive defect detection required for aerospace quality standards.

Material efficiency in DED systems has improved but typically ranges from 70-95%, with material waste occurring primarily through overspray. This represents an improvement over traditional subtractive manufacturing but falls short of the theoretical material utilization potential. Additionally, build envelope constraints (typically 1-2 cubic meters for industrial systems) limit the size of single-piece components, requiring assembly of larger aerospace structures.

Material versatility represents one of DED's key strengths in aerospace applications. Contemporary systems can process a wide range of aerospace-grade materials including titanium alloys (Ti-6Al-4V), nickel-based superalloys (Inconel 718, 625), aluminum alloys, and specialized steels. Multi-material capabilities have also emerged, allowing for functionally graded components that optimize weight, strength, and thermal properties simultaneously.

Despite these advancements, DED technology faces several significant technical limitations. Thermal management remains a critical challenge, as the high-energy input creates residual stresses and potential distortion in aerospace components. Current thermal monitoring systems provide feedback but often lack the predictive capabilities needed for aerospace-grade quality assurance. The resulting microstructural variations can lead to inconsistent mechanical properties throughout a single component.

Resolution and surface finish limitations persist as obstacles to wider adoption. While DED excels at building larger structures, it struggles with fine features below 0.5mm, necessitating post-processing operations that add time and cost to production. Surface roughness often requires extensive machining to meet aerospace specifications, reducing the net material efficiency advantage of the additive approach.

Process stability and repeatability present ongoing challenges for aerospace certification. Current DED systems exhibit parameter sensitivity that can lead to build-to-build variations, particularly problematic for safety-critical aerospace components. In-process monitoring capabilities, while improving, still lack the comprehensive defect detection required for aerospace quality standards.

Material efficiency in DED systems has improved but typically ranges from 70-95%, with material waste occurring primarily through overspray. This represents an improvement over traditional subtractive manufacturing but falls short of the theoretical material utilization potential. Additionally, build envelope constraints (typically 1-2 cubic meters for industrial systems) limit the size of single-piece components, requiring assembly of larger aerospace structures.

Current DED Implementation Strategies

01 Process parameter optimization for DED precision

Optimizing process parameters such as laser power, scanning speed, powder feed rate, and layer thickness is crucial for achieving high precision in Directed Energy Deposition. These parameters directly influence the melt pool dynamics, material deposition accuracy, and resulting microstructure. Advanced control systems can monitor and adjust these parameters in real-time to maintain consistent deposition quality and dimensional accuracy throughout the build process.- Process parameter optimization for DED precision: Optimizing process parameters is crucial for achieving high precision in Directed Energy Deposition (DED). Parameters such as laser power, scanning speed, powder feed rate, and layer thickness significantly impact the dimensional accuracy and surface quality of the fabricated parts. Advanced control systems can monitor and adjust these parameters in real-time to maintain consistent deposition quality and precision throughout the build process.

- Advanced monitoring and feedback systems: Integration of sophisticated monitoring and feedback systems enhances the precision of Directed Energy Deposition processes. These systems utilize sensors, cameras, and other measurement devices to track the melt pool dynamics, deposition height, and thermal conditions during fabrication. Real-time data collection enables closed-loop control that can make immediate adjustments to maintain dimensional accuracy and prevent defects, significantly improving the overall precision of the DED process.

- Multi-axis deposition strategies: Multi-axis deposition strategies enable the fabrication of complex geometries with enhanced precision in Directed Energy Deposition. By utilizing 5-axis or 6-axis motion systems, the deposition head can be oriented optimally relative to the build surface, maintaining consistent standoff distance and deposition angle. This approach minimizes the need for support structures, reduces material waste, and improves the accuracy of overhanging features and intricate details in the final part.

- Material-specific deposition techniques: Developing material-specific deposition techniques is essential for achieving high precision in Directed Energy Deposition processes. Different materials exhibit varying thermal properties, melting behaviors, and solidification characteristics that affect the deposition precision. Tailored processing parameters and specialized nozzle designs can be implemented for specific materials or material combinations to optimize flow dynamics, minimize thermal distortion, and enhance the dimensional accuracy of the fabricated components.

- Hybrid manufacturing approaches: Hybrid manufacturing approaches combine Directed Energy Deposition with subtractive machining processes to achieve superior precision. In these systems, DED is used for material addition, while integrated milling, grinding, or other machining operations are performed intermittently to correct dimensional inaccuracies and improve surface finish. This combination leverages the flexibility of additive manufacturing while maintaining the precision of traditional machining, resulting in components with tight tolerances and excellent surface quality.

02 Advanced monitoring and feedback systems

Integration of real-time monitoring systems with closed-loop feedback control significantly enhances DED precision. These systems utilize sensors, cameras, and thermal imaging to continuously monitor the deposition process, detecting variations in melt pool geometry, temperature distribution, and build quality. When deviations are detected, the system automatically adjusts process parameters to maintain precision, reducing defects and ensuring dimensional accuracy of the fabricated components.Expand Specific Solutions03 Multi-axis deposition strategies

Implementing multi-axis deposition strategies allows for complex geometries to be built with higher precision. By utilizing 5-axis or 6-axis motion systems, the DED process can deposit material from optimal angles, reducing the need for support structures and enabling the fabrication of overhanging features. This approach minimizes material waste, improves surface finish, and enhances the overall dimensional accuracy of printed components.Expand Specific Solutions04 Material-specific deposition strategies

Developing material-specific deposition strategies is essential for achieving high precision in DED processes. Different materials exhibit varying thermal properties, solidification behaviors, and susceptibility to defects. By tailoring process parameters, nozzle designs, and thermal management techniques to specific materials or alloys, manufacturers can optimize deposition precision, reduce thermal distortion, and improve microstructural control in the final components.Expand Specific Solutions05 Hybrid manufacturing approaches

Combining DED with subtractive manufacturing processes in hybrid systems significantly enhances precision capabilities. These systems integrate additive deposition with in-process machining, allowing for periodic material removal to achieve tight tolerances and superior surface finishes. The hybrid approach enables the correction of geometric deviations during the build process, resulting in higher dimensional accuracy and improved mechanical properties of the final components.Expand Specific Solutions

Leading Companies in Aerospace DED Manufacturing

Directed Energy Deposition (DED) technology for aerospace precision fabrication is currently in a growth phase, with the market expanding as adoption increases across major aerospace manufacturers. The global market size for DED in aerospace applications is projected to grow significantly due to increasing demand for lightweight, complex components with reduced lead times. Technologically, the field shows varying maturity levels among key players. Industry leaders like GE Avio, RTX Corp, and Lockheed Martin have achieved advanced implementation, while Airbus Operations and Safran Aircraft Engines are rapidly advancing their capabilities. Academic institutions, particularly Huazhong University of Science & Technology and Tsinghua University, are driving fundamental research innovations. Companies like Norsk Titanium and Arevo are developing specialized DED applications, creating a competitive landscape balanced between established aerospace giants and innovative technology specialists.

GE Avio Srl

Technical Solution: GE Avio has developed advanced DED systems specifically tailored for aerospace components manufacturing, focusing on their DMLM (Direct Metal Laser Melting) technology. Their approach combines high-power fiber lasers with precise powder delivery systems to create complex aerospace components with internal cooling channels and optimized geometries. The company has implemented a closed-loop monitoring system that uses thermal imaging cameras to track melt pool dynamics in real-time, allowing for microstructure control and defect prevention. GE Avio's DED technology enables the fabrication of large structural components for aircraft engines with titanium and nickel-based superalloys, achieving near-net shape production with minimal post-processing requirements. Their process incorporates multi-axis deposition capabilities that allow for building components without support structures, significantly reducing material waste and manufacturing time.

Strengths: Superior capability for producing complex internal geometries in engine components; integrated quality control systems that ensure aerospace-grade reliability; ability to process difficult-to-machine superalloys. Weaknesses: Higher initial equipment investment compared to conventional manufacturing; requires specialized operator training; limited material options compared to some competing technologies.

RTX Corp.

Technical Solution: RTX Corp. (formerly Raytheon Technologies) has pioneered a hybrid DED approach called EBAM (Electron Beam Additive Manufacturing) for aerospace applications. Their system utilizes electron beam technology rather than lasers, operating in a vacuum environment to prevent oxidation when working with reactive metals like titanium. RTX's process features a dual-wire feed system that enables the simultaneous deposition of different materials, creating functionally graded components that optimize weight-to-strength ratios for aircraft structures. The company has developed proprietary thermal management algorithms that control residual stress formation during deposition, resulting in parts with superior mechanical properties and dimensional accuracy. RTX's DED technology has been successfully implemented for in-situ repair of high-value aerospace components, extending the service life of critical parts and reducing maintenance costs for aircraft operators.

Strengths: Vacuum-based process provides superior results with reactive metals; ability to create functionally graded materials; excellent for repair applications that extend component lifecycle. Weaknesses: Slower deposition rates compared to some laser-based systems; vacuum chamber size limits maximum part dimensions; higher energy consumption than competing technologies.

Key Patents and Innovations in DED Technology

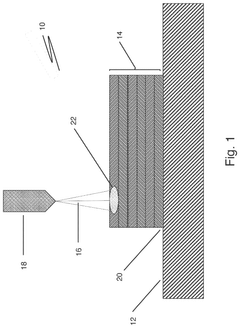

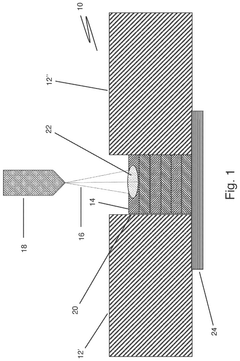

Engineered microstructure for enhanced performance during directed energy deposition repair process

PatentPendingUS20250242410A1

Innovation

- A directed energy deposition (DED) process is used to control the microstructure of each repair layer by adjusting parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling, ensuring each layer has a pre-determined microstructure to meet specific structural and functional needs.

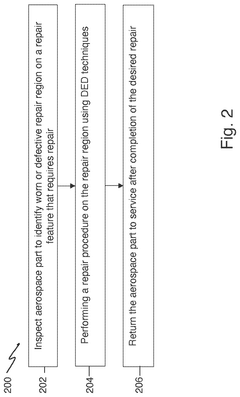

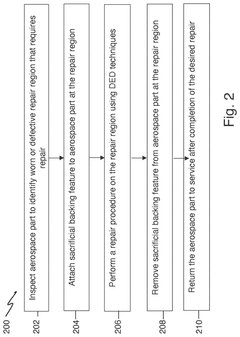

Use of sacrificial surface during directed energy deposition repair process

PatentPendingUS20250242409A1

Innovation

- The use of a sacrificial backing feature attached to the aerospace component provides a platform for DED repair, allowing the deposition of layers with controlled residual stress state and microstructure, using DED process parameters like powder feed rate, energy intensity, traversal rate, and auxiliary heating/cooling to extend the repair across sections and through holes.

Material Compatibility and Qualification Standards

Material compatibility represents a critical challenge in the implementation of Directed Energy Deposition (DED) for aerospace applications. The aerospace industry demands materials that can withstand extreme conditions while maintaining structural integrity and performance characteristics. Currently, qualification standards for DED-processed materials vary significantly across different regulatory bodies, creating inconsistencies in material validation protocols. The FAA, EASA, and other aerospace authorities have established preliminary frameworks, but comprehensive standardization remains under development.

The compatibility of different metal alloys with DED processes presents unique challenges. Titanium alloys (Ti-6Al-4V), widely used in aerospace components, demonstrate excellent processability through DED but require strict atmospheric controls to prevent oxygen contamination. Nickel-based superalloys, essential for high-temperature applications, exhibit complex solidification behaviors during deposition, necessitating precise parameter control to achieve desired microstructural properties. Aluminum alloys, despite their lightweight advantages, present significant challenges due to high reflectivity and thermal conductivity.

Material qualification standards for DED processes must address multiple dimensions of material performance. Mechanical property testing protocols typically include tensile strength, fatigue resistance, and fracture toughness evaluations across different build orientations to account for anisotropic behavior. Microstructural analysis requirements focus on grain structure, porosity levels, and phase composition, with aerospace standards generally permitting less than 1% porosity in critical components. Non-destructive testing methodologies, including CT scanning and ultrasonic inspection, have been adapted specifically for DED-manufactured parts but require further refinement.

Thermal post-processing represents another critical aspect of material qualification. Hot Isostatic Pressing (HIP) treatments have become standard practice for many DED aerospace components to eliminate internal porosity and homogenize microstructure. Heat treatment protocols must be tailored to specific alloy systems and component geometries to achieve optimal property profiles. Surface finishing requirements present additional challenges, as DED-produced parts typically exhibit rougher surface characteristics than traditionally manufactured components.

Interlayer material compatibility issues emerge when creating multi-material or functionally graded components. The formation of brittle intermetallic phases at material interfaces can compromise structural integrity. Research into transition zone composition control and gradient deposition strategies has shown promising results in mitigating these challenges, particularly for titanium-to-steel and aluminum-to-copper transitions commonly required in aerospace applications.

The compatibility of different metal alloys with DED processes presents unique challenges. Titanium alloys (Ti-6Al-4V), widely used in aerospace components, demonstrate excellent processability through DED but require strict atmospheric controls to prevent oxygen contamination. Nickel-based superalloys, essential for high-temperature applications, exhibit complex solidification behaviors during deposition, necessitating precise parameter control to achieve desired microstructural properties. Aluminum alloys, despite their lightweight advantages, present significant challenges due to high reflectivity and thermal conductivity.

Material qualification standards for DED processes must address multiple dimensions of material performance. Mechanical property testing protocols typically include tensile strength, fatigue resistance, and fracture toughness evaluations across different build orientations to account for anisotropic behavior. Microstructural analysis requirements focus on grain structure, porosity levels, and phase composition, with aerospace standards generally permitting less than 1% porosity in critical components. Non-destructive testing methodologies, including CT scanning and ultrasonic inspection, have been adapted specifically for DED-manufactured parts but require further refinement.

Thermal post-processing represents another critical aspect of material qualification. Hot Isostatic Pressing (HIP) treatments have become standard practice for many DED aerospace components to eliminate internal porosity and homogenize microstructure. Heat treatment protocols must be tailored to specific alloy systems and component geometries to achieve optimal property profiles. Surface finishing requirements present additional challenges, as DED-produced parts typically exhibit rougher surface characteristics than traditionally manufactured components.

Interlayer material compatibility issues emerge when creating multi-material or functionally graded components. The formation of brittle intermetallic phases at material interfaces can compromise structural integrity. Research into transition zone composition control and gradient deposition strategies has shown promising results in mitigating these challenges, particularly for titanium-to-steel and aluminum-to-copper transitions commonly required in aerospace applications.

Cost-Benefit Analysis of DED vs Traditional Manufacturing

When evaluating the economic viability of Directed Energy Deposition (DED) technology for aerospace applications, a comprehensive cost-benefit analysis reveals significant advantages over traditional manufacturing methods, despite certain initial barriers to adoption.

The capital investment for DED systems ranges from $500,000 to $2 million, depending on system capabilities and specifications. While this represents a substantial upfront cost compared to conventional CNC machining centers, the long-term economic benefits become apparent when analyzing the total cost of ownership over a 5-10 year operational period.

Material utilization represents one of the most compelling economic advantages of DED technology. Traditional subtractive manufacturing methods typically result in material waste rates of 70-90% for complex aerospace components, whereas DED processes achieve material utilization rates of 90-95%. For high-value aerospace alloys such as titanium ($200-400/kg) and nickel-based superalloys ($300-500/kg), this reduction in material waste translates to cost savings of $100,000-$500,000 annually for medium-volume production facilities.

Production efficiency metrics further strengthen the economic case for DED implementation. Lead times for complex aerospace components can be reduced by 40-60% compared to traditional manufacturing routes. This acceleration is particularly valuable for low-volume, high-mix production environments typical in aerospace manufacturing, where rapid prototyping and iterative design processes are essential.

Maintenance and operational costs present a more nuanced picture. DED systems require specialized training and maintenance protocols, with annual maintenance costs typically representing 8-12% of the initial system investment. However, these costs are partially offset by reduced tooling expenses, as DED processes eliminate the need for specialized fixtures and cutting tools required in conventional manufacturing.

Quality assurance and certification processes represent a significant cost factor in aerospace manufacturing. While DED technologies require investment in new inspection protocols and certification procedures, the ability to integrate in-situ monitoring systems provides opportunities for real-time quality control, potentially reducing overall quality-related costs by 15-25% compared to traditional inspection-intensive manufacturing approaches.

Energy consumption analysis reveals that DED processes typically consume 30-50% less energy than conventional manufacturing for equivalent components, particularly when considering the entire production chain from raw material to finished product. This translates to both direct cost savings and improved sustainability metrics, an increasingly important consideration in aerospace manufacturing.

The capital investment for DED systems ranges from $500,000 to $2 million, depending on system capabilities and specifications. While this represents a substantial upfront cost compared to conventional CNC machining centers, the long-term economic benefits become apparent when analyzing the total cost of ownership over a 5-10 year operational period.

Material utilization represents one of the most compelling economic advantages of DED technology. Traditional subtractive manufacturing methods typically result in material waste rates of 70-90% for complex aerospace components, whereas DED processes achieve material utilization rates of 90-95%. For high-value aerospace alloys such as titanium ($200-400/kg) and nickel-based superalloys ($300-500/kg), this reduction in material waste translates to cost savings of $100,000-$500,000 annually for medium-volume production facilities.

Production efficiency metrics further strengthen the economic case for DED implementation. Lead times for complex aerospace components can be reduced by 40-60% compared to traditional manufacturing routes. This acceleration is particularly valuable for low-volume, high-mix production environments typical in aerospace manufacturing, where rapid prototyping and iterative design processes are essential.

Maintenance and operational costs present a more nuanced picture. DED systems require specialized training and maintenance protocols, with annual maintenance costs typically representing 8-12% of the initial system investment. However, these costs are partially offset by reduced tooling expenses, as DED processes eliminate the need for specialized fixtures and cutting tools required in conventional manufacturing.

Quality assurance and certification processes represent a significant cost factor in aerospace manufacturing. While DED technologies require investment in new inspection protocols and certification procedures, the ability to integrate in-situ monitoring systems provides opportunities for real-time quality control, potentially reducing overall quality-related costs by 15-25% compared to traditional inspection-intensive manufacturing approaches.

Energy consumption analysis reveals that DED processes typically consume 30-50% less energy than conventional manufacturing for equivalent components, particularly when considering the entire production chain from raw material to finished product. This translates to both direct cost savings and improved sustainability metrics, an increasingly important consideration in aerospace manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!