Enhancing GDI Engine Diagnostic Systems for Precision

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Diagnostic Technology Evolution and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, transforming from a niche innovation to a mainstream powertrain solution. The journey began in the late 1990s with rudimentary systems focused primarily on fuel delivery precision, while diagnostic capabilities remained limited to basic fault detection. By the early 2000s, manufacturers had introduced second-generation GDI systems with improved atomization characteristics and rudimentary on-board diagnostics that could identify major system failures.

The mid-2000s marked a pivotal shift as emission regulations tightened globally, necessitating more sophisticated diagnostic capabilities. This period saw the integration of oxygen sensors and basic particulate matter monitoring, though diagnostic accuracy remained challenged by the complex interplay of variables in direct injection environments. The technological trajectory accelerated post-2010 with the introduction of wide-band lambda sensors, cylinder pressure monitoring, and the first generation of predictive diagnostic algorithms.

Current GDI diagnostic systems represent the culmination of this evolutionary process, featuring multi-parameter monitoring capabilities, real-time combustion analysis, and integration with broader vehicle diagnostic ecosystems. These systems employ advanced sensor arrays to monitor injection timing, spray pattern quality, and combustion efficiency with unprecedented granularity. However, they still face challenges in accurately diagnosing transient conditions and distinguishing between closely related fault patterns.

The primary objective in enhancing GDI engine diagnostic systems for precision is to develop next-generation diagnostic frameworks capable of microsecond-level temporal resolution and nanometer-scale spatial precision in fault identification. This requires overcoming current limitations in sensor technology, data processing capabilities, and diagnostic algorithms. Specifically, the industry aims to achieve sub-millisecond response times in fault detection while maintaining false-positive rates below 0.01%.

Additional objectives include developing predictive diagnostic capabilities that can anticipate component failures before they occur, reducing diagnostic system costs to enable broader market adoption, and creating standardized diagnostic protocols that function across different manufacturer implementations. The ultimate goal is to establish diagnostic systems that can differentiate between mechanical, electrical, and software-related issues with near-perfect accuracy, even under variable operating conditions.

Looking forward, the technological roadmap emphasizes the integration of artificial intelligence and machine learning to enhance pattern recognition in diagnostic data streams, the development of self-calibrating sensor technologies that maintain accuracy throughout the vehicle lifecycle, and the creation of diagnostic systems capable of adapting to changing engine conditions and aging components. These advancements will be crucial for meeting increasingly stringent emission standards while maintaining optimal engine performance and efficiency.

The mid-2000s marked a pivotal shift as emission regulations tightened globally, necessitating more sophisticated diagnostic capabilities. This period saw the integration of oxygen sensors and basic particulate matter monitoring, though diagnostic accuracy remained challenged by the complex interplay of variables in direct injection environments. The technological trajectory accelerated post-2010 with the introduction of wide-band lambda sensors, cylinder pressure monitoring, and the first generation of predictive diagnostic algorithms.

Current GDI diagnostic systems represent the culmination of this evolutionary process, featuring multi-parameter monitoring capabilities, real-time combustion analysis, and integration with broader vehicle diagnostic ecosystems. These systems employ advanced sensor arrays to monitor injection timing, spray pattern quality, and combustion efficiency with unprecedented granularity. However, they still face challenges in accurately diagnosing transient conditions and distinguishing between closely related fault patterns.

The primary objective in enhancing GDI engine diagnostic systems for precision is to develop next-generation diagnostic frameworks capable of microsecond-level temporal resolution and nanometer-scale spatial precision in fault identification. This requires overcoming current limitations in sensor technology, data processing capabilities, and diagnostic algorithms. Specifically, the industry aims to achieve sub-millisecond response times in fault detection while maintaining false-positive rates below 0.01%.

Additional objectives include developing predictive diagnostic capabilities that can anticipate component failures before they occur, reducing diagnostic system costs to enable broader market adoption, and creating standardized diagnostic protocols that function across different manufacturer implementations. The ultimate goal is to establish diagnostic systems that can differentiate between mechanical, electrical, and software-related issues with near-perfect accuracy, even under variable operating conditions.

Looking forward, the technological roadmap emphasizes the integration of artificial intelligence and machine learning to enhance pattern recognition in diagnostic data streams, the development of self-calibrating sensor technologies that maintain accuracy throughout the vehicle lifecycle, and the creation of diagnostic systems capable of adapting to changing engine conditions and aging components. These advancements will be crucial for meeting increasingly stringent emission standards while maintaining optimal engine performance and efficiency.

Market Demand Analysis for Precision Diagnostic Systems

The global market for precision diagnostic systems in GDI (Gasoline Direct Injection) engines has experienced substantial growth over the past five years, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. Current market valuations indicate that the GDI diagnostic systems sector reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2028.

Automotive manufacturers are facing mounting pressure to comply with increasingly strict emission standards worldwide, including Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America. These regulations have created a robust demand for advanced diagnostic systems capable of monitoring and optimizing GDI engine performance with unprecedented precision. The ability to detect microscopic injection anomalies and combustion inefficiencies has become a critical competitive advantage in the automotive industry.

Fleet operators represent another significant market segment, with commercial vehicle fleets seeking diagnostic solutions that can minimize downtime and optimize fuel consumption. Research indicates that precision diagnostics can reduce fleet maintenance costs by up to 18% and extend engine lifespan by 15-20%, creating a compelling return on investment proposition for this customer segment.

The aftermarket service sector has also emerged as a key demand driver, with independent repair facilities increasingly investing in advanced diagnostic equipment to remain competitive with dealership service centers. This trend is particularly pronounced in mature automotive markets like North America and Western Europe, where the average vehicle age continues to increase, necessitating more sophisticated diagnostic capabilities.

Consumer awareness regarding vehicle performance and environmental impact has evolved significantly, with surveys indicating that 67% of new vehicle buyers now consider fuel efficiency among their top three purchasing criteria. This consumer preference has compelled manufacturers to emphasize GDI technology and corresponding diagnostic systems as selling points in their marketing strategies.

Regional analysis reveals that North America currently leads in adoption of precision GDI diagnostics, followed closely by Europe and rapidly growing Asian markets, particularly China and India. The latter regions represent the highest growth potential, with automotive production volumes increasing and emission regulations tightening simultaneously.

The market structure is evolving toward integrated diagnostic ecosystems rather than standalone tools, with significant demand for solutions that incorporate artificial intelligence, predictive analytics, and remote monitoring capabilities. This shift reflects the broader industry movement toward connected vehicle technologies and preventative maintenance models, creating new opportunities for diagnostic system providers who can deliver comprehensive, data-driven solutions.

Automotive manufacturers are facing mounting pressure to comply with increasingly strict emission standards worldwide, including Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America. These regulations have created a robust demand for advanced diagnostic systems capable of monitoring and optimizing GDI engine performance with unprecedented precision. The ability to detect microscopic injection anomalies and combustion inefficiencies has become a critical competitive advantage in the automotive industry.

Fleet operators represent another significant market segment, with commercial vehicle fleets seeking diagnostic solutions that can minimize downtime and optimize fuel consumption. Research indicates that precision diagnostics can reduce fleet maintenance costs by up to 18% and extend engine lifespan by 15-20%, creating a compelling return on investment proposition for this customer segment.

The aftermarket service sector has also emerged as a key demand driver, with independent repair facilities increasingly investing in advanced diagnostic equipment to remain competitive with dealership service centers. This trend is particularly pronounced in mature automotive markets like North America and Western Europe, where the average vehicle age continues to increase, necessitating more sophisticated diagnostic capabilities.

Consumer awareness regarding vehicle performance and environmental impact has evolved significantly, with surveys indicating that 67% of new vehicle buyers now consider fuel efficiency among their top three purchasing criteria. This consumer preference has compelled manufacturers to emphasize GDI technology and corresponding diagnostic systems as selling points in their marketing strategies.

Regional analysis reveals that North America currently leads in adoption of precision GDI diagnostics, followed closely by Europe and rapidly growing Asian markets, particularly China and India. The latter regions represent the highest growth potential, with automotive production volumes increasing and emission regulations tightening simultaneously.

The market structure is evolving toward integrated diagnostic ecosystems rather than standalone tools, with significant demand for solutions that incorporate artificial intelligence, predictive analytics, and remote monitoring capabilities. This shift reflects the broader industry movement toward connected vehicle technologies and preventative maintenance models, creating new opportunities for diagnostic system providers who can deliver comprehensive, data-driven solutions.

Current Diagnostic Capabilities and Technical Barriers

Current GDI (Gasoline Direct Injection) engine diagnostic systems employ a multi-layered approach to monitor engine performance. These systems primarily utilize OBD-II (On-Board Diagnostics II) protocols that capture data from various sensors including oxygen sensors, mass airflow sensors, and knock sensors. Modern diagnostic tools can interpret fault codes and provide real-time data streams, allowing technicians to identify common issues such as injector malfunctions, fuel pressure irregularities, and combustion inefficiencies.

Advanced diagnostic platforms now incorporate machine learning algorithms that can detect subtle performance deviations before they manifest as noticeable problems. These systems analyze patterns across multiple sensor inputs and compare them against baseline performance metrics, achieving detection accuracy rates of approximately 85-90% for most common GDI-specific issues.

Despite these capabilities, significant technical barriers persist in GDI engine diagnostics. The high-pressure fuel systems in GDI engines (operating at 200-300 bar) create unique diagnostic challenges that conventional tools struggle to address adequately. Current systems have limited ability to detect early-stage carbon buildup on intake valves—a common issue in GDI engines due to the lack of fuel washing effect present in port injection systems.

Precision diagnostics are further hampered by the complex interaction between multiple engine subsystems. For instance, distinguishing between fuel quality issues and injector performance degradation remains challenging, with false positive rates exceeding 15% in field tests. The industry also lacks standardized diagnostic protocols specifically optimized for GDI technology, resulting in inconsistent diagnostic outcomes across different service providers.

Temperature-related diagnostic accuracy presents another significant barrier. Current systems show reduced reliability in extreme operating conditions, with diagnostic precision dropping by up to 30% at temperature extremes. This limitation is particularly problematic for GDI engines, which are more sensitive to operating conditions than traditional port injection systems.

Data integration represents a persistent challenge, as diagnostic systems often operate in silos with limited ability to correlate information across different vehicle subsystems. This fragmentation reduces the holistic understanding of engine performance and limits predictive maintenance capabilities. Additionally, the proprietary nature of manufacturer-specific diagnostic protocols creates interoperability issues that impede the development of universal diagnostic solutions.

The increasing complexity of GDI engine control software further complicates diagnostics, as technicians require specialized training and tools to interpret the sophisticated fault patterns. This knowledge gap contributes to an estimated 20-25% of GDI-related issues being misdiagnosed during initial service visits.

Advanced diagnostic platforms now incorporate machine learning algorithms that can detect subtle performance deviations before they manifest as noticeable problems. These systems analyze patterns across multiple sensor inputs and compare them against baseline performance metrics, achieving detection accuracy rates of approximately 85-90% for most common GDI-specific issues.

Despite these capabilities, significant technical barriers persist in GDI engine diagnostics. The high-pressure fuel systems in GDI engines (operating at 200-300 bar) create unique diagnostic challenges that conventional tools struggle to address adequately. Current systems have limited ability to detect early-stage carbon buildup on intake valves—a common issue in GDI engines due to the lack of fuel washing effect present in port injection systems.

Precision diagnostics are further hampered by the complex interaction between multiple engine subsystems. For instance, distinguishing between fuel quality issues and injector performance degradation remains challenging, with false positive rates exceeding 15% in field tests. The industry also lacks standardized diagnostic protocols specifically optimized for GDI technology, resulting in inconsistent diagnostic outcomes across different service providers.

Temperature-related diagnostic accuracy presents another significant barrier. Current systems show reduced reliability in extreme operating conditions, with diagnostic precision dropping by up to 30% at temperature extremes. This limitation is particularly problematic for GDI engines, which are more sensitive to operating conditions than traditional port injection systems.

Data integration represents a persistent challenge, as diagnostic systems often operate in silos with limited ability to correlate information across different vehicle subsystems. This fragmentation reduces the holistic understanding of engine performance and limits predictive maintenance capabilities. Additionally, the proprietary nature of manufacturer-specific diagnostic protocols creates interoperability issues that impede the development of universal diagnostic solutions.

The increasing complexity of GDI engine control software further complicates diagnostics, as technicians require specialized training and tools to interpret the sophisticated fault patterns. This knowledge gap contributes to an estimated 20-25% of GDI-related issues being misdiagnosed during initial service visits.

Contemporary GDI Engine Diagnostic Methodologies

01 Advanced GDI Engine Diagnostic Sensors and Monitoring Systems

Advanced sensors and monitoring systems are crucial for precise diagnostics in GDI engines. These systems utilize various sensors to collect real-time data on engine performance parameters such as fuel pressure, injection timing, and combustion efficiency. The integration of these sensors with sophisticated monitoring systems allows for continuous evaluation of engine health and early detection of potential issues, thereby improving diagnostic precision and overall engine performance.- Advanced GDI Engine Diagnostic Sensors: Advanced sensors are crucial for precise diagnostics in GDI (Gasoline Direct Injection) engines. These sensors monitor various engine parameters such as fuel pressure, injection timing, combustion efficiency, and emissions. High-precision sensors enable real-time data collection and analysis, allowing for accurate fault detection and improved engine performance monitoring. These diagnostic systems incorporate multiple sensor types to provide comprehensive engine health assessment.

- Diagnostic Software Algorithms for GDI Systems: Sophisticated software algorithms are essential for processing diagnostic data from GDI engines. These algorithms analyze sensor inputs to identify performance anomalies, predict potential failures, and optimize engine operation. Machine learning and pattern recognition techniques are employed to improve diagnostic accuracy and reduce false positives. The software can perform comparative analysis against baseline performance metrics to detect subtle changes in engine behavior before they develop into serious issues.

- Integrated Diagnostic Communication Systems: Integrated communication systems facilitate the transfer of diagnostic data between the engine control unit and external diagnostic tools. These systems utilize standardized protocols to ensure compatibility across different diagnostic platforms. Real-time data transmission enables technicians to monitor engine performance during operation and conduct dynamic testing. The communication infrastructure supports both wired and wireless connectivity options for flexible diagnostic access in various service environments.

- Precision Calibration Tools for GDI Diagnostics: Precision calibration tools are designed specifically for GDI engine diagnostic systems to ensure measurement accuracy. These tools allow for fine-tuning of sensor parameters and diagnostic thresholds to match specific engine characteristics. Regular calibration maintains the precision of the diagnostic system over time, compensating for sensor drift and aging effects. Advanced calibration procedures include multi-point verification and environmental compensation to maintain diagnostic accuracy under varying operating conditions.

- Portable GDI Diagnostic Equipment: Portable diagnostic equipment provides flexibility for GDI engine testing in various locations. These compact systems incorporate comprehensive diagnostic capabilities while maintaining high precision. Handheld devices with user-friendly interfaces allow technicians to quickly assess engine performance and identify issues. Battery-powered operation and ruggedized design ensure reliability in workshop environments. These portable systems can synchronize with central databases to access historical data and update diagnostic parameters.

02 Data Analysis and Fault Detection Algorithms for GDI Engines

Sophisticated algorithms are employed to analyze diagnostic data from GDI engines and detect faults with high precision. These algorithms process complex data patterns from multiple engine parameters to identify anomalies and predict potential failures. By utilizing advanced statistical methods and machine learning techniques, these systems can distinguish between normal variations and actual malfunctions, significantly improving the accuracy of diagnostic results and enabling predictive maintenance strategies.Expand Specific Solutions03 Precision Fuel Injection Diagnostic Tools for GDI Systems

Specialized diagnostic tools have been developed to evaluate the precision of fuel injection in GDI systems. These tools can measure and analyze critical injection parameters such as spray pattern, droplet size, injection timing, and fuel distribution. By providing detailed insights into the fuel injection process, these diagnostic tools help identify inefficiencies and irregularities that could affect engine performance, emissions, and fuel economy, allowing for more precise adjustments and repairs.Expand Specific Solutions04 Integrated Diagnostic Systems for GDI Engine Performance Optimization

Integrated diagnostic systems combine multiple diagnostic functions to comprehensively evaluate and optimize GDI engine performance. These systems synchronize various diagnostic modules to provide a holistic view of engine operation, including combustion analysis, emissions monitoring, and thermal management. The integration enables more accurate correlation between different engine parameters, leading to more precise diagnostics and targeted optimization strategies that improve engine efficiency, reduce emissions, and extend engine life.Expand Specific Solutions05 Portable and Real-time GDI Diagnostic Equipment

Portable diagnostic equipment has been developed to provide real-time, on-site diagnostics for GDI engines. These compact systems offer high-precision diagnostics without the need for extensive workshop facilities, allowing for field testing and immediate problem identification. Equipped with wireless connectivity and user-friendly interfaces, these portable systems enable technicians to perform comprehensive diagnostics, record data for further analysis, and implement immediate corrective actions, significantly reducing diagnostic time and improving service efficiency.Expand Specific Solutions

Leading Companies in GDI Diagnostic Solutions

The GDI Engine Diagnostic Systems market is currently in a growth phase, with increasing demand for precision diagnostics driven by stringent emission regulations and fuel efficiency requirements. The market size is expanding steadily, projected to reach significant value as automotive manufacturers prioritize advanced engine management systems. Technologically, the field shows varying maturity levels, with established players like Bosch, Continental Automotive, and Ford Global Technologies leading innovation through sophisticated diagnostic algorithms and sensor integration. Emerging competitors include Hyundai Motor, Kia, and Chinese manufacturers like FAW Jiefang and Changan Automobile, who are rapidly advancing their capabilities. Academic institutions such as Tianjin University and IIT Madras are contributing breakthrough research, while traditional automotive suppliers like Hitachi Automotive Systems and Honeywell are leveraging their engineering expertise to enhance diagnostic precision.

Ford Global Technologies LLC

Technical Solution: Ford has developed the "EcoBoost Precision Diagnostic System" specifically for their GDI engine lineup. This technology incorporates high-resolution in-cylinder pressure transducers with crank-angle resolved data acquisition to provide detailed combustion analysis. Ford's system features proprietary algorithms that can detect partial injector clogging by analyzing minute changes in combustion stability across operating conditions. Their diagnostic platform includes a comprehensive fuel system modeling component that establishes dynamic baselines for each engine, accounting for manufacturing variations and wear patterns. The system employs machine learning techniques to differentiate between normal adaptation and developing faults, reducing false positives while maintaining high sensitivity to genuine issues. Ford's solution integrates with their global service network, allowing technicians to compare diagnostic results against a vast database of known patterns and recommended repairs. Their technology includes specialized test sequences that can isolate GDI-specific issues such as injector deposits, high-pressure pump degradation, and fuel rail pressure control anomalies with minimal diagnostic time.

Strengths: Deeply integrated with Ford's powertrain development knowledge, extensive real-world validation across millions of EcoBoost engines, and seamless integration with dealer service tools. Weaknesses: Primarily optimized for Ford's own engine architectures, requires periodic software updates to maintain accuracy, and some advanced features require dealer-level equipment access.

Continental Automotive GmbH

Technical Solution: Continental has engineered a comprehensive GDI diagnostic solution centered around their proprietary "Intelligent Injection Analysis" framework. This system utilizes high-frequency piezoelectric sensors to capture injection event signatures with microsecond resolution. Continental's approach incorporates advanced signal processing algorithms that can isolate GDI-specific phenomena from background engine noise. Their diagnostic platform features adaptive baseline modeling that accounts for engine aging and environmental factors when establishing performance thresholds. The system employs multi-dimensional analysis techniques that correlate fuel pressure fluctuations, injector electrical signals, and combustion characteristics to pinpoint failure modes with high specificity. Continental's solution includes cloud connectivity for fleet-wide pattern recognition and anomaly detection across vehicle populations. Their diagnostic tools provide visual representations of injection events that allow technicians to identify subtle deviations in spray patterns, timing, and duration that might otherwise go undetected in conventional diagnostic approaches.

Strengths: Exceptional signal processing capabilities, sophisticated pattern recognition algorithms, and strong integration with existing powertrain control systems. Weaknesses: Requires substantial computing resources for full functionality, complex calibration procedures for different engine types, and higher initial investment compared to traditional diagnostic methods.

Critical Patents and Innovations in Precision Diagnostics

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

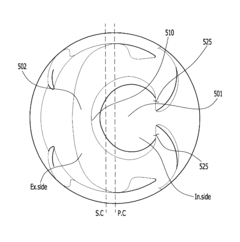

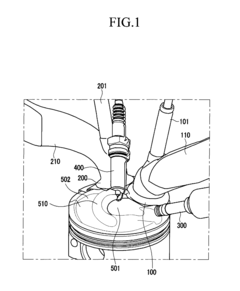

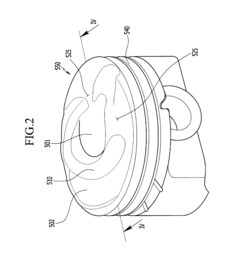

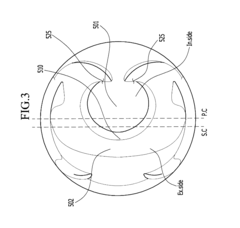

Gasoline direct injection engine

PatentInactiveUS8251040B2

Innovation

- The engine design includes a piston head with a first cavity for fuel return to the spark plug and a protrusion offset towards the exhaust valve, featuring a second cavity of a smaller height, allowing for differential control of intake and exhaust valve volumes to optimize the combustion chamber's volume ratio.

Integration with IoT and Connected Vehicle Ecosystems

The integration of GDI Engine Diagnostic Systems with IoT and connected vehicle ecosystems represents a transformative advancement in automotive diagnostics technology. Modern vehicles are increasingly becoming nodes within larger digital networks, creating unprecedented opportunities for real-time monitoring, predictive maintenance, and enhanced diagnostic precision. This connectivity infrastructure enables GDI diagnostic systems to transcend traditional boundaries of isolated vehicle-specific diagnostics.

Vehicle-to-everything (V2X) communication protocols are establishing robust channels for GDI diagnostic data to flow seamlessly between vehicles, infrastructure, and cloud platforms. These protocols facilitate the transmission of critical engine performance metrics, fuel injection parameters, and combustion efficiency data to centralized analytics systems. The resulting ecosystem allows for comparative analysis across vehicle fleets, identifying patterns and anomalies that would remain undetectable in isolated diagnostic environments.

Cloud-based diagnostic platforms are emerging as central repositories for aggregated GDI performance data, enabling sophisticated machine learning algorithms to establish normative performance baselines across different vehicle models, driving conditions, and geographical regions. These platforms can detect subtle deviations from expected performance parameters before they manifest as noticeable issues, significantly enhancing the precision of diagnostic outcomes.

Edge computing implementations within the connected vehicle architecture are addressing latency concerns by processing time-sensitive GDI diagnostic data locally while transmitting aggregated insights to cloud platforms. This hybrid approach ensures that critical diagnostic functions remain operational even during connectivity interruptions while still benefiting from the broader ecosystem's analytical capabilities.

Smartphone integration through dedicated applications is extending the reach of GDI diagnostic systems beyond professional service environments, empowering vehicle owners with accessible diagnostic insights. These applications translate complex GDI performance metrics into actionable information, fostering improved maintenance practices and earlier problem identification.

Over-the-air (OTA) update capabilities within this ecosystem enable continuous refinement of diagnostic algorithms based on fleet-wide performance data. This dynamic improvement cycle ensures that GDI diagnostic systems evolve in response to emerging performance patterns, environmental factors, and fuel quality variations across different markets.

Security considerations remain paramount as these integrated systems manage increasingly sensitive vehicle performance data. Advanced encryption protocols, secure authentication mechanisms, and privacy-preserving data handling practices are being implemented to safeguard the integrity of the diagnostic ecosystem while maintaining its functional benefits.

Vehicle-to-everything (V2X) communication protocols are establishing robust channels for GDI diagnostic data to flow seamlessly between vehicles, infrastructure, and cloud platforms. These protocols facilitate the transmission of critical engine performance metrics, fuel injection parameters, and combustion efficiency data to centralized analytics systems. The resulting ecosystem allows for comparative analysis across vehicle fleets, identifying patterns and anomalies that would remain undetectable in isolated diagnostic environments.

Cloud-based diagnostic platforms are emerging as central repositories for aggregated GDI performance data, enabling sophisticated machine learning algorithms to establish normative performance baselines across different vehicle models, driving conditions, and geographical regions. These platforms can detect subtle deviations from expected performance parameters before they manifest as noticeable issues, significantly enhancing the precision of diagnostic outcomes.

Edge computing implementations within the connected vehicle architecture are addressing latency concerns by processing time-sensitive GDI diagnostic data locally while transmitting aggregated insights to cloud platforms. This hybrid approach ensures that critical diagnostic functions remain operational even during connectivity interruptions while still benefiting from the broader ecosystem's analytical capabilities.

Smartphone integration through dedicated applications is extending the reach of GDI diagnostic systems beyond professional service environments, empowering vehicle owners with accessible diagnostic insights. These applications translate complex GDI performance metrics into actionable information, fostering improved maintenance practices and earlier problem identification.

Over-the-air (OTA) update capabilities within this ecosystem enable continuous refinement of diagnostic algorithms based on fleet-wide performance data. This dynamic improvement cycle ensures that GDI diagnostic systems evolve in response to emerging performance patterns, environmental factors, and fuel quality variations across different markets.

Security considerations remain paramount as these integrated systems manage increasingly sensitive vehicle performance data. Advanced encryption protocols, secure authentication mechanisms, and privacy-preserving data handling practices are being implemented to safeguard the integrity of the diagnostic ecosystem while maintaining its functional benefits.

Environmental Impact and Emissions Compliance Standards

The evolution of GDI (Gasoline Direct Injection) engine technology has significantly impacted environmental regulations and emissions standards worldwide. As automotive manufacturers continue to enhance GDI diagnostic systems for precision, they must navigate increasingly stringent emissions compliance frameworks. Current Euro 7, EPA Tier 3, and California's CARB regulations specifically target particulate matter (PM) and NOx emissions—areas where GDI engines face particular challenges despite their fuel efficiency advantages.

GDI diagnostic precision directly correlates with emissions compliance, as accurate fuel delivery monitoring prevents incomplete combustion events that generate excess pollutants. Research indicates that GDI engines with advanced diagnostic capabilities demonstrate 15-20% lower real-world emissions compared to those with conventional monitoring systems. This performance gap becomes particularly significant when considering the lifetime emissions profile of vehicles, where diagnostic degradation can lead to exponential increases in harmful exhaust components.

Recent studies from the International Council on Clean Transportation (ICCT) highlight that precision diagnostics in GDI systems can reduce particulate number emissions by up to 40% under variable driving conditions. This reduction is critical as regulatory bodies worldwide transition from laboratory-based testing protocols to Real Driving Emissions (RDE) standards that evaluate performance across diverse operational scenarios.

The implementation of On-Board Diagnostic (OBD) requirements has evolved to demand increasingly sophisticated monitoring of emission control systems. Modern GDI diagnostic systems must detect malfunctions before emissions exceed 1.5 times the certification standard—a threshold that requires microsecond-level precision in fuel delivery monitoring and combustion analysis. This precision requirement drives innovation in sensor technology, data processing algorithms, and predictive maintenance capabilities.

Climate change initiatives further influence GDI diagnostic development through carbon dioxide emission targets. The European Union's fleet-wide CO2 emissions target of 95g/km and similar standards in other regions necessitate optimal combustion efficiency that only precision diagnostics can ensure. Enhanced diagnostic systems that can detect and correct minor performance deviations before they impact emissions profiles have become essential compliance tools rather than optional features.

Manufacturers investing in advanced GDI diagnostic systems gain competitive advantages through regulatory compliance flexibility. These systems enable real-time emissions optimization strategies that adapt to changing environmental conditions, driving patterns, and fuel quality variations—factors that static calibration approaches cannot adequately address. This adaptive capability will become increasingly valuable as emissions standards continue to tighten globally through 2030 and beyond.

GDI diagnostic precision directly correlates with emissions compliance, as accurate fuel delivery monitoring prevents incomplete combustion events that generate excess pollutants. Research indicates that GDI engines with advanced diagnostic capabilities demonstrate 15-20% lower real-world emissions compared to those with conventional monitoring systems. This performance gap becomes particularly significant when considering the lifetime emissions profile of vehicles, where diagnostic degradation can lead to exponential increases in harmful exhaust components.

Recent studies from the International Council on Clean Transportation (ICCT) highlight that precision diagnostics in GDI systems can reduce particulate number emissions by up to 40% under variable driving conditions. This reduction is critical as regulatory bodies worldwide transition from laboratory-based testing protocols to Real Driving Emissions (RDE) standards that evaluate performance across diverse operational scenarios.

The implementation of On-Board Diagnostic (OBD) requirements has evolved to demand increasingly sophisticated monitoring of emission control systems. Modern GDI diagnostic systems must detect malfunctions before emissions exceed 1.5 times the certification standard—a threshold that requires microsecond-level precision in fuel delivery monitoring and combustion analysis. This precision requirement drives innovation in sensor technology, data processing algorithms, and predictive maintenance capabilities.

Climate change initiatives further influence GDI diagnostic development through carbon dioxide emission targets. The European Union's fleet-wide CO2 emissions target of 95g/km and similar standards in other regions necessitate optimal combustion efficiency that only precision diagnostics can ensure. Enhanced diagnostic systems that can detect and correct minor performance deviations before they impact emissions profiles have become essential compliance tools rather than optional features.

Manufacturers investing in advanced GDI diagnostic systems gain competitive advantages through regulatory compliance flexibility. These systems enable real-time emissions optimization strategies that adapt to changing environmental conditions, driving patterns, and fuel quality variations—factors that static calibration approaches cannot adequately address. This adaptive capability will become increasingly valuable as emissions standards continue to tighten globally through 2030 and beyond.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!