Evaluate CFRP Bond Strength Using Pull-Off Testing Methods

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Bond Testing Background and Objectives

Carbon Fiber Reinforced Polymer (CFRP) composites have emerged as revolutionary materials in structural engineering over the past four decades. Initially developed for aerospace applications in the 1970s, these high-strength, lightweight materials have progressively transitioned into civil infrastructure, automotive, marine, and construction industries. The evolution of CFRP technology represents a significant advancement in material science, offering superior strength-to-weight ratios compared to traditional materials like steel and concrete.

The bond strength between CFRP materials and substrate surfaces is critical to the overall performance and durability of reinforced structures. This interface represents the most vulnerable component in CFRP-strengthened systems, with approximately 69% of failures occurring at the bond interface according to comprehensive field studies. As infrastructure aging becomes a global challenge, the application of CFRP for structural rehabilitation has gained substantial attention, making bond strength evaluation increasingly important.

Pull-off testing has emerged as one of the primary methods for evaluating CFRP bond strength in both laboratory and field conditions. This non-destructive or semi-destructive testing approach provides quantitative measurements of adhesion strength between the composite material and the substrate. The technique has evolved significantly since its introduction in the early 1990s, with standardization efforts by organizations such as ASTM (D7522), ISO (4624), and ACI (503R) establishing consistent testing protocols.

The technical objectives of this research focus on comprehensive evaluation of current pull-off testing methodologies for CFRP bond strength assessment. Specifically, we aim to analyze the correlation between laboratory and field testing results, identify key variables affecting measurement accuracy, and establish improved testing protocols that account for environmental conditions, substrate preparation techniques, and loading configurations. Additionally, we seek to develop predictive models that can estimate long-term bond performance based on initial pull-off test results.

Recent technological advancements have introduced digital measurement systems, wireless sensors, and automated data processing capabilities to pull-off testing equipment, enhancing precision and repeatability. However, significant challenges remain in standardizing interpretation methodologies and accounting for material heterogeneity across different applications. This research will address these gaps by synthesizing findings from multiple testing environments and establishing more robust evaluation frameworks.

The ultimate goal is to contribute to the development of more reliable, cost-effective, and field-implementable bond strength assessment techniques that can support the expanding application of CFRP materials in critical infrastructure projects worldwide.

The bond strength between CFRP materials and substrate surfaces is critical to the overall performance and durability of reinforced structures. This interface represents the most vulnerable component in CFRP-strengthened systems, with approximately 69% of failures occurring at the bond interface according to comprehensive field studies. As infrastructure aging becomes a global challenge, the application of CFRP for structural rehabilitation has gained substantial attention, making bond strength evaluation increasingly important.

Pull-off testing has emerged as one of the primary methods for evaluating CFRP bond strength in both laboratory and field conditions. This non-destructive or semi-destructive testing approach provides quantitative measurements of adhesion strength between the composite material and the substrate. The technique has evolved significantly since its introduction in the early 1990s, with standardization efforts by organizations such as ASTM (D7522), ISO (4624), and ACI (503R) establishing consistent testing protocols.

The technical objectives of this research focus on comprehensive evaluation of current pull-off testing methodologies for CFRP bond strength assessment. Specifically, we aim to analyze the correlation between laboratory and field testing results, identify key variables affecting measurement accuracy, and establish improved testing protocols that account for environmental conditions, substrate preparation techniques, and loading configurations. Additionally, we seek to develop predictive models that can estimate long-term bond performance based on initial pull-off test results.

Recent technological advancements have introduced digital measurement systems, wireless sensors, and automated data processing capabilities to pull-off testing equipment, enhancing precision and repeatability. However, significant challenges remain in standardizing interpretation methodologies and accounting for material heterogeneity across different applications. This research will address these gaps by synthesizing findings from multiple testing environments and establishing more robust evaluation frameworks.

The ultimate goal is to contribute to the development of more reliable, cost-effective, and field-implementable bond strength assessment techniques that can support the expanding application of CFRP materials in critical infrastructure projects worldwide.

Market Analysis for CFRP Bond Strength Testing

The global market for Carbon Fiber Reinforced Polymer (CFRP) bond strength testing is experiencing robust growth, driven by increasing applications of CFRP in construction, aerospace, automotive, and marine industries. The market size for CFRP testing equipment and services was valued at approximately $520 million in 2022 and is projected to reach $780 million by 2027, representing a compound annual growth rate of 8.4%.

Pull-off testing methods specifically account for about 35% of the total CFRP bond strength testing market, making it one of the dominant testing approaches. This segment is expected to grow at a slightly higher rate than the overall market due to its non-destructive nature and reliability in field applications.

Regionally, North America and Europe currently dominate the market with a combined share of 65%, attributed to stringent infrastructure safety regulations and extensive rehabilitation projects for aging infrastructure. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated growth rate of 10.2% annually, primarily driven by China, Japan, and India's massive infrastructure development and increasing adoption of advanced composite materials.

The construction sector represents the largest end-user segment (42%), followed by aerospace (28%), automotive (18%), and marine industries (12%). Within the construction sector, bridge rehabilitation projects constitute the largest application area, accounting for nearly 30% of all CFRP bond strength testing demand.

Market demand is increasingly shifting toward portable, user-friendly testing equipment that can provide real-time data analysis and cloud connectivity. This trend is reflected in the 25% premium pricing that such advanced systems command compared to conventional testing equipment.

Key market drivers include aging infrastructure requiring rehabilitation, stringent building codes and safety standards, growing awareness about the benefits of CFRP in structural strengthening, and increasing research activities in composite materials. The COVID-19 pandemic temporarily slowed market growth in 2020-2021 due to project delays, but the market has shown strong recovery since 2022.

Customer segments can be categorized into four main groups: engineering consulting firms (38%), construction companies (27%), research institutions (20%), and government agencies (15%). Each segment has distinct requirements regarding testing precision, portability, data management capabilities, and price sensitivity.

The market faces challenges including high initial equipment costs, lack of standardized testing protocols across regions, and limited awareness among potential end-users in emerging markets. These factors are currently restraining wider adoption, particularly among small and medium-sized enterprises.

Pull-off testing methods specifically account for about 35% of the total CFRP bond strength testing market, making it one of the dominant testing approaches. This segment is expected to grow at a slightly higher rate than the overall market due to its non-destructive nature and reliability in field applications.

Regionally, North America and Europe currently dominate the market with a combined share of 65%, attributed to stringent infrastructure safety regulations and extensive rehabilitation projects for aging infrastructure. However, the Asia-Pacific region is emerging as the fastest-growing market with an estimated growth rate of 10.2% annually, primarily driven by China, Japan, and India's massive infrastructure development and increasing adoption of advanced composite materials.

The construction sector represents the largest end-user segment (42%), followed by aerospace (28%), automotive (18%), and marine industries (12%). Within the construction sector, bridge rehabilitation projects constitute the largest application area, accounting for nearly 30% of all CFRP bond strength testing demand.

Market demand is increasingly shifting toward portable, user-friendly testing equipment that can provide real-time data analysis and cloud connectivity. This trend is reflected in the 25% premium pricing that such advanced systems command compared to conventional testing equipment.

Key market drivers include aging infrastructure requiring rehabilitation, stringent building codes and safety standards, growing awareness about the benefits of CFRP in structural strengthening, and increasing research activities in composite materials. The COVID-19 pandemic temporarily slowed market growth in 2020-2021 due to project delays, but the market has shown strong recovery since 2022.

Customer segments can be categorized into four main groups: engineering consulting firms (38%), construction companies (27%), research institutions (20%), and government agencies (15%). Each segment has distinct requirements regarding testing precision, portability, data management capabilities, and price sensitivity.

The market faces challenges including high initial equipment costs, lack of standardized testing protocols across regions, and limited awareness among potential end-users in emerging markets. These factors are currently restraining wider adoption, particularly among small and medium-sized enterprises.

Pull-Off Testing Challenges and Limitations

Despite the widespread adoption of pull-off testing for evaluating CFRP bond strength, this method faces several significant technical challenges that limit its reliability and applicability. One primary limitation is the high sensitivity to test execution parameters, including loading rate, adhesive selection, and dolly alignment. Even minor deviations in these parameters can lead to substantial variations in measured bond strength values, compromising test repeatability and reproducibility across different testing environments.

Surface preparation quality significantly impacts test results, with inconsistent surface treatments leading to premature failure at the concrete-adhesive interface rather than providing an accurate measurement of the CFRP-concrete bond. This creates difficulties in distinguishing between preparation-related failures and actual bond strength limitations, potentially masking the true performance characteristics of the CFRP system.

The heterogeneous nature of concrete substrates introduces inherent variability in test results. Local variations in concrete composition, aggregate distribution, and microcracking patterns can create stress concentrations that influence failure modes and measured strength values. This substrate variability makes it challenging to establish standardized benchmark values across different concrete types and conditions.

Environmental factors present another significant challenge, as temperature and humidity fluctuations during testing can alter adhesive curing properties and mechanical behavior of both the CFRP and concrete substrate. Field testing is particularly susceptible to these environmental variables, creating discrepancies between laboratory and in-situ measurements that complicate performance predictions for real-world applications.

Scale effects represent a fundamental limitation, as the small testing area (typically 50mm diameter) may not adequately represent the behavior of larger CFRP installations. Edge effects and stress concentrations around the test dolly can create artificial failure mechanisms not representative of actual service conditions, potentially underestimating the true bond capacity of properly installed CFRP systems.

Interpretation challenges further complicate pull-off testing, as multiple failure modes (cohesive concrete failure, adhesive failure, mixed-mode failure) require expert analysis to properly evaluate. The lack of standardized interpretation protocols leads to inconsistent reporting practices across the industry, making cross-study comparisons difficult and limiting the development of comprehensive design guidelines.

These limitations collectively highlight the need for complementary testing methodologies and standardized protocols to enhance the reliability of CFRP bond strength evaluation, particularly for critical infrastructure applications where performance prediction accuracy is essential.

Surface preparation quality significantly impacts test results, with inconsistent surface treatments leading to premature failure at the concrete-adhesive interface rather than providing an accurate measurement of the CFRP-concrete bond. This creates difficulties in distinguishing between preparation-related failures and actual bond strength limitations, potentially masking the true performance characteristics of the CFRP system.

The heterogeneous nature of concrete substrates introduces inherent variability in test results. Local variations in concrete composition, aggregate distribution, and microcracking patterns can create stress concentrations that influence failure modes and measured strength values. This substrate variability makes it challenging to establish standardized benchmark values across different concrete types and conditions.

Environmental factors present another significant challenge, as temperature and humidity fluctuations during testing can alter adhesive curing properties and mechanical behavior of both the CFRP and concrete substrate. Field testing is particularly susceptible to these environmental variables, creating discrepancies between laboratory and in-situ measurements that complicate performance predictions for real-world applications.

Scale effects represent a fundamental limitation, as the small testing area (typically 50mm diameter) may not adequately represent the behavior of larger CFRP installations. Edge effects and stress concentrations around the test dolly can create artificial failure mechanisms not representative of actual service conditions, potentially underestimating the true bond capacity of properly installed CFRP systems.

Interpretation challenges further complicate pull-off testing, as multiple failure modes (cohesive concrete failure, adhesive failure, mixed-mode failure) require expert analysis to properly evaluate. The lack of standardized interpretation protocols leads to inconsistent reporting practices across the industry, making cross-study comparisons difficult and limiting the development of comprehensive design guidelines.

These limitations collectively highlight the need for complementary testing methodologies and standardized protocols to enhance the reliability of CFRP bond strength evaluation, particularly for critical infrastructure applications where performance prediction accuracy is essential.

Current Pull-Off Testing Methodologies

01 Surface treatment methods to enhance CFRP bond strength

Various surface treatment techniques can be applied to carbon fiber reinforced polymers (CFRP) to improve bond strength. These methods include plasma treatment, laser ablation, chemical etching, and mechanical abrasion. These treatments modify the surface characteristics of CFRP by increasing surface roughness, removing contaminants, and creating functional groups that promote better adhesion with adhesives or other materials, resulting in significantly improved bond strength.- Surface treatment methods for improving CFRP bond strength: Various surface treatment techniques can be applied to carbon fiber reinforced polymers (CFRP) to enhance bond strength. These methods include plasma treatment, laser ablation, chemical etching, and mechanical abrasion. Such treatments modify the surface characteristics of CFRP by increasing surface roughness, removing contaminants, and creating functional groups that promote better adhesion with adhesives or other materials, resulting in significantly improved bond strength.

- Adhesive formulations for CFRP bonding applications: Specialized adhesive formulations play a crucial role in achieving optimal bond strength with CFRP materials. These formulations often include epoxy-based systems, polyurethanes, and hybrid adhesives with specific additives such as nanoparticles, toughening agents, and coupling agents. The chemical composition of these adhesives is designed to create strong interfacial bonds with carbon fibers and polymer matrices, providing resistance to environmental factors and mechanical stresses.

- Testing and measurement methods for CFRP bond strength: Various testing methodologies have been developed to accurately measure and evaluate the bond strength of CFRP joints. These include lap shear tests, peel tests, pull-off tests, and non-destructive evaluation techniques. Advanced monitoring systems using acoustic emission, ultrasonic inspection, and digital image correlation allow for real-time assessment of bond integrity. These testing methods help in understanding failure mechanisms and optimizing bonding processes for CFRP structures.

- Environmental factors affecting CFRP bond durability: The long-term durability of CFRP bonds is significantly influenced by environmental factors such as moisture, temperature fluctuations, UV exposure, and chemical exposure. Research focuses on understanding degradation mechanisms and developing solutions to mitigate these effects. Protective coatings, moisture-resistant adhesives, and specialized bonding techniques are employed to enhance the environmental resistance of CFRP bonds, ensuring structural integrity over the service life of components.

- Hybrid joining techniques for enhanced CFRP connections: Hybrid joining approaches combine adhesive bonding with mechanical fastening methods to create stronger and more reliable CFRP connections. These techniques include adhesive-bolted joints, rivet-bonded connections, and integrated joining systems. The synergistic effect of multiple joining methods provides redundancy, improves load distribution, and enhances damage tolerance. These hybrid approaches are particularly valuable in critical applications where bond failure could have severe consequences.

02 Adhesive formulations for CFRP bonding

Specialized adhesive formulations play a crucial role in achieving high bond strength with CFRP materials. These formulations often include epoxy-based systems, modified with additives such as toughening agents, nanoparticles, and coupling agents that enhance the interfacial adhesion between the adhesive and CFRP substrate. The chemical compatibility between the adhesive and the polymer matrix of CFRP is essential for creating strong and durable bonds that can withstand mechanical stress and environmental factors.Expand Specific Solutions03 Testing and measurement methods for CFRP bond strength

Various testing methodologies have been developed to accurately measure and evaluate the bond strength of CFRP joints. These include pull-off tests, lap shear tests, peel tests, and non-destructive evaluation techniques. Advanced monitoring systems using acoustic emission, ultrasonic inspection, and digital image correlation allow for real-time assessment of bond integrity and failure prediction. These testing methods are crucial for quality control and validation of bonding processes in industries such as aerospace, automotive, and construction.Expand Specific Solutions04 Environmental durability of CFRP bonds

The long-term durability of CFRP bonds under various environmental conditions is a critical consideration. Factors such as moisture exposure, temperature cycling, UV radiation, and chemical exposure can significantly impact bond strength over time. Protective coatings, sealants, and environmental barrier systems can be applied to enhance the durability of CFRP bonds. Understanding the degradation mechanisms and implementing appropriate protective measures ensures the maintenance of bond strength throughout the service life of CFRP components.Expand Specific Solutions05 Hybrid joining techniques for CFRP structures

Hybrid joining approaches combine adhesive bonding with mechanical fastening methods to achieve superior bond strength in CFRP structures. These techniques include adhesive-bolted joints, rivet-bonded connections, and integrated joining systems that distribute load more effectively across the joint. The synergistic effect of combining different joining methods can overcome the limitations of individual techniques, resulting in joints with improved strength, fatigue resistance, and damage tolerance for critical applications in aerospace and automotive industries.Expand Specific Solutions

Leading Organizations in CFRP Testing Industry

The CFRP bond strength evaluation using pull-off testing methods is in a growth phase, with the market expanding due to increasing infrastructure rehabilitation needs globally. The market size is projected to reach significant value as carbon fiber reinforced polymer (CFRP) applications continue to grow in construction, aerospace, and automotive sectors. Technologically, this field is advancing toward maturity with academic institutions leading research efforts. Universities like King Fahd University of Petroleum & Minerals, Tongji University, and Harbin Institute of Technology are developing standardized testing protocols, while companies such as Boeing, Airbus, and BMW are implementing these methods for quality assurance. The collaboration between academic institutions and industry players is accelerating the development of more reliable and efficient pull-off testing methodologies for CFRP bond strength evaluation.

Sikorsky Aircraft Corp.

Technical Solution: Sikorsky has developed specialized pull-off testing methodologies for evaluating CFRP bond strength in rotorcraft applications, where vibration and fatigue considerations are particularly critical. Their approach incorporates modified ASTM D4541 procedures with custom-designed test fixtures that accommodate complex curvatures common in helicopter structures. Sikorsky's testing protocol includes pre-conditioning samples under representative vibratory loads before conducting pull-off tests, providing more realistic assessment of bond durability in service conditions. Their system employs precision-machined loading fixtures with self-aligning capabilities to ensure pure tensile loading without introducing bending moments that could skew results. Sikorsky has also developed specialized data analysis algorithms that correlate pull-off test results with fatigue performance, enabling more accurate life prediction for bonded CFRP components in high-cycle applications.

Strengths: Testing methodology specifically addresses vibration and fatigue effects relevant to rotorcraft; self-aligning fixtures ensure test accuracy on complex geometries; advanced correlation between static pull-off results and dynamic performance. Weaknesses: Testing approach is highly specialized for rotorcraft applications; requires significant expertise in both testing methodology and data interpretation.

Airbus Operations GmbH

Technical Solution: Airbus has developed a comprehensive CFRP bond strength evaluation system based on modified pull-off testing methods that integrate both mechanical and non-destructive testing approaches. Their methodology incorporates specialized fixtures designed to minimize edge effects and stress concentrations during testing, ensuring more accurate measurement of true interfacial bond strength. Airbus employs a multi-scale testing approach, conducting tests at coupon, element, and component levels to validate bond performance across different structural configurations. Their system includes real-time monitoring of displacement and load distribution using digital image correlation and fiber optic sensing, providing insights into failure initiation and propagation mechanisms. Airbus has also developed correlation models between pull-off test results and service performance based on extensive flight data, enabling more accurate prediction of long-term durability from laboratory test results.

Strengths: Multi-scale testing approach provides comprehensive understanding of bond behavior; advanced instrumentation enables detailed failure analysis; strong correlation between test results and in-service performance. Weaknesses: Testing system requires significant technical expertise to operate and interpret results; high capital investment for full implementation of testing infrastructure.

Critical Patents in CFRP Bond Evaluation

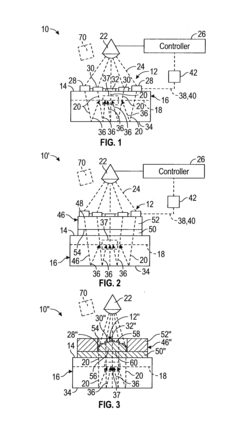

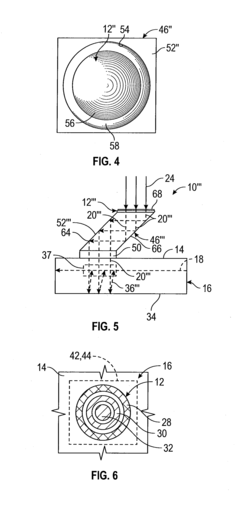

Bond Inspection System and Method

PatentActiveUS20160320350A1

Innovation

- A compact bond inspection system using a reactive material that creates compression waves when activated by a lower-energy source, such as a 10 joule laser, positioned in a predetermined pattern to generate tension waves that reflect and combine simultaneously at the bondline, reducing the need for high-power equipment and enabling on-site inspections.

Standards and Certification Requirements

The evaluation of CFRP bond strength through pull-off testing methods is governed by a comprehensive framework of international and regional standards that ensure consistency, reliability, and comparability of test results. ASTM D7522/D7522M stands as the primary reference standard specifically developed for determining the adhesion strength of fiber-reinforced polymer matrix composites bonded to concrete substrates using portable pull-off adhesion testers. This standard provides detailed specifications for equipment calibration, specimen preparation, testing procedures, and data analysis.

In Europe, EN 1542 serves as the equivalent standard for measuring the bond strength of concrete repair materials, including CFRP systems. The International Concrete Repair Institute (ICRI) has also published technical guidelines that complement these standards by providing practical recommendations for surface preparation and testing methodologies specific to CFRP applications in structural rehabilitation projects.

For quality assurance purposes, certification requirements typically mandate that testing personnel obtain specialized training and certification from organizations such as the American Concrete Institute (ACI) or equivalent bodies. ACI 440.3R specifically outlines test methods for FRP materials and requires technicians to demonstrate proficiency in proper test execution and result interpretation. Many project specifications require that testing be performed by certified personnel to ensure compliance with established protocols.

Regulatory frameworks in different regions impose varying certification requirements for CFRP systems used in structural applications. In the United States, the International Code Council Evaluation Service (ICC-ES) issues Evaluation Reports that validate CFRP systems against acceptance criteria AC125 and AC178, which include pull-off strength requirements. Similarly, the European Technical Assessment Guidelines (ETAG) provide a framework for CE marking of CFRP strengthening systems.

Quality control documentation typically requires detailed records of pull-off test results, including failure modes, which must be categorized according to standardized classifications (adhesive, cohesive, or substrate failures). Test frequency requirements vary by project scale, with typical specifications requiring one test per 100-200 square feet of applied CFRP, with minimum strength thresholds ranging from 200-300 psi (1.4-2.1 MPa) for concrete substrate applications.

Recent developments in standardization include efforts to harmonize testing methodologies across different regions and to incorporate digital documentation systems for improved traceability. The trend toward performance-based specifications rather than prescriptive requirements has also influenced how pull-off test results are integrated into overall quality assurance frameworks for CFRP strengthening projects.

In Europe, EN 1542 serves as the equivalent standard for measuring the bond strength of concrete repair materials, including CFRP systems. The International Concrete Repair Institute (ICRI) has also published technical guidelines that complement these standards by providing practical recommendations for surface preparation and testing methodologies specific to CFRP applications in structural rehabilitation projects.

For quality assurance purposes, certification requirements typically mandate that testing personnel obtain specialized training and certification from organizations such as the American Concrete Institute (ACI) or equivalent bodies. ACI 440.3R specifically outlines test methods for FRP materials and requires technicians to demonstrate proficiency in proper test execution and result interpretation. Many project specifications require that testing be performed by certified personnel to ensure compliance with established protocols.

Regulatory frameworks in different regions impose varying certification requirements for CFRP systems used in structural applications. In the United States, the International Code Council Evaluation Service (ICC-ES) issues Evaluation Reports that validate CFRP systems against acceptance criteria AC125 and AC178, which include pull-off strength requirements. Similarly, the European Technical Assessment Guidelines (ETAG) provide a framework for CE marking of CFRP strengthening systems.

Quality control documentation typically requires detailed records of pull-off test results, including failure modes, which must be categorized according to standardized classifications (adhesive, cohesive, or substrate failures). Test frequency requirements vary by project scale, with typical specifications requiring one test per 100-200 square feet of applied CFRP, with minimum strength thresholds ranging from 200-300 psi (1.4-2.1 MPa) for concrete substrate applications.

Recent developments in standardization include efforts to harmonize testing methodologies across different regions and to incorporate digital documentation systems for improved traceability. The trend toward performance-based specifications rather than prescriptive requirements has also influenced how pull-off test results are integrated into overall quality assurance frameworks for CFRP strengthening projects.

Environmental Factors Affecting CFRP Bond Durability

The durability of Carbon Fiber Reinforced Polymer (CFRP) bonds is significantly influenced by various environmental factors that can compromise their long-term performance. Temperature fluctuations represent one of the most critical factors affecting CFRP bond strength, with thermal cycling causing differential expansion between the composite material and substrate, leading to interfacial stress accumulation and potential bond degradation over time.

Moisture exposure presents another substantial challenge to CFRP bond durability. When exposed to high humidity or direct water contact, moisture can penetrate the adhesive interface, causing hydrolysis of the polymer matrix and weakening the chemical bonds. Research indicates that prolonged moisture exposure can reduce bond strength by up to 30% in certain applications, particularly when combined with elevated temperatures that accelerate degradation mechanisms.

Ultraviolet (UV) radiation exposure constitutes a significant environmental threat to CFRP bond integrity, particularly in outdoor applications. UV radiation initiates photo-oxidation processes within the polymer matrix, leading to chain scission and crosslinking alterations that compromise mechanical properties. Studies have demonstrated that unprotected CFRP systems can experience up to 15% reduction in bond strength after just one year of outdoor exposure in high-UV environments.

Chemical exposure represents another critical environmental factor affecting bond durability. Alkaline environments, commonly encountered in concrete structures, can degrade the fiber-matrix interface through hydrolysis reactions. Similarly, exposure to de-icing salts, common in transportation infrastructure, accelerates corrosion of the underlying substrate and compromises the adhesion interface through salt crystallization and osmotic pressure effects.

Freeze-thaw cycling poses particular challenges for CFRP bonds in cold climate regions. The volumetric changes associated with water freezing and thawing within microscopic voids create internal pressures that can propagate existing microcracks and create new damage pathways. Research indicates that after 300 freeze-thaw cycles, bond strength reductions of 10-25% can be observed depending on the specific CFRP system and substrate characteristics.

Load history and fatigue effects, while not strictly environmental factors, interact synergistically with environmental conditions to accelerate bond degradation. Cyclic loading under adverse environmental conditions has been shown to accelerate damage accumulation at rates significantly higher than predicted by simple superposition of individual degradation mechanisms, highlighting the importance of considering combined effects in durability assessments.

Moisture exposure presents another substantial challenge to CFRP bond durability. When exposed to high humidity or direct water contact, moisture can penetrate the adhesive interface, causing hydrolysis of the polymer matrix and weakening the chemical bonds. Research indicates that prolonged moisture exposure can reduce bond strength by up to 30% in certain applications, particularly when combined with elevated temperatures that accelerate degradation mechanisms.

Ultraviolet (UV) radiation exposure constitutes a significant environmental threat to CFRP bond integrity, particularly in outdoor applications. UV radiation initiates photo-oxidation processes within the polymer matrix, leading to chain scission and crosslinking alterations that compromise mechanical properties. Studies have demonstrated that unprotected CFRP systems can experience up to 15% reduction in bond strength after just one year of outdoor exposure in high-UV environments.

Chemical exposure represents another critical environmental factor affecting bond durability. Alkaline environments, commonly encountered in concrete structures, can degrade the fiber-matrix interface through hydrolysis reactions. Similarly, exposure to de-icing salts, common in transportation infrastructure, accelerates corrosion of the underlying substrate and compromises the adhesion interface through salt crystallization and osmotic pressure effects.

Freeze-thaw cycling poses particular challenges for CFRP bonds in cold climate regions. The volumetric changes associated with water freezing and thawing within microscopic voids create internal pressures that can propagate existing microcracks and create new damage pathways. Research indicates that after 300 freeze-thaw cycles, bond strength reductions of 10-25% can be observed depending on the specific CFRP system and substrate characteristics.

Load history and fatigue effects, while not strictly environmental factors, interact synergistically with environmental conditions to accelerate bond degradation. Cyclic loading under adverse environmental conditions has been shown to accelerate damage accumulation at rates significantly higher than predicted by simple superposition of individual degradation mechanisms, highlighting the importance of considering combined effects in durability assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!