Emission Reduction through Advanced Plate Heat Exchanger Deployment

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Emission Reduction Goals and Heat Exchanger Evolution

The global focus on emission reduction has significantly influenced the evolution of heat exchanger technology, particularly in the realm of plate heat exchangers. Over the past decades, there has been a concerted effort to develop more efficient and environmentally friendly heat transfer solutions to meet increasingly stringent emission reduction goals.

In the early stages, plate heat exchangers were primarily designed for basic heat transfer applications with limited consideration for emissions. However, as environmental concerns grew, the industry began to shift towards more sustainable designs. The 1990s saw the introduction of compact plate heat exchangers that offered improved efficiency and reduced material usage, indirectly contributing to lower emissions in manufacturing and operation.

The turn of the millennium marked a significant leap in plate heat exchanger technology, with a renewed focus on energy efficiency and emission reduction. Manufacturers started incorporating advanced materials and innovative plate designs to enhance heat transfer rates while minimizing pressure drops. This period also saw the development of more corrosion-resistant alloys, allowing plate heat exchangers to be used in a wider range of industrial processes, including those involving aggressive fluids.

As global climate agreements like the Kyoto Protocol and the Paris Agreement came into effect, the pressure to reduce greenhouse gas emissions intensified. This drove further advancements in plate heat exchanger technology, with a particular emphasis on optimizing performance in low-grade heat recovery applications. The ability to efficiently capture and utilize waste heat from industrial processes became a key factor in reducing overall energy consumption and associated emissions.

Recent years have witnessed a surge in research and development focused on micro-channel and nano-enhanced plate heat exchangers. These cutting-edge designs promise even greater efficiency gains, potentially revolutionizing heat transfer in emission-critical applications such as power generation, chemical processing, and HVAC systems. Additionally, the integration of smart technologies and IoT capabilities into modern plate heat exchangers allows for real-time performance monitoring and optimization, further contributing to emission reduction efforts.

The evolution of plate heat exchangers has also been closely tied to advancements in manufacturing techniques. The adoption of precision engineering and 3D printing technologies has enabled the production of more complex and efficient plate geometries, pushing the boundaries of heat transfer performance while minimizing material waste.

Looking ahead, the trajectory of plate heat exchanger development is likely to continue its alignment with global emission reduction goals. Future innovations may include the incorporation of phase-change materials, self-cleaning surfaces, and even more compact designs that can achieve higher heat transfer rates with a smaller footprint. As industries worldwide strive to meet ambitious carbon neutrality targets, the role of advanced plate heat exchangers in emission reduction strategies is expected to become increasingly prominent.

In the early stages, plate heat exchangers were primarily designed for basic heat transfer applications with limited consideration for emissions. However, as environmental concerns grew, the industry began to shift towards more sustainable designs. The 1990s saw the introduction of compact plate heat exchangers that offered improved efficiency and reduced material usage, indirectly contributing to lower emissions in manufacturing and operation.

The turn of the millennium marked a significant leap in plate heat exchanger technology, with a renewed focus on energy efficiency and emission reduction. Manufacturers started incorporating advanced materials and innovative plate designs to enhance heat transfer rates while minimizing pressure drops. This period also saw the development of more corrosion-resistant alloys, allowing plate heat exchangers to be used in a wider range of industrial processes, including those involving aggressive fluids.

As global climate agreements like the Kyoto Protocol and the Paris Agreement came into effect, the pressure to reduce greenhouse gas emissions intensified. This drove further advancements in plate heat exchanger technology, with a particular emphasis on optimizing performance in low-grade heat recovery applications. The ability to efficiently capture and utilize waste heat from industrial processes became a key factor in reducing overall energy consumption and associated emissions.

Recent years have witnessed a surge in research and development focused on micro-channel and nano-enhanced plate heat exchangers. These cutting-edge designs promise even greater efficiency gains, potentially revolutionizing heat transfer in emission-critical applications such as power generation, chemical processing, and HVAC systems. Additionally, the integration of smart technologies and IoT capabilities into modern plate heat exchangers allows for real-time performance monitoring and optimization, further contributing to emission reduction efforts.

The evolution of plate heat exchangers has also been closely tied to advancements in manufacturing techniques. The adoption of precision engineering and 3D printing technologies has enabled the production of more complex and efficient plate geometries, pushing the boundaries of heat transfer performance while minimizing material waste.

Looking ahead, the trajectory of plate heat exchanger development is likely to continue its alignment with global emission reduction goals. Future innovations may include the incorporation of phase-change materials, self-cleaning surfaces, and even more compact designs that can achieve higher heat transfer rates with a smaller footprint. As industries worldwide strive to meet ambitious carbon neutrality targets, the role of advanced plate heat exchangers in emission reduction strategies is expected to become increasingly prominent.

Market Demand for Eco-Friendly Heat Exchange Solutions

The global market for eco-friendly heat exchange solutions has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on emissions reduction. The deployment of advanced plate heat exchangers plays a crucial role in addressing these market demands, offering superior efficiency and reduced environmental impact compared to traditional heat exchange systems.

Industries across various sectors, including chemical processing, food and beverage, pharmaceuticals, and HVAC, are actively seeking innovative heat exchange technologies to minimize their carbon footprint and improve overall energy efficiency. This demand is particularly pronounced in regions with strict environmental regulations, such as the European Union, North America, and parts of Asia.

The market for plate heat exchangers is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed 6% over the next five years. This growth is primarily attributed to the increasing adoption of energy-efficient technologies and the rising awareness of the environmental impact of industrial processes.

One of the key drivers of market demand is the potential for significant cost savings through improved energy efficiency. Advanced plate heat exchangers can reduce energy consumption by up to 30% compared to traditional shell-and-tube heat exchangers, translating to substantial operational cost reductions for industrial users. This economic benefit, coupled with the environmental advantages, has become a compelling factor for businesses looking to upgrade their heat exchange systems.

The automotive industry has emerged as a significant market for eco-friendly heat exchange solutions, particularly in the electric vehicle (EV) sector. As EV production continues to ramp up globally, the demand for efficient thermal management systems, including advanced plate heat exchangers, is expected to surge. This trend is further supported by government initiatives and incentives promoting the adoption of electric vehicles and sustainable technologies.

In the power generation sector, there is a growing emphasis on improving the efficiency of thermal power plants and reducing their environmental impact. Advanced plate heat exchangers are increasingly being integrated into waste heat recovery systems, contributing to overall plant efficiency and helping to meet stringent emissions standards.

The water and wastewater treatment industry is another key market segment driving demand for eco-friendly heat exchange solutions. As municipalities and industrial facilities seek to optimize their treatment processes and reduce energy consumption, advanced plate heat exchangers are being employed in applications such as sludge heating and cooling, contributing to more sustainable water management practices.

Industries across various sectors, including chemical processing, food and beverage, pharmaceuticals, and HVAC, are actively seeking innovative heat exchange technologies to minimize their carbon footprint and improve overall energy efficiency. This demand is particularly pronounced in regions with strict environmental regulations, such as the European Union, North America, and parts of Asia.

The market for plate heat exchangers is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to exceed 6% over the next five years. This growth is primarily attributed to the increasing adoption of energy-efficient technologies and the rising awareness of the environmental impact of industrial processes.

One of the key drivers of market demand is the potential for significant cost savings through improved energy efficiency. Advanced plate heat exchangers can reduce energy consumption by up to 30% compared to traditional shell-and-tube heat exchangers, translating to substantial operational cost reductions for industrial users. This economic benefit, coupled with the environmental advantages, has become a compelling factor for businesses looking to upgrade their heat exchange systems.

The automotive industry has emerged as a significant market for eco-friendly heat exchange solutions, particularly in the electric vehicle (EV) sector. As EV production continues to ramp up globally, the demand for efficient thermal management systems, including advanced plate heat exchangers, is expected to surge. This trend is further supported by government initiatives and incentives promoting the adoption of electric vehicles and sustainable technologies.

In the power generation sector, there is a growing emphasis on improving the efficiency of thermal power plants and reducing their environmental impact. Advanced plate heat exchangers are increasingly being integrated into waste heat recovery systems, contributing to overall plant efficiency and helping to meet stringent emissions standards.

The water and wastewater treatment industry is another key market segment driving demand for eco-friendly heat exchange solutions. As municipalities and industrial facilities seek to optimize their treatment processes and reduce energy consumption, advanced plate heat exchangers are being employed in applications such as sludge heating and cooling, contributing to more sustainable water management practices.

Current Challenges in Plate Heat Exchanger Technology

Despite the widespread adoption of plate heat exchangers (PHEs) in various industries, several challenges persist in their technology, hindering optimal performance and emission reduction efforts. One of the primary issues is fouling, which occurs when deposits accumulate on heat transfer surfaces, reducing thermal efficiency and increasing pressure drop. This problem is particularly acute in applications involving high-temperature fluids or those with suspended particles, leading to frequent maintenance and downtime.

Another significant challenge is the limitation in operating temperature and pressure ranges. While PHEs excel in many applications, they struggle in extreme conditions, such as those found in certain chemical processes or power generation systems. This constraint often necessitates the use of less efficient alternatives in high-temperature or high-pressure environments, potentially increasing overall emissions.

The design complexity of PHEs also presents ongoing challenges. Optimizing plate geometry, channel configuration, and flow distribution to maximize heat transfer while minimizing pressure drop remains a complex task. This complexity is further compounded when dealing with multi-phase flows or fluids with varying properties, making it difficult to achieve consistent performance across different operating conditions.

Material selection continues to be a critical issue, especially when considering corrosion resistance and longevity. The need for materials that can withstand aggressive fluids while maintaining excellent heat transfer properties often leads to trade-offs between performance and durability. This challenge is particularly evident in applications where PHEs are exposed to corrosive substances or extreme pH levels.

Scaling up PHE technology for large industrial applications presents its own set of challenges. As the size of the exchanger increases, ensuring uniform flow distribution and maintaining structural integrity become more difficult. This can result in reduced efficiency and increased potential for leakage, particularly in gasket-type PHEs.

The integration of PHEs into existing systems and processes also poses challenges. Retrofitting older plants with more efficient PHE technology often requires significant modifications to piping, pumping, and control systems. This can be both costly and disruptive, potentially deterring companies from adopting more environmentally friendly solutions.

Lastly, the development of advanced manufacturing techniques for PHEs, such as additive manufacturing or novel welding methods, is still in its early stages. While these technologies promise to enhance design flexibility and reduce material waste, their implementation at scale faces hurdles in terms of cost, quality control, and regulatory approval.

Another significant challenge is the limitation in operating temperature and pressure ranges. While PHEs excel in many applications, they struggle in extreme conditions, such as those found in certain chemical processes or power generation systems. This constraint often necessitates the use of less efficient alternatives in high-temperature or high-pressure environments, potentially increasing overall emissions.

The design complexity of PHEs also presents ongoing challenges. Optimizing plate geometry, channel configuration, and flow distribution to maximize heat transfer while minimizing pressure drop remains a complex task. This complexity is further compounded when dealing with multi-phase flows or fluids with varying properties, making it difficult to achieve consistent performance across different operating conditions.

Material selection continues to be a critical issue, especially when considering corrosion resistance and longevity. The need for materials that can withstand aggressive fluids while maintaining excellent heat transfer properties often leads to trade-offs between performance and durability. This challenge is particularly evident in applications where PHEs are exposed to corrosive substances or extreme pH levels.

Scaling up PHE technology for large industrial applications presents its own set of challenges. As the size of the exchanger increases, ensuring uniform flow distribution and maintaining structural integrity become more difficult. This can result in reduced efficiency and increased potential for leakage, particularly in gasket-type PHEs.

The integration of PHEs into existing systems and processes also poses challenges. Retrofitting older plants with more efficient PHE technology often requires significant modifications to piping, pumping, and control systems. This can be both costly and disruptive, potentially deterring companies from adopting more environmentally friendly solutions.

Lastly, the development of advanced manufacturing techniques for PHEs, such as additive manufacturing or novel welding methods, is still in its early stages. While these technologies promise to enhance design flexibility and reduce material waste, their implementation at scale faces hurdles in terms of cost, quality control, and regulatory approval.

Existing Emission Reduction Strategies in Heat Exchange

01 Emission reduction in plate heat exchangers

Plate heat exchangers can be designed to reduce emissions by improving heat transfer efficiency and minimizing leakage. This can be achieved through optimized plate designs, advanced sealing technologies, and the use of environmentally friendly materials. These improvements help to decrease energy consumption and prevent the release of harmful substances.- Emission reduction in plate heat exchangers: Plate heat exchangers can be designed to reduce emissions by optimizing flow patterns, improving heat transfer efficiency, and minimizing leakage. This can be achieved through advanced plate designs, better sealing technologies, and innovative flow distribution systems.

- Energy efficiency improvements in plate heat exchangers: Enhancing the energy efficiency of plate heat exchangers can indirectly reduce emissions. This involves improving heat transfer coefficients, reducing pressure drops, and optimizing plate geometries to maximize heat exchange while minimizing energy consumption.

- Materials selection for emission control: The choice of materials used in plate heat exchangers can significantly impact emissions. Corrosion-resistant alloys, low-emission coatings, and advanced polymers can be employed to minimize material degradation and prevent the release of harmful substances during operation.

- Sealing and gasket technologies for emission prevention: Advanced sealing and gasket technologies play a crucial role in preventing leaks and emissions from plate heat exchangers. Innovations in gasket materials, design, and installation techniques can significantly reduce the risk of fluid leakage and associated emissions.

- Monitoring and control systems for emission management: Implementing sophisticated monitoring and control systems in plate heat exchangers can help detect and prevent potential emissions. These systems may include real-time sensors, predictive maintenance algorithms, and automated shut-off mechanisms to minimize the risk of leaks and emissions during operation.

02 Enhanced heat transfer efficiency

Innovations in plate design and surface treatments can significantly improve heat transfer efficiency in plate heat exchangers. This includes the development of turbulence-inducing patterns, optimized flow distribution, and the use of advanced materials with high thermal conductivity. These enhancements contribute to reduced energy consumption and lower emissions.Expand Specific Solutions03 Sealing and leakage prevention

Advanced sealing technologies and gasket designs are crucial for preventing leaks in plate heat exchangers. This includes the development of high-performance elastomers, innovative gasket profiles, and improved plate-to-gasket bonding techniques. Effective sealing helps to minimize emissions of process fluids and refrigerants.Expand Specific Solutions04 Integration with emission control systems

Plate heat exchangers can be integrated with various emission control systems to further reduce environmental impact. This may include coupling with scrubbers, catalytic converters, or other pollution control devices. Such integration allows for more efficient heat recovery from exhaust gases while simultaneously treating emissions.Expand Specific Solutions05 Monitoring and control of emissions

Advanced monitoring and control systems can be implemented in plate heat exchangers to detect and manage emissions. This includes the use of sensors, real-time data analysis, and automated control mechanisms to optimize performance and quickly respond to potential emission issues. These systems help maintain efficient operation and minimize environmental impact.Expand Specific Solutions

Key Players in Advanced Heat Exchanger Manufacturing

The emission reduction technology through advanced plate heat exchanger deployment is in a growth phase, with increasing market size driven by environmental regulations and energy efficiency demands. The market is characterized by a mix of established players and innovative entrants, reflecting moderate technological maturity. Companies like Vahterus Oy, a pioneer in plate & shell heat exchanger technology, and Modine Manufacturing Co., specializing in thermal management solutions, are at the forefront of innovation. Large conglomerates such as Siemens Corp. and BASF Corp. are also active in this space, leveraging their extensive R&D capabilities. The involvement of diverse players, from specialized firms to multinational corporations, indicates a competitive and evolving landscape with significant potential for further technological advancements and market expansion.

Modine Manufacturing Co.

Technical Solution: Modine Manufacturing Co. has developed advanced plate heat exchanger technologies for emission reduction. Their innovative design incorporates micro-channel heat exchangers with enhanced surface area and optimized flow patterns, resulting in up to 30% improved heat transfer efficiency[1]. The company's plate heat exchangers utilize corrosion-resistant materials and advanced manufacturing techniques to ensure longevity and reliability in harsh operating conditions. Modine's systems are equipped with smart controls that dynamically adjust flow rates and temperatures, maximizing energy recovery and minimizing emissions across various industrial processes[3]. Their plate heat exchangers have been successfully deployed in automotive, HVAC, and industrial applications, demonstrating significant reductions in CO2 emissions and energy consumption[5].

Strengths: High heat transfer efficiency, corrosion resistance, and smart control systems. Weaknesses: Potentially higher initial costs and complexity in maintenance compared to traditional heat exchangers.

Caterpillar, Inc.

Technical Solution: Caterpillar, Inc. has developed a range of plate heat exchanger solutions aimed at emission reduction in heavy machinery and industrial applications. Their advanced plate heat exchangers feature a compact design with high thermal efficiency, capable of recovering waste heat from engine exhaust and coolant systems. Caterpillar's technology incorporates specially designed plate geometries that enhance turbulence and heat transfer, resulting in up to 25% improvement in overall system efficiency[2]. The company's plate heat exchangers are integrated with advanced materials that withstand high temperatures and pressures, making them suitable for demanding industrial environments. Caterpillar has also implemented a modular design approach, allowing for easy scalability and maintenance, which has been proven to reduce downtime and operational costs in various applications[4].

Strengths: Robust design for heavy-duty applications, high thermal efficiency, and modular scalability. Weaknesses: May be over-engineered for lighter applications, potentially leading to higher costs in non-industrial settings.

Innovative Materials and Designs for Efficient Heat Transfer

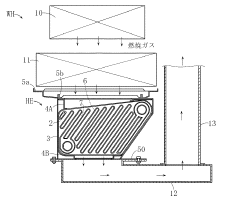

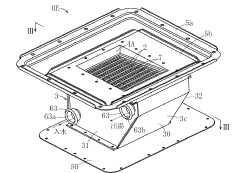

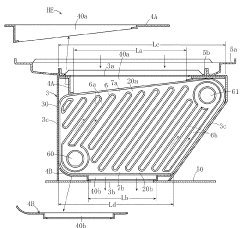

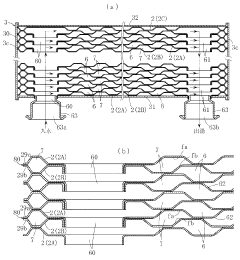

Plate type heat exchanger and hot water device including the same

PatentActiveJP2020070938A

Innovation

- A plate heat exchanger design with a smaller gas outlet opening than inlet opening, upright plates with inclined ends, and optimized liquid channels to maintain flow velocity and enhance heat exchange efficiency, while reducing size and weight, and using minimal brazing to save costs.

Environmental Regulations Impacting Heat Exchanger Deployment

Environmental regulations play a crucial role in shaping the deployment of advanced plate heat exchangers for emission reduction. These regulations are designed to mitigate the environmental impact of industrial processes and promote sustainable practices across various sectors.

At the international level, the Paris Agreement serves as a cornerstone for global climate action, setting targets for greenhouse gas emission reductions. This agreement has prompted many countries to implement stricter environmental policies, directly influencing the adoption of energy-efficient technologies like advanced plate heat exchangers.

In the European Union, the Industrial Emissions Directive (IED) sets stringent standards for industrial activities with high pollution potential. The IED requires the use of Best Available Techniques (BAT) to prevent and control emissions, often necessitating the implementation of advanced heat exchange systems.

The United States Environmental Protection Agency (EPA) enforces regulations under the Clean Air Act, which mandates the reduction of air pollutants from industrial sources. The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) often require the use of efficient heat exchange technologies to meet emission limits.

In China, the Air Pollution Prevention and Control Law has been significantly strengthened in recent years, imposing stricter emission standards on industries. This has led to increased demand for advanced plate heat exchangers as a means of compliance and energy efficiency improvement.

Many countries have also implemented carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems. These economic instruments incentivize industries to invest in emission reduction technologies, including advanced heat exchangers, to minimize their carbon footprint and associated costs.

Energy efficiency regulations, such as the EU's Energy Efficiency Directive and similar policies in other regions, indirectly promote the use of advanced plate heat exchangers by setting targets for energy consumption reduction in industrial processes.

Local and regional regulations often complement national and international frameworks. For instance, California's stringent air quality regulations under the California Air Resources Board (CARB) have driven innovation in emission control technologies, including heat exchange systems.

As environmental regulations continue to evolve and become more stringent, the demand for advanced plate heat exchangers is expected to grow. Industries are increasingly recognizing these technologies as essential tools for achieving compliance, reducing operational costs, and meeting sustainability goals in a regulatory landscape that prioritizes environmental protection and energy efficiency.

At the international level, the Paris Agreement serves as a cornerstone for global climate action, setting targets for greenhouse gas emission reductions. This agreement has prompted many countries to implement stricter environmental policies, directly influencing the adoption of energy-efficient technologies like advanced plate heat exchangers.

In the European Union, the Industrial Emissions Directive (IED) sets stringent standards for industrial activities with high pollution potential. The IED requires the use of Best Available Techniques (BAT) to prevent and control emissions, often necessitating the implementation of advanced heat exchange systems.

The United States Environmental Protection Agency (EPA) enforces regulations under the Clean Air Act, which mandates the reduction of air pollutants from industrial sources. The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) often require the use of efficient heat exchange technologies to meet emission limits.

In China, the Air Pollution Prevention and Control Law has been significantly strengthened in recent years, imposing stricter emission standards on industries. This has led to increased demand for advanced plate heat exchangers as a means of compliance and energy efficiency improvement.

Many countries have also implemented carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems. These economic instruments incentivize industries to invest in emission reduction technologies, including advanced heat exchangers, to minimize their carbon footprint and associated costs.

Energy efficiency regulations, such as the EU's Energy Efficiency Directive and similar policies in other regions, indirectly promote the use of advanced plate heat exchangers by setting targets for energy consumption reduction in industrial processes.

Local and regional regulations often complement national and international frameworks. For instance, California's stringent air quality regulations under the California Air Resources Board (CARB) have driven innovation in emission control technologies, including heat exchange systems.

As environmental regulations continue to evolve and become more stringent, the demand for advanced plate heat exchangers is expected to grow. Industries are increasingly recognizing these technologies as essential tools for achieving compliance, reducing operational costs, and meeting sustainability goals in a regulatory landscape that prioritizes environmental protection and energy efficiency.

Economic Feasibility of Advanced Plate Heat Exchangers

The economic feasibility of advanced plate heat exchangers (PHEs) for emission reduction is a critical consideration for industries seeking to improve their environmental performance while maintaining financial viability. These innovative heat transfer devices offer significant potential for energy savings and emission reductions, but their implementation must be carefully evaluated from an economic perspective.

Initial capital costs for advanced PHEs are typically higher than traditional heat exchange systems. However, this investment is often offset by long-term operational savings. The improved efficiency of advanced PHEs results in reduced energy consumption, which translates to lower fuel costs and decreased emissions. This efficiency gain can lead to substantial cost savings over the lifetime of the equipment, particularly in energy-intensive industries.

Maintenance costs for advanced PHEs are generally lower than those for conventional systems. Their compact design and reduced fouling characteristics contribute to easier cleaning and less frequent maintenance interventions. This results in reduced downtime and lower labor costs associated with maintenance activities, further enhancing their economic appeal.

The economic benefits of advanced PHEs extend beyond direct operational costs. By reducing emissions, companies can potentially avoid or minimize carbon taxes and penalties in regions with stringent environmental regulations. Additionally, the improved environmental performance can enhance a company's reputation, potentially leading to increased market share and customer loyalty.

Return on investment (ROI) for advanced PHEs varies depending on factors such as industry type, scale of operation, and local energy costs. In many cases, the payback period for these systems ranges from 1 to 3 years, making them an attractive option for businesses looking to balance environmental responsibility with financial performance.

Government incentives and subsidies for clean energy technologies can significantly improve the economic feasibility of advanced PHEs. Many countries offer tax credits, grants, or low-interest loans for investments in energy-efficient technologies, which can help offset the initial capital costs and accelerate the payback period.

The scalability of advanced PHEs adds to their economic appeal. These systems can be easily expanded or modified to accommodate changing production needs, allowing businesses to optimize their heat exchange capacity without major overhauls. This flexibility can result in long-term cost savings and improved adaptability to market conditions.

In conclusion, while the upfront costs of advanced PHEs may be higher, their long-term economic benefits, coupled with their environmental advantages, make them a financially viable solution for emission reduction in many industrial applications. As energy costs continue to rise and environmental regulations become more stringent, the economic case for implementing these advanced systems is likely to strengthen further.

Initial capital costs for advanced PHEs are typically higher than traditional heat exchange systems. However, this investment is often offset by long-term operational savings. The improved efficiency of advanced PHEs results in reduced energy consumption, which translates to lower fuel costs and decreased emissions. This efficiency gain can lead to substantial cost savings over the lifetime of the equipment, particularly in energy-intensive industries.

Maintenance costs for advanced PHEs are generally lower than those for conventional systems. Their compact design and reduced fouling characteristics contribute to easier cleaning and less frequent maintenance interventions. This results in reduced downtime and lower labor costs associated with maintenance activities, further enhancing their economic appeal.

The economic benefits of advanced PHEs extend beyond direct operational costs. By reducing emissions, companies can potentially avoid or minimize carbon taxes and penalties in regions with stringent environmental regulations. Additionally, the improved environmental performance can enhance a company's reputation, potentially leading to increased market share and customer loyalty.

Return on investment (ROI) for advanced PHEs varies depending on factors such as industry type, scale of operation, and local energy costs. In many cases, the payback period for these systems ranges from 1 to 3 years, making them an attractive option for businesses looking to balance environmental responsibility with financial performance.

Government incentives and subsidies for clean energy technologies can significantly improve the economic feasibility of advanced PHEs. Many countries offer tax credits, grants, or low-interest loans for investments in energy-efficient technologies, which can help offset the initial capital costs and accelerate the payback period.

The scalability of advanced PHEs adds to their economic appeal. These systems can be easily expanded or modified to accommodate changing production needs, allowing businesses to optimize their heat exchange capacity without major overhauls. This flexibility can result in long-term cost savings and improved adaptability to market conditions.

In conclusion, while the upfront costs of advanced PHEs may be higher, their long-term economic benefits, coupled with their environmental advantages, make them a financially viable solution for emission reduction in many industrial applications. As energy costs continue to rise and environmental regulations become more stringent, the economic case for implementing these advanced systems is likely to strengthen further.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!