Ethyl Acetate Applications in Pharmaceuticals: An Overview

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Pharma: Background and Objectives

Ethyl acetate, a versatile organic compound, has been a cornerstone in pharmaceutical applications for decades. Its journey in the pharmaceutical industry began in the early 20th century when its solvent properties were first recognized and utilized in drug formulation processes. As the pharmaceutical sector evolved, so did the applications of ethyl acetate, expanding from simple solvent uses to more complex roles in drug synthesis and delivery systems.

The primary objective of exploring ethyl acetate in pharmaceuticals is to harness its unique chemical properties for enhancing drug development and manufacturing processes. Its low toxicity, high volatility, and excellent solvency make it an ideal candidate for various pharmaceutical applications. These properties have driven continuous research and innovation in its use, aiming to improve drug efficacy, stability, and production efficiency.

Over the years, the pharmaceutical industry has witnessed significant technological advancements, with ethyl acetate playing a crucial role in many of these developments. From its initial use as a simple extraction solvent, it has progressed to become an integral component in advanced drug delivery systems and controlled release formulations. This evolution reflects the broader trend in pharmaceutical technology towards more sophisticated and targeted drug delivery mechanisms.

The current landscape of ethyl acetate in pharmaceuticals is characterized by its multifaceted applications. It serves as a critical solvent in the synthesis of various active pharmaceutical ingredients (APIs), acts as a crucial component in tablet coating processes, and plays a vital role in the production of transdermal patches. Its use extends to analytical processes in pharmaceutical quality control, where it is employed in chromatography and other analytical techniques.

Looking ahead, the future of ethyl acetate in pharmaceuticals appears promising, with emerging trends pointing towards its increased use in green chemistry applications. As the industry moves towards more sustainable practices, ethyl acetate's relatively low environmental impact compared to other solvents positions it as a key player in eco-friendly pharmaceutical manufacturing processes.

The ongoing research in nanotechnology and advanced drug delivery systems also opens new avenues for ethyl acetate applications. Its potential in nanoparticle formulations and as a component in novel drug encapsulation techniques is being actively explored, promising to revolutionize drug delivery methods and enhance therapeutic outcomes.

In conclusion, the background and objectives of ethyl acetate use in pharmaceuticals reflect a journey of continuous innovation and adaptation. From its humble beginnings as a simple solvent to its current status as a versatile component in advanced pharmaceutical processes, ethyl acetate continues to be a subject of intense research and development. The ongoing exploration of its properties and applications aims to unlock new possibilities in drug formulation, delivery, and manufacturing, ultimately contributing to advancements in patient care and treatment efficacy.

The primary objective of exploring ethyl acetate in pharmaceuticals is to harness its unique chemical properties for enhancing drug development and manufacturing processes. Its low toxicity, high volatility, and excellent solvency make it an ideal candidate for various pharmaceutical applications. These properties have driven continuous research and innovation in its use, aiming to improve drug efficacy, stability, and production efficiency.

Over the years, the pharmaceutical industry has witnessed significant technological advancements, with ethyl acetate playing a crucial role in many of these developments. From its initial use as a simple extraction solvent, it has progressed to become an integral component in advanced drug delivery systems and controlled release formulations. This evolution reflects the broader trend in pharmaceutical technology towards more sophisticated and targeted drug delivery mechanisms.

The current landscape of ethyl acetate in pharmaceuticals is characterized by its multifaceted applications. It serves as a critical solvent in the synthesis of various active pharmaceutical ingredients (APIs), acts as a crucial component in tablet coating processes, and plays a vital role in the production of transdermal patches. Its use extends to analytical processes in pharmaceutical quality control, where it is employed in chromatography and other analytical techniques.

Looking ahead, the future of ethyl acetate in pharmaceuticals appears promising, with emerging trends pointing towards its increased use in green chemistry applications. As the industry moves towards more sustainable practices, ethyl acetate's relatively low environmental impact compared to other solvents positions it as a key player in eco-friendly pharmaceutical manufacturing processes.

The ongoing research in nanotechnology and advanced drug delivery systems also opens new avenues for ethyl acetate applications. Its potential in nanoparticle formulations and as a component in novel drug encapsulation techniques is being actively explored, promising to revolutionize drug delivery methods and enhance therapeutic outcomes.

In conclusion, the background and objectives of ethyl acetate use in pharmaceuticals reflect a journey of continuous innovation and adaptation. From its humble beginnings as a simple solvent to its current status as a versatile component in advanced pharmaceutical processes, ethyl acetate continues to be a subject of intense research and development. The ongoing exploration of its properties and applications aims to unlock new possibilities in drug formulation, delivery, and manufacturing, ultimately contributing to advancements in patient care and treatment efficacy.

Pharmaceutical Market Demand for Ethyl Acetate

The pharmaceutical industry's demand for ethyl acetate has been steadily increasing due to its versatile applications in drug manufacturing processes. Ethyl acetate serves as a crucial solvent in various pharmaceutical operations, including drug synthesis, extraction, and purification. Its low toxicity, high volatility, and excellent solvency properties make it an ideal choice for many pharmaceutical applications.

In recent years, the global pharmaceutical market has experienced significant growth, driven by factors such as an aging population, increasing prevalence of chronic diseases, and advancements in drug discovery technologies. This growth has directly contributed to the rising demand for ethyl acetate in the pharmaceutical sector.

One of the primary applications of ethyl acetate in pharmaceuticals is as a reaction medium for the synthesis of active pharmaceutical ingredients (APIs). Its ability to dissolve a wide range of organic compounds makes it an excellent solvent for various chemical reactions involved in drug production. Additionally, ethyl acetate is extensively used in the extraction and purification of natural products, which are often utilized as raw materials or intermediates in pharmaceutical manufacturing.

The pharmaceutical industry also employs ethyl acetate in the formulation of drug delivery systems. Its low boiling point and rapid evaporation rate make it suitable for coating processes, particularly in the production of controlled-release tablets and capsules. This application has gained importance as the demand for advanced drug delivery systems continues to grow.

Furthermore, ethyl acetate plays a crucial role in the analytical processes within pharmaceutical laboratories. It is commonly used as a mobile phase in high-performance liquid chromatography (HPLC) and as an extraction solvent in sample preparation for various analytical techniques. The increasing focus on quality control and regulatory compliance in the pharmaceutical industry has led to a higher demand for analytical-grade ethyl acetate.

The market demand for ethyl acetate in pharmaceuticals is also influenced by the growing trend towards green chemistry and sustainable manufacturing practices. As a relatively environmentally friendly solvent, ethyl acetate is often preferred over more hazardous alternatives, aligning with the industry's efforts to reduce its environmental footprint.

As the pharmaceutical industry continues to expand and innovate, the demand for ethyl acetate is expected to grow further. Emerging markets, particularly in Asia-Pacific and Latin America, are likely to drive significant increases in consumption as their pharmaceutical sectors develop and mature. Additionally, the ongoing research and development of novel drug formulations and manufacturing processes may create new applications for ethyl acetate, further boosting its demand in the pharmaceutical market.

In recent years, the global pharmaceutical market has experienced significant growth, driven by factors such as an aging population, increasing prevalence of chronic diseases, and advancements in drug discovery technologies. This growth has directly contributed to the rising demand for ethyl acetate in the pharmaceutical sector.

One of the primary applications of ethyl acetate in pharmaceuticals is as a reaction medium for the synthesis of active pharmaceutical ingredients (APIs). Its ability to dissolve a wide range of organic compounds makes it an excellent solvent for various chemical reactions involved in drug production. Additionally, ethyl acetate is extensively used in the extraction and purification of natural products, which are often utilized as raw materials or intermediates in pharmaceutical manufacturing.

The pharmaceutical industry also employs ethyl acetate in the formulation of drug delivery systems. Its low boiling point and rapid evaporation rate make it suitable for coating processes, particularly in the production of controlled-release tablets and capsules. This application has gained importance as the demand for advanced drug delivery systems continues to grow.

Furthermore, ethyl acetate plays a crucial role in the analytical processes within pharmaceutical laboratories. It is commonly used as a mobile phase in high-performance liquid chromatography (HPLC) and as an extraction solvent in sample preparation for various analytical techniques. The increasing focus on quality control and regulatory compliance in the pharmaceutical industry has led to a higher demand for analytical-grade ethyl acetate.

The market demand for ethyl acetate in pharmaceuticals is also influenced by the growing trend towards green chemistry and sustainable manufacturing practices. As a relatively environmentally friendly solvent, ethyl acetate is often preferred over more hazardous alternatives, aligning with the industry's efforts to reduce its environmental footprint.

As the pharmaceutical industry continues to expand and innovate, the demand for ethyl acetate is expected to grow further. Emerging markets, particularly in Asia-Pacific and Latin America, are likely to drive significant increases in consumption as their pharmaceutical sectors develop and mature. Additionally, the ongoing research and development of novel drug formulations and manufacturing processes may create new applications for ethyl acetate, further boosting its demand in the pharmaceutical market.

Current Status and Challenges in Ethyl Acetate Usage

Ethyl acetate has established itself as a crucial solvent in the pharmaceutical industry, with widespread applications in drug formulation, extraction processes, and as a reaction medium. Currently, its usage is prevalent in various stages of pharmaceutical manufacturing, from the synthesis of active pharmaceutical ingredients (APIs) to the production of final dosage forms.

In API synthesis, ethyl acetate serves as an effective solvent for numerous organic reactions, facilitating the formation of complex molecular structures. Its moderate polarity and low boiling point make it ideal for extracting and purifying pharmaceutical compounds. Additionally, ethyl acetate is extensively used in the preparation of tablet coatings and as a vehicle in topical formulations.

Despite its widespread adoption, the pharmaceutical industry faces several challenges in ethyl acetate usage. One primary concern is the solvent's volatility, which can lead to significant losses during handling and storage. This not only impacts process efficiency but also raises environmental and safety concerns due to potential emissions.

Another challenge lies in the purity requirements for pharmaceutical-grade ethyl acetate. Trace impurities can significantly affect drug quality and stability, necessitating stringent purification processes and quality control measures. This adds complexity and cost to pharmaceutical manufacturing operations.

The industry is also grappling with regulatory pressures to reduce the use of organic solvents in pharmaceutical processes. While ethyl acetate is considered less harmful compared to many other solvents, there is a growing push towards green chemistry principles, which advocate for the use of more environmentally friendly alternatives.

Furthermore, the fluctuating prices of ethyl acetate, driven by raw material costs and market demand, pose challenges for long-term planning and cost management in pharmaceutical production. This volatility can impact the overall economics of drug manufacturing processes.

Lastly, the pharmaceutical industry is exploring continuous manufacturing techniques to improve efficiency and reduce costs. Integrating ethyl acetate into these continuous processes presents technical challenges, particularly in solvent recovery and recycling systems, which are crucial for sustainable and economical operations.

Addressing these challenges requires ongoing research and development efforts. The industry is actively seeking innovative solutions, such as the development of more efficient solvent recovery systems, exploration of alternative green solvents, and optimization of processes to minimize solvent usage. These efforts aim to enhance the sustainability and efficiency of ethyl acetate usage in pharmaceutical applications while meeting stringent quality and regulatory requirements.

In API synthesis, ethyl acetate serves as an effective solvent for numerous organic reactions, facilitating the formation of complex molecular structures. Its moderate polarity and low boiling point make it ideal for extracting and purifying pharmaceutical compounds. Additionally, ethyl acetate is extensively used in the preparation of tablet coatings and as a vehicle in topical formulations.

Despite its widespread adoption, the pharmaceutical industry faces several challenges in ethyl acetate usage. One primary concern is the solvent's volatility, which can lead to significant losses during handling and storage. This not only impacts process efficiency but also raises environmental and safety concerns due to potential emissions.

Another challenge lies in the purity requirements for pharmaceutical-grade ethyl acetate. Trace impurities can significantly affect drug quality and stability, necessitating stringent purification processes and quality control measures. This adds complexity and cost to pharmaceutical manufacturing operations.

The industry is also grappling with regulatory pressures to reduce the use of organic solvents in pharmaceutical processes. While ethyl acetate is considered less harmful compared to many other solvents, there is a growing push towards green chemistry principles, which advocate for the use of more environmentally friendly alternatives.

Furthermore, the fluctuating prices of ethyl acetate, driven by raw material costs and market demand, pose challenges for long-term planning and cost management in pharmaceutical production. This volatility can impact the overall economics of drug manufacturing processes.

Lastly, the pharmaceutical industry is exploring continuous manufacturing techniques to improve efficiency and reduce costs. Integrating ethyl acetate into these continuous processes presents technical challenges, particularly in solvent recovery and recycling systems, which are crucial for sustainable and economical operations.

Addressing these challenges requires ongoing research and development efforts. The industry is actively seeking innovative solutions, such as the development of more efficient solvent recovery systems, exploration of alternative green solvents, and optimization of processes to minimize solvent usage. These efforts aim to enhance the sustainability and efficiency of ethyl acetate usage in pharmaceutical applications while meeting stringent quality and regulatory requirements.

Current Pharmaceutical Applications of Ethyl Acetate

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The processes aim to optimize the production of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The processes aim to optimize the production of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in various chemical processes and industries. It serves as a solvent, reactant, or intermediate in the production of other chemicals, pharmaceuticals, and materials. Its versatility makes it valuable in diverse applications across different sectors.

- Ethyl acetate in extraction and separation processes: Ethyl acetate is employed in extraction and separation processes for various compounds. Its properties make it suitable for liquid-liquid extraction, azeotropic distillation, and other separation techniques. These processes are used in the purification of chemicals and the isolation of specific compounds.

- Environmental and safety considerations for ethyl acetate: The use and handling of ethyl acetate involve environmental and safety considerations. This includes methods for reducing emissions, improving workplace safety, and developing more sustainable production processes. Efforts are made to minimize the environmental impact of ethyl acetate production and use.

- Novel applications and formulations of ethyl acetate: Research into new applications and formulations of ethyl acetate is ongoing. This includes its use in novel materials, coatings, and specialty chemicals. Innovations in formulation and application techniques aim to expand the utility of ethyl acetate in various industries.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes as a solvent, reactant, or intermediate. It finds applications in the production of other chemicals, pharmaceuticals, and materials. The compound's versatility makes it valuable in different industrial sectors.Expand Specific Solutions03 Ethyl acetate in extraction and separation processes

Ethyl acetate is employed in extraction and separation processes for various compounds. Its properties make it suitable for liquid-liquid extraction, chromatography, and other separation techniques. These processes are used in analytical chemistry, pharmaceutical production, and other industries.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

Research and development efforts focus on improving the environmental impact and safety of ethyl acetate production and use. This includes developing greener production methods, reducing emissions, and enhancing handling and storage practices to minimize risks associated with this volatile organic compound.Expand Specific Solutions05 Novel derivatives and modifications of ethyl acetate

Investigations into novel derivatives and modifications of ethyl acetate aim to enhance its properties or create new compounds with improved characteristics. These efforts may lead to the development of new materials or chemicals with unique applications in various industries.Expand Specific Solutions

Key Players in Ethyl Acetate Production and Application

The ethyl acetate applications in pharmaceuticals market is in a growth phase, driven by increasing demand for pharmaceutical products and expanding drug development activities. The market size is substantial, with projections indicating continued expansion due to the versatile uses of ethyl acetate in drug formulation and manufacturing processes. Technologically, the field is relatively mature, with established players like Celanese International Corp., Eastman Chemical Co., and BASF Corp. leading in production and innovation. However, emerging companies such as Nantong Acetic Acid Chemical Co., Ltd. and Jiangsu Baichuan High-Tech New Materials Co., Ltd. are also making significant contributions, particularly in the Asian market. The involvement of pharmaceutical giants like GlaxoSmithKline LLC and Astellas Pharma, Inc. further underscores the importance of ethyl acetate in drug development and production.

Celanese International Corp.

Technical Solution: Celanese has developed advanced ethyl acetate production processes for pharmaceutical applications. Their technology utilizes a reactive distillation process, which combines esterification and distillation in a single unit operation[1]. This method offers improved yield and purity of ethyl acetate, crucial for pharmaceutical-grade products. Celanese's approach also incorporates green chemistry principles, using bio-based feedstocks and catalysts to reduce environmental impact[3]. The company has implemented continuous flow manufacturing techniques, allowing for better process control and consistent product quality[5].

Strengths: High-purity product, eco-friendly production, scalable process. Weaknesses: Higher initial investment, potential complexity in process control.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has innovated in ethyl acetate applications for pharmaceuticals through their proprietary esterification technology. They utilize a heterogeneous catalyst system that enhances reaction efficiency and reduces byproduct formation[2]. Eastman's process incorporates advanced separation techniques, including membrane technology, to achieve high-purity ethyl acetate suitable for pharmaceutical use[4]. The company has also developed specialized grades of ethyl acetate with tailored properties for specific pharmaceutical applications, such as controlled-release drug formulations[6].

Strengths: High-efficiency production, specialized product grades, advanced purification methods. Weaknesses: Potentially higher production costs, reliance on proprietary technology.

Innovative Uses of Ethyl Acetate in Drug Formulation

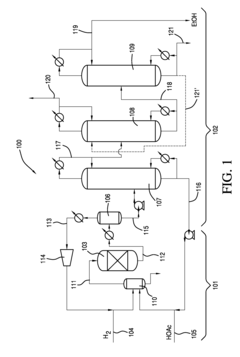

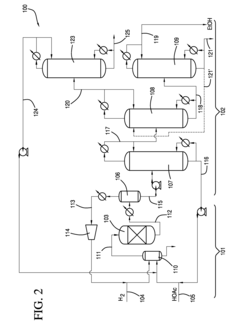

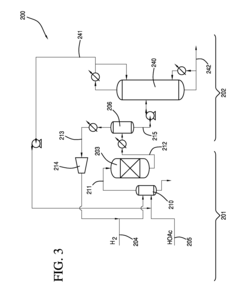

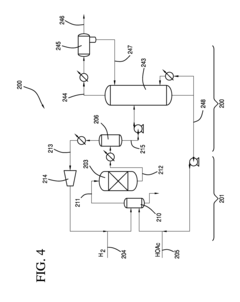

Process for producing an ethyl acetate solvent and co-production of ethanol

PatentInactiveUS20110190531A1

Innovation

- A process involving the hydrogenation of acetic acid in the presence of a catalyst, followed by a series of distillation columns to separate and recover ethanol and ethyl acetate solvent, with specific catalyst compositions and conditions to optimize ethanol and ethyl acetate production, including the use of platinum-based catalysts and modified silica supports.

Chemical for the treatment, prevention and control of virus's diseases, bacterial diseases, cardiovascular diseases and lipids

PatentPendingCA3109802A1

Innovation

- Ethyl acetate (CH3C00C2H5) is used as the active substance in combination with pharmaceutical and/or dermatological acceptable auxiliary agents, formulated into forms such as dermal patches, creams, ointments, and solutions for transdermal, topical, or other applications.

Environmental Impact of Ethyl Acetate in Pharma

The use of ethyl acetate in pharmaceutical manufacturing processes has significant environmental implications that warrant careful consideration. As a widely used solvent in drug production, its environmental impact extends across multiple stages of the pharmaceutical lifecycle.

Ethyl acetate is known for its relatively low toxicity and high volatility, which contributes to its widespread use in the industry. However, these properties also present environmental challenges. The compound's high volatility means it can easily evaporate into the atmosphere, potentially contributing to air pollution and the formation of ground-level ozone when it reacts with other pollutants in the presence of sunlight.

In pharmaceutical manufacturing facilities, the release of ethyl acetate into the environment is a primary concern. Proper handling, storage, and disposal practices are crucial to minimize emissions. Many facilities employ advanced vapor recovery systems and closed-loop processes to capture and recycle ethyl acetate, reducing its release into the atmosphere. Despite these efforts, some amount of the solvent inevitably escapes during production processes.

Water contamination is another potential environmental risk associated with ethyl acetate use in pharmaceuticals. Although the compound is only slightly soluble in water, improper disposal or accidental spills can lead to its presence in aquatic ecosystems. While ethyl acetate is biodegradable and does not persist long in the environment, high concentrations can still have short-term impacts on aquatic life.

The production of ethyl acetate itself also has environmental implications. Traditionally synthesized from ethanol and acetic acid, the manufacturing process consumes energy and resources. However, recent advancements in green chemistry have led to more sustainable production methods, including the use of bio-based feedstocks and catalytic processes that reduce energy consumption and waste generation.

From a lifecycle perspective, the environmental impact of ethyl acetate extends beyond its immediate use in pharmaceutical production. The transportation and distribution of the solvent contribute to carbon emissions, while the energy-intensive processes required for its recovery and purification add to the overall environmental footprint of pharmaceutical operations.

Regulatory bodies worldwide have implemented stringent guidelines for the use and disposal of ethyl acetate in pharmaceutical manufacturing. These regulations aim to minimize environmental risks and promote sustainable practices within the industry. Compliance with these standards often necessitates significant investments in emission control technologies and waste management systems by pharmaceutical companies.

As the industry continues to evolve, there is a growing emphasis on finding more environmentally friendly alternatives to traditional solvents like ethyl acetate. Research into green solvents and solvent-free processes is ongoing, with the potential to further reduce the environmental impact of pharmaceutical manufacturing in the future.

Ethyl acetate is known for its relatively low toxicity and high volatility, which contributes to its widespread use in the industry. However, these properties also present environmental challenges. The compound's high volatility means it can easily evaporate into the atmosphere, potentially contributing to air pollution and the formation of ground-level ozone when it reacts with other pollutants in the presence of sunlight.

In pharmaceutical manufacturing facilities, the release of ethyl acetate into the environment is a primary concern. Proper handling, storage, and disposal practices are crucial to minimize emissions. Many facilities employ advanced vapor recovery systems and closed-loop processes to capture and recycle ethyl acetate, reducing its release into the atmosphere. Despite these efforts, some amount of the solvent inevitably escapes during production processes.

Water contamination is another potential environmental risk associated with ethyl acetate use in pharmaceuticals. Although the compound is only slightly soluble in water, improper disposal or accidental spills can lead to its presence in aquatic ecosystems. While ethyl acetate is biodegradable and does not persist long in the environment, high concentrations can still have short-term impacts on aquatic life.

The production of ethyl acetate itself also has environmental implications. Traditionally synthesized from ethanol and acetic acid, the manufacturing process consumes energy and resources. However, recent advancements in green chemistry have led to more sustainable production methods, including the use of bio-based feedstocks and catalytic processes that reduce energy consumption and waste generation.

From a lifecycle perspective, the environmental impact of ethyl acetate extends beyond its immediate use in pharmaceutical production. The transportation and distribution of the solvent contribute to carbon emissions, while the energy-intensive processes required for its recovery and purification add to the overall environmental footprint of pharmaceutical operations.

Regulatory bodies worldwide have implemented stringent guidelines for the use and disposal of ethyl acetate in pharmaceutical manufacturing. These regulations aim to minimize environmental risks and promote sustainable practices within the industry. Compliance with these standards often necessitates significant investments in emission control technologies and waste management systems by pharmaceutical companies.

As the industry continues to evolve, there is a growing emphasis on finding more environmentally friendly alternatives to traditional solvents like ethyl acetate. Research into green solvents and solvent-free processes is ongoing, with the potential to further reduce the environmental impact of pharmaceutical manufacturing in the future.

Regulatory Framework for Ethyl Acetate in Pharmaceuticals

The regulatory framework for ethyl acetate in pharmaceuticals is a complex and evolving landscape that encompasses various national and international guidelines. At the forefront of these regulations is the U.S. Food and Drug Administration (FDA), which classifies ethyl acetate as a Generally Recognized as Safe (GRAS) substance. This designation allows for its use in food and pharmaceutical applications, subject to good manufacturing practices and appropriate safety assessments.

In the European Union, the European Medicines Agency (EMA) provides guidance on the use of ethyl acetate in pharmaceutical manufacturing. The EMA's guidelines on residual solvents in medicinal products set specific limits for ethyl acetate, categorizing it as a Class 3 solvent with low toxic potential. This classification permits its use with less stringent control measures compared to more hazardous solvents.

The International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) has also established guidelines for residual solvents, including ethyl acetate. The ICH Q3C guideline on impurities classifies ethyl acetate as a Class 3 solvent, aligning with the EMA's stance and providing a harmonized approach for global pharmaceutical manufacturers.

Regulatory bodies in other major pharmaceutical markets, such as Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA), generally follow similar principles in their approach to ethyl acetate regulation. These agencies often reference ICH guidelines, ensuring a degree of global consistency in regulatory requirements.

Despite its GRAS status and relatively low toxicity profile, manufacturers must still adhere to strict quality control measures when using ethyl acetate in pharmaceutical production. This includes monitoring and controlling residual solvent levels in final drug products, as well as implementing appropriate handling and disposal procedures to minimize environmental impact.

The regulatory framework also extends to the sourcing and quality of ethyl acetate used in pharmaceutical applications. Manufacturers must ensure that the ethyl acetate they use meets pharmacopoeial standards, such as those outlined in the United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.). These standards specify purity requirements and analytical methods for quality control.

As sustainability becomes an increasingly important consideration in pharmaceutical manufacturing, regulatory bodies are beginning to incorporate environmental impact assessments into their frameworks. This trend may influence future regulations on the use of solvents like ethyl acetate, potentially favoring more environmentally friendly alternatives or encouraging the development of greener production processes.

In the European Union, the European Medicines Agency (EMA) provides guidance on the use of ethyl acetate in pharmaceutical manufacturing. The EMA's guidelines on residual solvents in medicinal products set specific limits for ethyl acetate, categorizing it as a Class 3 solvent with low toxic potential. This classification permits its use with less stringent control measures compared to more hazardous solvents.

The International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human Use (ICH) has also established guidelines for residual solvents, including ethyl acetate. The ICH Q3C guideline on impurities classifies ethyl acetate as a Class 3 solvent, aligning with the EMA's stance and providing a harmonized approach for global pharmaceutical manufacturers.

Regulatory bodies in other major pharmaceutical markets, such as Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA), generally follow similar principles in their approach to ethyl acetate regulation. These agencies often reference ICH guidelines, ensuring a degree of global consistency in regulatory requirements.

Despite its GRAS status and relatively low toxicity profile, manufacturers must still adhere to strict quality control measures when using ethyl acetate in pharmaceutical production. This includes monitoring and controlling residual solvent levels in final drug products, as well as implementing appropriate handling and disposal procedures to minimize environmental impact.

The regulatory framework also extends to the sourcing and quality of ethyl acetate used in pharmaceutical applications. Manufacturers must ensure that the ethyl acetate they use meets pharmacopoeial standards, such as those outlined in the United States Pharmacopeia (USP) and European Pharmacopoeia (Ph. Eur.). These standards specify purity requirements and analytical methods for quality control.

As sustainability becomes an increasingly important consideration in pharmaceutical manufacturing, regulatory bodies are beginning to incorporate environmental impact assessments into their frameworks. This trend may influence future regulations on the use of solvents like ethyl acetate, potentially favoring more environmentally friendly alternatives or encouraging the development of greener production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!