Energy Efficiency in Directed Energy Deposition: Techniques and Strategies

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DED Energy Efficiency Background and Objectives

Directed Energy Deposition (DED) has emerged as a transformative additive manufacturing technology since its inception in the late 1990s. Initially developed for rapid prototyping and repair applications, DED has evolved significantly over the past two decades to become a viable production method for complex metal components across aerospace, defense, medical, and automotive industries. The technology utilizes focused thermal energy to fuse materials as they are deposited, creating fully dense metal parts with excellent mechanical properties.

Energy efficiency in DED processes represents a critical frontier in advancing this technology toward wider industrial adoption. Historical data indicates that traditional DED systems operate at energy efficiency rates of merely 10-20%, with substantial energy losses occurring through heat dissipation, unused powder, and inefficient laser or electron beam utilization. This inefficiency translates directly to higher operational costs, increased carbon footprint, and limitations in scaling the technology for mass production scenarios.

The technological evolution trajectory shows a clear trend toward more energy-conscious DED systems, with innovations focusing on precise energy delivery, advanced thermal management, and optimized process parameters. Recent advancements in beam shaping technology, multi-material capabilities, and real-time monitoring systems have contributed to incremental improvements in energy utilization, yet significant challenges remain in achieving truly efficient energy consumption profiles.

Current global sustainability imperatives and rising energy costs have accelerated interest in energy-efficient manufacturing processes. Industry analyses project that improvements in DED energy efficiency could reduce operational costs by 15-30% while simultaneously decreasing carbon emissions associated with the manufacturing process. These economic and environmental factors have positioned energy efficiency as a primary objective in DED technology development.

The primary technical objectives for advancing energy efficiency in DED include: reducing energy consumption per unit volume of deposited material by at least 40%; minimizing heat-affected zones through precise energy control; developing intelligent feedback systems for real-time energy optimization; and creating standardized metrics for energy efficiency assessment across different DED platforms and applications.

Additionally, research aims to establish correlations between energy input parameters and resulting material properties, enabling manufacturers to achieve optimal energy utilization without compromising part quality or mechanical performance. The ultimate goal is to develop next-generation DED systems that maximize material deposition efficiency while minimizing energy inputs, thereby creating a more sustainable and economically viable additive manufacturing solution for industrial applications.

Energy efficiency in DED processes represents a critical frontier in advancing this technology toward wider industrial adoption. Historical data indicates that traditional DED systems operate at energy efficiency rates of merely 10-20%, with substantial energy losses occurring through heat dissipation, unused powder, and inefficient laser or electron beam utilization. This inefficiency translates directly to higher operational costs, increased carbon footprint, and limitations in scaling the technology for mass production scenarios.

The technological evolution trajectory shows a clear trend toward more energy-conscious DED systems, with innovations focusing on precise energy delivery, advanced thermal management, and optimized process parameters. Recent advancements in beam shaping technology, multi-material capabilities, and real-time monitoring systems have contributed to incremental improvements in energy utilization, yet significant challenges remain in achieving truly efficient energy consumption profiles.

Current global sustainability imperatives and rising energy costs have accelerated interest in energy-efficient manufacturing processes. Industry analyses project that improvements in DED energy efficiency could reduce operational costs by 15-30% while simultaneously decreasing carbon emissions associated with the manufacturing process. These economic and environmental factors have positioned energy efficiency as a primary objective in DED technology development.

The primary technical objectives for advancing energy efficiency in DED include: reducing energy consumption per unit volume of deposited material by at least 40%; minimizing heat-affected zones through precise energy control; developing intelligent feedback systems for real-time energy optimization; and creating standardized metrics for energy efficiency assessment across different DED platforms and applications.

Additionally, research aims to establish correlations between energy input parameters and resulting material properties, enabling manufacturers to achieve optimal energy utilization without compromising part quality or mechanical performance. The ultimate goal is to develop next-generation DED systems that maximize material deposition efficiency while minimizing energy inputs, thereby creating a more sustainable and economically viable additive manufacturing solution for industrial applications.

Market Analysis for Energy-Efficient DED Technologies

The global market for energy-efficient Directed Energy Deposition (DED) technologies is experiencing robust growth, driven by increasing industrial demand for sustainable manufacturing solutions. Current market valuations indicate that the energy-efficient additive manufacturing sector reached approximately 2.3 billion USD in 2022, with DED-specific technologies accounting for roughly 18% of this segment. Industry forecasts project a compound annual growth rate of 15-20% over the next five years, significantly outpacing traditional manufacturing technologies.

The demand for energy-efficient DED solutions stems primarily from aerospace, automotive, and medical device manufacturing sectors, which collectively represent over 65% of the current market share. Aerospace manufacturers are particularly motivated by the potential for weight reduction in components while maintaining structural integrity, resulting in fuel savings throughout aircraft lifecycles. The automotive industry's shift toward electric vehicles has similarly accelerated interest in energy-efficient manufacturing processes that align with broader sustainability goals.

Regional market analysis reveals that North America currently leads in adoption of energy-efficient DED technologies with approximately 40% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and South Korea making substantial investments in advanced manufacturing capabilities. Government initiatives supporting green manufacturing technologies have become significant market drivers, particularly in the European Union where regulatory frameworks increasingly favor energy-efficient production methods.

Customer segmentation within the DED technology market shows distinct preferences based on organization size. Large enterprises prioritize comprehensive solutions with proven energy efficiency metrics and integration capabilities with existing systems. Small and medium enterprises demonstrate greater price sensitivity but increasing willingness to invest in energy-efficient DED technologies that offer demonstrable operational cost reductions through energy savings.

Market barriers include high initial capital expenditure requirements, technical complexity of implementation, and limited awareness of total cost of ownership benefits. The average return on investment period for energy-efficient DED systems ranges from 3-5 years, depending on utilization rates and energy costs in the deployment region. This represents a significant improvement from the 7-8 year ROI periods observed just five years ago, indicating technological maturation and increasing cost-effectiveness.

Pricing trends show gradual democratization of energy-efficient DED technologies, with entry-level systems becoming more accessible to smaller manufacturers. Premium systems with advanced energy optimization features command price premiums of 25-35% but deliver energy consumption reductions of 30-45% compared to conventional DED systems, creating compelling value propositions for energy-intensive manufacturing operations.

The demand for energy-efficient DED solutions stems primarily from aerospace, automotive, and medical device manufacturing sectors, which collectively represent over 65% of the current market share. Aerospace manufacturers are particularly motivated by the potential for weight reduction in components while maintaining structural integrity, resulting in fuel savings throughout aircraft lifecycles. The automotive industry's shift toward electric vehicles has similarly accelerated interest in energy-efficient manufacturing processes that align with broader sustainability goals.

Regional market analysis reveals that North America currently leads in adoption of energy-efficient DED technologies with approximately 40% market share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China and South Korea making substantial investments in advanced manufacturing capabilities. Government initiatives supporting green manufacturing technologies have become significant market drivers, particularly in the European Union where regulatory frameworks increasingly favor energy-efficient production methods.

Customer segmentation within the DED technology market shows distinct preferences based on organization size. Large enterprises prioritize comprehensive solutions with proven energy efficiency metrics and integration capabilities with existing systems. Small and medium enterprises demonstrate greater price sensitivity but increasing willingness to invest in energy-efficient DED technologies that offer demonstrable operational cost reductions through energy savings.

Market barriers include high initial capital expenditure requirements, technical complexity of implementation, and limited awareness of total cost of ownership benefits. The average return on investment period for energy-efficient DED systems ranges from 3-5 years, depending on utilization rates and energy costs in the deployment region. This represents a significant improvement from the 7-8 year ROI periods observed just five years ago, indicating technological maturation and increasing cost-effectiveness.

Pricing trends show gradual democratization of energy-efficient DED technologies, with entry-level systems becoming more accessible to smaller manufacturers. Premium systems with advanced energy optimization features command price premiums of 25-35% but deliver energy consumption reductions of 30-45% compared to conventional DED systems, creating compelling value propositions for energy-intensive manufacturing operations.

Current Energy Challenges in Directed Energy Deposition

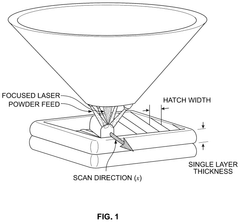

Directed Energy Deposition (DED) processes currently face significant energy efficiency challenges that impact both operational costs and environmental sustainability. The primary energy consumption in DED occurs during material melting, which typically requires high-power lasers, electron beams, or plasma arcs operating at power levels ranging from 500W to 4kW. This energy-intensive process results in thermal efficiency rates often below 40%, with substantial energy losses occurring through radiation, conduction, and convection mechanisms.

Material properties present another major challenge, as different metals and alloys require varying energy inputs to achieve optimal deposition. High-reflectivity materials like aluminum and copper can reflect up to 90% of laser energy, dramatically reducing process efficiency. Additionally, the thermal conductivity of the substrate and feedstock materials significantly affects energy utilization, with highly conductive materials dissipating heat rapidly away from the melt pool.

Process parameters contribute substantially to energy inefficiencies. Suboptimal travel speeds, excessive layer thicknesses, and improper powder feed rates can lead to energy wastage of 15-30%. The lack of standardized energy optimization protocols across different DED systems further exacerbates these issues, resulting in inconsistent energy consumption patterns across the industry.

Equipment limitations also pose significant challenges. Many commercial DED systems utilize older laser technologies with wall-plug efficiencies of only 20-30%, compared to newer fiber or diode lasers that can achieve 40-50% efficiency. Inadequate thermal management systems fail to capture and reuse waste heat, while outdated control systems lack the precision needed for real-time energy optimization.

The absence of comprehensive energy monitoring capabilities in most DED systems prevents accurate measurement and management of energy consumption. Without real-time feedback on energy utilization, operators cannot make informed adjustments to improve efficiency. This data gap also hinders the development of energy-efficient process parameters and machine learning algorithms that could potentially optimize energy usage.

Regulatory pressures and sustainability requirements are increasingly influencing the DED landscape. Many regions now impose carbon pricing mechanisms and energy efficiency standards that directly impact operational costs. Companies utilizing energy-intensive manufacturing processes face growing scrutiny from investors and customers concerned about environmental impact, creating market pressure for more efficient technologies.

These challenges collectively represent significant barriers to the widespread industrial adoption of DED technologies, particularly in cost-sensitive sectors. Addressing these energy efficiency issues is crucial for improving the economic viability and environmental sustainability of DED processes in advanced manufacturing applications.

Material properties present another major challenge, as different metals and alloys require varying energy inputs to achieve optimal deposition. High-reflectivity materials like aluminum and copper can reflect up to 90% of laser energy, dramatically reducing process efficiency. Additionally, the thermal conductivity of the substrate and feedstock materials significantly affects energy utilization, with highly conductive materials dissipating heat rapidly away from the melt pool.

Process parameters contribute substantially to energy inefficiencies. Suboptimal travel speeds, excessive layer thicknesses, and improper powder feed rates can lead to energy wastage of 15-30%. The lack of standardized energy optimization protocols across different DED systems further exacerbates these issues, resulting in inconsistent energy consumption patterns across the industry.

Equipment limitations also pose significant challenges. Many commercial DED systems utilize older laser technologies with wall-plug efficiencies of only 20-30%, compared to newer fiber or diode lasers that can achieve 40-50% efficiency. Inadequate thermal management systems fail to capture and reuse waste heat, while outdated control systems lack the precision needed for real-time energy optimization.

The absence of comprehensive energy monitoring capabilities in most DED systems prevents accurate measurement and management of energy consumption. Without real-time feedback on energy utilization, operators cannot make informed adjustments to improve efficiency. This data gap also hinders the development of energy-efficient process parameters and machine learning algorithms that could potentially optimize energy usage.

Regulatory pressures and sustainability requirements are increasingly influencing the DED landscape. Many regions now impose carbon pricing mechanisms and energy efficiency standards that directly impact operational costs. Companies utilizing energy-intensive manufacturing processes face growing scrutiny from investors and customers concerned about environmental impact, creating market pressure for more efficient technologies.

These challenges collectively represent significant barriers to the widespread industrial adoption of DED technologies, particularly in cost-sensitive sectors. Addressing these energy efficiency issues is crucial for improving the economic viability and environmental sustainability of DED processes in advanced manufacturing applications.

Current Energy Optimization Techniques in DED Processes

01 Process parameter optimization for energy efficiency

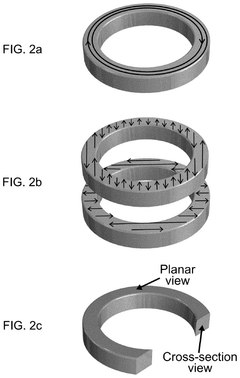

Optimizing process parameters in directed energy deposition (DED) can significantly improve energy efficiency. This includes adjusting laser power, scanning speed, powder feed rate, and layer thickness to minimize energy consumption while maintaining build quality. Advanced control systems can dynamically adjust these parameters during the build process to optimize energy usage based on real-time feedback from the system.- Process parameter optimization for energy efficiency: Optimizing process parameters in directed energy deposition (DED) can significantly improve energy efficiency. This includes adjusting laser power, scanning speed, powder feed rate, and layer thickness to minimize energy consumption while maintaining build quality. Advanced control systems can dynamically adjust these parameters during the build process to optimize energy usage based on real-time feedback from the system.

- Energy-efficient laser and power source designs: Innovations in laser technology and power source designs specifically for directed energy deposition processes focus on improving energy conversion efficiency. These include high-efficiency fiber lasers, diode lasers with improved beam quality, and pulsed laser systems that reduce overall energy consumption. Power management systems that provide precise control over energy delivery and minimize standby power consumption also contribute to overall process efficiency.

- Material recycling and feedstock optimization: Energy efficiency in directed energy deposition can be improved through better material utilization strategies. This includes recycling unused powder, optimizing powder characteristics for better flowability and deposition efficiency, and developing closed-loop material handling systems. Pre-heating feedstock materials can reduce the energy required during the deposition process, while specialized powder compositions can lower the melting energy requirements.

- Thermal management and heat recovery systems: Advanced thermal management strategies can significantly improve the energy efficiency of directed energy deposition processes. These include heat recovery systems that capture and reuse waste heat, improved insulation designs, and thermal monitoring systems that optimize energy input based on part geometry and thermal history. Controlled cooling strategies can also reduce the need for post-process heat treatments, further improving overall energy efficiency.

- Multi-material and hybrid process approaches: Combining directed energy deposition with other manufacturing processes or enabling multi-material deposition can improve overall energy efficiency. Hybrid systems that integrate subtractive and additive processes reduce material waste and energy consumption. Functionally graded materials can be designed to optimize material usage and energy requirements. Process planning algorithms that determine the most energy-efficient build strategies for complex geometries also contribute to improved efficiency.

02 Energy-efficient laser and power source designs

Innovations in laser technology and power source designs specifically for directed energy deposition processes can substantially improve energy efficiency. This includes high-efficiency fiber lasers, diode lasers with improved beam quality, and pulsed laser systems that deliver energy more precisely. Power management systems that reduce standby power consumption and recover waste heat also contribute to overall energy efficiency improvements.Expand Specific Solutions03 Material feed system improvements

Enhancing the efficiency of material delivery systems in directed energy deposition processes can reduce energy consumption. This includes optimized powder or wire feeding mechanisms that minimize waste, precise delivery systems that ensure material is deposited only where needed, and recycling systems that capture and reuse unmelted powder. These improvements reduce the energy required for material processing and minimize the environmental impact of the manufacturing process.Expand Specific Solutions04 Thermal management and energy recovery systems

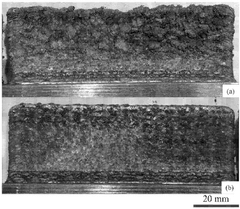

Advanced thermal management strategies can significantly improve the energy efficiency of directed energy deposition processes. This includes systems for capturing and reusing waste heat, improved insulation to reduce heat loss, and cooling systems optimized for energy efficiency. Some innovative approaches incorporate heat exchangers that recover thermal energy from the process and redirect it for other manufacturing operations or facility heating needs.Expand Specific Solutions05 Process monitoring and adaptive control systems

Implementing sophisticated monitoring and control systems enables real-time optimization of energy usage in directed energy deposition processes. These systems use sensors to track thermal conditions, melt pool dynamics, and build quality, allowing for adaptive adjustments to process parameters. Machine learning algorithms can analyze this data to continuously improve energy efficiency while maintaining or enhancing part quality, reducing the need for energy-intensive post-processing or part rejection.Expand Specific Solutions

Leading Companies and Research Institutions in DED

The energy efficiency landscape in Directed Energy Deposition (DED) is evolving rapidly, currently positioned at an early growth stage with increasing market adoption. The global market is expanding as industries recognize DED's potential for reducing material waste and energy consumption in additive manufacturing. Leading players include RTX Corp. and GE Avio, who are advancing aerospace applications, while Siemens AG focuses on industrial automation integration. Academic institutions like MIT and Tsinghua University are driving fundamental research, with SolarEdge Technologies and State Grid contributing energy management expertise. The technology is approaching commercial maturity, with companies like Spar Systems developing novel energy recovery solutions. Collaboration between defense contractors, energy providers, and research institutions is accelerating innovation in thermal efficiency and power management for DED systems.

GE Avio Srl

Technical Solution: GE Avio has pioneered a comprehensive energy efficiency framework for DED processes focused on aerospace applications. Their system employs multi-beam laser technology that distributes energy more effectively across the deposition surface, reducing hotspots and minimizing thermal gradients. This approach has demonstrated energy savings of approximately 25% while improving microstructural uniformity in complex aerospace components. GE Avio's technology incorporates predictive modeling software that simulates energy requirements before production, allowing for pre-optimization of build parameters. Their system features intelligent power ramping that adjusts energy input based on geometry complexity and thermal accumulation during the build process. Additionally, GE Avio has developed specialized nozzle designs that improve gas flow dynamics around the melt pool, reducing shielding gas consumption by up to 40% while maintaining adequate protection from oxidation. The company has also implemented energy recovery systems that capture and repurpose waste heat from the DED process for facility heating or other manufacturing operations.

Strengths: Multi-beam technology provides superior energy distribution and microstructural control, particularly valuable for complex aerospace components. Comprehensive approach addresses multiple energy consumption vectors simultaneously. Weaknesses: System is highly specialized for high-value aerospace applications and may be cost-prohibitive for general manufacturing. Requires significant computational resources for predictive modeling capabilities.

Siemens AG

Technical Solution: Siemens has developed an integrated energy management platform for DED manufacturing that leverages their expertise in industrial automation and digital twins. Their system creates a comprehensive digital model of the DED process that simulates energy flows and identifies optimization opportunities in real-time. The platform incorporates machine learning algorithms that continuously refine process parameters based on historical build data, achieving progressive energy efficiency improvements over time. Siemens' approach includes variable power laser sources that can dynamically adjust output based on material requirements, reducing energy consumption by up to 35% compared to fixed-power systems. Their technology features advanced path planning algorithms that optimize deposition strategies to minimize idle time and energy waste during non-deposition movements. Additionally, Siemens has implemented smart grid integration capabilities that allow DED systems to operate during off-peak energy periods or leverage renewable energy sources when available. The platform also includes energy monitoring dashboards that provide operators with real-time efficiency metrics and recommendations for further optimization.

Strengths: Comprehensive digital twin approach provides unparalleled process visibility and optimization opportunities. Integration with broader factory systems enables enterprise-level energy management. Weaknesses: Requires significant digital infrastructure and may be challenging to implement in facilities without existing Siemens automation systems. Complex implementation process requires specialized expertise and longer setup times.

Key Innovations in DED Energy Management Systems

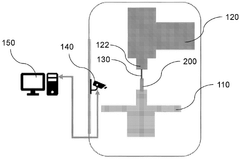

Directed energy deposition apparatus and method

PatentWO2024242628A1

Innovation

- A method and apparatus that incorporate a temperature-based cooling time feedback loop, where each layer is cooled to a predefined temperature before adding the next, using a thermal device to measure and control the cooling process, thereby minimizing overheating and oxidation.

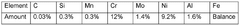

High silicon electrical steel alloys using directed energy deposition

PatentPendingUS20250262669A1

Innovation

- Laser beam-directed energy deposition (LB-DED) is used to create bulk geometries of high-silicon content Fe—Si alloys through layer-by-layer printing and heat treatment, minimizing residual stresses and enabling near-net-shape manufacturing.

Environmental Impact Assessment of DED Technologies

The environmental impact of Directed Energy Deposition (DED) technologies must be comprehensively evaluated to ensure sustainable manufacturing practices. DED processes consume significant energy during operation, primarily through high-power lasers, electron beams, or plasma arcs that melt feedstock materials. A typical laser-based DED system operates at 1-5 kW power levels, resulting in energy consumption of 20-100 kWh per kilogram of deposited material, depending on process parameters and material properties.

Carbon footprint analysis reveals that DED technologies generally produce fewer emissions compared to conventional manufacturing when considering the entire product lifecycle. This advantage stems from reduced material waste, as DED typically achieves material utilization rates of 95-98% compared to 60-70% in traditional subtractive manufacturing. Additionally, localized repair capabilities extend component lifespans, further reducing environmental impact through decreased replacement part production.

Waste generation in DED processes primarily consists of unused powder, process gases, and filtration residues. Modern DED systems incorporate recycling mechanisms that can recover up to 95% of unused powder materials, significantly reducing waste streams. However, the environmental impact of specialized gas mixtures used as shielding agents, particularly argon and helium, remains a concern due to their extraction and processing requirements.

Water usage in DED operations is primarily associated with cooling systems and post-processing. Closed-loop cooling systems have demonstrated water consumption reductions of 40-60% compared to open systems, representing a significant environmental improvement. The implementation of dry post-processing techniques further reduces water requirements and prevents contaminated wastewater generation.

Noise and electromagnetic emissions from DED equipment present additional environmental considerations. Laser-based systems typically generate 70-85 dB of operational noise, while electron beam systems may produce electromagnetic interference requiring specialized shielding to prevent workplace and environmental impacts.

Life cycle assessment (LCA) studies indicate that the environmental benefits of DED technologies are most pronounced in applications requiring complex geometries, lightweight structures, or repair operations. For instance, aerospace components manufactured via DED can achieve weight reductions of 25-40%, translating to substantial fuel savings and emissions reductions throughout the component's operational life.

Future environmental improvements in DED technologies will likely focus on renewable energy integration, enhanced material recycling systems, and process optimization algorithms that minimize energy consumption while maintaining build quality. Research indicates potential energy efficiency improvements of 30-50% through these combined approaches, further enhancing the environmental sustainability of DED manufacturing.

Carbon footprint analysis reveals that DED technologies generally produce fewer emissions compared to conventional manufacturing when considering the entire product lifecycle. This advantage stems from reduced material waste, as DED typically achieves material utilization rates of 95-98% compared to 60-70% in traditional subtractive manufacturing. Additionally, localized repair capabilities extend component lifespans, further reducing environmental impact through decreased replacement part production.

Waste generation in DED processes primarily consists of unused powder, process gases, and filtration residues. Modern DED systems incorporate recycling mechanisms that can recover up to 95% of unused powder materials, significantly reducing waste streams. However, the environmental impact of specialized gas mixtures used as shielding agents, particularly argon and helium, remains a concern due to their extraction and processing requirements.

Water usage in DED operations is primarily associated with cooling systems and post-processing. Closed-loop cooling systems have demonstrated water consumption reductions of 40-60% compared to open systems, representing a significant environmental improvement. The implementation of dry post-processing techniques further reduces water requirements and prevents contaminated wastewater generation.

Noise and electromagnetic emissions from DED equipment present additional environmental considerations. Laser-based systems typically generate 70-85 dB of operational noise, while electron beam systems may produce electromagnetic interference requiring specialized shielding to prevent workplace and environmental impacts.

Life cycle assessment (LCA) studies indicate that the environmental benefits of DED technologies are most pronounced in applications requiring complex geometries, lightweight structures, or repair operations. For instance, aerospace components manufactured via DED can achieve weight reductions of 25-40%, translating to substantial fuel savings and emissions reductions throughout the component's operational life.

Future environmental improvements in DED technologies will likely focus on renewable energy integration, enhanced material recycling systems, and process optimization algorithms that minimize energy consumption while maintaining build quality. Research indicates potential energy efficiency improvements of 30-50% through these combined approaches, further enhancing the environmental sustainability of DED manufacturing.

Cost-Benefit Analysis of Energy Efficiency Investments

Implementing energy efficiency measures in Directed Energy Deposition (DED) processes requires substantial initial investments, necessitating thorough cost-benefit analysis to justify these expenditures. The financial assessment of energy efficiency investments in DED technology must consider both immediate capital outlays and long-term operational savings to provide a comprehensive economic perspective.

Initial investment costs for energy-efficient DED systems typically include equipment upgrades, advanced monitoring systems, and potentially redesigned process workflows. These capital expenditures range from $50,000 for basic efficiency improvements to over $500,000 for comprehensive system overhauls incorporating the latest energy management technologies. While these figures represent significant investments, particularly for small and medium enterprises, they must be evaluated against projected returns.

Operational cost reductions constitute the primary benefit stream, with energy consumption typically decreasing by 15-30% following implementation of efficiency measures. For a medium-sized DED operation consuming 500,000 kWh annually at industrial electricity rates, this translates to $15,000-$30,000 in annual energy cost savings. Additional financial benefits include reduced maintenance costs (typically 10-15% lower) due to optimized system operation and extended equipment lifespan.

Return on investment (ROI) calculations for DED energy efficiency projects generally show payback periods ranging from 2-5 years, depending on implementation scope and energy prices. More sophisticated financial metrics like Net Present Value (NPV) and Internal Rate of Return (IRR) often demonstrate favorable long-term economics, with IRRs frequently exceeding 20% for well-designed efficiency initiatives.

Beyond direct financial returns, comprehensive cost-benefit analysis must incorporate less tangible benefits. These include improved product quality through more stable process conditions, enhanced production capacity from reduced downtime, and strengthened regulatory compliance positioning. Carbon footprint reduction also represents a significant benefit, particularly in jurisdictions with carbon pricing mechanisms or for organizations with sustainability commitments.

Risk factors affecting the economic assessment include energy price volatility, technology obsolescence concerns, and potential production disruptions during implementation. Sensitivity analysis incorporating these variables is essential for robust decision-making, especially given the rapid evolution of DED technologies and energy markets.

Government incentives, including tax credits, grants, and accelerated depreciation allowances for energy efficiency investments, can substantially improve project economics. These incentives typically reduce payback periods by 15-30%, making marginal projects financially viable and accelerating adoption of energy-efficient DED technologies across the industry.

Initial investment costs for energy-efficient DED systems typically include equipment upgrades, advanced monitoring systems, and potentially redesigned process workflows. These capital expenditures range from $50,000 for basic efficiency improvements to over $500,000 for comprehensive system overhauls incorporating the latest energy management technologies. While these figures represent significant investments, particularly for small and medium enterprises, they must be evaluated against projected returns.

Operational cost reductions constitute the primary benefit stream, with energy consumption typically decreasing by 15-30% following implementation of efficiency measures. For a medium-sized DED operation consuming 500,000 kWh annually at industrial electricity rates, this translates to $15,000-$30,000 in annual energy cost savings. Additional financial benefits include reduced maintenance costs (typically 10-15% lower) due to optimized system operation and extended equipment lifespan.

Return on investment (ROI) calculations for DED energy efficiency projects generally show payback periods ranging from 2-5 years, depending on implementation scope and energy prices. More sophisticated financial metrics like Net Present Value (NPV) and Internal Rate of Return (IRR) often demonstrate favorable long-term economics, with IRRs frequently exceeding 20% for well-designed efficiency initiatives.

Beyond direct financial returns, comprehensive cost-benefit analysis must incorporate less tangible benefits. These include improved product quality through more stable process conditions, enhanced production capacity from reduced downtime, and strengthened regulatory compliance positioning. Carbon footprint reduction also represents a significant benefit, particularly in jurisdictions with carbon pricing mechanisms or for organizations with sustainability commitments.

Risk factors affecting the economic assessment include energy price volatility, technology obsolescence concerns, and potential production disruptions during implementation. Sensitivity analysis incorporating these variables is essential for robust decision-making, especially given the rapid evolution of DED technologies and energy markets.

Government incentives, including tax credits, grants, and accelerated depreciation allowances for energy efficiency investments, can substantially improve project economics. These incentives typically reduce payback periods by 15-30%, making marginal projects financially viable and accelerating adoption of energy-efficient DED technologies across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!