Enhancing GDI Engine Turbocharger Integration Strategies

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Turbocharger Technology Background and Objectives

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s, revolutionizing internal combustion engine efficiency. This evolution has been characterized by progressive improvements in fuel atomization, injection timing precision, and combustion control strategies. The integration of turbocharging with GDI systems represents a critical advancement in addressing increasingly stringent emissions regulations while meeting consumer demands for enhanced performance and fuel economy.

The historical trajectory of GDI-turbocharger integration began with rudimentary systems that suffered from turbo lag and limited boost control. Early implementations focused primarily on power enhancement rather than comprehensive efficiency gains. The technological inflection point occurred around 2010-2015, when sophisticated electronic control units (ECUs) enabled more precise coordination between injection events and turbocharger operation, fundamentally transforming the capability of these integrated systems.

Current GDI-turbocharger technology leverages multi-stage injection strategies synchronized with variable geometry turbochargers to optimize air-fuel mixture formation across diverse operating conditions. This synergy has enabled downsized engines to deliver performance comparable to naturally aspirated engines of larger displacement while achieving 15-30% improvements in fuel efficiency and corresponding reductions in CO2 emissions.

The primary technical objectives for enhancing GDI-turbocharger integration strategies center on four key areas: minimizing turbo lag through advanced control algorithms and electrification; optimizing transient response characteristics during rapid load changes; reducing particulate matter emissions that are inherent to direct injection systems; and maximizing thermal efficiency across the entire operating envelope.

Industry projections indicate that GDI-turbocharger systems will remain dominant in the internal combustion landscape for at least another decade, serving as a bridge technology during the transition toward electrification. This creates an imperative to further refine integration strategies to extract maximum efficiency from conventional powertrains.

The technological trajectory is now moving toward 48V mild-hybrid systems that incorporate electric turbochargers or compressors to complement traditional exhaust-driven turbochargers. These hybrid boosting solutions promise to eliminate turbo lag entirely while enabling more aggressive engine downsizing and higher compression ratios.

Our research objectives include developing next-generation control strategies that leverage artificial intelligence to predict and optimize boost requirements based on driver behavior patterns and road conditions, creating adaptive systems that continuously optimize the GDI-turbocharger relationship for maximum efficiency and minimal emissions across all operating conditions.

The historical trajectory of GDI-turbocharger integration began with rudimentary systems that suffered from turbo lag and limited boost control. Early implementations focused primarily on power enhancement rather than comprehensive efficiency gains. The technological inflection point occurred around 2010-2015, when sophisticated electronic control units (ECUs) enabled more precise coordination between injection events and turbocharger operation, fundamentally transforming the capability of these integrated systems.

Current GDI-turbocharger technology leverages multi-stage injection strategies synchronized with variable geometry turbochargers to optimize air-fuel mixture formation across diverse operating conditions. This synergy has enabled downsized engines to deliver performance comparable to naturally aspirated engines of larger displacement while achieving 15-30% improvements in fuel efficiency and corresponding reductions in CO2 emissions.

The primary technical objectives for enhancing GDI-turbocharger integration strategies center on four key areas: minimizing turbo lag through advanced control algorithms and electrification; optimizing transient response characteristics during rapid load changes; reducing particulate matter emissions that are inherent to direct injection systems; and maximizing thermal efficiency across the entire operating envelope.

Industry projections indicate that GDI-turbocharger systems will remain dominant in the internal combustion landscape for at least another decade, serving as a bridge technology during the transition toward electrification. This creates an imperative to further refine integration strategies to extract maximum efficiency from conventional powertrains.

The technological trajectory is now moving toward 48V mild-hybrid systems that incorporate electric turbochargers or compressors to complement traditional exhaust-driven turbochargers. These hybrid boosting solutions promise to eliminate turbo lag entirely while enabling more aggressive engine downsizing and higher compression ratios.

Our research objectives include developing next-generation control strategies that leverage artificial intelligence to predict and optimize boost requirements based on driver behavior patterns and road conditions, creating adaptive systems that continuously optimize the GDI-turbocharger relationship for maximum efficiency and minimal emissions across all operating conditions.

Market Analysis for Turbocharged GDI Engines

The global market for turbocharged Gasoline Direct Injection (GDI) engines has experienced significant growth over the past decade, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles without compromising performance. According to recent industry reports, the turbocharged GDI engine market reached approximately $12.5 billion in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2028.

Europe currently leads the market adoption of turbocharged GDI technology, accounting for nearly 40% of the global market share. This dominance is largely attributed to the region's strict emission standards and high fuel prices. North America follows with roughly 30% market share, while Asia-Pacific represents the fastest-growing region with China and India as key growth drivers due to their rapidly expanding automotive sectors and increasing environmental regulations.

Consumer preferences have shifted noticeably toward vehicles offering improved fuel economy without sacrificing performance. Market research indicates that vehicles equipped with turbocharged GDI engines typically deliver 15-20% better fuel efficiency compared to conventional port fuel injection systems, while simultaneously providing 10-15% more torque at lower RPMs. This performance-efficiency balance has proven particularly attractive in the premium and mid-range vehicle segments.

The passenger vehicle segment dominates the application landscape, representing approximately 65% of turbocharged GDI engine installations. However, the commercial vehicle sector is showing accelerated adoption rates as fleet operators increasingly prioritize total cost of ownership calculations where fuel savings become significant over vehicle lifetimes.

Major automotive manufacturers have responded to this market trend by expanding their turbocharged GDI engine offerings. Volkswagen Group, Ford, BMW, and Hyundai-Kia have been particularly aggressive in implementing this technology across their model lineups. The supplier ecosystem has also evolved, with companies like Bosch, Continental, Delphi, and Denso developing increasingly sophisticated fuel injection systems and turbocharger technologies specifically optimized for GDI applications.

Market analysis reveals several emerging trends that will likely shape future development. Downsized turbocharged GDI engines (typically three-cylinder configurations) are gaining popularity in smaller vehicle segments. Additionally, the integration of turbocharged GDI technology with hybrid powertrains represents a growing market segment, offering further efficiency improvements while addressing emission challenges.

Challenges remain in terms of particulate emissions from GDI engines, which has spurred development of gasoline particulate filters and advanced combustion strategies. The market for these complementary technologies is expected to grow in parallel with turbocharged GDI adoption, creating additional opportunities for component suppliers and technology developers.

Europe currently leads the market adoption of turbocharged GDI technology, accounting for nearly 40% of the global market share. This dominance is largely attributed to the region's strict emission standards and high fuel prices. North America follows with roughly 30% market share, while Asia-Pacific represents the fastest-growing region with China and India as key growth drivers due to their rapidly expanding automotive sectors and increasing environmental regulations.

Consumer preferences have shifted noticeably toward vehicles offering improved fuel economy without sacrificing performance. Market research indicates that vehicles equipped with turbocharged GDI engines typically deliver 15-20% better fuel efficiency compared to conventional port fuel injection systems, while simultaneously providing 10-15% more torque at lower RPMs. This performance-efficiency balance has proven particularly attractive in the premium and mid-range vehicle segments.

The passenger vehicle segment dominates the application landscape, representing approximately 65% of turbocharged GDI engine installations. However, the commercial vehicle sector is showing accelerated adoption rates as fleet operators increasingly prioritize total cost of ownership calculations where fuel savings become significant over vehicle lifetimes.

Major automotive manufacturers have responded to this market trend by expanding their turbocharged GDI engine offerings. Volkswagen Group, Ford, BMW, and Hyundai-Kia have been particularly aggressive in implementing this technology across their model lineups. The supplier ecosystem has also evolved, with companies like Bosch, Continental, Delphi, and Denso developing increasingly sophisticated fuel injection systems and turbocharger technologies specifically optimized for GDI applications.

Market analysis reveals several emerging trends that will likely shape future development. Downsized turbocharged GDI engines (typically three-cylinder configurations) are gaining popularity in smaller vehicle segments. Additionally, the integration of turbocharged GDI technology with hybrid powertrains represents a growing market segment, offering further efficiency improvements while addressing emission challenges.

Challenges remain in terms of particulate emissions from GDI engines, which has spurred development of gasoline particulate filters and advanced combustion strategies. The market for these complementary technologies is expected to grow in parallel with turbocharged GDI adoption, creating additional opportunities for component suppliers and technology developers.

Current Integration Challenges and Technical Limitations

The integration of turbochargers with Gasoline Direct Injection (GDI) engines presents several significant technical challenges that currently limit optimization potential. One primary obstacle is thermal management, as GDI engines operate at higher combustion temperatures than port fuel injection systems. The proximity of turbochargers to these high-temperature environments creates material stress and potential durability issues, particularly at the turbine housing and wastegate components.

Transient response characteristics remain a critical limitation in GDI-turbocharger systems. The inherent lag between driver demand and turbocharger response—commonly known as "turbo lag"—continues to impact drivability and performance perception. While various mitigation strategies exist, including variable geometry turbochargers and twin-scroll designs, these solutions add complexity and cost while still not completely eliminating the phenomenon.

Packaging constraints represent another significant challenge, particularly as emission control systems grow more complex. The integration of turbochargers, intercoolers, exhaust gas recirculation systems, and catalytic converters in increasingly compact engine compartments creates thermal management difficulties and potential interference issues. This spatial limitation often forces compromises in turbocharger sizing and positioning that can impact overall system efficiency.

Control system integration presents substantial technical hurdles. The sophisticated electronic control units must precisely manage boost pressure, fuel injection timing, and ignition timing across widely varying operating conditions. Current systems struggle to maintain optimal air-fuel ratios during rapid transient events, leading to momentary efficiency losses and potential drivability issues.

Knock resistance remains a persistent challenge in turbocharged GDI applications. The increased cylinder pressures and temperatures from forced induction increase the propensity for engine knock, requiring sophisticated detection systems and preventative control strategies that often result in performance derating under certain conditions.

Material limitations also constrain current integration strategies. While advanced alloys and manufacturing techniques have improved turbocharger durability, the extreme thermal cycling and mechanical stress in modern high-output GDI applications continue to challenge component longevity, particularly in smaller displacement engines with higher specific outputs.

Emissions compliance adds another layer of complexity, as turbocharger operation significantly impacts exhaust gas composition and temperature profiles. Meeting stringent NOx, particulate matter, and CO2 regulations simultaneously requires precise balancing of boost pressure, EGR rates, and aftertreatment thermal management—a balance that current integration strategies struggle to maintain across all operating conditions.

Transient response characteristics remain a critical limitation in GDI-turbocharger systems. The inherent lag between driver demand and turbocharger response—commonly known as "turbo lag"—continues to impact drivability and performance perception. While various mitigation strategies exist, including variable geometry turbochargers and twin-scroll designs, these solutions add complexity and cost while still not completely eliminating the phenomenon.

Packaging constraints represent another significant challenge, particularly as emission control systems grow more complex. The integration of turbochargers, intercoolers, exhaust gas recirculation systems, and catalytic converters in increasingly compact engine compartments creates thermal management difficulties and potential interference issues. This spatial limitation often forces compromises in turbocharger sizing and positioning that can impact overall system efficiency.

Control system integration presents substantial technical hurdles. The sophisticated electronic control units must precisely manage boost pressure, fuel injection timing, and ignition timing across widely varying operating conditions. Current systems struggle to maintain optimal air-fuel ratios during rapid transient events, leading to momentary efficiency losses and potential drivability issues.

Knock resistance remains a persistent challenge in turbocharged GDI applications. The increased cylinder pressures and temperatures from forced induction increase the propensity for engine knock, requiring sophisticated detection systems and preventative control strategies that often result in performance derating under certain conditions.

Material limitations also constrain current integration strategies. While advanced alloys and manufacturing techniques have improved turbocharger durability, the extreme thermal cycling and mechanical stress in modern high-output GDI applications continue to challenge component longevity, particularly in smaller displacement engines with higher specific outputs.

Emissions compliance adds another layer of complexity, as turbocharger operation significantly impacts exhaust gas composition and temperature profiles. Meeting stringent NOx, particulate matter, and CO2 regulations simultaneously requires precise balancing of boost pressure, EGR rates, and aftertreatment thermal management—a balance that current integration strategies struggle to maintain across all operating conditions.

Current GDI-Turbocharger Integration Solutions

01 Turbocharger integration with GDI engine systems

Integration of turbochargers with Gasoline Direct Injection (GDI) engines involves specific design considerations to optimize performance. The turbocharger system must be properly sized and configured to work efficiently with the direct injection system, ensuring proper air-fuel mixture and combustion. This integration enhances engine power output while maintaining fuel efficiency and reducing emissions through precise control of boost pressure relative to the direct injection timing.- Turbocharger integration with GDI engine systems: Integration of turbochargers with Gasoline Direct Injection (GDI) engines involves specific design considerations to optimize performance. The turbocharger system must be carefully matched to the GDI engine's characteristics to enhance fuel efficiency and power output. This integration typically includes specialized manifold designs, optimized boost control systems, and proper sizing of the turbocharger relative to the engine displacement to ensure efficient operation across the entire RPM range.

- Exhaust gas recirculation systems for turbocharged GDI engines: Exhaust gas recirculation (EGR) systems play a crucial role in turbocharged GDI engines by helping to control emissions and improve fuel efficiency. These systems redirect a portion of exhaust gases back into the intake manifold, reducing combustion temperatures and NOx emissions. In turbocharged GDI applications, specialized EGR configurations are required to work effectively with the pressurized intake system, often incorporating cooling systems to further enhance performance and emissions control.

- Boost control strategies for GDI turbocharger systems: Advanced boost control strategies are essential for optimizing turbocharged GDI engine performance. These strategies involve electronic control systems that regulate boost pressure based on various engine parameters such as load, speed, and ambient conditions. Modern systems may incorporate variable geometry turbochargers, wastegate control mechanisms, or multi-stage turbocharging to provide optimal boost across different operating conditions, enhancing both performance and fuel efficiency while minimizing turbo lag.

- Thermal management in turbocharged GDI engines: Thermal management is critical in turbocharged GDI engines due to the higher operating temperatures resulting from increased compression and direct fuel injection. Advanced cooling systems are implemented to manage heat in critical components such as the turbocharger, cylinder head, and exhaust manifold. These systems may include specialized intercoolers, oil cooling circuits, and heat shields to protect sensitive components and maintain optimal operating temperatures, thereby enhancing durability and performance.

- Fuel injection timing and strategies for turbocharged GDI engines: Precise fuel injection timing and strategies are essential for optimizing the performance of turbocharged GDI engines. These strategies involve sophisticated control algorithms that adjust injection timing, duration, and pressure based on engine load, speed, and boost pressure. Multiple injection events per cycle may be employed to improve combustion efficiency and reduce emissions. Advanced fuel system components, including high-pressure pumps and precision injectors, are required to deliver fuel effectively under the increased pressure conditions of turbocharged operation.

02 Exhaust gas recirculation systems for turbocharged GDI engines

Exhaust gas recirculation (EGR) systems are integrated with turbocharged GDI engines to reduce emissions and improve efficiency. These systems redirect a portion of exhaust gases back into the intake manifold, lowering combustion temperatures and reducing NOx emissions. The integration requires careful design of flow paths, cooling systems, and control strategies to ensure optimal engine performance while meeting emission standards.Expand Specific Solutions03 Boost pressure control strategies for GDI turbocharger systems

Advanced control strategies for managing boost pressure in turbocharged GDI engines are essential for optimizing performance across various operating conditions. These strategies involve electronic control units that adjust wastegate operation, variable geometry turbocharger settings, and fuel injection parameters based on engine load, speed, and environmental conditions. Proper boost control prevents knock, ensures efficient combustion, and maximizes power output while protecting engine components.Expand Specific Solutions04 Thermal management in turbocharged GDI engines

Thermal management systems are critical in turbocharged GDI engines due to increased heat generation from both direct injection and turbocharging. These systems include advanced cooling circuits, heat shields, and temperature sensors to maintain optimal operating temperatures for both the engine and turbocharger. Effective thermal management prevents component damage, reduces thermal stress, improves efficiency, and ensures consistent performance under varying load conditions.Expand Specific Solutions05 Twin-turbo and sequential turbocharging for GDI engines

Twin-turbo and sequential turbocharging configurations are implemented in GDI engines to overcome turbo lag and provide optimal boost across the entire RPM range. These systems use multiple turbochargers of different sizes or configurations working either in parallel or in sequence. Smaller turbochargers provide quick response at low engine speeds, while larger ones deliver higher boost at higher RPMs. This approach maximizes torque availability, improves transient response, and enhances overall engine efficiency.Expand Specific Solutions

Leading Manufacturers and Industry Competition Landscape

The GDI Engine Turbocharger Integration market is currently in a growth phase, with increasing demand driven by stringent emission regulations and fuel efficiency requirements. The market size is estimated to be expanding at a CAGR of 5-7%, particularly in automotive and commercial vehicle segments. From a technological maturity perspective, established players like Ford Global Technologies and Volkswagen AG lead with advanced integration solutions, while Hyundai Motor, Kia, and FCA US are rapidly advancing their capabilities. Asian manufacturers including Dongfeng Commercial Vehicles and Chery Automobile are emerging as significant competitors, especially in developing markets. Companies like Lubrizol, Chevron Oronite, and Afton Chemical are contributing specialized lubricant technologies that enhance turbocharger performance and durability, indicating a collaborative ecosystem developing around this technology.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced turbocharger integration system specifically for GDI (Gasoline Direct Injection) engines that incorporates variable geometry technology with electronic wastegate control. Their solution features a dual-scroll turbocharger design that separates exhaust pulses to minimize interference and maximize energy extraction from exhaust gases. Ford's system includes integrated cooling channels within the turbocharger housing to manage thermal loads during high-performance operation and prevent carbon buildup common in GDI systems. The company has also implemented a proprietary anti-lag system that maintains turbocharger speed during throttle-off conditions, significantly reducing turbo lag when power is reapplied. Their EcoBoost engine family demonstrates this technology with integrated exhaust manifolds and water-cooled charge air coolers positioned directly on the intake manifold to minimize lag and improve throttle response.

Strengths: Superior thermal management capabilities prevent carbon deposits in GDI injectors while maintaining optimal turbocharger efficiency. The dual-scroll design provides excellent low-end torque and responsiveness. Weaknesses: The complex integration system requires more precise manufacturing tolerances and may increase production costs compared to simpler turbocharger implementations.

Delphi Technology, Inc.

Technical Solution: Delphi has engineered a comprehensive turbocharger integration solution for GDI engines that focuses on system-level optimization rather than individual component performance. Their approach centers on a holistic view of the air and fuel management systems, with the turbocharger designed to work in precise harmony with their advanced GDI injectors. Delphi's system features variable-flow turbochargers with electronic wastegate control that continuously adjusts boost pressure based on real-time combustion feedback. Their technology includes specialized coatings on turbocharger components to resist the unique chemical composition of GDI exhaust gases, which contain higher levels of particulates and potential fuel contaminants. Delphi has also developed an integrated charge air cooling system that maintains optimal intake temperatures across all operating conditions, preventing knock while maximizing volumetric efficiency. Their solution incorporates advanced sensors throughout the air path to provide comprehensive data to the engine management system, enabling predictive boost control strategies that anticipate driver demands.

Strengths: Exceptional system integration provides optimized performance across the entire operating range. The specialized component coatings significantly extend service life in the harsh GDI environment. Weaknesses: The highly integrated approach makes individual component replacement more difficult and potentially more expensive than modular systems.

Key Patents and Innovations in Turbocharger-GDI Integration

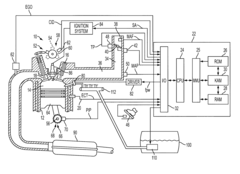

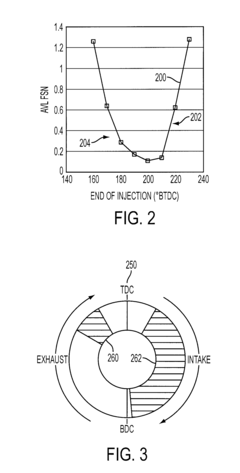

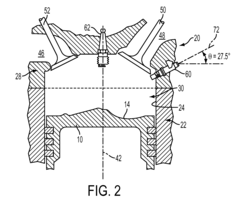

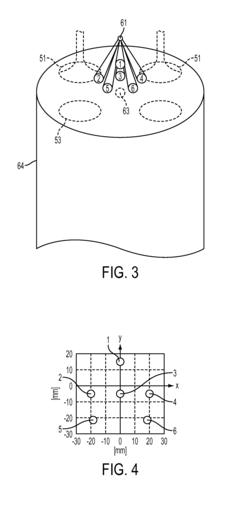

Fuel injection strategy for gasoline direct injection engine during high speed/load operation

PatentInactiveUS7720593B2

Innovation

- A system and method that injects a fraction of the total fuel during the exhaust stroke, followed by a second injection during the intake or compression stroke, to enhance mixing time and reduce the impact of intake airflow, thereby improving fuel-air homogeneity and eliminating the need for an auxiliary high-pressure fuel pump.

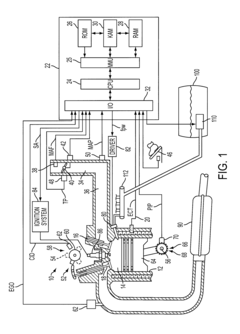

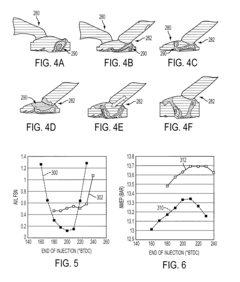

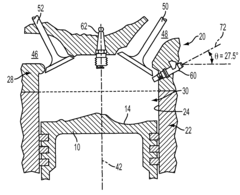

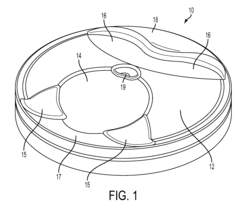

Shallow piston bowl and injector spray pattern for a gasoline, direct-injection engine

PatentActiveUS8056531B2

Innovation

- A combustion system design featuring a piston with a shallow spherical bowl and a fuel injector with six orifices, where the injector axis forms an angle greater than 60 degrees with the cylinder bore axis, and two orifices are directed toward the bowl to create a stable stratified mixture around the spark plug, minimizing soot emissions and improving thermal efficiency.

Emissions Compliance and Regulatory Considerations

The integration of GDI (Gasoline Direct Injection) engines with turbocharger systems must navigate an increasingly complex regulatory landscape. Current emissions standards worldwide have evolved significantly, with Euro 7, China 6b, and US Tier 3 regulations imposing stringent limits on particulate matter (PM), NOx, and CO2 emissions. These regulations directly impact turbocharger integration strategies, as the combination of high-pressure fuel injection and forced induction creates unique emissions challenges.

Particulate matter emissions present a particular concern for GDI-turbo systems. The high combustion temperatures and pressures created by this combination can lead to increased soot formation, especially during transient operations when air-fuel mixture preparation is suboptimal. Regulatory bodies have responded by implementing particle number (PN) limits alongside traditional mass-based measurements, requiring manufacturers to adopt sophisticated particulate filtration technologies.

Real Driving Emissions (RDE) testing protocols have fundamentally changed compliance strategies. Unlike laboratory cycles, RDE evaluates emissions performance across diverse driving conditions, including cold starts, high loads, and rapid accelerations—all scenarios where turbocharger-GDI integration faces challenges. This shift demands more robust calibration strategies that maintain emissions compliance across the entire operating envelope rather than optimizing for specific test points.

Cold-start emissions management represents another critical regulatory consideration. Turbochargers inherently increase thermal mass in the exhaust system, potentially delaying catalyst light-off. With regulations increasingly focusing on the first few minutes of operation, integration strategies must address this conflict between turbocharger performance and emissions compliance during warm-up phases.

Regional regulatory divergence creates additional complexity for global powertrain platforms. China's emphasis on particulate control, Europe's focus on NOx and CO2, and California's zero-emission vehicle mandates represent different priorities that influence turbocharger-GDI integration approaches. Manufacturers must develop flexible architectures capable of meeting these varied requirements without complete redesigns for each market.

Looking forward, upcoming regulatory changes will likely accelerate the adoption of 48V mild-hybrid systems working in conjunction with turbocharger-GDI powertrains. These electrified solutions can address transient response limitations while simultaneously reducing emissions during high-load conditions. The regulatory pathway appears to be steering development toward increasingly electrified boosting solutions that complement traditional turbocharging approaches while meeting ever-tightening emissions standards.

Particulate matter emissions present a particular concern for GDI-turbo systems. The high combustion temperatures and pressures created by this combination can lead to increased soot formation, especially during transient operations when air-fuel mixture preparation is suboptimal. Regulatory bodies have responded by implementing particle number (PN) limits alongside traditional mass-based measurements, requiring manufacturers to adopt sophisticated particulate filtration technologies.

Real Driving Emissions (RDE) testing protocols have fundamentally changed compliance strategies. Unlike laboratory cycles, RDE evaluates emissions performance across diverse driving conditions, including cold starts, high loads, and rapid accelerations—all scenarios where turbocharger-GDI integration faces challenges. This shift demands more robust calibration strategies that maintain emissions compliance across the entire operating envelope rather than optimizing for specific test points.

Cold-start emissions management represents another critical regulatory consideration. Turbochargers inherently increase thermal mass in the exhaust system, potentially delaying catalyst light-off. With regulations increasingly focusing on the first few minutes of operation, integration strategies must address this conflict between turbocharger performance and emissions compliance during warm-up phases.

Regional regulatory divergence creates additional complexity for global powertrain platforms. China's emphasis on particulate control, Europe's focus on NOx and CO2, and California's zero-emission vehicle mandates represent different priorities that influence turbocharger-GDI integration approaches. Manufacturers must develop flexible architectures capable of meeting these varied requirements without complete redesigns for each market.

Looking forward, upcoming regulatory changes will likely accelerate the adoption of 48V mild-hybrid systems working in conjunction with turbocharger-GDI powertrains. These electrified solutions can address transient response limitations while simultaneously reducing emissions during high-load conditions. The regulatory pathway appears to be steering development toward increasingly electrified boosting solutions that complement traditional turbocharging approaches while meeting ever-tightening emissions standards.

Thermal Management Strategies for Turbocharged GDI Systems

Thermal management represents a critical challenge in turbocharged Gasoline Direct Injection (GDI) systems due to the elevated operating temperatures resulting from increased power density. Effective thermal management strategies are essential to maintain optimal performance, reliability, and emissions compliance while preventing component degradation under high thermal loads.

The integration of turbochargers with GDI engines creates distinct thermal challenges, particularly at the turbine housing where exhaust gas temperatures can exceed 950°C during high-load operation. These extreme temperatures necessitate sophisticated cooling solutions to protect both the turbocharger bearings and surrounding components from thermal damage.

Water-cooled charge air coolers (WCAC) have emerged as a preferred solution over traditional air-to-air intercoolers in modern turbocharged GDI applications. WCACs offer superior cooling efficiency and more compact packaging, enabling intake air temperature reductions of up to 30°C compared to conventional systems, which directly improves volumetric efficiency and knock resistance.

Split cooling systems represent another advanced thermal management approach, utilizing separate cooling circuits operating at different temperature levels. The primary circuit maintains optimal engine block temperatures (around 90-105°C), while a lower-temperature secondary circuit (65-75°C) serves heat-sensitive components such as the charge air cooler and EGR cooler, optimizing the thermal efficiency across the entire system.

Integrated exhaust manifolds (IEM) have gained prominence in recent GDI turbocharger applications, where the exhaust manifold is cast directly into the cylinder head. This design facilitates faster catalyst light-off through improved heat retention during cold starts while enabling more effective cooling during sustained high-load operation through the engine's cooling system.

Active thermal management systems employing electronically controlled valves and pumps allow for precise temperature regulation across various operating conditions. These systems can prioritize rapid warm-up during cold starts to reduce emissions, then transition to optimized cooling during high-load operation, improving overall thermal efficiency by up to 5% compared to conventional passive systems.

Heat shields and thermal barrier coatings provide localized thermal protection for sensitive components near the turbocharger. Advanced ceramic coatings can reduce heat transfer by up to 40%, protecting electronic components and preventing oil coking in bearing assemblies, thereby extending turbocharger service life and maintaining performance over time.

The integration of turbochargers with GDI engines creates distinct thermal challenges, particularly at the turbine housing where exhaust gas temperatures can exceed 950°C during high-load operation. These extreme temperatures necessitate sophisticated cooling solutions to protect both the turbocharger bearings and surrounding components from thermal damage.

Water-cooled charge air coolers (WCAC) have emerged as a preferred solution over traditional air-to-air intercoolers in modern turbocharged GDI applications. WCACs offer superior cooling efficiency and more compact packaging, enabling intake air temperature reductions of up to 30°C compared to conventional systems, which directly improves volumetric efficiency and knock resistance.

Split cooling systems represent another advanced thermal management approach, utilizing separate cooling circuits operating at different temperature levels. The primary circuit maintains optimal engine block temperatures (around 90-105°C), while a lower-temperature secondary circuit (65-75°C) serves heat-sensitive components such as the charge air cooler and EGR cooler, optimizing the thermal efficiency across the entire system.

Integrated exhaust manifolds (IEM) have gained prominence in recent GDI turbocharger applications, where the exhaust manifold is cast directly into the cylinder head. This design facilitates faster catalyst light-off through improved heat retention during cold starts while enabling more effective cooling during sustained high-load operation through the engine's cooling system.

Active thermal management systems employing electronically controlled valves and pumps allow for precise temperature regulation across various operating conditions. These systems can prioritize rapid warm-up during cold starts to reduce emissions, then transition to optimized cooling during high-load operation, improving overall thermal efficiency by up to 5% compared to conventional passive systems.

Heat shields and thermal barrier coatings provide localized thermal protection for sensitive components near the turbocharger. Advanced ceramic coatings can reduce heat transfer by up to 40%, protecting electronic components and preventing oil coking in bearing assemblies, thereby extending turbocharger service life and maintaining performance over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!